Easy-to-clean high-temperature-resistant polylactic acid composite material for environment-friendly tableware

A composite material and polylactic acid technology, which is applied in the field of high temperature resistant polylactic acid composite material and its preparation, can solve the problem of increasing the interface bonding force between inorganic fillers and organisms, improving the easy cleaning performance of polylactic acid products, and crystallization of polylactic acid composite materials. Slow speed and other problems, to achieve the effects of excellent hydrophilic ability, improved interfacial adhesion, and good hydrolytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

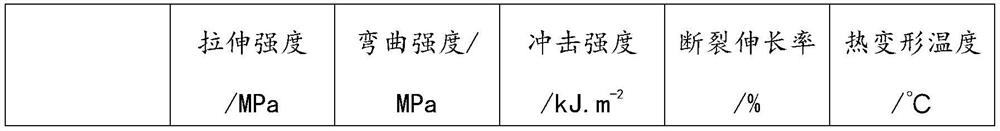

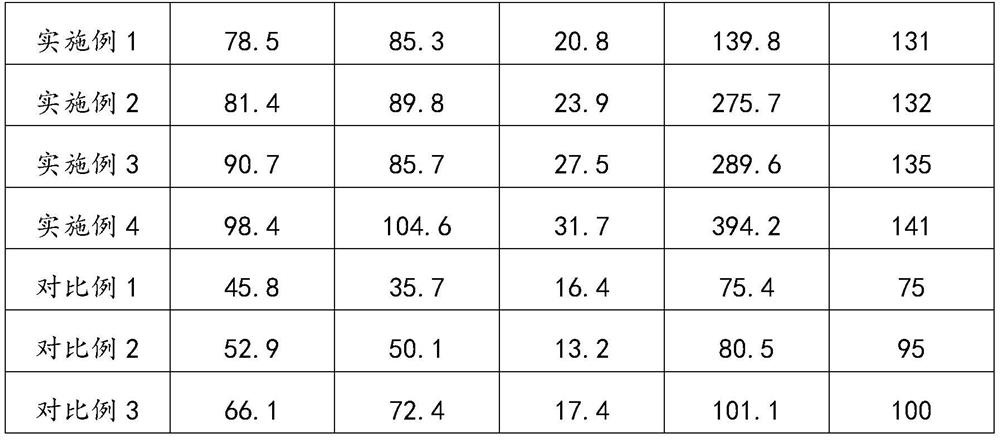

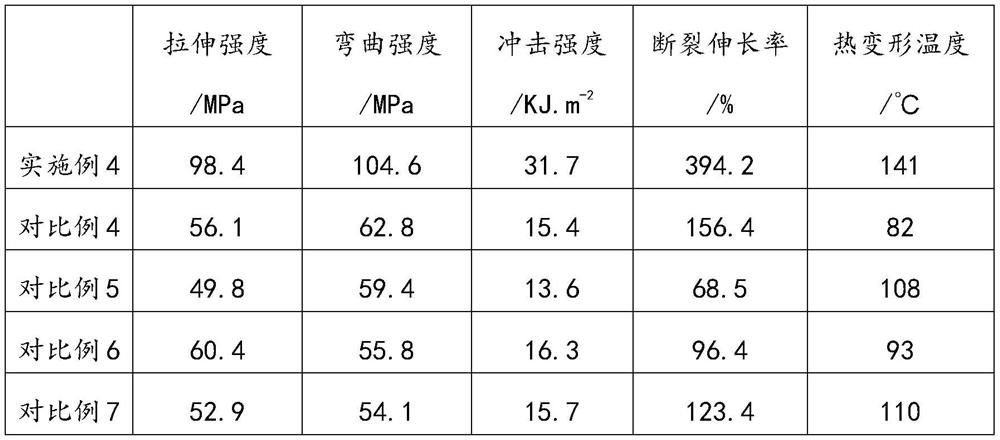

Examples

Embodiment 1

[0031] An easy-to-clean high-temperature-resistant polylactic acid composite material used for environmentally friendly tableware is composed of the following raw materials in parts by weight: 35 parts of modified polylactic acid, 65 parts of plant fiber, 1.5 parts of sodium rosinate, 0.3 parts of magnesium aluminum silicate, 25 parts of polyethylene glycol and 3 parts of polyethylene waxes, its preparation method comprises the following steps:

[0032]Add the weighed plant fiber and polyethylene glycol into a high-speed mixer and stir for 5-10 minutes, set the stirring speed at 320-450r / min, raise the temperature to 80-90°C, add and weigh at 80-90°C Sodium rosinate and modified polylactic acid, then stirred for 1-1.5h, after cooling to room temperature, magnesium aluminum silicate and polyethylene wax were added in sequence, after stirring for 10-15min, the evenly stirred mixture was added to the twin-screw extruder Melting and blending in the machine, extrusion, drawing, and...

Embodiment 2

[0037] An easy-to-clean high-temperature-resistant polylactic acid composite material used for environmentally friendly tableware is composed of the following raw materials in parts by weight: 70 parts of modified polylactic acid, 30 parts of plant fiber, 0.8 part of sodium rosinate, 0.1 part of magnesium aluminum silicate, 10 parts of polyethylene glycol, 3 parts of polyethylene wax and 3 parts of N,N,-ethylenebisstearamide, the preparation method is the same as in Example 1, specifically referring to Example 1, the difference is that polyethylene wax (i.e. lubricant) replaced by polyethylene wax and N, N, - ethylene bis stearamide.

[0038] The preparation method of above-mentioned modified polylactic acid comprises the following steps:

[0039] Add 100 parts of polylactic acid to an appropriate amount of tetrahydrofuran solution, stir at 50°C until dissolved, add 2.4 parts of FC-99 and 0.5 parts of TM-200S to the mixed solution at a constant temperature, stir for 2.5-4 hour...

Embodiment 3

[0042] An easy-to-clean high-temperature-resistant polylactic acid composite material used for environmentally friendly tableware is composed of the following raw materials in parts by weight: 45 parts of modified polylactic acid, 55 parts of plant fiber, 1.2 parts of sodium rosinate, 0.2 parts of magnesium aluminum silicate, 20 parts of polyethylene glycol and 4 parts of glycerol trihydroxystearate, its preparation method is the same as in Example 1, specifically with reference to Example 1, the difference is that polyethylene wax (i.e. lubricant) is changed into glycerol trihydroxystearate Fatty acid ester.

[0043] The preparation method of above-mentioned modified polylactic acid comprises the following steps:

[0044] Add 100 parts of polylactic acid to an appropriate amount of tetrahydrofuran solution, stir at 50°C until dissolved, add 3.0 parts of FC-99 and 0.7 parts of TM-200S to the mixed solution at a constant temperature, stir for 2.5-4 hours, and then raise the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com