Method for treating petroleum industrial wastewater by using complex microbial inoculant

A compound bacterial agent, a technology of the petroleum industry, applied in sedimentation treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of low microbial survival and reproduction rate, large changes in water quality, equipment and pipeline blockage, etc., to reduce sludge. Yield, simplified processing, effect of reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

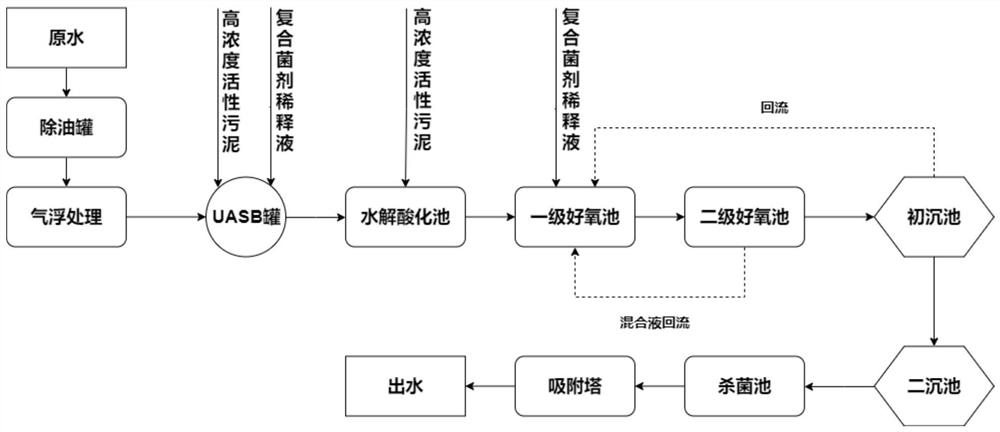

[0037] Such as figure 1 As shown, the method for the application of the compound bacterial agent of the present embodiment to treat petroleum industry wastewater specifically comprises the following steps:

[0038] (1) Mix various bacteria in proportion to form a microbial composite bacterial agent;

[0039] Bacteria name Percent content Lactobacillus 64% Prevotella 20% Acetobacter 5% Candida boidinii 1.76% Veillonella 1.49% Rhodospirillum 0.25% Phosphorus accumulating bacteria 2.5% Photosynthetic bacteria (eg: Rhodopseudomonas, etc.) 5%

[0040] (2) Mix 1 part by weight of the composite bacterial agent with 5 parts by weight of molasses and 100 parts by weight of water to prepare a solution a; place the solution a in an anaerobic environment for sealed cultivation for 5 days to obtain the activated solution a;

[0041] Take 1 part by weight of activated solution a, 0.8 parts by weight of molasses, and 50 parts b...

Embodiment 2

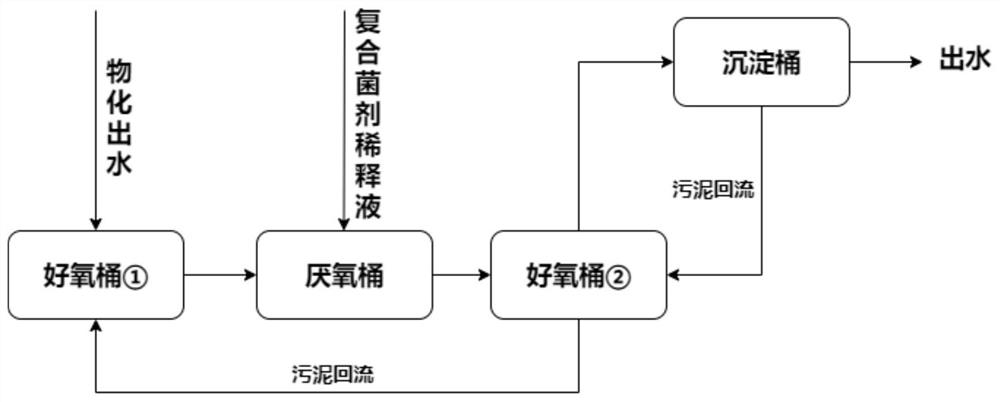

[0052] The method for the application of compound bacteria agent of the present embodiment to treat petroleum industry wastewater specifically comprises the following steps:

[0053] (1) Mix a variety of bacteria in proportion to form a microbial composite bacterial agent

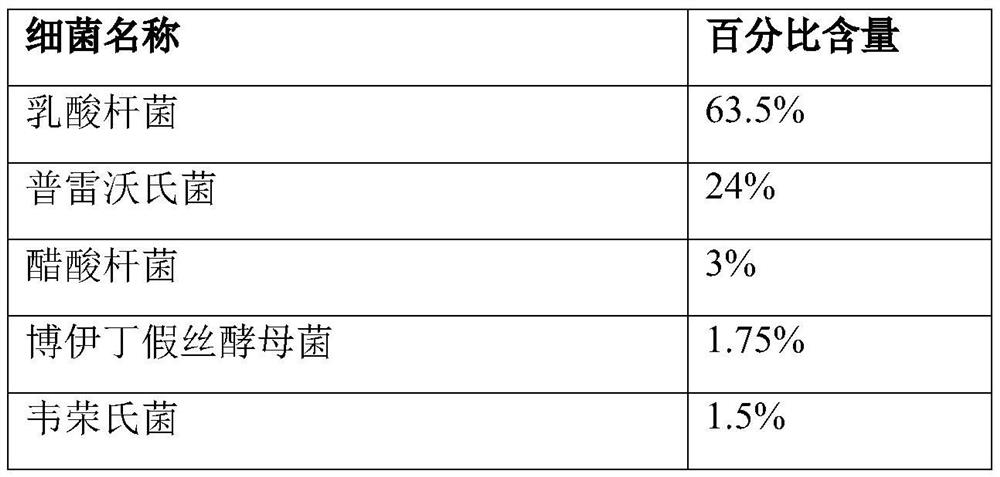

[0054]

[0055]

[0056] (2) Mix 1 part by weight of the composite bacterial agent with 5 parts by weight of molasses and 100 parts by weight of water to prepare a solution a; place the solution a in an anaerobic environment for sealed cultivation for 5 days to obtain the activated solution a;

[0057] Take 1 part by weight of activated solution a, 1 part by weight of molasses, and 50 parts by weight of water, mix evenly, and configure solution b; place solution b in an aerobic environment for 3 days, and aerate 1-7 times a day. Inhale for 3-8 minutes to obtain the activated solution b; place the activated solution b at 36.5°C for 30 hours at a constant temperature to obtain a compound bacterial agent...

Embodiment 3

[0069] The method for the application of compound bacteria agent of the present embodiment to treat petroleum industry wastewater specifically comprises the following steps:

[0070] (1) Mix various bacteria in proportion to form a microbial composite bacterial agent;

[0071]

[0072]

[0073] (2) Mix 1 part by weight of the composite bacterial agent with 6 parts by weight of molasses and 100 parts by weight of water to prepare a solution a; place the solution a in an anaerobic environment for sealed cultivation for 5 days to obtain the activated solution a;

[0074]Take 1 part by weight of activated solution a, 0.9 parts by weight of molasses, and 50 parts by weight of water, mix evenly, and configure solution b; place solution b in an aerobic environment for 4 days, and aerate 1-7 times a day. Gas for 3-8 minutes to obtain the activated solution b; place the activated solution b at 32°C for 30 hours at a constant temperature to obtain a compound bacterial agent diluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com