Oxygen hole-containing BiOBr/TiO2 nanotube array composite electrode and preparation method thereof, and application of BiOBr/TiO2 nanotube array composite electrode to photoelectrocatalytic nitrogen fixation

A nanotube array, composite electrode technology, applied in electrodes, electrolytic coatings, electrophoretic plating, etc., can solve the problems of large energy band gap, high photo-generated electron recombination rate, limited application, etc., to reduce the recombination rate and stability. Good and efficient selective synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) The base material is conductive glass (FTO) with a thickness of 2.2 mm and a size of 2 cm×3 cm. After the FTO was ultrasonically cleaned with acetone, ethanol and deionized water for 20 min each, it was blown dry with pure nitrogen.

[0042] (2) Add 2mmol of Bi(NO 3 ) 3 ·5H 2 Dissolve O in 30mL of ethylene glycol, and then add NaBr in an equal amount to it under magnetic stirring. After it is completely dissolved, add 200mg of polyvinylpyrrolidone, stir for 0.5-1h, and then transfer to a 50mL hydrothermal kettle In 160 ℃ hydrothermal reaction for 12h. After the reaction, the hydrothermal kettle was naturally cooled to room temperature, and the product was centrifuged and washed 3 times with absolute ethanol and deionized water, and then dried in an oven at 60°C for 6 hours to obtain a brownish-yellow ν O - BiOBr powder.

[0043] (3) Prepare 1mg·mL -1 of ν O -BiOBr acetone solution, to which 0.05g of I was added 2 Simple substance. With FTO in step (1) as ca...

Embodiment 2

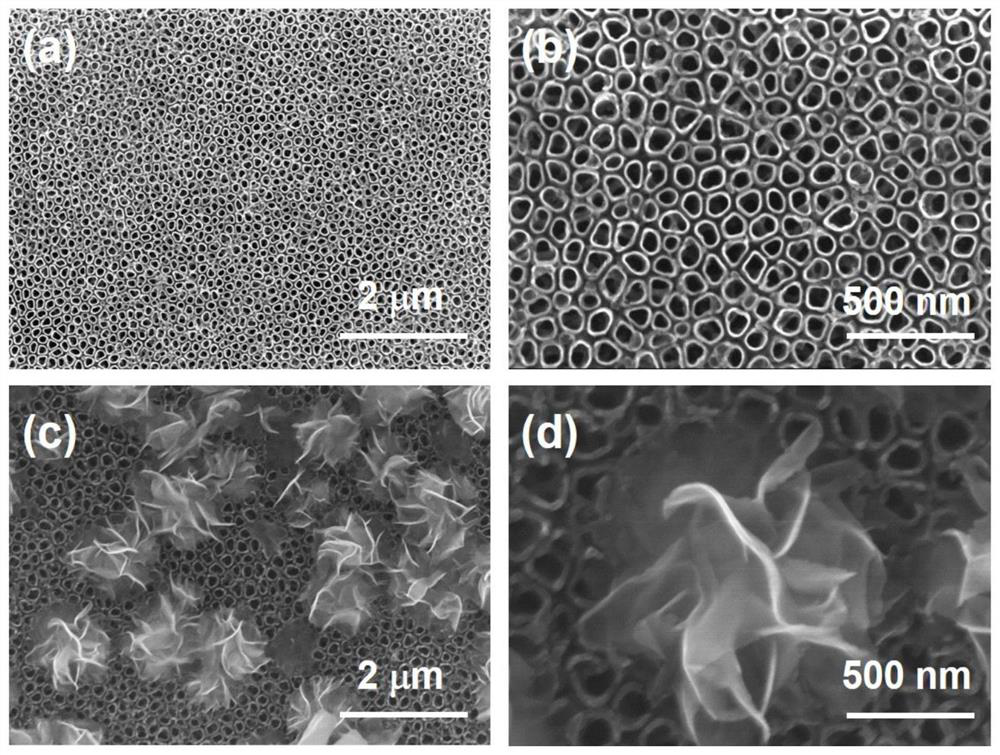

[0046] (1) The base material is an industrial titanium plate with a thickness of 2mm and a size of 2cm×3cm. The surface is polished with metallographic sandpaper until there are no scratches, cleaned ultrasonically with acetone, ethanol and three times of water, and dried for later use. Prepare a 0.5wt% HF electrolyte, use an industrial titanium plate as an anode and platinum as a counter electrode at room temperature, electrochemically anodize at 30V for 1h, and then heat-treat at 500°C for 2h, that is, the surface of the industrial titanium plate is obtained. ordered TiO 2 The film layer of the nanotube array ( figure 1 a and b).

[0047] (2) ν O -The preparation of the BiOBr nanosheets is the same as in Example 1.

[0048] (3) Prepare 1mg·mL -1 of ν O -BiOBr acetone solution, add 0.05g of I in this solution of 30~50mL 2 Simple substance. The TiO prepared in step (1) 2 Nanotube array as cathode, Ti foil as anode, ν O -BiOBr's acetone solution is used as the electrol...

Embodiment 3

[0051] (1) TiO 2 The preparation of the nanotube array film layer is the same as in Example 2.

[0052] (2) ν O -The preparation of the BiOBr nanosheets is the same as in Example 1.

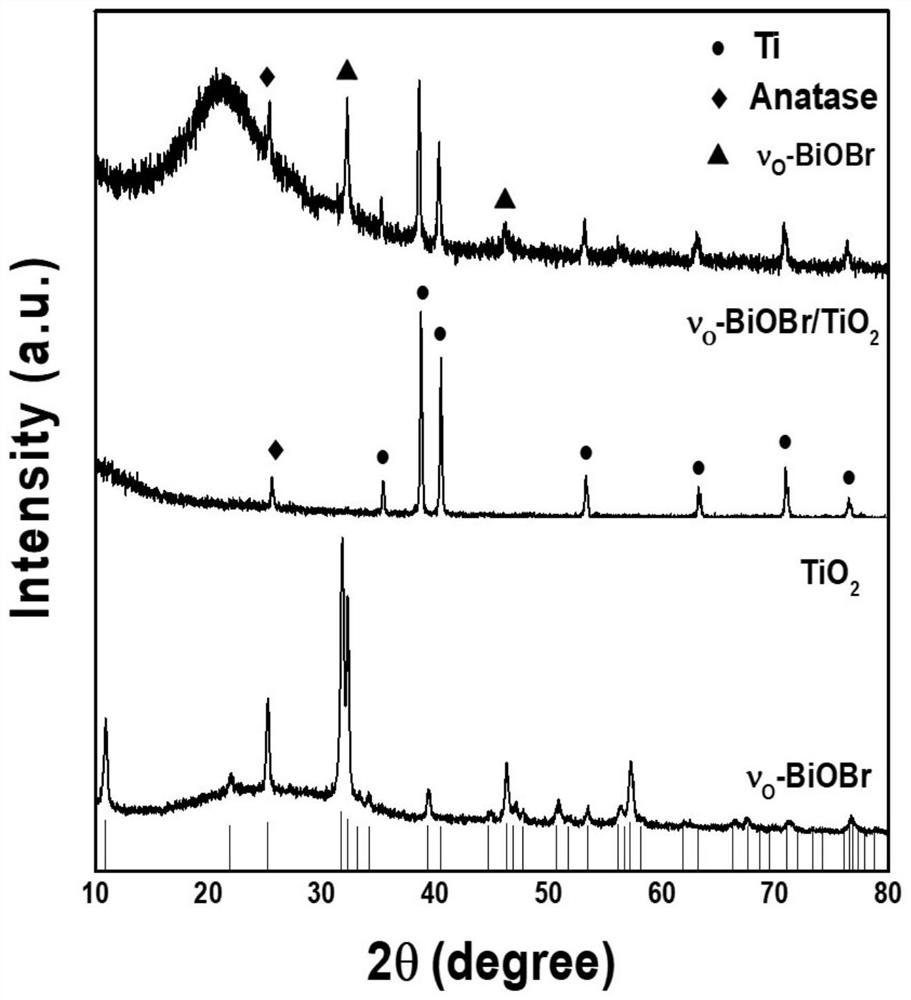

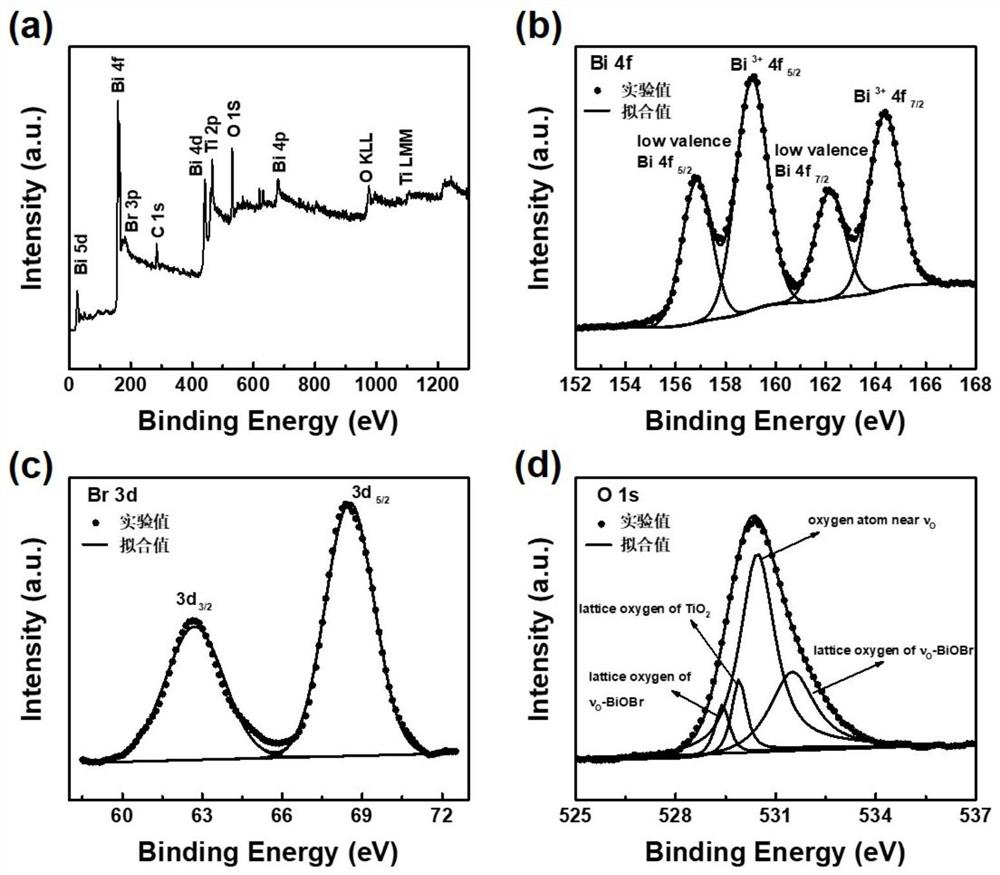

[0053] (3) Prepare 1mg / mL of ν O -BiOBr acetone solution, to which 0.05g of I was added 2 elemental substance to increase the electropositivity of the solute. The TiO prepared in (1) 2 Nanotube array as cathode, Ti foil as anode, ν O -The acetone solution of BiOBr is used as the electrolyte, under the DC voltage of 10V, after ultrasonic electrophoresis for 20min, 10V-20min-ν O -BiOBr / TiO 2 Nanotube array composite electrode ( figure 1 c and d). ν O -BiOBr particles exhibit a flower-like morphology composed of nanosheets. figure 2 TiO 2 nanotube array and ν O -BiOBr / TiO 2 XRD pattern of the nanotube array composite electrode. TiO 2 The nanotube array is anatase crystal form, when deposited ν O -After BiOBr particles, compared with pure substrate, except TiO 2 In addition to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com