Construction method and application of high-yield lactoyl-N-tetrasaccharide microorganism

A lactoyl and galactosyl technology, applied in the field of microorganism construction, can solve the problems of low yield of lactoyl-N-tetrasaccharide, inability to meet the requirements of industrialized large-scale production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 4. Preparation of competent E. coli: TAKARA kit.

[0031] 5. Culture medium and detection method for lacto-N-tetrasaccharide fermentation:

[0032](1) LB liquid medium: peptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L.

[0033] (2) LB solid medium: 10g / L peptone, 5g / L yeast extract powder, 10g / L sodium chloride, 15g / L agar powder.

[0034] (3) Fermentation medium: 20g / L glucose, 13.5g / L potassium dihydrogen phosphate, 4.0g / L diammonium hydrogen phosphate, 1.7g / L citric acid, 1.4g / L magnesium sulfate heptahydrate and 10ml / L trace Metal elements; trace metal elements include: 10g / L ferrous sulfate, 2.25g / L zinc sulfate heptahydrate, 1.0g / L anhydrous copper sulfate, 0.35g / L manganese sulfate monohydrate, 0.23g / L sodium borate decahydrate , 0.11g / L ammonium molybdate, 2.0g / L calcium chloride dihydrate.

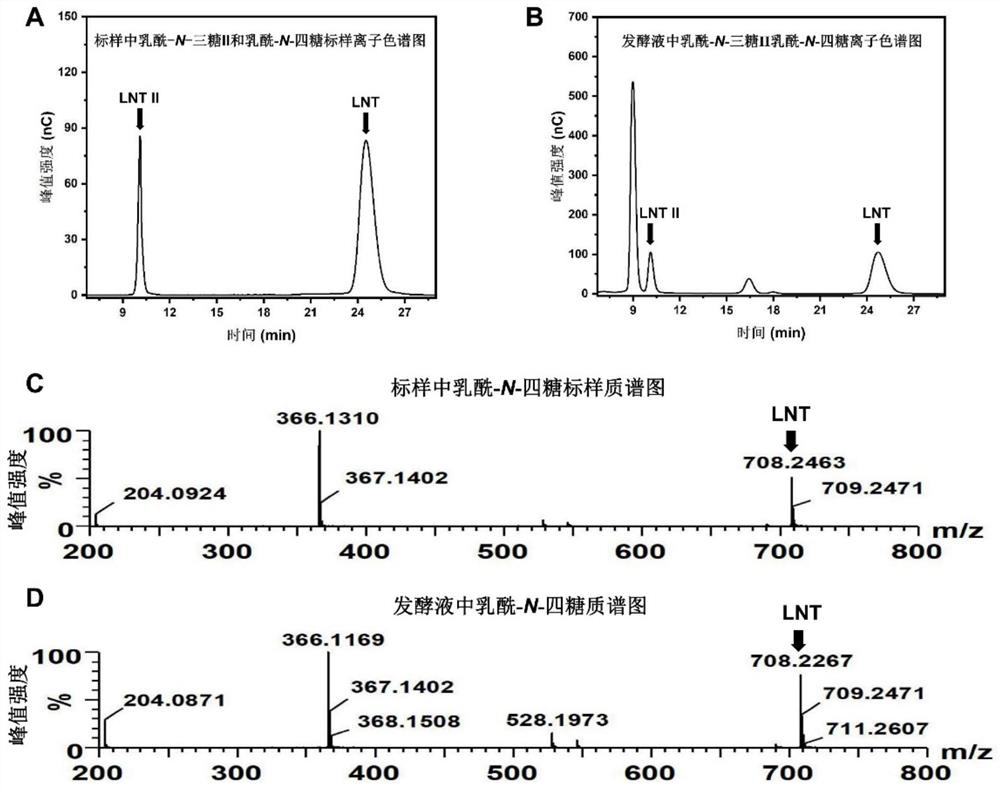

[0035] (4) HPLC detection conditions: high-efficiency ion-exchange chromatography; chromatographic column: CarboPac PA10 (4mm×250mm); detector: pulsed amperometr...

Embodiment 1

[0036] Embodiment 1: Construction of recombinant vector

[0037] The specific steps of recombinant expression vector construction are as follows (see Table 1 for the primer sequences involved):

[0038] (1) glmM, glmU-glmS, and lgtA gene (the nucleotide sequences of glmM, glmU, glmS, and lgtA are shown in SEQID NO.1-4 respectively) fragment acquisition and plasmid pRSF-(29)glmM-(29 The construction of )glmU-glmS and pET-(T7)lgtA is described in the patent whose publication number is CN111979168A.

[0039] (2) Obtaining of wbgO and galE gene fragments and construction of plasmid pCD-wbgO-galE:

[0040] wbgO was synthesized by Suzhou Jinweizhi after codon optimization. The nucleotide sequence of the wbgO gene fragment is shown in SEQ ID NO.7. Using the synthesized gene as a template and using WbgO-F / R as primers, wbgO was amplified by PCR Gene fragment, gel recovery DNA fragment; With the genome of Escherichia coli K-12 (Escherichia coli) as template, with WbgO-GalE-F / R as pri...

Embodiment 2

[0048] Embodiment 2: Construction of recombinant bacterial strain

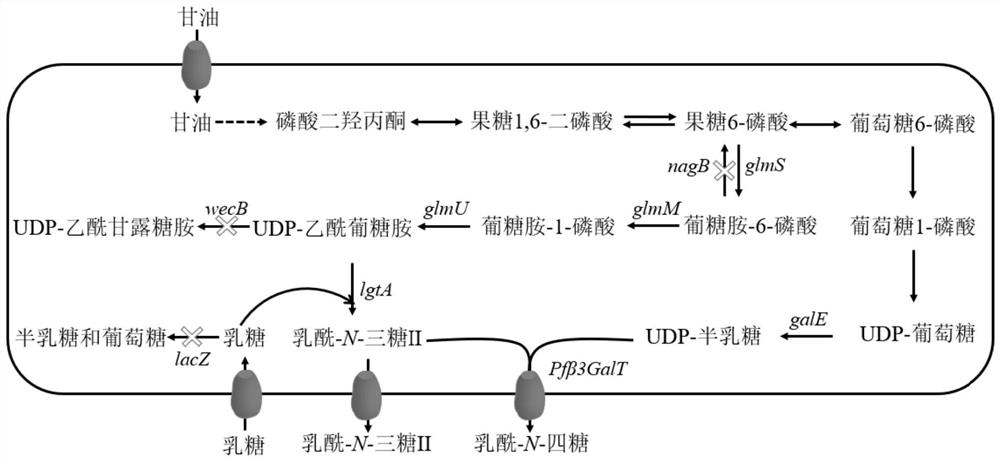

[0049] Knockout the gene wecB encoding UDP-N-acetylglucosamine-2-epimerase WecB (NCBI sequence number YP_026253.1) and NagB encoding glucosamine-6 phosphate deaminase (NCBI sequence number YP_026253.1) in Escherichia coli BL21 It is the gene nagB of NP_415204.1) and the gene lacZ of encoding β-galactosidase LacZ (NCBI sequence number is NP_414878.1), and the recombinant plasmid pRSF-(29 )glmM-(29)glmU-glmS and pET-(T7)lgtA, gene knockout and recombinant plasmid transfer method refer to the patent with publication number CN111979168A, to construct a recombinant large intestine producing lactyl-N-triose II Bacillus E10-WNL.

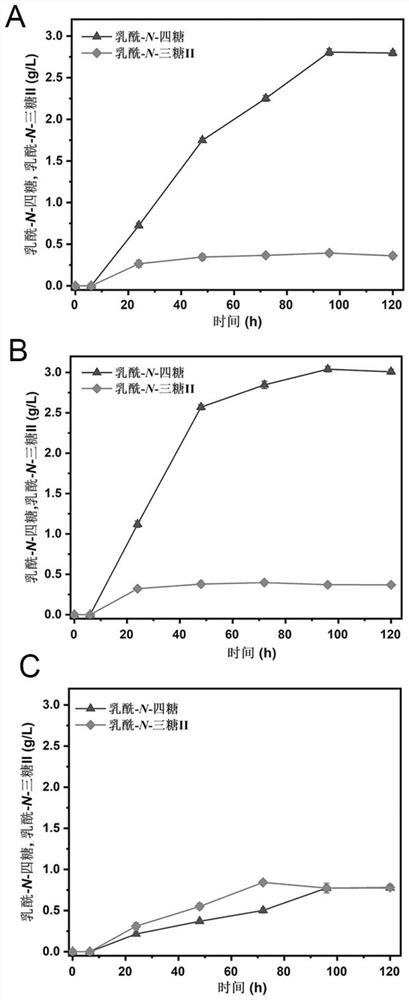

[0050] (1) The recombinant plasmid pCD-wbgO-galE constructed in Example 1 was transformed into Escherichia coli E10-WNL to construct a recombinant strain ELO1.

[0051] (2) The recombinant plasmid pCD-pf-galE constructed in Example 1 was transformed into Escherichia coli E10-WNL to cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com