ZnO@C negative electrode material for zinc-nickel battery and preparation method thereof

A technology of zinc-nickel battery and negative electrode material, applied in battery electrodes, nickel accumulators, carbon preparation/purification, etc., can solve the problems of small contact area, incomplete dendrite growth inhibition, etc., to improve mass transfer rate, excellent Electrochemical performance, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a ZnO@C negative electrode material for a zinc-nickel battery, comprising the following steps:

[0039] Step 1: Add 6 g of zinc acetate into 300 mL of diethylene glycol, heat in an oil bath at 170° C., stir and react for 30 min to obtain a reaction solution.

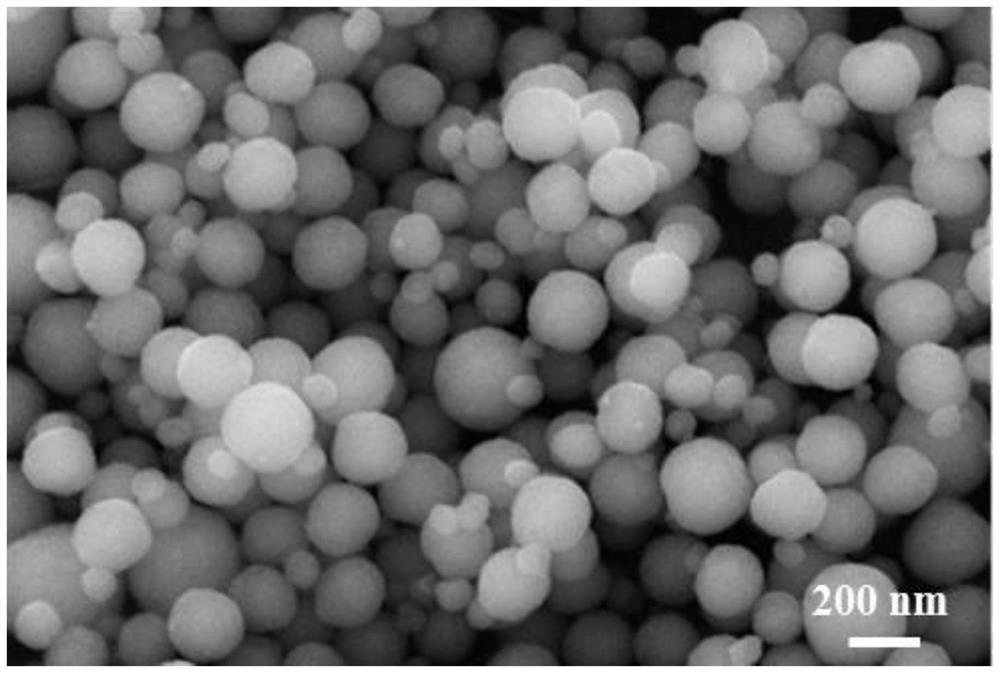

[0040] After the reaction solution was cooled to room temperature, centrifugal separation was carried out, and the product was repeatedly washed 3 times with absolute ethanol and deionized water, and dried under vacuum for 12 hours to obtain ZnO microspheres;

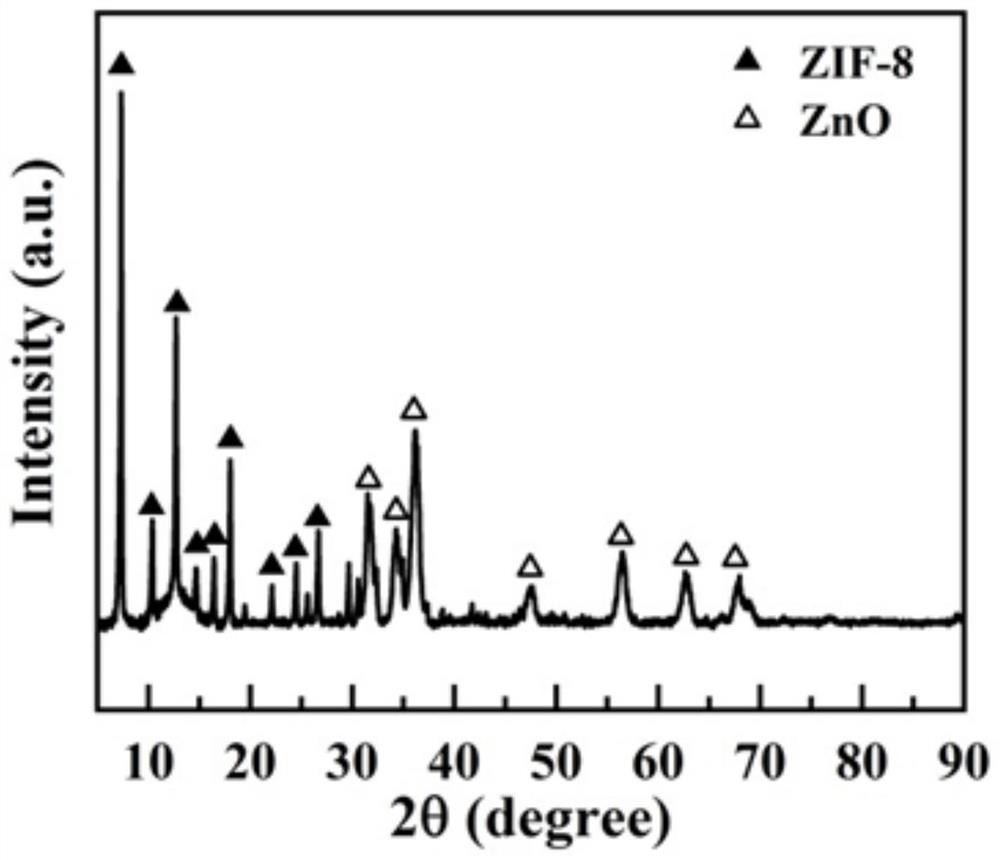

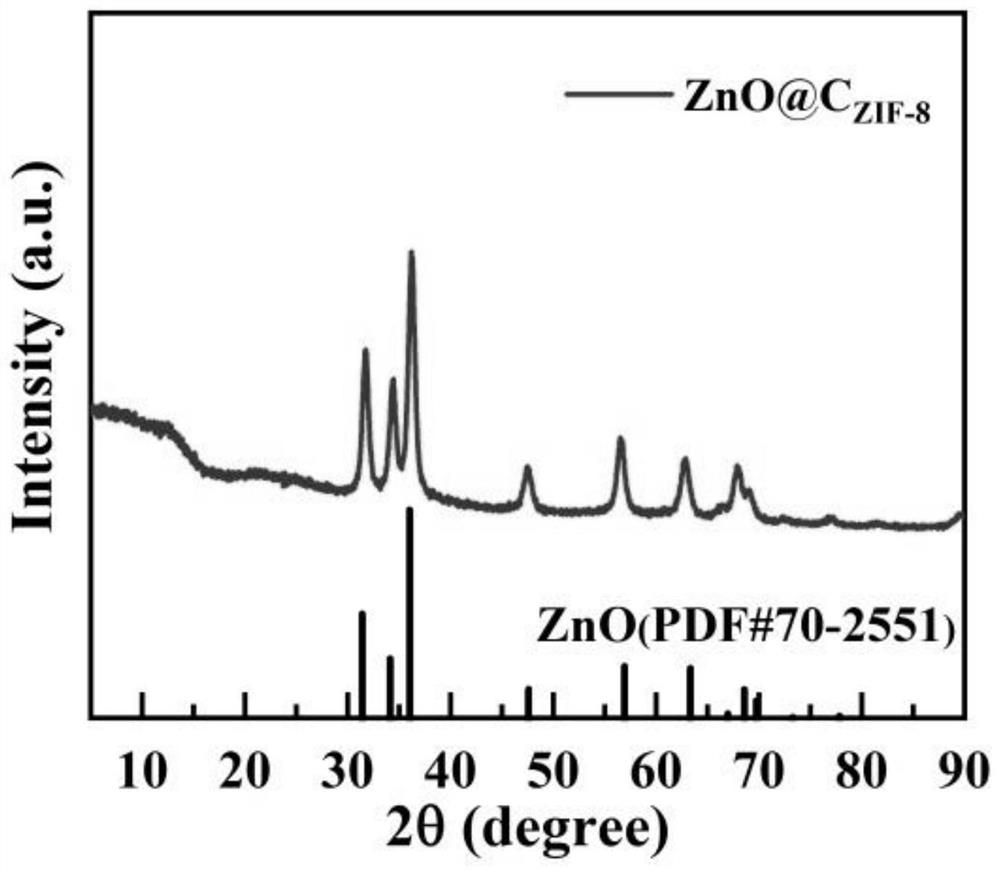

[0041] Step 2: Take 0.825g of 2-methylimidazole and 0.102g of the above-prepared ZnO pellets, and sequentially add them to the N,N-dimethylformamide (DMF) / H 2 The mixed solution of O (80mL, the volume ratio of the two is DMF:H 2 O=3:1), and fully stirred to obtain a mixed liquid. The above mixed liquid was transferred to a hydrothermal reaction kettle (volume 100mL), and the hydrothermal reaction was carried out at 70°C for 24 hours...

Embodiment 2

[0052] A method for preparing a ZnO@C negative electrode material for a zinc-nickel battery, comprising the following steps:

[0053] Step 1: Add 5 g of zinc acetate into 300 mL of diethylene glycol, heat in an oil bath at 180° C., and stir for 40 minutes to obtain a reaction solution.

[0054] After the reaction solution was cooled to room temperature, centrifugation was carried out, and the product was repeatedly washed 3 times with absolute ethanol and deionized water, and dried under vacuum for 11 hours to obtain ZnO microspheres;

[0055] Step 2: Take 0.7425g of 2-methylimidazole and 0.102g of the above-prepared ZnO pellets, and sequentially add them to the N,N-dimethylformamide (DMF) / H 2 The mixed solution of O (60mL, the volume ratio of the two is DMF:H 2 O=2:1), and fully stirred to obtain a mixed liquid.

[0056] The above mixed liquid was transferred to a hydrothermal reaction kettle (volume 100mL), and the hydrothermal reaction was carried out at 60°C for 20h. Aft...

Embodiment 3

[0061] A method for preparing a ZnO@C negative electrode material for a zinc-nickel battery, comprising the following steps:

[0062] Step 1: Add 5 g of zinc acetate into 200 mL of diethylene glycol, heat in an oil bath at 160° C., stir and react for 20 min to obtain a reaction solution.

[0063] After the reaction solution was cooled to room temperature, centrifugation was carried out, and the product was repeatedly washed twice with absolute ethanol and deionized water, and dried under vacuum for 10 hours to obtain ZnO microspheres;

[0064] Step 2: Take 0.66g of 2-methylimidazole and 0.102g of the above-prepared ZnO pellets, and sequentially add them to the N,N-dimethylformamide (DMF) / H 2 The mixed solution of O (80mL, the volume ratio of the two is DMF:H 2 O=1:1), and fully stirred to obtain a mixed liquid. The above mixed liquid was transferred to a hydrothermal reaction kettle (volume 100mL), and the hydrothermal reaction was carried out at 80°C for 22 hours. After coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com