A kind of sesame core biochar and its preparation method and application

A biochar and sesame core technology, applied in the field of materials, can solve problems such as unfavorable environmental sustainable development, catalytic performance needs to be strengthened, greenhouse gas emissions, etc., achieve good use value and application prospects, excellent graphitized structure, and increase porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

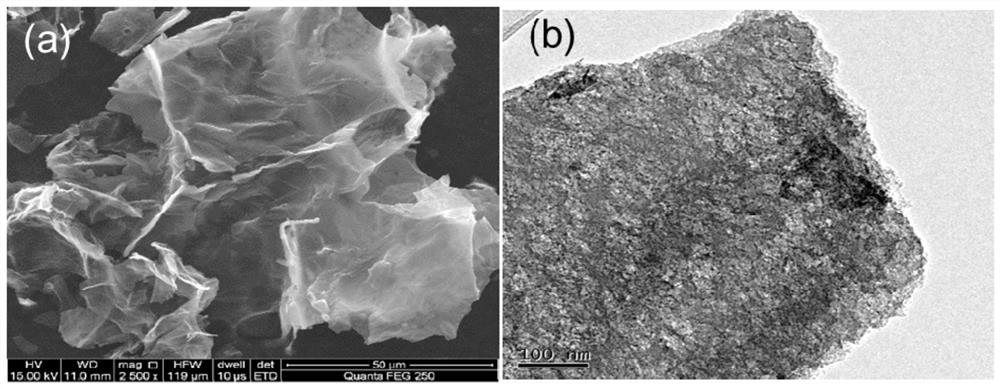

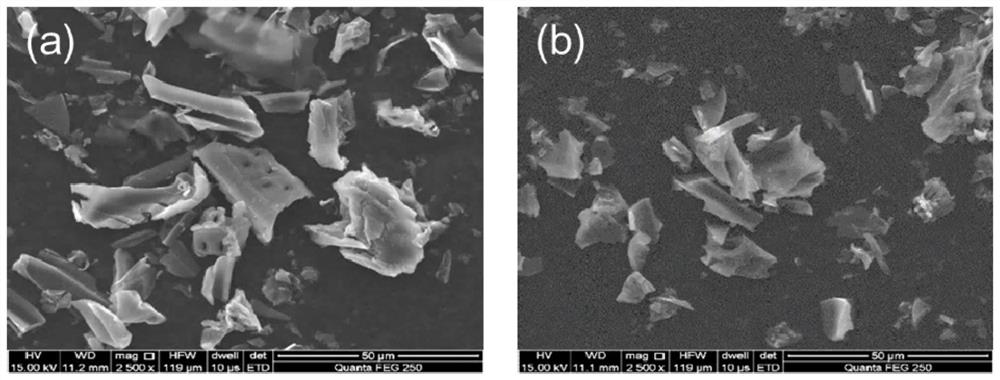

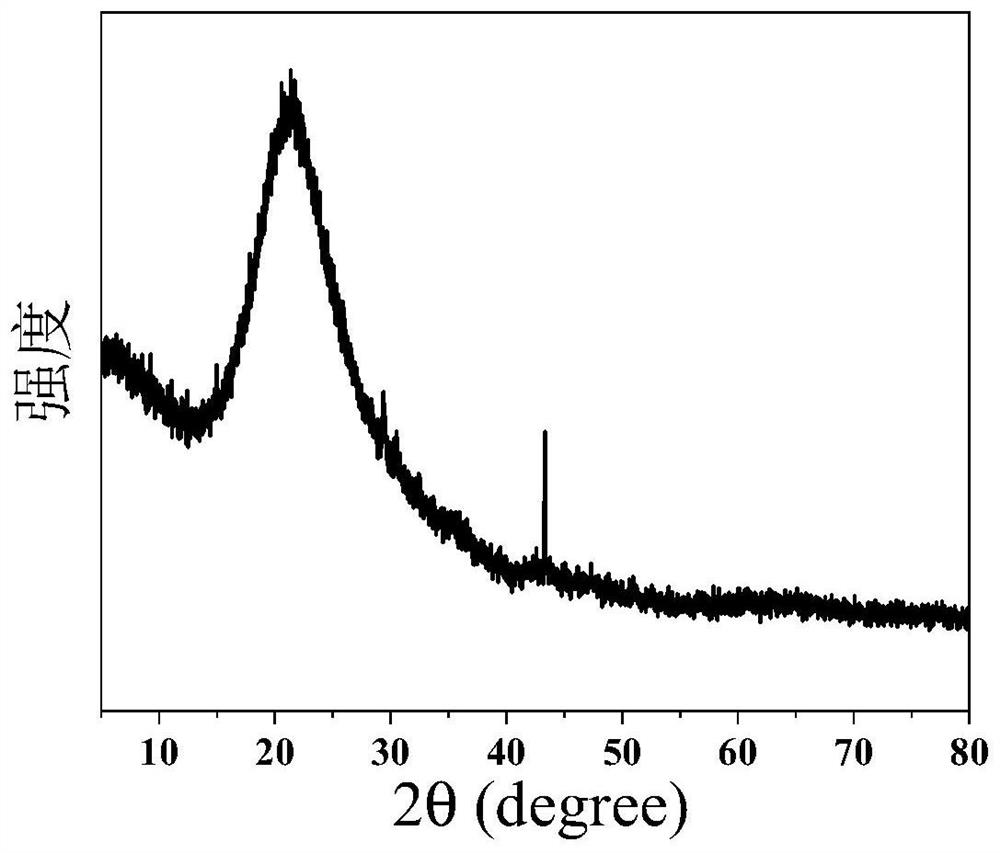

[0039] A method for preparing sesame core biochar, which is prepared by calcining and acid treatment (acid modification) with the sesame core of sesame stalks as raw material, comprising the following steps:

[0040] (1) Separate (peel) the inner core of the sesame stalk from the sesame stalk to obtain the sesame core; use ultrapure water to wash the sesame core, dry it, grind it with a pulverizer, and pass through a 200-mesh sieve (0.075mm ), to obtain the sesame core raw material powder; place the sesame core raw material powder in ultrapure water, ultrasonically clean for 30 min, dry, and set aside.

[0041] (2) Put the raw material powder of sesame cores ultrasonically cleaned and dried in step (1) in a tube furnace, heat up to 800°C at a rate of 5min / °C under nitrogen atmosphere, and keep the temperature for calcination for 2h.

[0042] (3) Place the calcined powder in step (2) in 2M hydrochloric acid solution, stir continuously at a speed of 200r / min for 12h, carry out a...

Embodiment 2

[0055] An application of sesame core biochar in removing organic pollutants in water, specifically utilizing sesame core biochar to activate sodium peroxodisulfate to degrade phenol in water, comprising the following steps:

[0056] Get three parts of volume and be 30mL, the concentration is the phenol solution of 15mg / L, place respectively in three 50mL Erlenmeyer flasks, add the sesame core biochar that makes in the embodiment 1 of different doses respectively, make the sesame core biological charcoal in the solution The concentration of charcoal is 0.11g / L, 0.22g / L and 0.42g / L. At the same time, sodium peroxodisulfate is added to make the concentration 1g / L. Stir at a temperature of 25°C and a shaking rate of 200rpm. The mixed solution was reacted (oxidative degradation treatment), and the reaction time was 180min. After the treatment, the sesame core biochar is separated from the solution to realize catalyst recovery and complete the degradation and removal of organic matt...

Embodiment 3

[0067]An application of sesame core biochar in removing organic pollutants in water, specifically utilizing sesame core biochar to activate sodium peroxodisulfate to degrade phenol in water under different pH conditions, comprising the following steps:

[0068] The sesame core biochar prepared in Example 1 was added to the phenol solutions with a pH of 3.21, 4.98, 6.76, 9.07, and 11.08 respectively (these phenol solutions had a volume of 30 mL and a concentration of 15 mg / L), so that the sesame seeds in the solution The concentration of the core biochar is 0.11g / L, and sodium peroxodisulfate is added separately so that the concentration is 1g / L, and the mixed solution is stirred under the conditions of a temperature of 25°C and a shaking rate of 200rpm to react, and the reaction time is 180min. After the treatment, the sesame core biochar is separated from the solution to realize catalyst recovery and complete the degradation and removal of organic matter phenol.

[0069] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com