Lead oxide preparation process based on waste lead-acid storage battery lead plaster

A lead-acid battery and a preparation process technology, applied in the direction of lead monoxide, lead oxide, battery recycling, etc., can solve problems such as ecological environment and human health threats, harmful environment and human health, environmental and human hazards, etc., to avoid waste. Acid discharge, avoid the use of sulfuric acid, high recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Present embodiment is a kind of preparation method of lead catcher, comprises the steps:

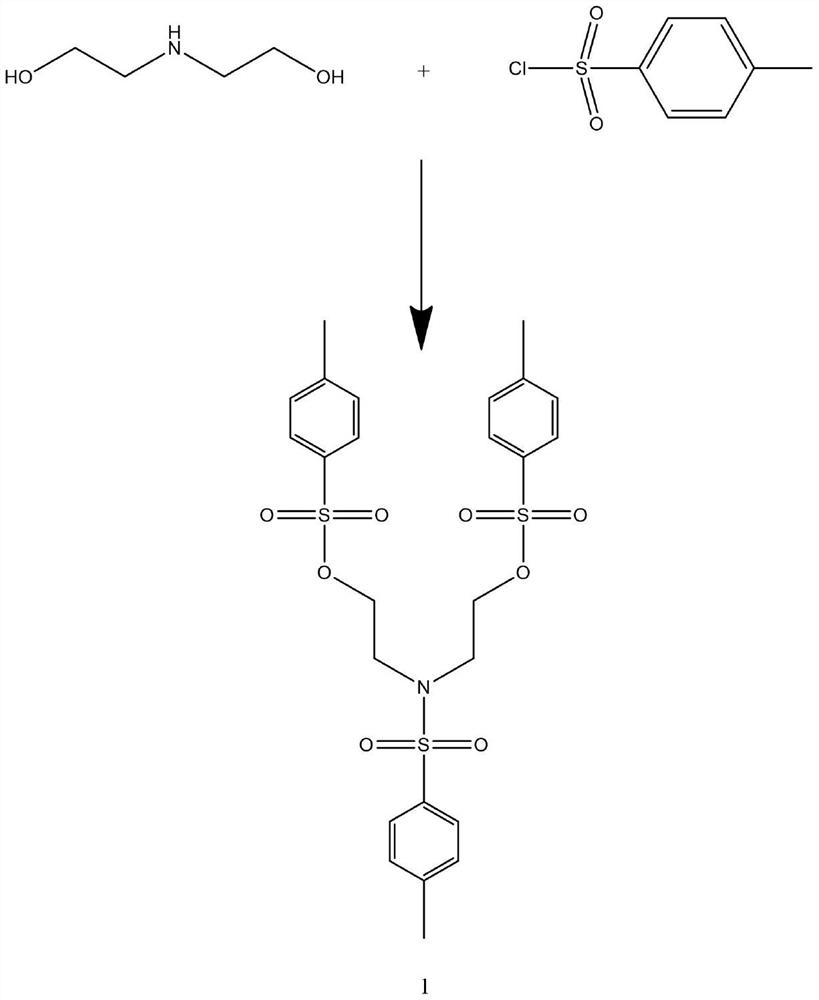

[0057] A1: Add 0.1mol diethanolamine and 50mL triethylamine into a three-necked flask equipped with a stirrer, condensing reflux tube, thermometer and constant pressure dropping funnel, at a temperature of 0°C and a stirring rate of 100r / min. Add 150mL p-toluenesulfonyl chloride dropwise while stirring according to the p-toluenesulfonyl chloride solution a formed by dissolving 0.11mol:50mL in dichloromethane, control the dropping rate at 1 drop / s, and heat up to 20°C after the dropwise addition The reaction was continued under stirring for 4 h, after the reaction was completed, the reaction product was added to ice water, the organic phase was separated and washed twice with dilute hydrochloric acid and distilled water with a mass fraction of 10%, then dried with anhydrous magnesium sulfate, filtered, and the filtrate was rotary evaporated, Obtain intermediate 1;

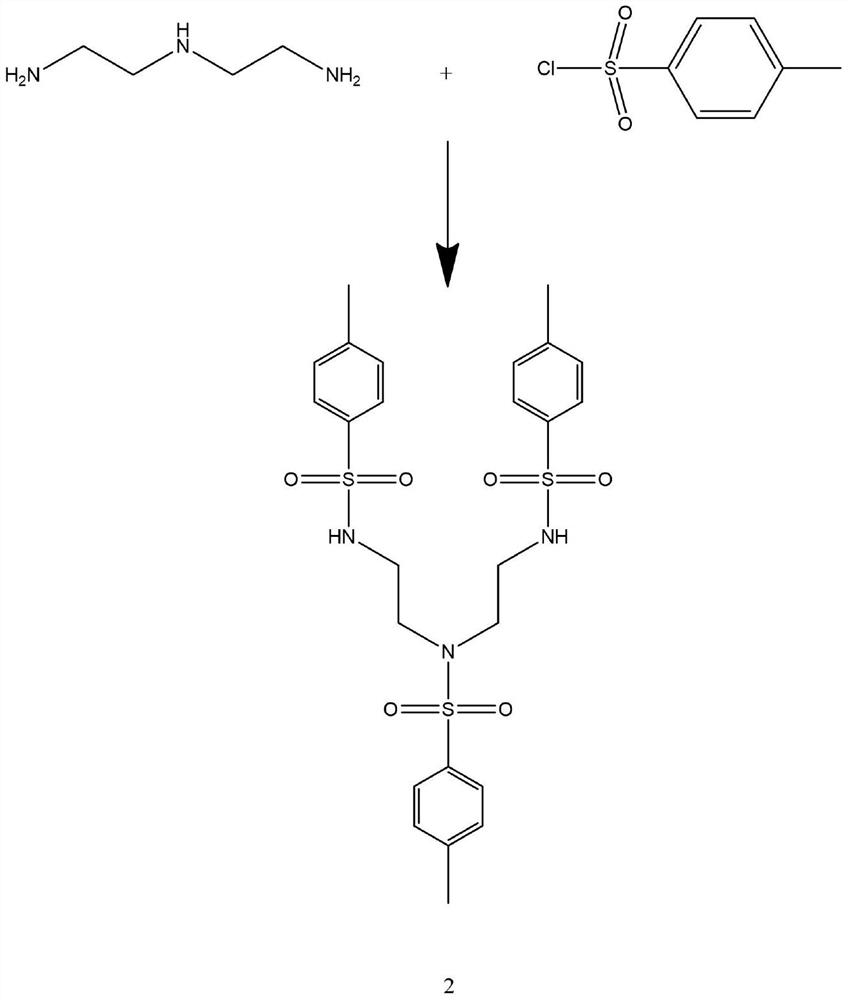

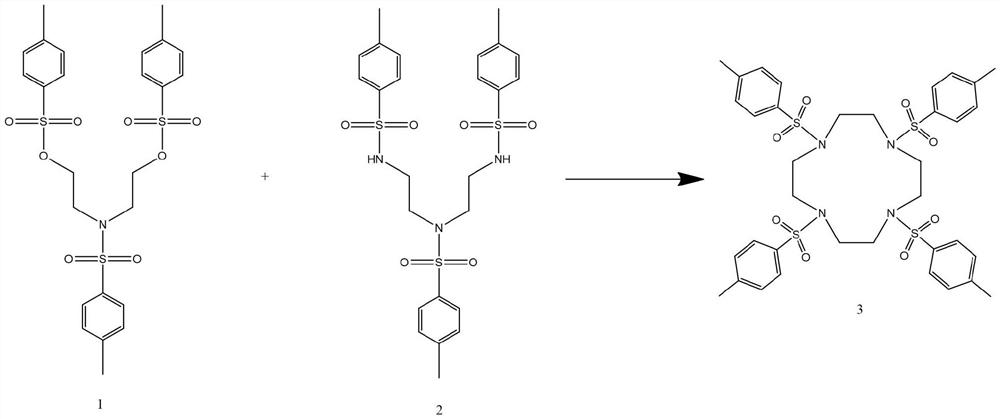

[0058] A2: Add...

Embodiment 2

[0067] Present embodiment is a kind of preparation method of lead catcher, comprises the steps:

[0068] A1: Add 0.1mol diethanolamine and 50mL triethylamine into a three-necked flask equipped with a stirrer, a condensing reflux tube, a thermometer and a constant pressure dropping funnel, at a temperature of 5°C and a stirring rate of 200r / min. Add 150mL p-toluenesulfonyl chloride dropwise while stirring according to the p-toluenesulfonyl chloride solution a formed by dissolving 0.11mol:50mL in dichloromethane, control the dropping rate at 1 drop / s, and raise the temperature to 25°C after the dropwise addition The reaction was continued under stirring for 6 h, after the reaction was completed, the reaction product was added to ice water, the organic phase was separated and washed 3 times with dilute hydrochloric acid and distilled water with a mass fraction of 10%, then dried with anhydrous magnesium sulfate, filtered, and the filtrate was rotary evaporated, Obtain intermediat...

Embodiment 3

[0078] This embodiment is a process for preparing lead oxide based on waste lead-acid battery lead paste, comprising the following steps:

[0079] Step 1: Weigh 50 parts of waste lead-acid battery lead paste, 10% sodium carbonate solution by mass fraction, 10 parts of lead scavenger from Example 1, and 300 parts of water according to parts by weight, and set aside;

[0080] Step 2: send the waste lead-acid battery lead paste and lye into a ball mill for ball milling for 1 hour to obtain a pre-desulfurization paste;

[0081] Step 3: Stir and react the pre-desulfurization paste, hydrogen peroxide, lead scavenger and water for 5 hours at a stirring rate of 400 r / min to obtain a mixed solution;

[0082] Step 4: Introduce carbon dioxide into the mixed solution, and roast the precipitated product to obtain lead oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com