Metal oxide cathode material, composite cathode material and battery

A technology of oxide cathodes and cathode materials, which is applied in fuel cells, solid electrolyte fuel cells, battery electrodes, etc., can solve the problems of mismatching thermal expansion coefficients between cathodes and electrolytes, complex synthesis of cathode materials, and reduced catalytic activity of cathodes. Synthetic preparation process requirements, superior performance, and the effect of more reaction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] For the preparation method of the above-mentioned cathode material, sol-gel method, precipitation method, solid-phase reaction method, hydrothermal method or solid-liquid composite method, and other preparation methods can be freely selected according to requirements.

[0035] In terms of sol-gel method, the process flow is as follows: according to the stoichiometric ratio of the elements in the chemical composition formula of the cathode material, the corresponding mass of metal salt is mixed with deionized water, complexing agent, etc., and then placed in a water bath to evaporate The precursor is obtained by stirring and evaporating in the container; the precursor is dried and calcined at 700-900° C. for 1-5 hours, and the target powder is obtained after ball milling and drying.

[0036] In terms of the precipitation method, the process flow is as follows: according to the stoichiometric ratio of the elements in the chemical composition formula of the cathode material...

Embodiment 1

[0047] Preparation of YCu by sol-gel method 1.85 Fe 0.15 o 4.85 cathode

[0048] 1. Preparation of cathode material: Take yttrium nitrate, copper acetate, and ferric nitrate as raw materials according to the corresponding chemical formula, put the raw materials into a glass container, add deionized water and citric acid as complexing agents, wherein the raw materials, The mass ratio of deionized water to citric acid is 1:5:1.2. After stirring the raw material mixture with a glass rod to fully dissolve it, heat it in a water bath. The sol was evaporated to dryness, dried in an oven at 250°C for 3 hours, and then calcined in a furnace at 800°C for 2 hours. Add alcohol to the calcined product, the mass ratio of calcined product to alcohol is 1:3, and the mixture is ground and dried at high speed in a ball mill to obtain the target product.

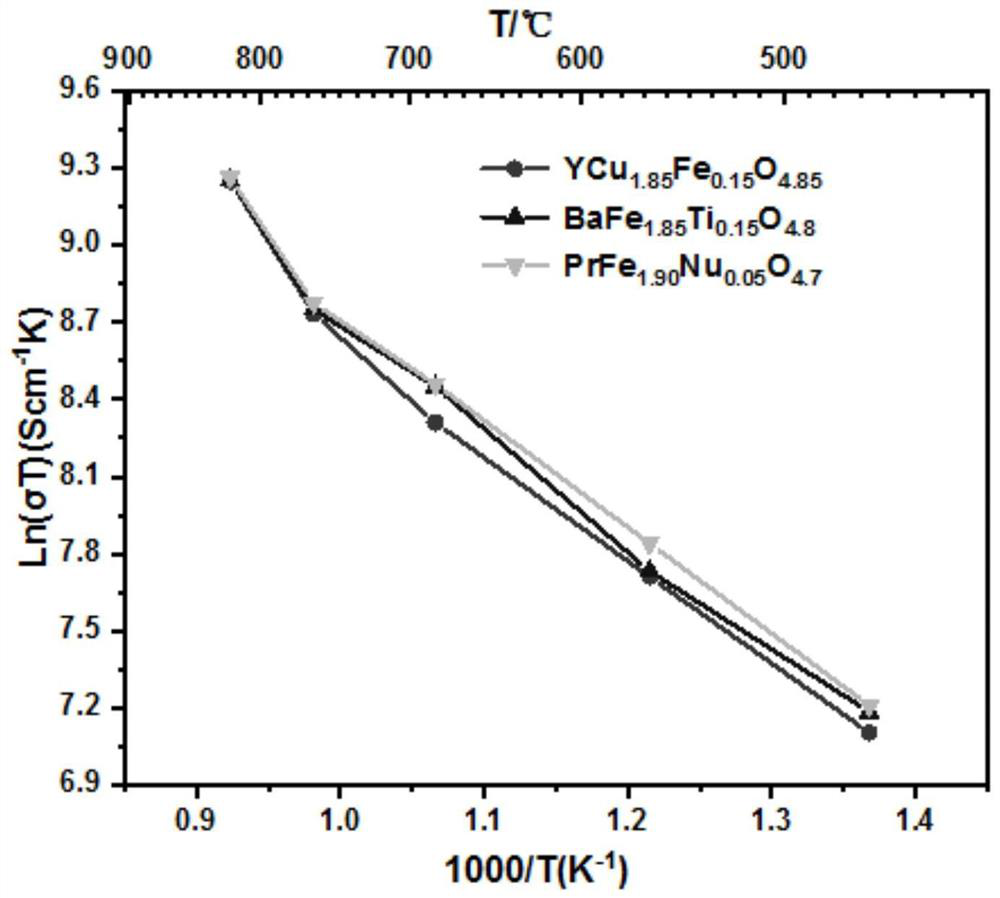

[0049] In order to test the electrical conductivity of the cathode material, the prepared powder was dry-pressed into a green body of 5*...

Embodiment 2

[0057] Preparation of BaFe by Precipitation 1.85 Ti 0.15 o 4.8 cathode

[0058] 1. Preparation of cathode material: Weigh barium nitrate, iron nitrate, and titanium acetate as raw materials according to the corresponding chemical formula, put the raw materials into a container, add deionized water to fully dissolve, and then add oxalic acid, wherein the raw materials, deionized The mass ratio of water and oxalic acid is 1:8:4. The raw materials are fully stirred to form a suspension solution, dried in a spray dryer, and then put into a furnace for calcination at 800°C for 2 hours. Add alcohol to the calcined product, the mass ratio of calcined product to alcohol is 1:3, and the mixture is ground and dried at high speed in a ball mill to obtain the target product.

[0059] The conductivity testing method of cathode material is identical with embodiment one, and its test result is as follows figure 2 , it can be seen that at 750 °C BaFe 1.85 Ti 0.15 o 4.8 The conductivit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com