Method for synthesizing cyanobenzene by recycling and reusing byproducts of benzotripolycyanamide

A technology of benzomelamine and benzonitrile is applied in the field of recycling and reusing benzonitrile by-products to synthesize benzonitrile, which can solve the problems of large amount of benzomelamine sewage and high wastewater treatment costs, and achieve the reduction of types and COD, Realize the effect of recycling and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of method that benzomelamine by-product recovery reuses synthetic benzonitrile comprises the steps:

[0040] S1, add 140g benzomelamine by-product (contain about 42g 2,4,6-triphenyl-1,3,5-triazine and 52g benzamide) in reaction container, then add 500mL butanol, 25g hydrochloric acid , 15g of acetic acid and 1.4g of nickel chloride catalyst, heated to 100°C and reacted for 5 hours. After the raw materials were completely acidolyzed, butanol and water were removed under reduced pressure; the reaction materials continued to heat up to 150°C and stirred for 15 hours until the reaction was complete Crude distillation under reduced pressure, collecting the distilled fractions to obtain the crude product of benzonitrile reaction;

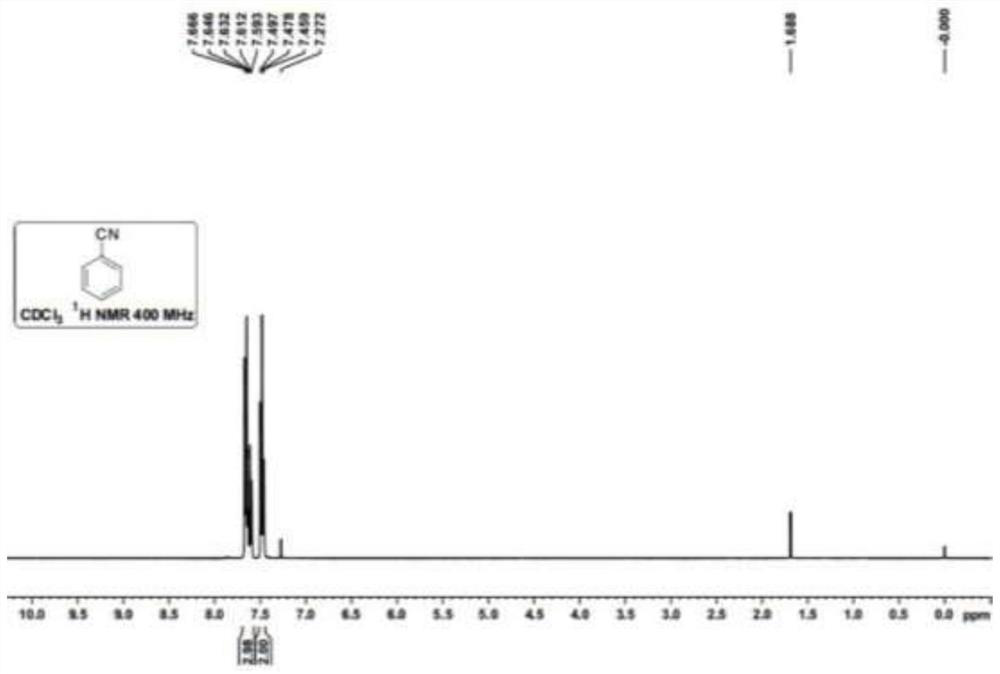

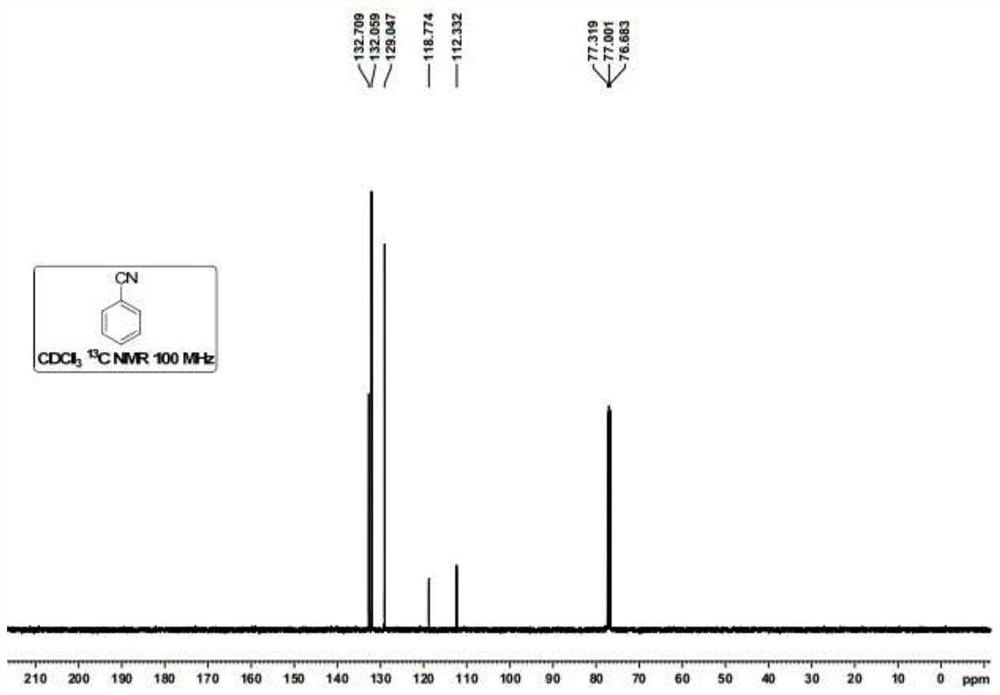

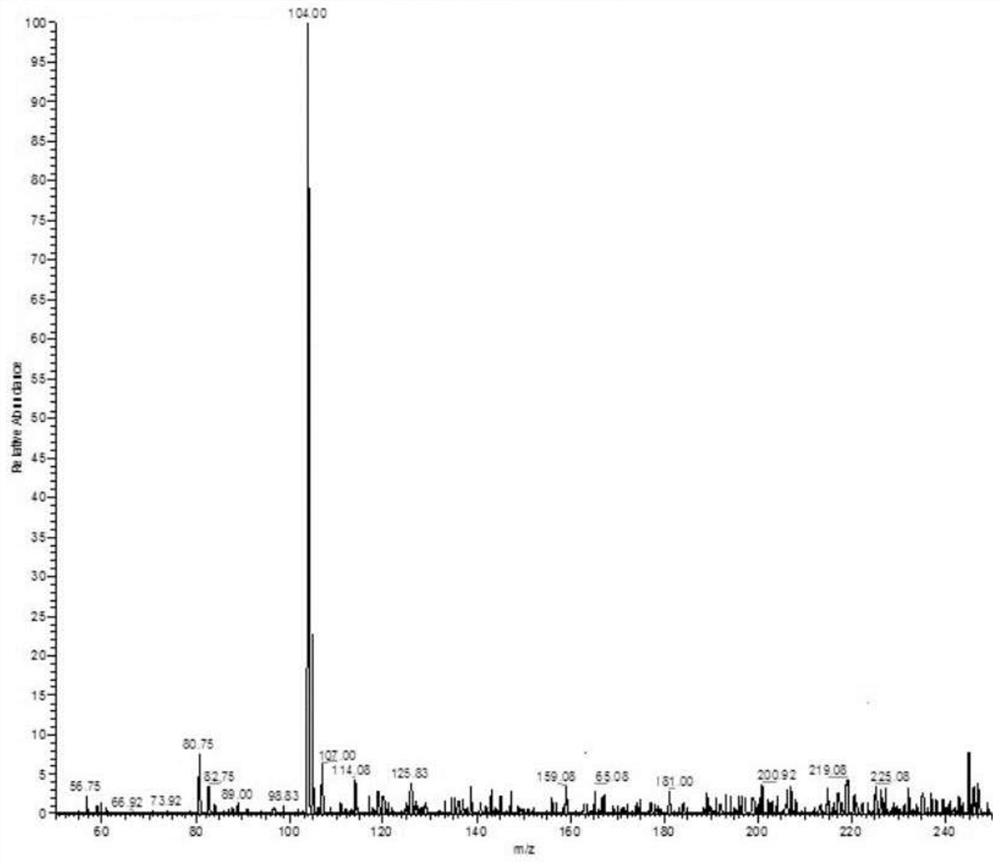

[0041] S2, the described benzonitrile reaction crude product that step S1 obtains is transferred in the crude distillation tower, and vacuum distillation collects tower top product and obtains benzonitrile crude product 86.8g (gas phase cont...

Embodiment 2-7

[0048] A kind of benzomelamine by-product recycling method that embodiment 2-7 provides is reused to synthesize benzonitrile, compared with embodiment 1, the difference is that the benzomelamine by-product described in step S1 and hydrochloric acid, acetic acid The quality ratio is shown in Table 1. Except for the above differences, other operations are roughly the same and will not be repeated here. The specific experimental conditions, parameters and measurement results are shown in Table 1.

[0049] As can be seen from the results in Table 1, changing the ratio of 2,4,6-triphenyl-1,3,5-triazine, benzamide to hydrochloric acid and acetic acid in step S1 will affect the obtained benzonitrile The mass yield and purity of the product have a significant impact. When using hydrochloric acid or acetic acid alone, benzonitrile can also be obtained by acid hydrolysis, but the mass yield and purity are low. The present invention uses the mixed acid of hydrochloric acid and acetic a...

Embodiment 8-10

[0054] A kind of method that embodiment 8-10 provides a kind of benzomelamine by-product recovery and reuse synthesis benzonitrile, compared with embodiment 1, the difference is that in step S1, change 2,4,6-triphenyl- The mass ratio of 1,3,5-triazine to nickel chloride, except for the above differences, other operations are roughly the same, and will not be repeated here. The specific experimental conditions, parameters and measurement results are shown in Table 2.

[0055] Preparation conditions and experimental result parameters of table 2 embodiment 1,8-10

[0056]

[0057]

[0058] Comparative example 1 and embodiment 8-10 result can know, along with the increase of transition metal nickel catalyst consumption, the mass yield and the purity of benzonitrile after the reaction present the trend that first increases and then decreases, when the benzomelamine of recovery When the consumption ratio of by-product and nickel chloride is controlled in the scope of 1:(0.005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com