Preparation method of overbased bactericide

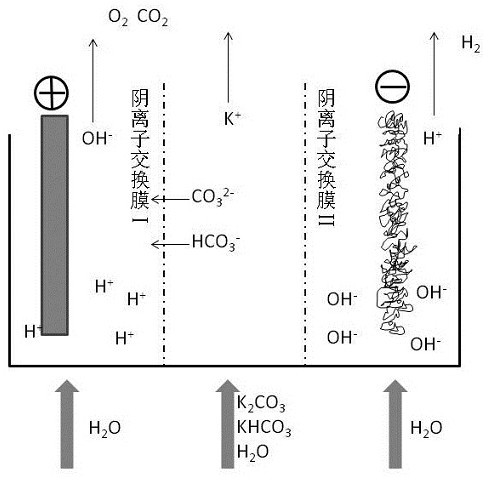

A bactericide and alkaline technology, which is applied in the preparation of super-alkaline bactericide and electrolyzed water to prepare super-alkaline ionized water, which can solve the problems of poor bactericidal effect of bactericide, high energy consumption, and small amount of treated water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

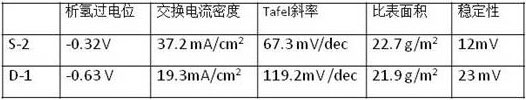

Examples

Embodiment 1

[0079] The preparation method of negative electrode comprises following preparation method:

[0080] (1) Use nickel salt, aluminum salt, lanthanum salt, alkylimidazole halide, ethanedithiol as electrolyte molten salt, copper mesh or nickel mesh as cathode, high-purity aluminum plate as anode, electrodeposition condition 5A / dm 2 , temperature 40 o C, time 30minh, inert gas atmosphere.

[0081] (2) Place the electrode deposited in step (2) in an alkaline solution for corrosion treatment: the alkaline solution is 30wt.% NaOH, a mixture of deionized water and ethanol with a volume ratio of 4:1, accompanied by ultrasound Stirring 30kHz, temperature 30 o c.

[0082] (3) Place the cathode heat-treated in step (2) under the condition of inert gas for heat treatment. The heat treatment takes 12 hours and the temperature is 450 o c.

[0083] (4) Washing and drying: washing with deionized water and air drying in cold air.

[0084] Nickel salt is nickel sulfate or nickel nitrate, 15...

Embodiment 2

[0090] The preparation method of negative electrode comprises following preparation method:

[0091] (1) Use nickel salt, aluminum salt, lanthanum salt, alkylimidazole halide, ethanedithiol as electrolyte molten salt, copper mesh or nickel mesh as cathode, high-purity aluminum plate as anode, electrodeposition condition 10A / dm 2 , temperature 45 o C, time 2h, inert gas atmosphere.

[0092] (2) Place the electrode deposited in step (2) in an alkaline solution for corrosion treatment: the alkaline solution is 32.5wt.% NaOH, a mixture of deionized water and ethanol with a volume ratio of 4:1.25, accompanied by Ultrasonic stirring 35kHz, temperature 33 o c.

[0093] (3) Place the cathode that has been heat-treated in step (2) under inert gas conditions for heat treatment. The heat treatment takes 18 hours and the temperature is 600 o c.

[0094] (4) Washing and drying: washing with deionized water and air drying in cold air.

Embodiment 3

[0101] The preparation method of negative electrode comprises following preparation method:

[0102] (1) Use nickel salt, aluminum salt, lanthanum salt, alkylimidazole halide, ethanedithiol as electrolyte molten salt, copper mesh or nickel mesh as cathode, high-purity aluminum plate as anode, electrodeposition condition 15A / dm 2 , temperature 50 o C, time 4h, inert gas atmosphere.

[0103] (2) Place the electrode deposited in step (2) in an alkaline solution for corrosion treatment: the alkaline solution is 35wt.% NaOH, a mixture of deionized water and ethanol with a volume ratio of 4:1.5, accompanied by ultrasound Stirring 40kHz, temperature 35 o c.

[0104] (3) Place the cathode heat-treated in step (2) under the condition of inert gas for heat treatment, the heat treatment time is 24 hours, and the temperature is 650 o c.

[0105] (4) Washing and drying: washing with deionized water and air drying in cold air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com