Preparation method of bio-based chinlon 5X fiber material

A fiber material, bio-based technology, applied in the field of fiber materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

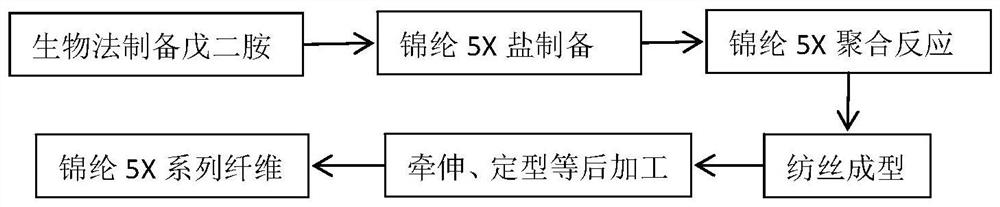

Method used

Image

Examples

Embodiment 1

[0053] 1. Preparation of pentamethylenediamine monomer by biological method:

[0054] The lysine decarboxylase synthesized by Escherichia coli can biocatalyze the decarboxylation of L-lysine to obtain a mixed liquid fermentation liquid containing 1,5-pentanediamine, inorganic salts, sugars, proteins, bacteria and other metabolic organic substances , which is the 1,5-pentanediamine mixed liquor fermentation broth, add activated carbon with a mass percentage of 5% to the fermentation broth containing 1,5-pentamethylenediamine, and stir for 1 hour at 25°C for decolorization reaction After decolorization, add adipic acid of the same quality to the filtrate, react at 40°C for 40 minutes to obtain a mixed solution containing nylon salt, and concentrate the mixed solution 4 times under reduced pressure at 55°C and 110mmHg to obtain a concentrated solution. The temperature of the liquid was lowered to 3°C, and crystals were precipitated, and then crystals were obtained by centrifugati...

Embodiment 2

[0057] Embodiment 2, the preparation of PA56 with flame retardant effect

[0058] Example 1 of the present invention does not add additives when preparing pure PA56, but it is necessary to add different additives to produce PA56 with antistatic / flame retardant effects.

[0059] Using the nylon 56 salt prepared in Example 1 of the present invention, under the protection of a nitrogen atmosphere, a 50% nylon salt solution was prepared to adjust the pH value to 7.85. Add 5kg of the prepared nylon saline solution, 1.75g of molecular weight modifier, and 1.75g of flame retardant MAC (melamine cyanurate) into the reactor together. The temperature of the material outlet of the concentration tank: 119°C; Temperature: 265°C, outlet 1 temperature: 265°C, outlet 2 temperature: 265°C, reactor pressure 17.5MPa; pre-condensation heat medium temperature: 280°C, time 1.5h; post-condensation heat medium temperature: 280°C, time 10min, Post-poly vacuum: 65kPa; control spinning melt viscosi...

Embodiment 3

[0061] Embodiment 3, the preparation of nylon staple fiber

[0062] Step 2 in the embodiment of the present invention 1 of polymerization in front, there is change behind drafting, specifically as follows:

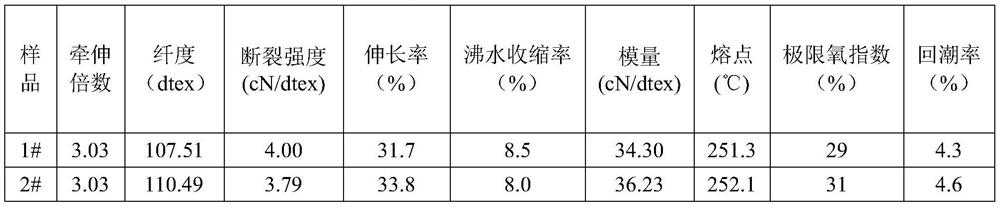

[0063] The drawing ratio and heating temperature are: the first drawing ratio is 2.78; the second drawing ratio is 1.05; the temperature of the first roll of the drawing box is 70°C; / min, the number of crimps is 15, and the nylon staple fibers are obtained by cutting. The mechanical properties of the staple fibers are shown in Table 2.

[0064] testing method:

[0065] 1. Linear density is tested according to GB / T14335-2008;

[0066] 2. Strong elongation: breaking strength and breaking elongation are tested according to GB / T14337-2008;

[0067] 3. The limiting oxygen index is tested according to GB / T5454-1997;

[0068] 4. The melting enthalpy (ΔH) of the fiber is tested by differential scanning calorimetry (DSC) f ), melting point (T m ), crystallinity (X c );

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com