Three-dimensional electrochemical-ozonation coupling treatment device for wastewater difficult to treat, and wastewater treatment method

A treatment device, electrochemical technology, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problem of low space-time efficiency in wastewater treatment, and achieve the purpose of inhibiting the formation of carcinogenic bromate, The effect of improving the utilization rate and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

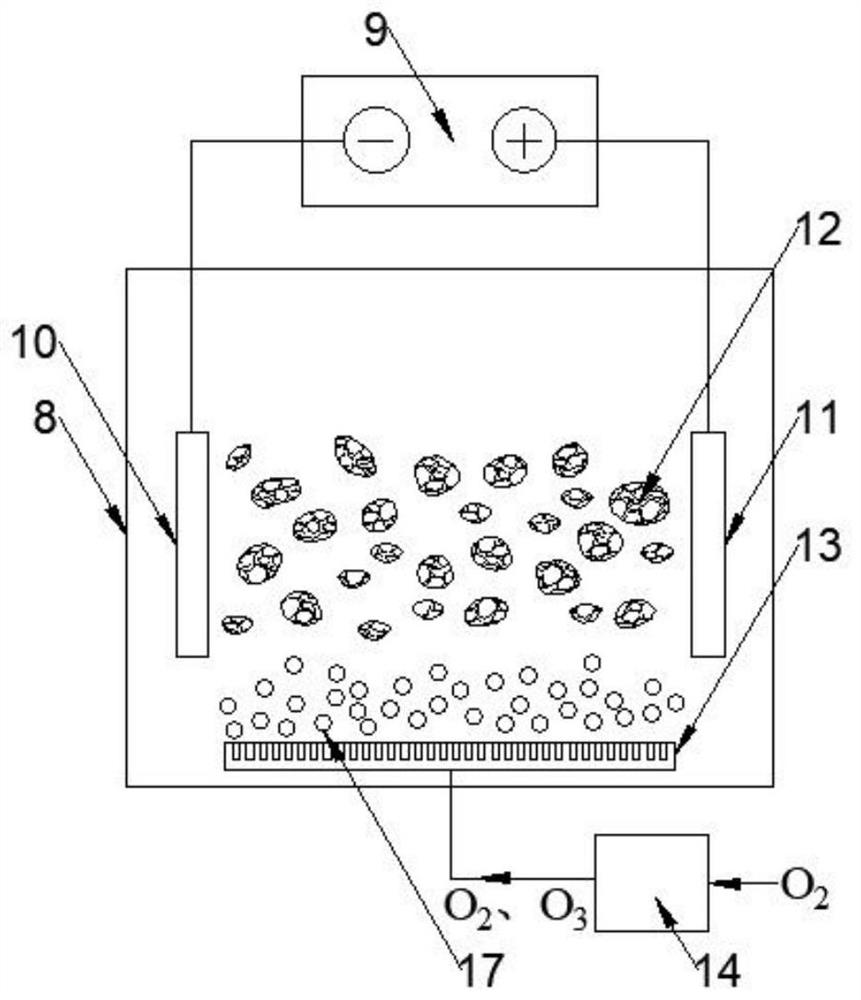

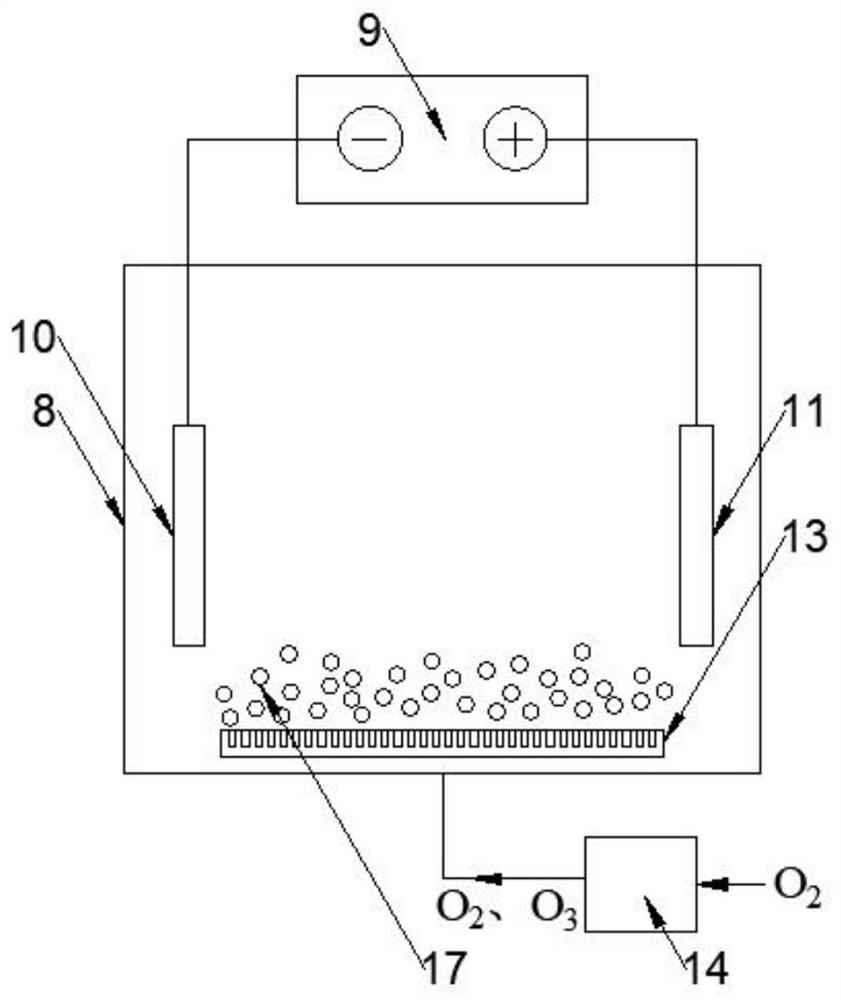

[0040] Such as figure 1 As shown, a three-dimensional electrochemical-perozone coupled treatment device for refractory wastewater includes a three-dimensional electrochemical-perozone coupled reactor 3, and the three-dimensional electrochemical-perozone coupled reactor 3 includes a reactor tank 8, a reactor tank The body 8 is provided with a cathode 10 and an anode 11 connected to each other through a DC power supply 9. The reactor tank 8 is also filled with a particle electrode 12. The particle electrode 12 is located between the cathode 10 and the anode 11. The bottom of the reactor tank 8 is provided with Microbubble ozone distributor 13 is arranged, and microbubble ozone distributor 13 is connected to ozone generator 14;

[0041] Wherein, the cathode 10 is at least one of stainless steel, activated carbon felt, activated carbon fiber, carbon black-PTFE or foamed nickel;

[0042] The anode 11 is a titanium plate or a titanium mesh coated with a metal oxide coating on the s...

Embodiment 2

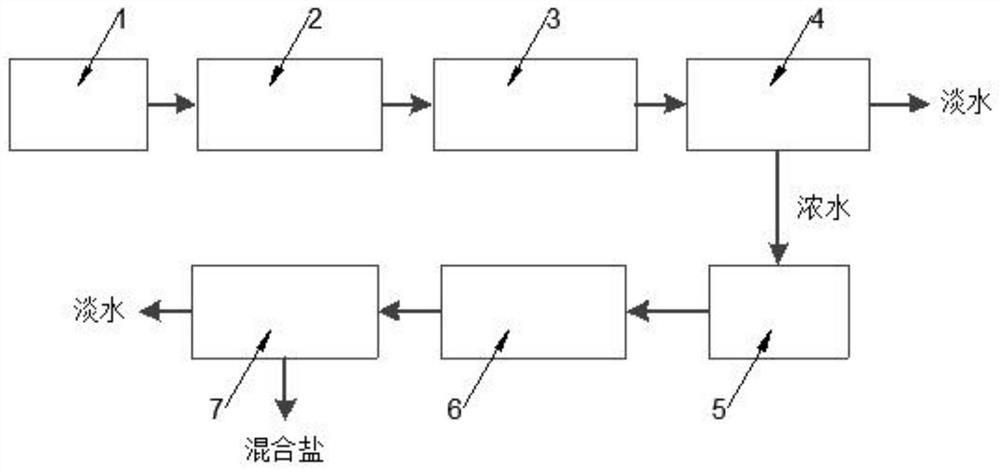

[0045] Such as figure 2 As shown, a three-dimensional electrochemical-perozone coupled treatment device for difficult-to-treat wastewater includes an electroflocculator 1, a first filter 2, a three-dimensional electrochemical-perozone coupled reactor 3, and a second filter connected sequentially through pipelines 4. Reverse osmosis device 5. CO 2 Hardening reactor 6 and MVR evaporator 7;

[0046] Wherein the anode of the electrocoagulator 1 is a soluble aluminum electrode;

[0047] The first filter 2 is a filter combination of a quartz sand filter and a polyethylene sintered filter core (the aperture is 2 μm);

[0048] The three-dimensional electrochemical-overozone coupled reactor 3 includes a reactor tank 8, the reactor tank 8 is provided with a water inlet and a water outlet, and the reactor tank 8 is provided with a cathode 10 and an anode connected to each other by a DC power supply 9 11. The cathode 10 is made of stainless steel, the anode 11 is a titanium plate coat...

Embodiment 3

[0051] Adopt embodiment 2 device to treat waste water, the COD of waste water is 83mg / L, TN is 66mg / L, and salt is 2594mg / L, and concrete processing method comprises the following steps:

[0052] (1) Refractory wastewater is electrocoagulated by an electroflocculator, and is pre-filtered through a quartz sand filter and a polyethylene sintered filter element, and then enters a three-dimensional electrochemical-ozone coupling reactor, and the ozone generator is turned on, and the ozone is 80mg / L The concentration is added to the three-dimensional electrochemical-perozone coupling reactor to form microbubbles 17, and the DC power is turned on to make the current density reach 10mA / cm 2 , the treatment time is 45 minutes, and the wastewater indicators after treatment are reduced to COD≤30mg / L, TN≤10mg / L;

[0053] (2) Use the ultrafiltration membrane to filter the wastewater after the three-dimensional electrochemical-ozone coupling treatment for the second time, and intercept mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com