Lightweight environment-friendly elastic sound insulation composite material, sound insulation pad and preparation method of sound insulation pad

A technology of composite materials and sound insulation pads, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of poor softness of sound insulation materials, failure to meet environmental protection requirements, heavy weight, etc., and achieve improvement Fire and heat insulation or tensile strength performance, improve market application space, and achieve lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

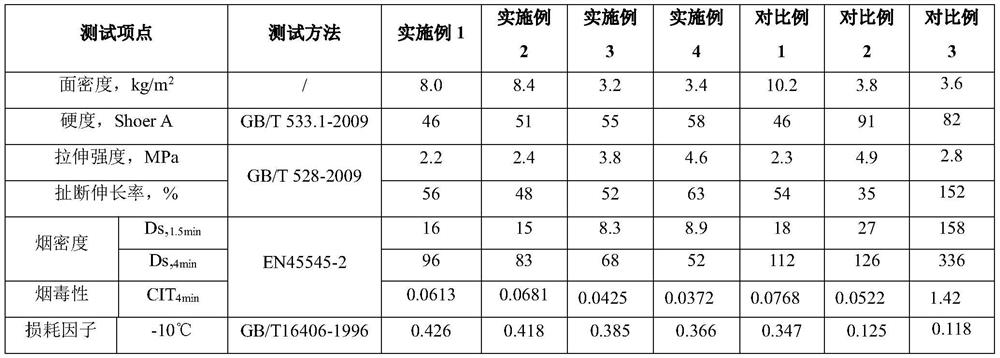

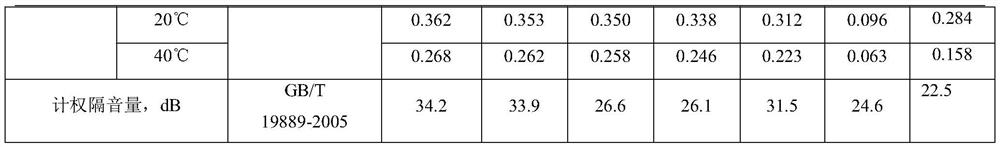

Examples

Embodiment 1

[0056] A lightweight, environment-friendly, elastic and sound-insulating composite material, prepared from the following raw materials in parts by weight:

[0057] Butyl rubber: 18 parts,

[0058] Styrenic elastomer: 6 parts,

[0059] Floating beads: 50 parts,

[0060] Aluminum hydroxide: 40 parts,

[0061] Barium sulfate: 60 parts,

[0062] Naphthenic oil: 8 parts,

[0063] Stearic acid: 1 part,

[0064] Antioxidant: 1 part.

[0065] A sound-insulating pad, comprising a sound-insulating rubber layer and a cladding layer, the sound-insulating rubber layer is plasticized from the light-weight environmentally friendly elastic sound-insulating composite material of this embodiment, the cladding layer is calendered and connected to the upper and lower surfaces of the sound-insulating rubber layer, and composited into three layers Structure; one side of the cladding layer is aluminum-plastic film and non-woven fabric.

[0066] The preparation method of the lightweight enviro...

Embodiment 2

[0073] A lightweight, environment-friendly, elastic and sound-insulating composite material, prepared from the following raw materials in parts by weight:

[0074] Butyl rubber: 15 parts,

[0075] Styrenic elastomer: 9 parts,

[0076] Floating beads: 40 parts,

[0077] Aluminum hypophosphite: 40 parts,

[0078] Barium sulfate: 70 parts,

[0079] Naphthenic oil: 10 parts,

[0080] Additives: 2 parts.

[0081] A sound-insulating pad, comprising a sound-insulating rubber layer and a cladding layer, the sound-insulating rubber layer is plasticized from the light-weight environmentally friendly elastic sound-insulating composite material of this embodiment, the cladding layer is calendered and connected to the upper and lower surfaces of the sound-insulating rubber layer, and composited into three layers Structure; one side of the cladding layer is aluminum-plastic film and non-woven fabric.

[0082] The preparation method of the lightweight environment-friendly elastic sound...

Embodiment 3

[0089] A lightweight, environment-friendly, elastic and sound-insulating composite material, prepared from the following raw materials in parts by weight:

[0090] Butyl rubber: 12 parts,

[0091] Styrenic elastomer: 12 parts,

[0092] Floating beads: 30 parts,

[0093] Melamine polyphosphate: 30 parts,

[0094] Calcium carbonate: 60 parts,

[0095] Paraffin oil: 10 parts,

[0096] Additives: 2 parts.

[0097] A sound-insulating pad, comprising a sound-insulating rubber layer and a cladding layer, the sound-insulating rubber layer is plasticized from the light-weight environmentally friendly elastic sound-insulating composite material of this embodiment, the cladding layer is calendered and connected to the upper and lower surfaces of the sound-insulating rubber layer, and composited into three layers Structure; one side of the cladding layer is aluminum-plastic film and non-woven fabric.

[0098] The preparation method of the lightweight environment-friendly elastic sou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com