Maleic anhydride selective hydrogenation catalyst as well as preparation method and application method thereof

A hydrogenation catalyst and application method technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of high hydrogen pressure, high application cost, loss of catalytically active components, etc. mass resistance, good catalytic performance, and the effect of improving the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

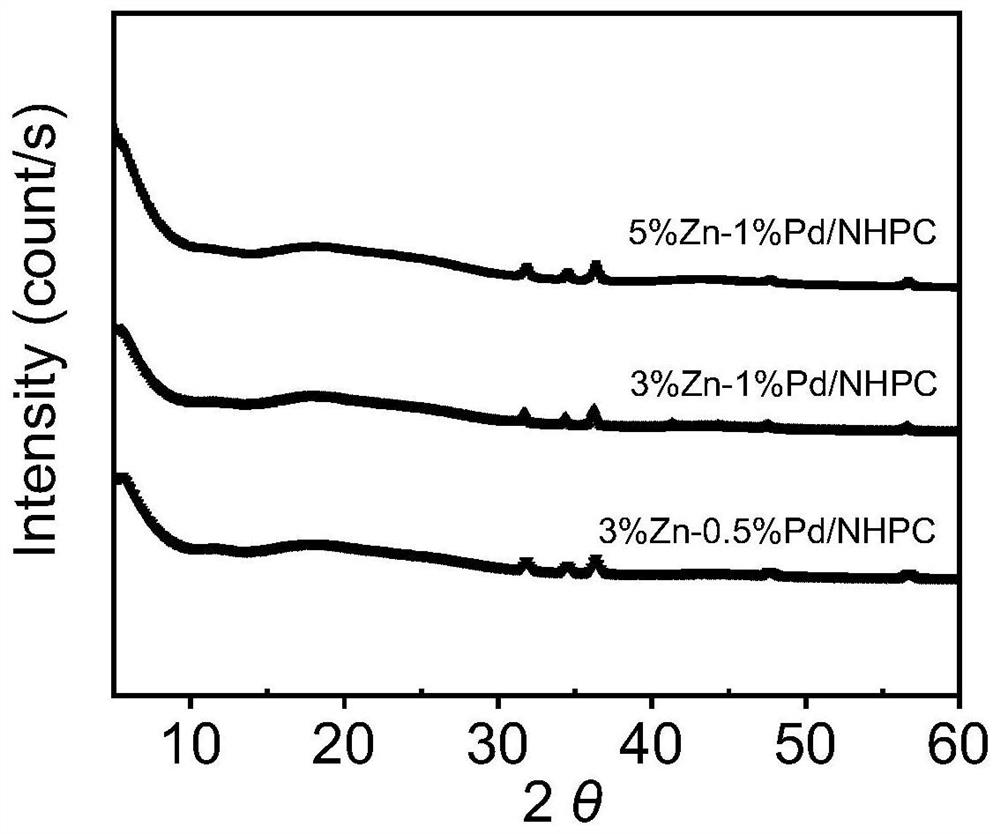

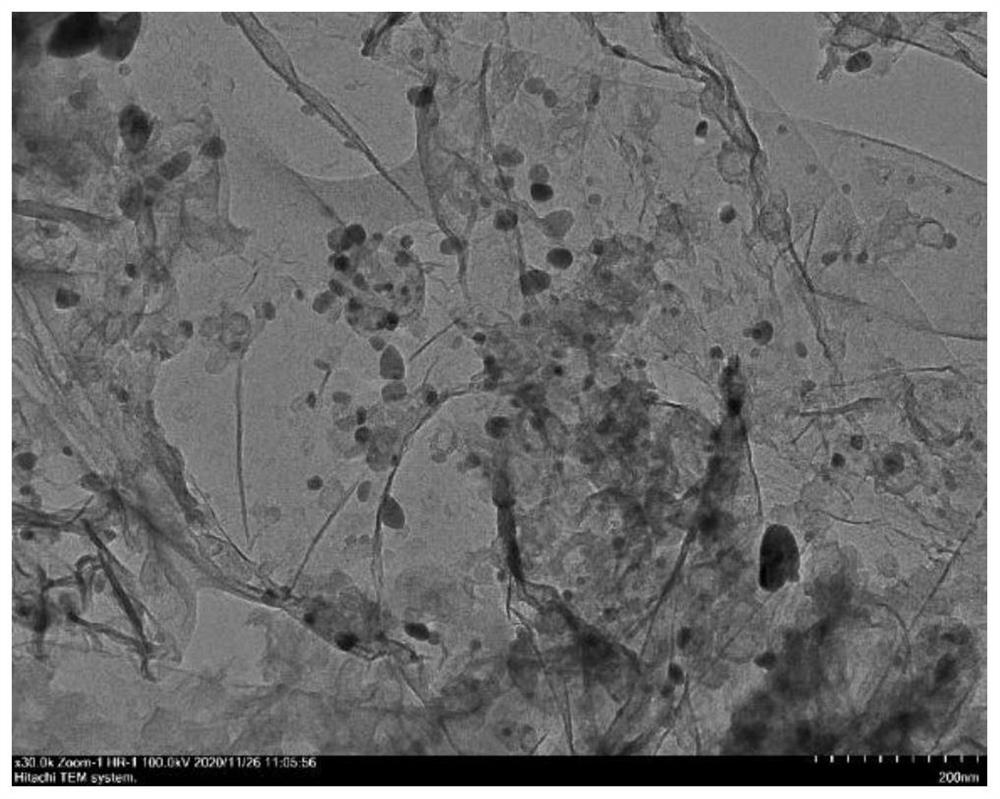

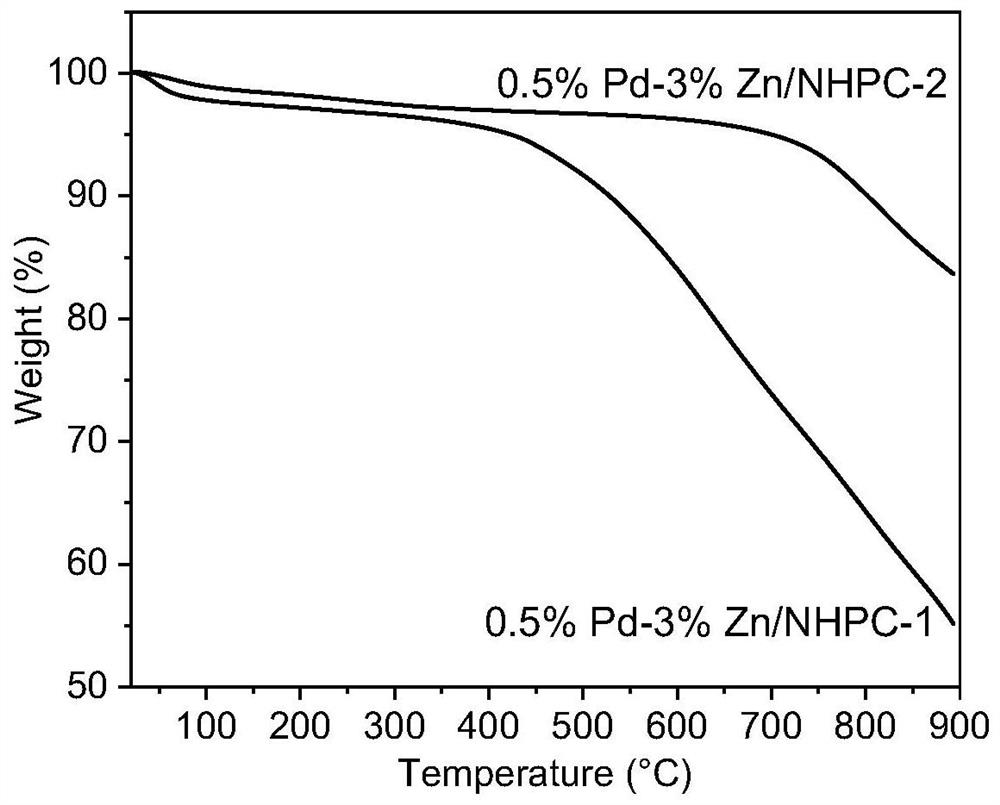

[0031] Embodiment 1 is about Pd-Zn / NHPC catalyst

[0032] At room temperature, weigh 20g of cellulose, 60g of sodium bicarbonate and 60g of ammonium oxalate monohydrate according to the ratio of 1:3:3 and mix them. The heating rate of ℃ / min was heated to 600℃ and kept for 1h. After cooling down, the obtained sample was added to 1000mL distilled water, stirred for 24h, then filtered and washed repeatedly, and finally dried at 70℃ for 24h to obtain nitrogen-doped mesoporous The carrier composed of carbon material NHPC. The specific surface area of the nitrogen-doped mesoporous carbon material NHPC is 230m 2 / g.

[0033] Weigh 1.5g of zinc nitrate, add 20mL of distilled water to dissolve it, and add it dropwise to 5g of the above-prepared carrier, and keep stirring. After all the addition is completed, stir in a 70°C water bath for 24h, then take it out and dry it in a 70°C oven for 12h Sample 1 was obtained; sample 1 was heated up to 500°C at a heating rate of 10°C / min and ...

Embodiment 2

[0036] Embodiment 2 is about Pd-Zn / NHPC catalyst

[0037] At room temperature, weigh 20g of cellulose, 60g of sodium bicarbonate and 60g of ammonium oxalate monohydrate according to the ratio of 1:3:3 and mix them. The heating rate of ℃ / min was heated to 800℃ and kept for 1h. After cooling down, the obtained sample was added to 1000mL distilled water, stirred for 24h, then filtered and washed repeatedly, and finally dried at 70℃ for 24h to obtain nitrogen-doped mesoporous The carrier composed of carbon material NHPC. The specific surface area of the nitrogen-doped mesoporous carbon material NHPC is 230m 2 / g.

[0038] Weigh 1.5g of zinc nitrate, add 20mL of distilled water to dissolve it, and add it dropwise to 5g of the above-prepared carrier, and keep stirring. After all the addition is completed, stir in a 70°C water bath for 24h, then take it out and dry it in a 70°C oven for 12h To obtain sample 1, the sample was heated to 500°C at a heating rate of 10°C / min under a ...

Embodiment 3

[0041] Embodiment 3 is about Pd-Zn / NHPC catalyst

[0042] At room temperature, weigh 10g of cellulose, 50g of sodium bicarbonate and 80g of ammonium oxalate monohydrate according to the ratio of 1:5:8 and mix them. The heating rate of ℃ / min was heated to 600℃ and kept for 1h. After cooling down, the obtained sample was added to 1000mL distilled water, stirred for 24h, then filtered and washed repeatedly, and finally dried at 70℃ for 24h to obtain nitrogen-doped mesoporous The carrier composed of carbon material NHPC. The specific surface area of the nitrogen-doped mesoporous carbon material NHPC is 1180m 2 / g.

[0043] Weigh 1.5g of zinc nitrate, add 20mL of distilled water to dissolve it, and add it dropwise to 5g of the above-prepared carrier, and keep stirring. After all the addition is completed, stir in a 70°C water bath for 24h, then take it out and dry it in a 70°C oven for 12h To obtain sample 1, the sample was heated up to 500°C at a heating rate of 10°C / min unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com