Fireproof magnesium oxide board and manufacturing process thereof

A technology of magnesium oxide and plates, applied in the field of plates, can solve the problems of poor dispersion effect, restricting the wide application of products, embrittlement of plates, etc., and achieve the effect of increasing specific surface area, realizing water loss and water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

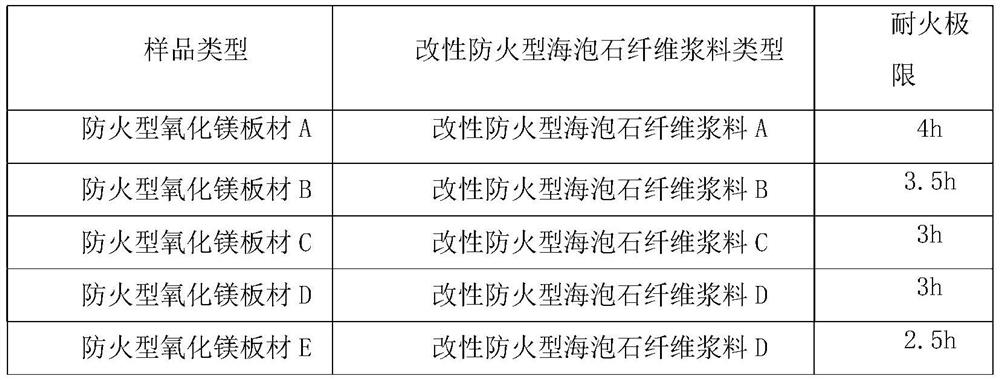

Examples

Embodiment 1

[0033] The embodiment of the present invention provides a fireproof sepiolite fiber slurry, which comprises the following parts by weight: modified sepiolite wool 30, talcum powder 5, vegetable rubber powder 12, polypropylene fiber 15. Cellulose ether 3, surfactant 2, deionized water 80, its preparation method is:

[0034] (1) Preparation of modified sepiolite wool: acid activation: mix sepiolite and acid solution according to the ratio of solid to liquid weight ratio of 1:1.5, stir for 12 hours, and the volume fraction of acid solution is 2% mixed acid to obtain the first sepiolite slurry; wherein the mixed acid is a mixture of hydrochloric acid and phosphoric acid, and its molar ratio is 1:1;

[0035] (2) Alkali neutralization: the first sepiolite slurry after acid activation is mixed with ammonia according to the ratio of solid-to-liquid weight ratio of 1:1.5, and stirred for 12 hours to obtain the second sepiolite slurry, wherein , the molar ratio of mixed acid and ammoni...

Embodiment 2

[0038] On the basis of embodiment 1, step (1) changes sepiolite and acid liquid 1 according to the ratio of solid-liquid weight ratio from 1:1.5 to the ratio according to solid-liquid weight ratio of 1:2, and other preparation steps are the same, Obtain fireproof sepiolite fiber slurry B

Embodiment 3

[0040] On the basis of Example 1, hydrochloric acid in step 1 was replaced with sulfuric acid, and other preparation steps were the same to obtain fireproof sepiolite fiber slurry C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com