High-thermal-conductivity modified asphalt mixture based on carbon fibers and preparation method thereof

A technology of asphalt mixture and modified asphalt, applied in heat exchange materials, chemical instruments and methods, building insulation materials, etc., can solve the problems of high road repair cost, poor thermal conductivity, accelerated road surface, etc. The effect of improving strength liquid, enhancing thermal conductivity, and strengthening network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

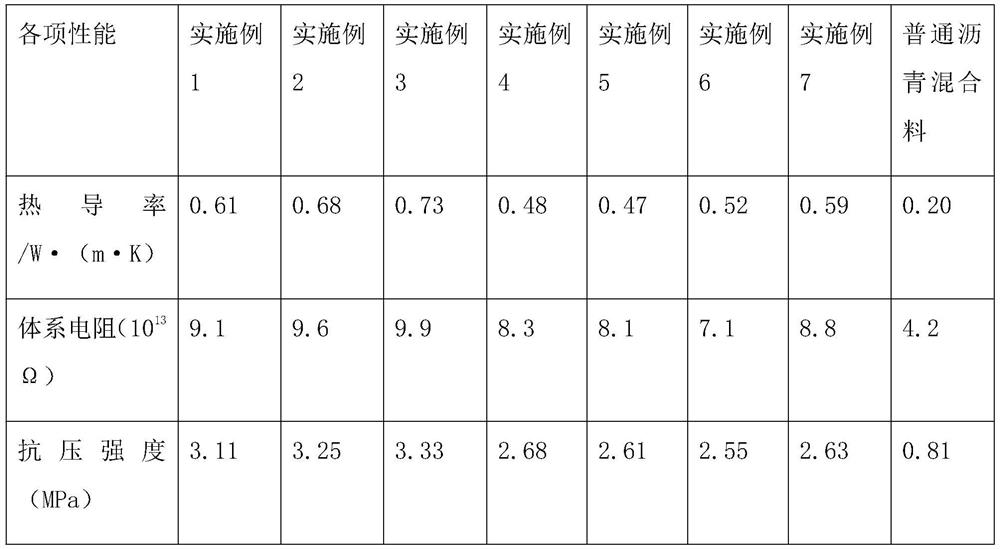

Embodiment 1

[0061] A modified asphalt mixture based on carbon fiber with high thermal conductivity. The raw material components are as follows: in parts by weight, 80 parts of three-dimensional heat conductive material, 50 parts of styrene monomer, 50 parts of divinylbenzene, 10 parts of initiator, cyclic 100 parts of epoxy resin, 70 parts of carboxyl silicone oil, 200 parts of epoxy pitch, 80 parts of mineral fiber, and 60 parts of aggregate.

[0062] The three-dimensional heat-conducting material includes the following raw material components: in parts by weight, 80 parts of modified carbon fiber, 20 parts of aminohydrocarbyl silane coupling agent, 20 parts of three-dimensional carbon boron nitride nanopowder, 20 parts of epoxy hydrocarbyl silane coupling agent share.

[0063] The modified carbon fiber includes the following raw material components: in parts by weight, 100 parts of carbon fiber, 30 parts of polyurethane emulsion, 60 parts of mercaptosilane coupling agent, 60 parts of al...

Embodiment 2

[0083] A modified asphalt mixture based on carbon fiber with high thermal conductivity. The raw material components are as follows: in parts by weight, 100 parts of three-dimensional heat conductive material, 55 parts of styrene monomer, 55 parts of divinylbenzene, 13 parts of initiator, cyclic 150 parts of epoxy resin, 75 parts of carboxyl silicone oil, 250 parts of epoxy pitch, 90 parts of mineral fiber, and 70 parts of aggregate.

[0084] The three-dimensional heat-conducting material includes the following raw material components: in parts by weight, 85 parts of modified carbon fiber, 25 parts of aminohydrocarbyl silane coupling agent, 25 parts of three-dimensional carbon boron nitride nanopowder, 25 parts of epoxy hydrocarbyl silane coupling agent share.

[0085] The modified carbon fiber includes the following raw material components: in parts by weight, 150 parts of carbon fiber, 40 parts of polyurethane emulsion, 70 parts of mercaptosilane coupling agent, 65 parts of a...

Embodiment 3

[0105] A modified asphalt mixture based on carbon fiber high thermal conductivity, the raw material components are as follows: in parts by weight, 120 parts of three-dimensional thermal conductive material, 60 parts of styrene monomer, 60 parts of divinylbenzene, 15 parts of initiator, cyclic 200 parts of oxygen resin, 80 parts of carboxyl silicone oil, 300 parts of epoxy pitch, 100 parts of mineral fiber, and 90 parts of aggregate.

[0106] The three-dimensional thermally conductive material includes the following raw material components: in parts by weight, 90 parts of modified carbon fibers, 30 parts of aminohydrocarbyl silane coupling agent, 30 parts of three-dimensional carbon boron nitride nanopowder, and 30 parts of epoxy hydrocarbyl silane coupling agent share.

[0107] The modified carbon fiber includes the following raw material components: in parts by weight, 200 parts of carbon fiber, 50 parts of polyurethane emulsion, 80 parts of mercaptosilane coupling agent, 70 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com