A kind of high silicon ZSM-5 molecular sieve for adsorbing vocs and its preparation method and application

A technology of ZSM-5 and molecular sieve, which is applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of high crystallization temperature, increased production process, and high production cost, and achieve strong hydrophobicity and improved utilization rate , the effect of low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

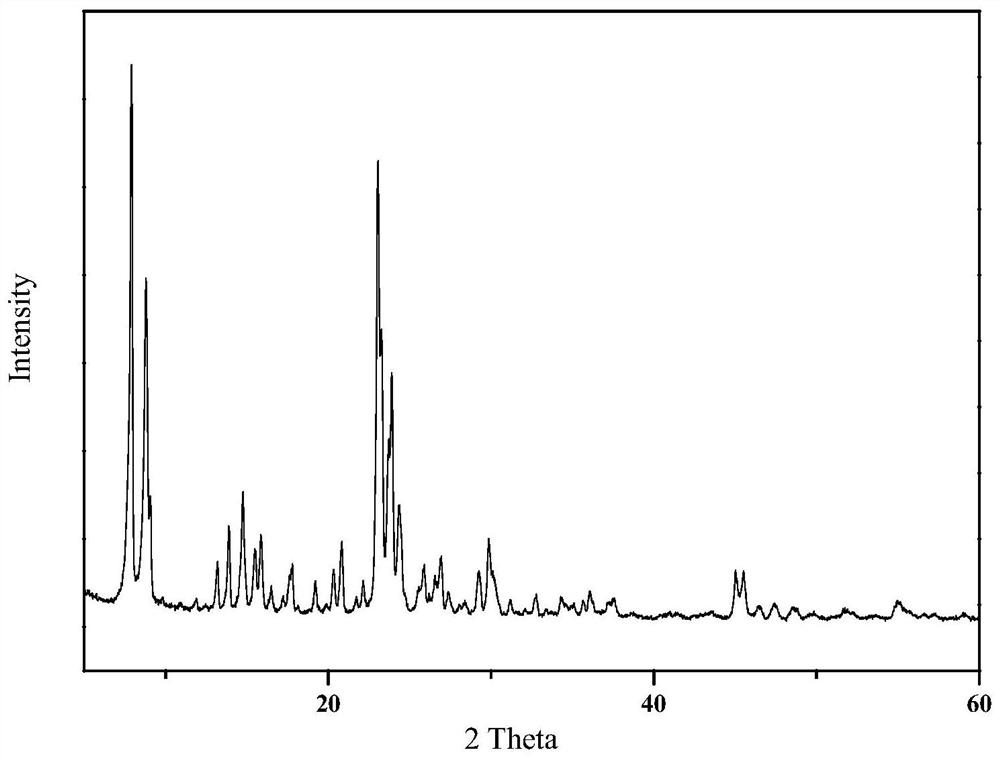

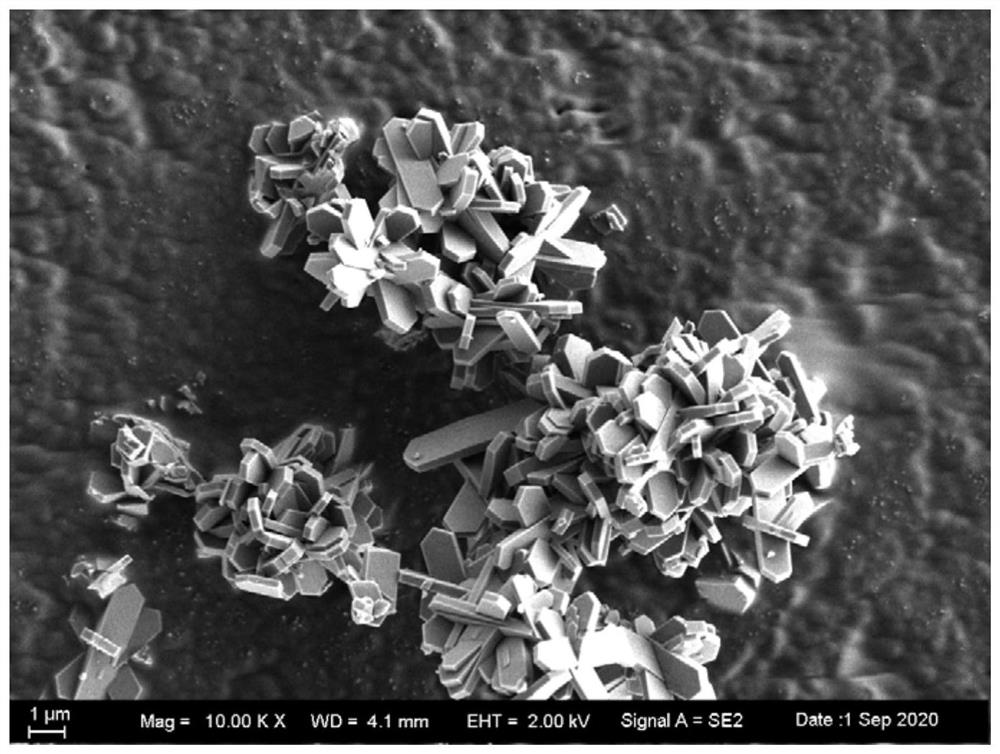

[0051] Take 0.9g NaOH, dissolve it in 80g deionized water, after the dissolution is complete, add 8.0g tetrapropylammonium bromide, then add 0.3g aluminum sulfate, after the dissolution is complete, stir evenly, add 1.2g ammonium chloride, and then slowly Add 40g of silica sol (30wt%) and stir evenly, then add 0.6g of ZSM-5 seed crystal. Stir to form a uniform gel, put it into a hydrothermal reaction kettle, age at 90°C for 4h, then heat up to 170°C to crystallize for 20h, filter, wash, and dry after the reaction, and it is identified as ZSM-5 molecular sieve by XRD (such as figure 1 shown), the SEM pattern is as figure 2 shown. Its relative crystallinity is 99%, n(SiO 2 / Al 2 o 3 )=305, BET specific surface area is 339.05m 2 / g, the particle size is about 3.5 μm, and the adsorption properties are shown in Table 1.

Embodiment 2

[0053] Take 1.0g NaOH, dissolve it in 150g deionized water, after the dissolution is complete, add 6.0g tetrapropylammonium bromide, then add 0.3g aluminum sulfate, after the dissolution is complete, stir evenly, add 1.3g ammonium chloride, and then slowly Add 48g of silica sol (25wt%) and stir evenly, then add 0.6g of ZSM-5 seed crystal. Stir to form a uniform gel, put it into a hydrothermal reaction kettle, age at 90°C for 4 hours, then heat up to 170°C to crystallize for 20 hours, after the reaction is completed, filter, wash, and dry, it is identified as ZSM-5 molecular sieve by XRD, the relative crystallinity 101%, n(SiO 2 / Al 2 o 3 )=330, BET specific surface area is 334.05m 2 / g, the particle size is about 1.6 μm, and the adsorption properties are shown in Table 1.

Embodiment 3

[0055] Take 1.6g NaOH, dissolve it in 90g deionized water, after the dissolution is complete, add 10.6g tetrapropylammonium bromide, then add 0.6g aluminum sulfate, after the dissolution is complete, stir evenly, add 3.1g ammonium acetate, and then slowly add 80g of silica sol (30wt%) was stirred evenly, and then 0.6g of ZSM-5 seed crystal was added. Stir to form a uniform gel, put it into a hydrothermal reaction kettle, age at 70°C for 4 hours, then heat up to 170°C to crystallize for 20 hours, filter, wash, and dry after the reaction, and it is identified as ZSM-5 molecular sieve by XRD. Relative crystallinity 99%, n(SiO 2 / Al 2 o 3 )=290, BET specific surface area is 330.62m 2 / g, the particle size is about 4.5 μm, and the adsorption properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com