Multi-element association type fracturing fluid thickening agent and preparation method thereof

An associative, fracturing fluid technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of thickening performance and drag reduction performance that need to be further improved, needs to be further improved, etc., and is not easy to explode. Phenomenon, the effect of fast dissolution rate and high monomer conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method of preparing polyol associative thickener of the fracturing fluid in a first aspect, the method comprising the steps of:

[0032] (1) acrylamide, methacrylic acid, monomer salt, anti-temperature monomer, a hydrophobic monomer, co-solvent, water and an oxidizing agent as raw materials preparation initiator aqueous phase, and then the aqueous phase into an aqueous phase A part B and the water phase two, in the present invention, when the aqueous phase into the aqueous phase a and water phase B of two parts, the mass ratio of the aqueous phase a and phase B as the water is (0.5 to 1.5 ): 1; or acrylamide, methacrylic acid, monomer salt, anti-temperature monomer, a hydrophobic monomer, co-solvent, water and oxidation initiators are formulated raw material aqueous phase A and aqueous phase B; in the present invention, and more preferably are formulated in an aqueous phase a and aqueous phase B; in the present invention, the formulation of ...

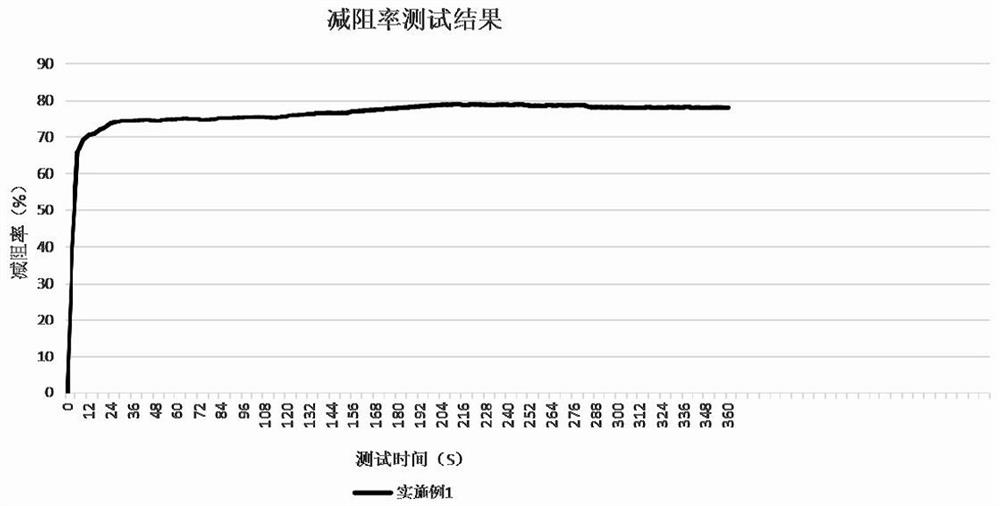

Embodiment 1

[0053] ① A formulation of aqueous phase: 180g deionized water was added kettle ingredients, were added 110g acrylamide monomer, methacrylate, 45g, 2- acrylamido-2-methylpropane sulfonate (salt monomers) 10g, N- phenyl-acrylamide (temperature resistance monomer) 3.5g, octadecyl acrylate (hydrophobic monomer) 3.0 g of, sodium formate (co-solvent) 10g, thoroughly stirred and uniformly dissolved, and then adjusted with sodium hydroxide pH to 6.35; final addition of potassium persulfate (oxidizing initiator) 0.021 g, uniformly mixed and stirred to obtain an aqueous phase A.

[0054] ② aqueous phase B is prepared: 167g deionized water was added in the formulation kettle, 105g were added acrylamide monomer, methyl methacrylate 20g, 2- acrylamido-2-methylpropane sulfonate (salt monomers) 10g, N- phenyl-acrylamide (monomer temperature resistance) 2.0 g of, octadecyl acrylate (hydrophobic monomer) 1.5 g, sodium formate (co-solvent) 10g, thoroughly stirred and uniformly dissolved, and then a...

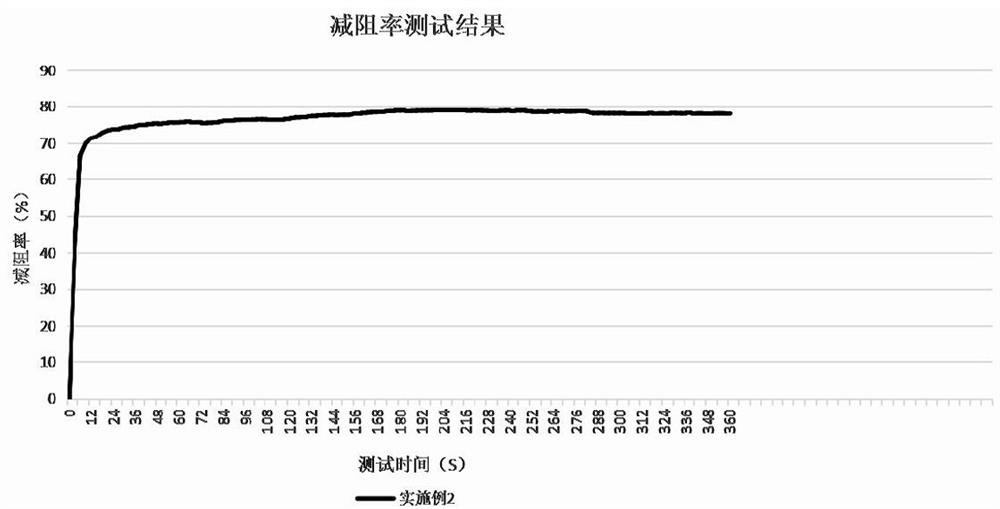

Embodiment 2

[0060] ① A formulation of aqueous phase: 190g deionized water was added ingredients kettle, acrylamide monomer were added 120g, 35g methacrylic acid, 2- acrylamido-2-methylpropane sulfonate (salt monomers) 10g, N, N- diethyl-2-propenamide (temperature resistance monomer) 3.2g, cetyl dimethyl ammonium chloride (hydrophobic monomer) 3.0g, acetamide (co-solvent) 10g, thoroughly stirred and uniformly dissolved, then the pH is adjusted to 6.40 with sodium hydroxide; final addition of ammonium persulfate (oxidizing initiator) 0.026 g, uniformly mixed and stirred to obtain an aqueous phase A.

[0061] ② aqueous phase B is prepared: 178.5g of deionized water was added in the formulation kettle, acrylamide monomer were added 100g, 25g methacrylic acid, 2- acrylamido-2-methylpropane sulfonate (salt monomer ) 8g, N, N- diethyl-2-propenamide (temperature resistance monomer) 2.3g, cetyl dimethyl ammonium chloride (hydrophobic monomer) 3.0g, acetamide (co-solvent ) 10g, thoroughly stirred and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com