Preparation method of composite membrane material applied to lithium battery diaphragm

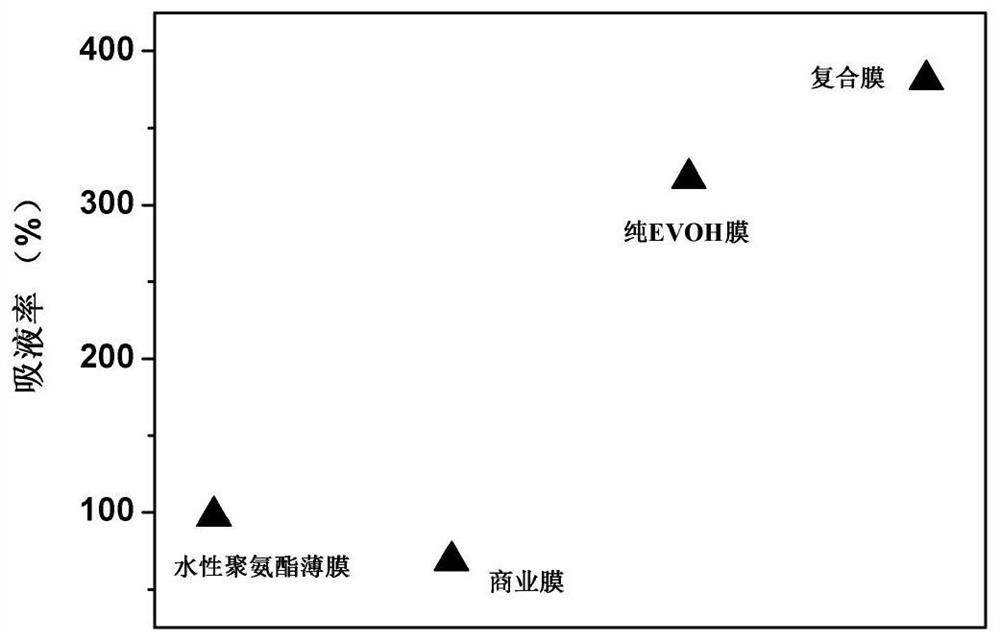

A lithium battery separator and composite film technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of low density of layered films, high ionic conductivity, large specific surface area, etc., and achieve high liquid absorption rate , high affinity, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

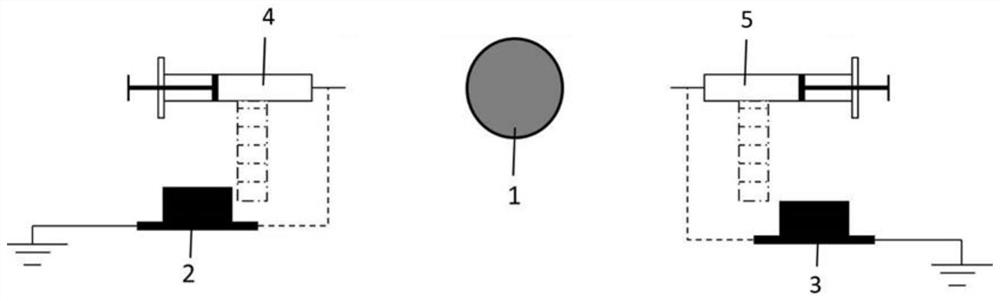

Method used

Image

Examples

Embodiment 1

[0036] A preparation method for a composite membrane material applied to lithium battery separators, specifically comprising the following steps:

[0037] S1: Put polyethylene adipate diol and ethylene glycol in an oven at 110°C for 50 minutes and heat and dry them for 50 minutes, then take them out and cool them down to 40°C for use in the next step.

[0038] S2: Polyethylene adipate diol and ethylene glycol are joined in the ratio that is 50:1.1 with mass ratio to have thermometer, magnetic stirrer, reflux condensing tube and N 2 In the protected three-necked flask, turn on the magnetic stirrer to allow it to stir continuously, then add butanone, react at 45°C for 10 minutes, add toluene diisocyanate, raise the temperature to 65°C, and react for 3 hours to obtain a prepolymer .

[0039] S3: Add 2,2-dimethylolpropionic acid to the prepolymer, and continue to react at 65°C for 1 hour; then lower the temperature to 40°C, add triethylamine for neutralization, and then add deion...

Embodiment 2

[0043] A preparation method for a composite membrane material applied to lithium battery separators, specifically comprising the following steps:

[0044] S1: Put polyethylene adipate diol and ethylene glycol in an oven at 110°C for 50 minutes and heat and dry them for 50 minutes, then take them out and cool them down to 40°C for use in the next step.

[0045] S2: Polyethylene adipate diol and ethylene glycol are joined in the ratio that is 50:1.6 with mass ratio to have thermometer, magnetic stirrer, reflux condenser and N 2 In the protected three-necked flask, turn on the magnetic stirrer to allow it to stir continuously, then add butanone, react at 60°C for 10 minutes, add toluene diisocyanate, raise the temperature to 80°C, react for 3 hours, and obtain a prepolymer .

[0046] S3: Add 2,2-dimethylolpropionic acid to the prepolymer, and continue to react at 80°C for 1 hour; then lower the temperature to 50°C, add triethylamine for neutralization, and then add deionized wat...

Embodiment 3

[0050] A preparation method for a composite membrane material applied to lithium battery separators, specifically comprising the following steps:

[0051] S1: Put polyethylene adipate diol and ethylene glycol in an oven at 110°C for 50 minutes and heat and dry them for 50 minutes, then take them out and cool them down to 40°C for use in the next step.

[0052] S2: Polyethylene adipate diol and ethylene glycol are joined in the ratio that is 50:1.2 with mass ratio to have thermometer, magnetic stirrer, reflux condenser and N 2 In the protected three-necked flask, turn on the magnetic stirrer to allow it to stir continuously, then add methyl ethyl ketone, react at 45-60°C for 10min, add toluene diisocyanate, raise the temperature to 70°C, react for 3h, and obtain the prepared Polymer.

[0053] S3: Add 2,2-dimethylolpropionic acid to the prepolymer, and continue to react at 70°C for 1 hour; then lower the temperature to 45°C, add triethylamine for neutralization, and then add de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com