A kind of graphene-modified silicon-titanium nanopolymer slurry and its preparation method and application

A nano-polymer, graphene modification technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of broken bonds between coatings and substrates, limited penetration resistance, and large amount of powder added. , to achieve the effect of improving compactness and mechanical properties, improving medium penetration resistance, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

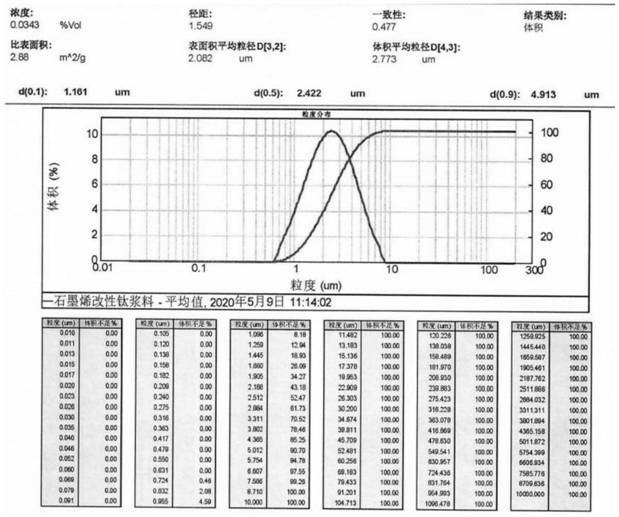

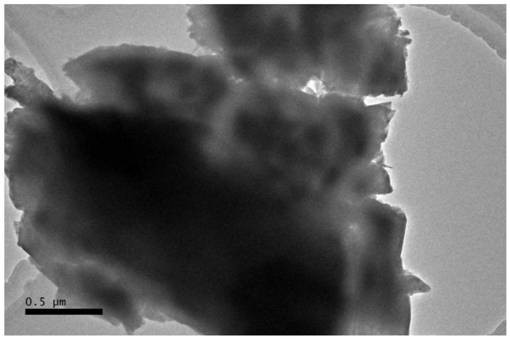

Image

Examples

preparation example Construction

[0048] In the present invention, the preparation method of described silane coupling agent modified graphene preferably comprises the following steps:

[0049] The graphene, propylene glycol methyl ether acetate, silane coupling agent and water are mixed and subjected to ultraviolet radiation to obtain the silane coupling agent modified graphene.

[0050] In the present invention, the silane coupling agent in the silane coupling agent modified graphene is preferably γ-aminopropyltriethoxysilane, more preferably KH-550, A-1100, Z-6011, KBE- 903 or AMEO.

[0051] In the present invention, the structural formula of the γ-aminopropyltriethoxysilane is shown in the following formula:

[0052]

[0053] In the present invention, the mass ratio of the graphene, propylene glycol methyl ether acetate, silane coupling agent and water is preferably (10~300):(5000~10000):(1~20):(1~20) , more preferably 100:7900:5:5.

[0054] In the present invention, the ultraviolet wavelength of the...

Embodiment 1

[0115] Mix 100g graphene with 7900g propylene glycol methyl ether acetate and stir evenly, add 5gKH-550 and 5g deionized water dropwise, continue to stir evenly, put the mixed solution in a 500×300mm stainless steel tray, and place it under the ultraviolet light of 254nm band Exposed to ultraviolet high-energy radiation for 60 minutes in the cleaning machine to obtain KH-550 modified graphene;

[0116] Mix 50 parts of titanium hydride (≥500 mesh), 3 parts of active silicon dioxide (2-15nm), KH-550 modified diluent (type 692 active diluent (benzyl glycidyl ether) of Anhui Xinyuan Technology Co., Ltd. active diluent)) 4 parts, N-methylpyrrolidone 5 parts, dispersant (Changshapet VK-DP345) 3 parts, coupling agent (Changshapet VK SL113) 3 parts, catalyst (mass ratio is 2: 1 nano-cerium oxide and silicon-modified nano-crystalline alumina) 0.05 parts, wetting agent (Digo 450) 0.15 parts, wetting aid (Allnex brand ADDITOLXL180 type) 0.15 parts, in the order of first liquid and then s...

Embodiment 2

[0118]The difference from Example 1 is that the raw materials are 45 parts of titanium hydride (≥500 mesh), 3 parts of active silica (2-15nm), 2 parts of KH-550 modified graphene, silicon-modified epoxy resin (active Silicon-modified novolac epoxy resin) 25 parts, reactive diluent (692 type reactive diluent (benzyl glycidyl ether reactive diluent) of Anhui Xinyuan Technology Co., Ltd.) 4 parts, N-methylpyrrolidone 5 parts , dispersant (Changshapet VK-DP345) 3 parts, coupling agent (Changshapet VK SL113) 3 parts, catalyst (mass ratio of 2:1 nano-cerium oxide and silicon-modified nano-γ crystal alumina) 0.05 part, 0.15 part of wetting agent (Digo 450), 0.15 part of wetting aid (ADDITOL XL180 type of Allnex brand), and the remaining contents are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com