Preparation method and application of tissue engineering biological scaffold

A biological scaffold and tissue engineering technology, applied in the field of biomedicine, can solve the problems of low biological activity, high content, difficult three-dimensional network structure of tissue engineering scaffolds, etc., achieve high specific surface area, increase biological activity, good three-dimensional porous effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides a kind of preparation method of tissue engineering biological scaffold, comprising the following steps:

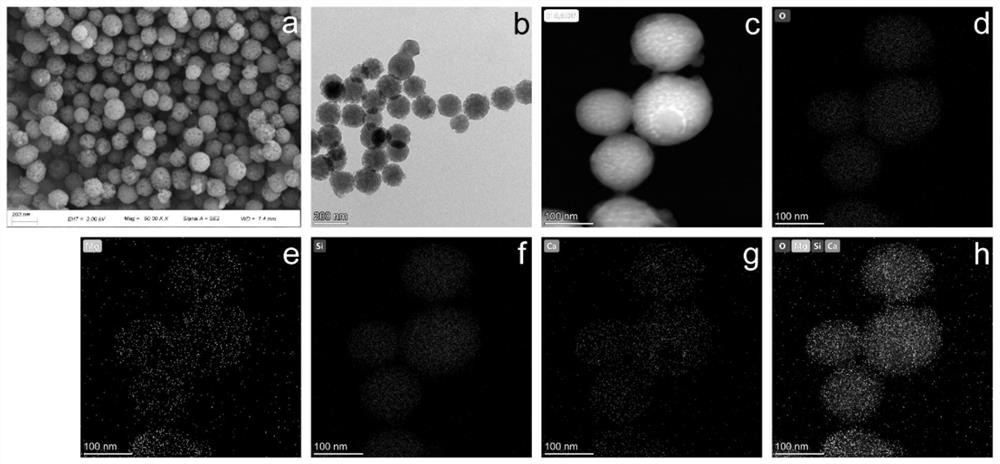

[0034] Step 1: Prepare bioactive glass nanospheres by sol-gel method, mix a certain amount of distilled water and absolute ethanol, add ammonia water to adjust the pH to alkaline; add ethyl orthosilicate, stir rapidly, and react for 30 minutes; add four Calcium nitrate in water, reacted for 4 hours; 8000 rpm, centrifuged for 10 minutes, collected the reaction product, then separated, washed twice with deionized water and absolute ethanol; dried in an oven at 50°C overnight, and then placed in a muffle furnace at 700°C Sintering and grinding to obtain ordinary biological glass nanospheres;

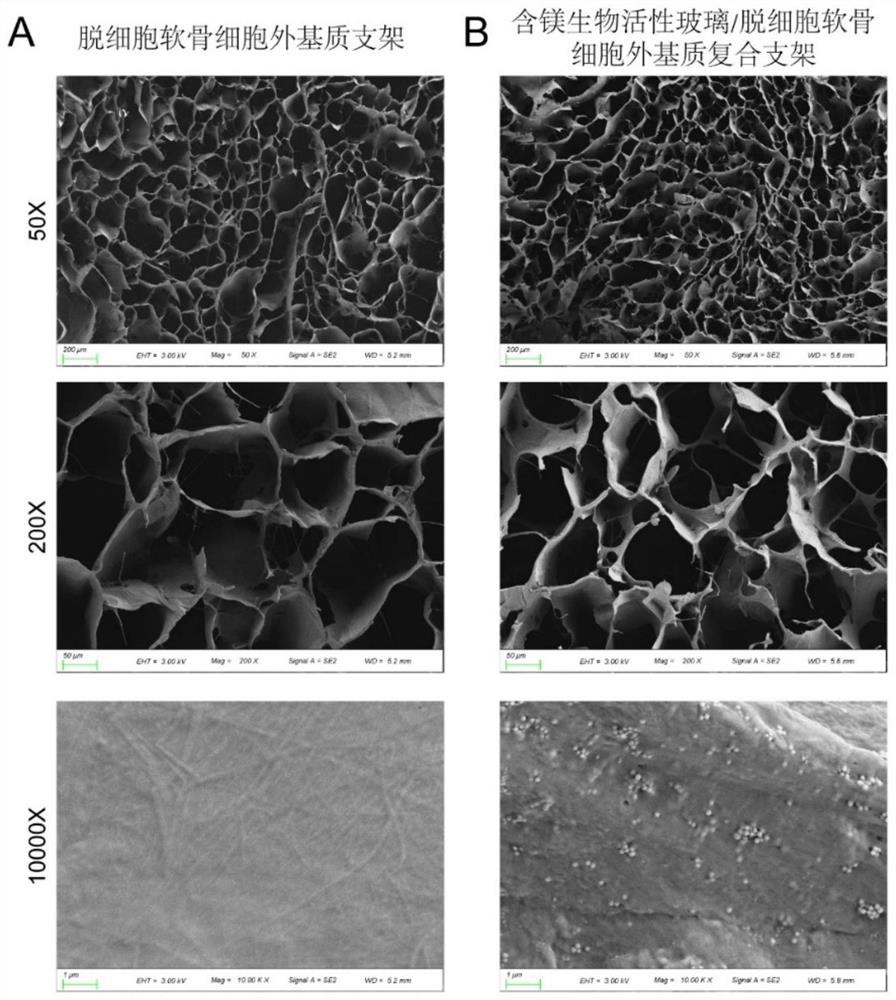

[0035] Step 2: Prepare the extracellular matrix gel of acellular cartilage by physical pulverization and differential centrifugation; take some fresh cartilage slices, wash them with sterile distilled water, and freeze and thaw them repeatedly; phys...

Embodiment

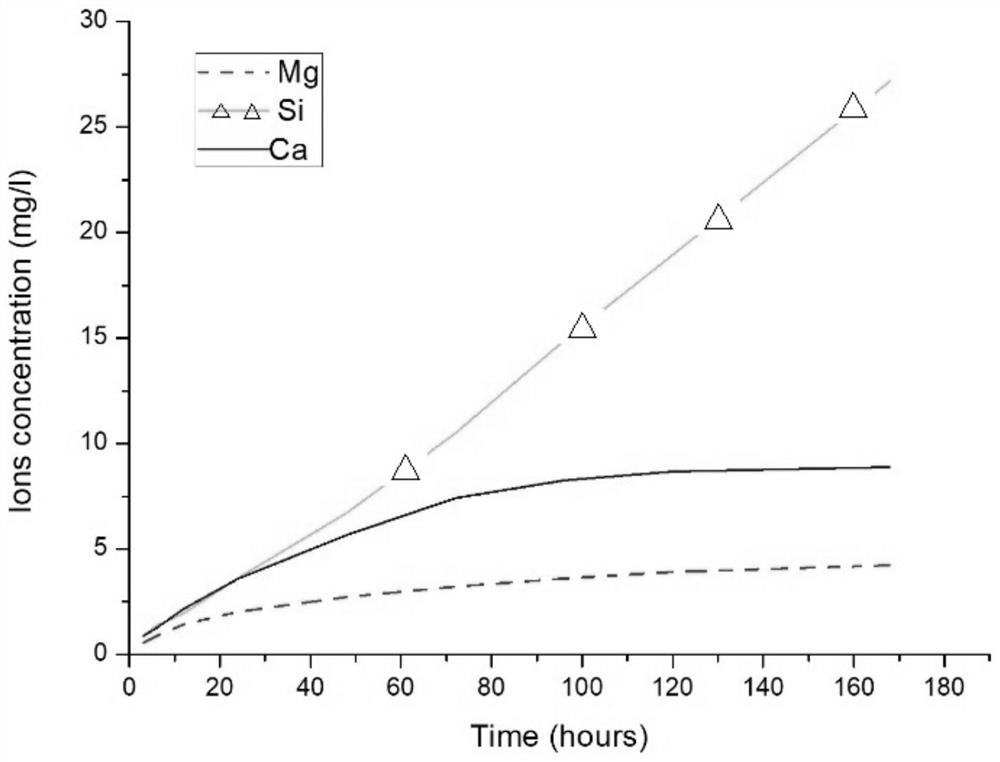

[0045] This example discloses a preparation method for constructing a bioscaffold composed of magnesium-containing bioactive glass nanospheres composited with decellularized cartilage extracellular matrix and its use for repairing tissue engineered cartilage. The preparation method includes the following steps:

[0046] 1. Preparation of magnesium-containing bioactive glass nanospheres:

[0047] Step 1. Make a mixed liquid with 12ml tetraethyl orthosilicate (99%) and 48ml alcohol (96% VWR), shake and mix well.

[0048] Step 2. Mix 33ml of absolute ethanol, 18ml of ammonium hydroxide (25%), and 100ml of deionized water to prepare a reaction solution.

[0049] Step 3. Add the mixed solution prepared in step 1 to the reaction solution prepared in step 2, stir with a magnetic stirrer, and react for 30 minutes.

[0050] Step 4. Add a certain amount of calcium nitrate tetrahydrate (99%) and magnesium nitrate tetrahydrate (99.8%), continue stirring with a magnetic stirrer for 90 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com