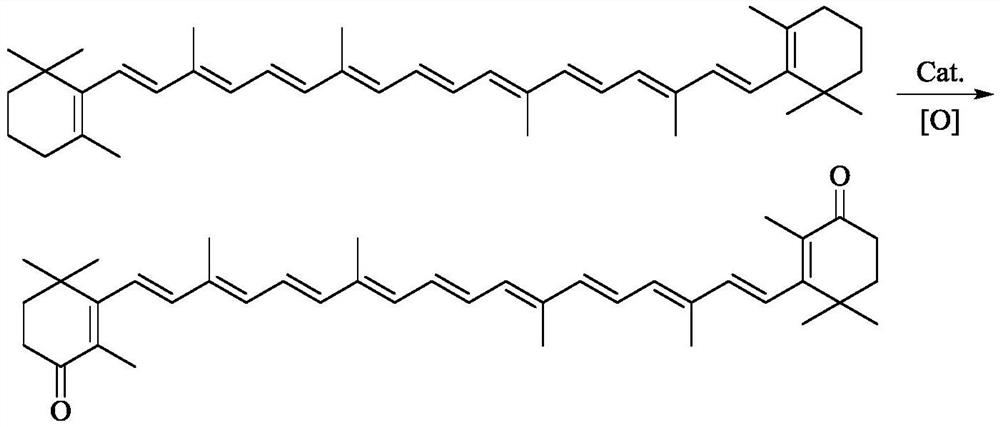

Catalyst for preparing canthaxanthin from beta-carotene and preparation method and application thereof

A carotene and catalyst technology, which is applied in catalytic reactions, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst stability difference, low reaction yield, generation of halogen-containing wastewater, etc., and achieves mild reaction conditions, The preparation process is simple and the route is environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Preparation of catalyst a:

[0071] Catalyst carrier preparation: Take 60 g of melamine and 10 g of triphenylphosphine in a mortar, grind and mix for 30 minutes. The mixed powder was transferred into a crucible and calcined at 550°C for 5h with a heating rate of 3°C / min. After cooling down, the solid was taken out, and ground to a solid particle size of 500 mesh to obtain the carrier phosphorus-doped graphite phase carbon nitride (P-g-C 3 N 4 ), the phosphorus content is 1.0%.

[0072] Preparation of tetrapyridyl porphyrin copper: Take equimolar tetrapyridyl porphyrin (referred to as L-1) and copper acetate in a three-necked flask, add N,N-dimethylformaldehyde 6 times the weight of L-1 ligand Amide, heated to reflux for 2h. Cool, filter with suction, wash the filter cake with absolute ethanol, and dry.

[0073] Weigh 7.8g tetrapyridyl porphyrin copper and 50g carrier P-g-C 3 N 4 Grind in an agate mortar for 30 minutes, transfer to a beaker and add 200g N,N-dimeth...

Embodiment 2

[0076] Preparation of catalyst b:

[0077] Catalyst carrier preparation: Take 60 g of melamine and 30 g of triphenylphosphine oxide in a mortar, grind and mix for 30 minutes. The mixed powder was transferred into a crucible and calcined at 450°C for 9h with a heating rate of 1.5°C / min. After cooling down, the solid was taken out, and ground to a solid particle size of 300 mesh to obtain the carrier phosphorus-doped graphite phase carbon nitride (P-g-C 3 N 4 ), the phosphorus content is 2.5%.

[0078] Preparation of copper tetraphenylporphyrin: Take tetraphenylporphyrin (referred to as L-2) and copper chloride in a three-necked flask at a molar ratio of 0.6:1, add N that is 4 times the weight of L-2 ligand, N-dimethylformamide was heated to reflux for 5h. Cool, filter with suction, wash the filter cake with absolute ethanol, and dry.

[0079] Weigh 12.9g tetraphenylporphyrin copper and 50g carrier P-g-C 3 N 4 Grind in an agate mortar for 30 minutes, transfer to a beaker ...

Embodiment 3

[0082] Preparation of catalyst c:

[0083] Catalyst carrier preparation: Take 60 g of melamine and 8 g of ammonium phosphate in a mortar, grind and mix for 30 minutes. The mixed powder was transferred into a crucible and calcined at 650°C for 3h with a heating rate of 4°C / min. After cooling down, the solid was taken out and ground to a solid particle size of 600 mesh to obtain the carrier phosphorus-doped graphite phase carbon nitride (P-g-C 3 N 4 ), the phosphorus content is 0.8%.

[0084] Preparation of tetrakis(4-hydroxyphenyl)porphyrin copper: Take tetrakis(4-hydroxyphenyl)porphyrin (referred to as L-3) and copper sulfate in a three-necked flask at a molar ratio of 1.3:1, add L- 3. N,N-dimethylformamide with 8 times the weight of the ligand was heated to reflux for 3 hours. Cool, filter with suction, wash the filter cake with absolute ethanol, and dry.

[0085] Weigh 6.2g tetrakis(4-hydroxyphenyl)porphyrin copper and 50g carrier P-g-C 3 N 4 Grind in an agate mortar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com