Catalyst for carbon nanotube and preparation method and application thereof

A technology of carbon nanotubes and catalysts, which is applied in the field of catalysts for carbon nanotubes and their preparation, and can solve the problems of high volume density, poor dispersion, and complex interlacing and interlacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

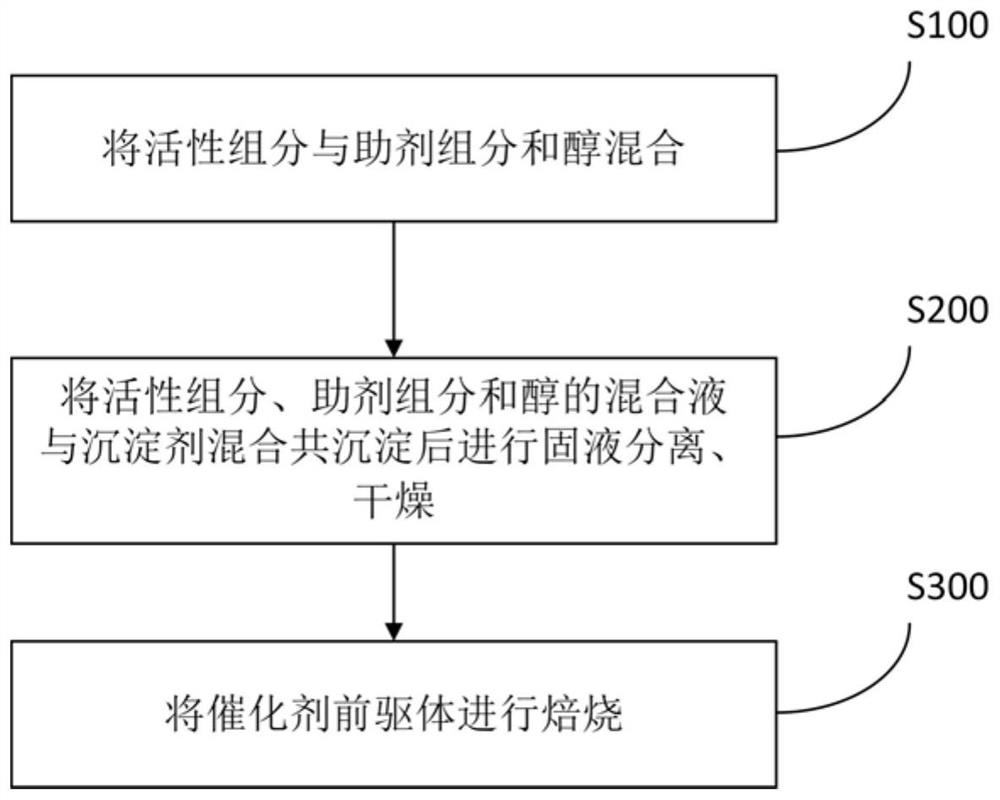

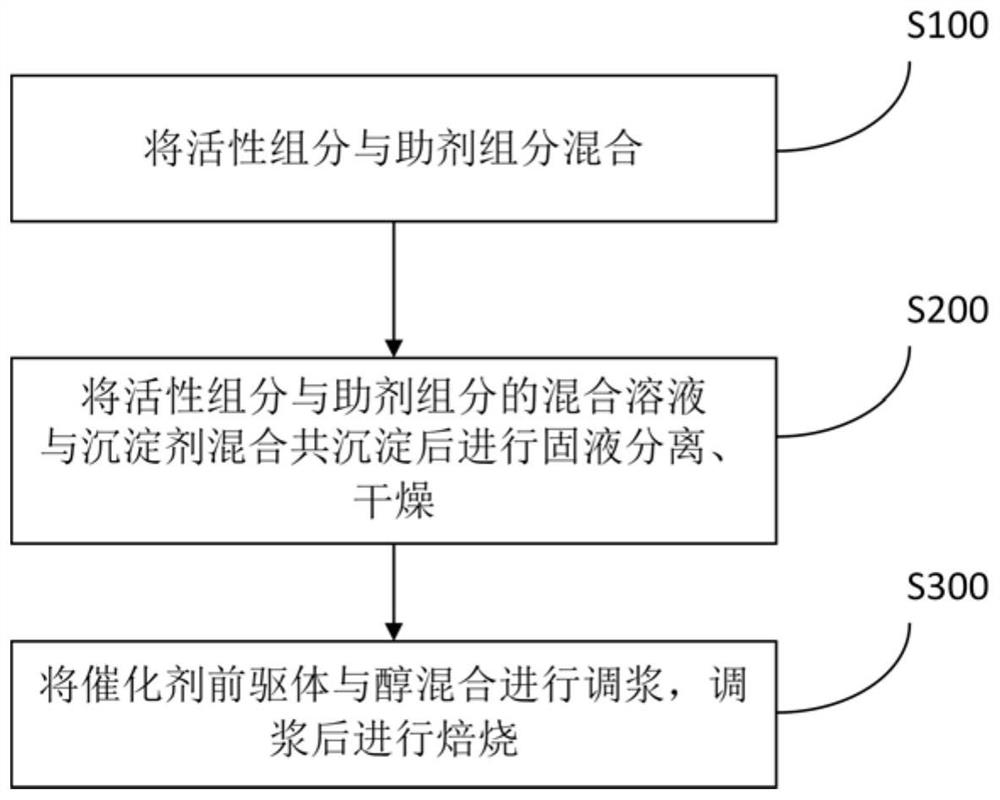

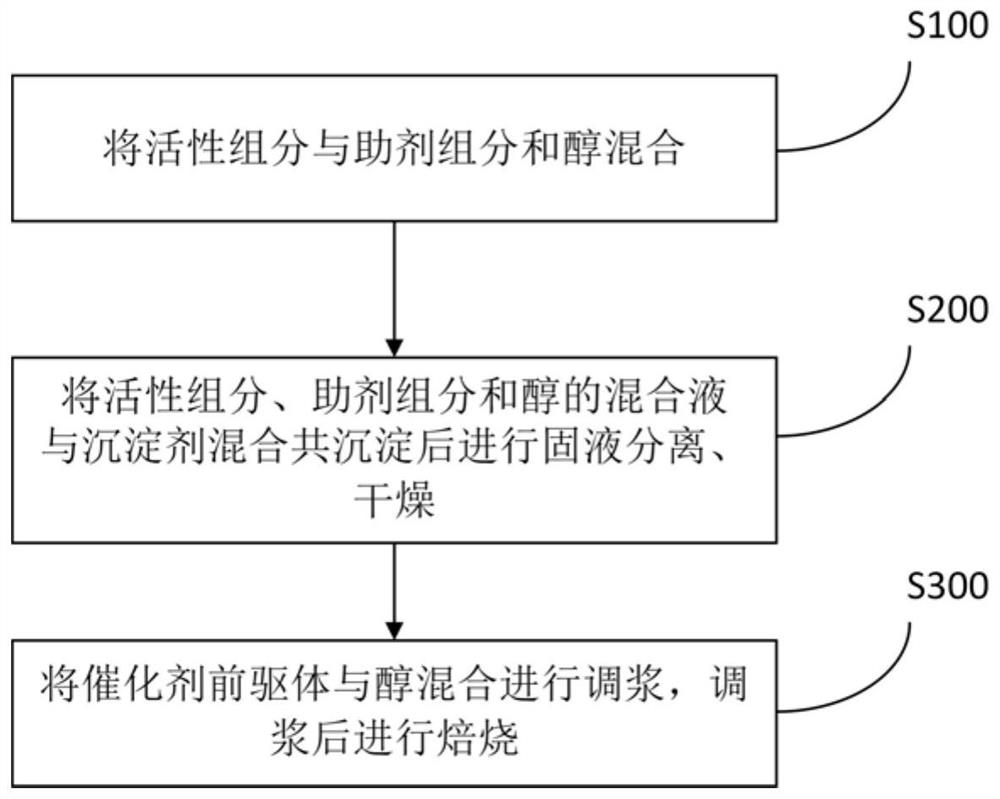

Method used

Image

Examples

Embodiment 1

[0080] Preparation of catalysts for carbon nanotubes:

[0081]Step 1: Mix nickel nitrate, aluminum nitrate, and ferric nitrate in 200mL of water and stir evenly, and control the concentrations of nickel nitrate, aluminum nitrate, and ferric nitrate to 0.1mol / L, 0.3mol / L, and 1mol / L respectively to obtain active components Salt solution; use ammonium molybdate tetrahydrate to prepare 50ml of a solution with a molybdenum content of 0.1mol / L, and use polyvinylpyrrolidone to prepare 5mL of a solution with a concentration of 0.05mol / L; add the molybdenum salt solution and polyvinylpyrrolidone solution to the stirred nitric acid In the salt solution, continue to stir for 30 minutes after the dropwise addition is completed, and then mix with 20mL ethanol to obtain a mixed solution;

[0082] Step 2: Pour 100mL of ammonia water with a concentration of 1mol / L into the above mixed solution, mix it evenly by ultrasonication for 30min, then place it in a hydrothermal reaction kettle, react...

Embodiment 2

[0087] Preparation of catalysts for carbon nanotubes:

[0088] Step 1: Mix nickel nitrate, magnesium nitrate, and ferric nitrate in 300mL of water and stir evenly, and control the concentrations of nickel nitrate, magnesium nitrate, and ferric nitrate to 0.1mol / L, 0.5mol / L, and 0.5mol / L respectively to obtain the active group 300ml of salt solution; use copper nitrate to prepare 50ml of a solution with a copper content of 0.1mol / L, and use polyvinylpyrrolidone to prepare 5mL of a solution with a concentration of 0.05mol / L; add the copper salt solution and polyvinylpyrrolidone solution to the stirred nitrate solution, continue to stir for 30 minutes after the dropwise addition, and then mix with 20mL ethanol to obtain a mixed solution;

[0089] Step 2: Pour the above-mentioned mixed solution into the mixed solution of 300ml sodium hydroxide (concentration: 2mol / L) + ammonium carbonate solution (concentration: 2mol / L), and ultrasonically mix for 30min; place it in a hydrothermal...

Embodiment 3

[0094] Preparation of catalysts for carbon nanotubes:

[0095] Step 1: mix cobalt nitrate, magnesium nitrate, ferric nitrate in 200mL water and mix evenly, control the concentration of cobalt nitrate, magnesium nitrate, ferric nitrate to be 0.2mol / L, 0.5mol / L, 0.3mol / L respectively, obtain active group Salt separation solution; 10ml of a solution with a molybdenum content of 0.1mol / L was prepared with ammonium molybdate tetrahydrate, and 5mL of a solution with a concentration of 0.05mol / L was prepared with polyvinylpyrrolidone; the molybdenum salt solution and polyvinylpyrrolidone solution were slowly added dropwise to In the rapidly stirred nitrate solution, continue to stir for 30 minutes after the dropwise addition is completed, and then mix with 200mL ethylene glycol to obtain a mixed solution;

[0096] Step 2: Pour the above mixed solution into 300mL ammonium carbonate (concentration: 0.3mol / L) and ammonia water (concentration: 0.5mol / L) mixture, stir evenly; place it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com