Preparation method of super-long potassium tetratitanate whisker

A technology of potassium tetratitanate and whiskers, which is applied in the field of preparation of ultra-long potassium tetratitanate whiskers, can solve the problems of complex process, high cost, and difficulty in large-scale production, and achieve simple operation, low cost, and short production cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

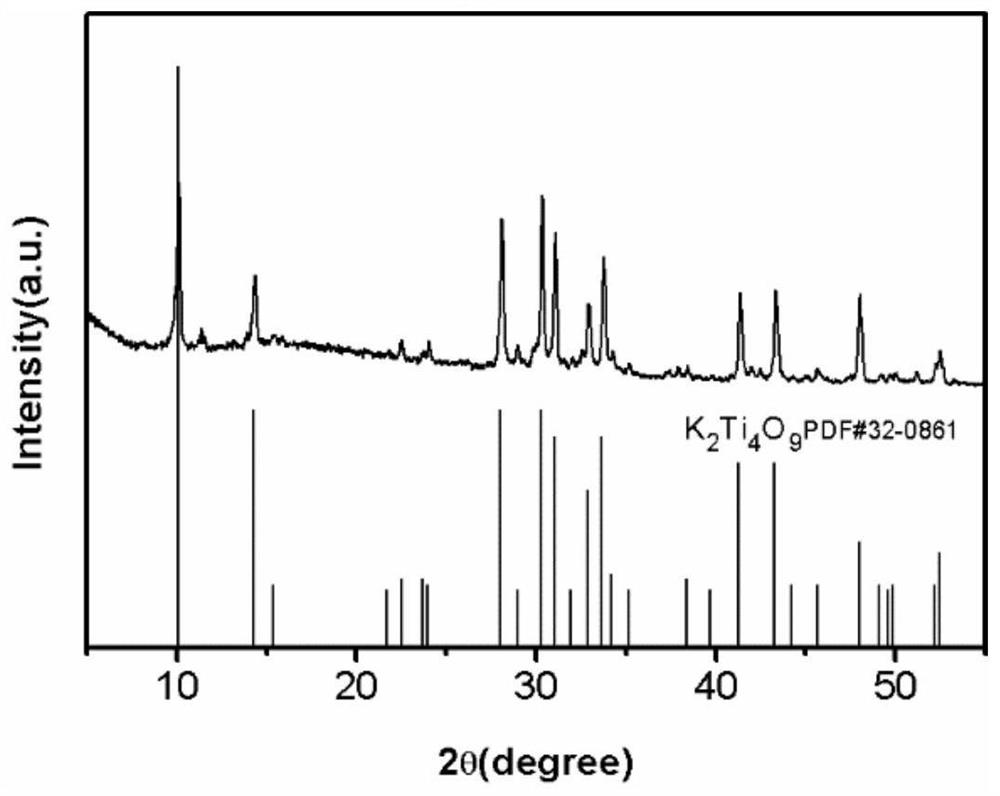

Embodiment 1

[0040] Metatitanic acid (TiO 2 ·nH 2 O) and potassium carbonate (K 2 CO 3 ) as raw material, according to TiO 2 / K 2The molar ratio of O=2.8:1 Weigh raw materials, adopt kneader to mix 6h, obtain TK mixture; Then add wheat flour with 0.05 times of TK mixture quality, carboxymethyl cellulose sodium with 0.01 times of TK mixture quality, TK mixture Potassium hydrogen tartrate of 0.01 times the mass of the material, glycerol accounting for 30wt% of the total mass of the mixture (metatitanic acid, potassium carbonate, additives and glycerin), kneaded for 6 hours, heated to 120 ° C for 2 hours with a kneader, and opened The kneader reverses the mode to pulverize, and sieves through 100 mesh to obtain a uniformly mixed powder.

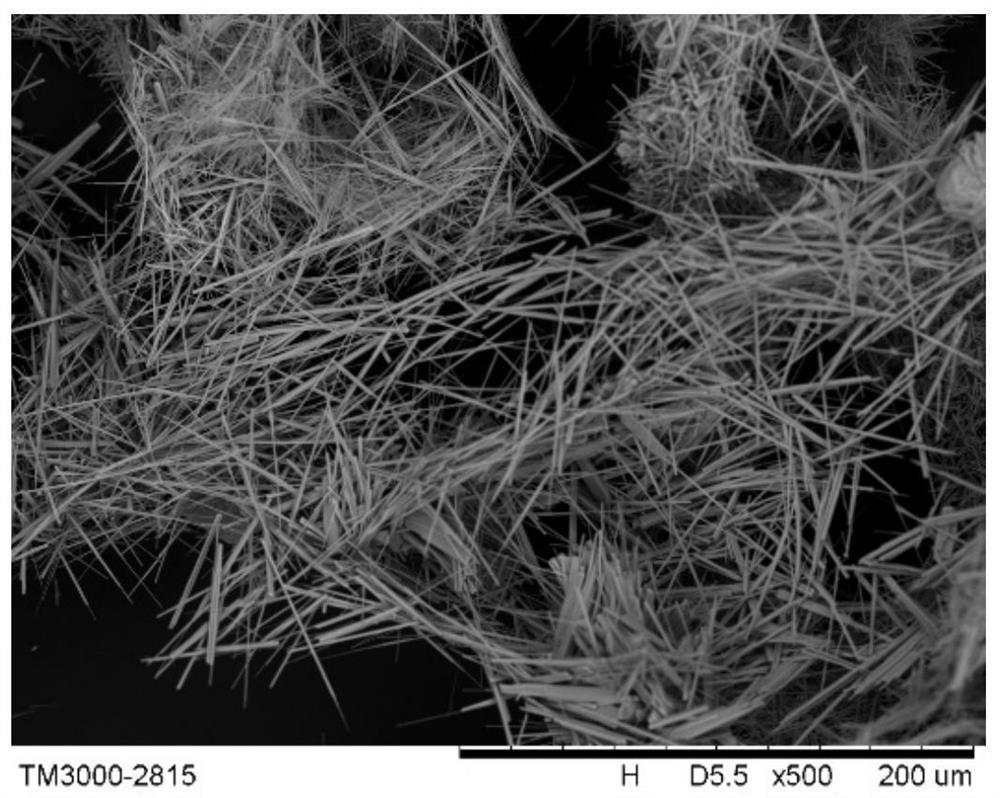

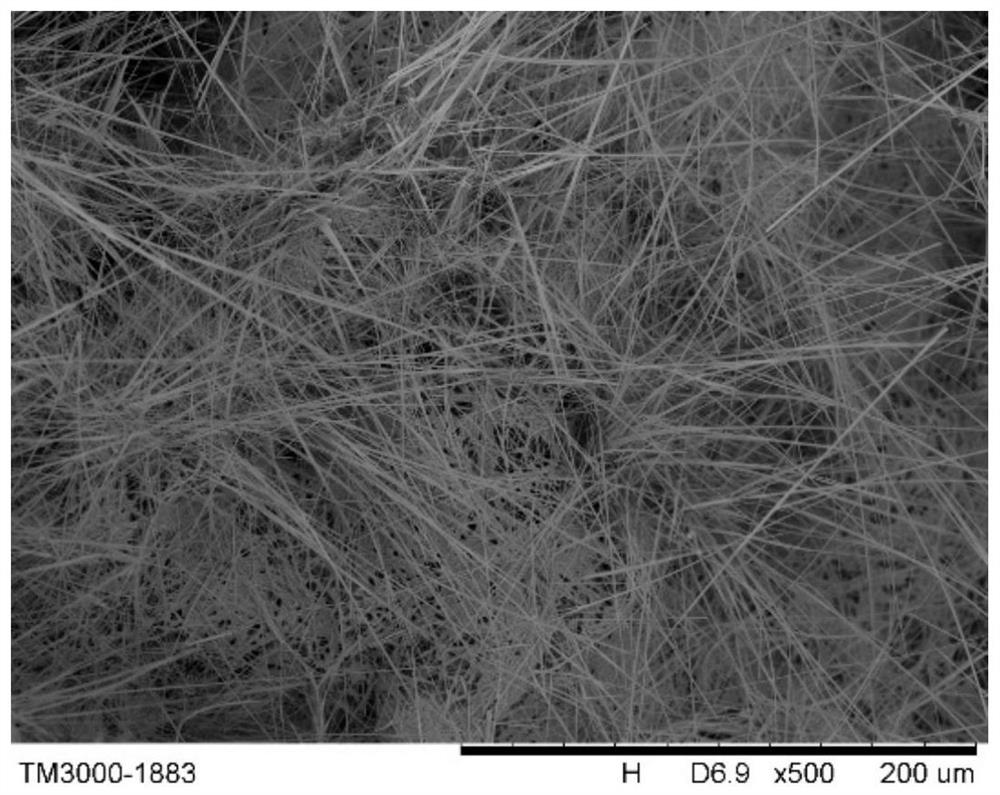

[0041] Put the mixed powder in a crucible, put the crucible into a resistance furnace, heat from 30°C to 900°C at 5°C / min, keep the temperature at 900°C for 2 hours, cool with the furnace, take out the sintered product and disperse it with water, filter...

Embodiment 2

[0043] Anatase titanium dioxide (TiO 2 ) and potassium carbonate (K 2 CO 3 ) as raw material, first press TiO 2 / K 2 The molar ratio of O=3.0:1 Weigh raw materials, adopt ball milling mode 300r / min to mix 6h, obtain TK mixture; Then add the corn starch of TK mixture quality 0.1 times, the baking soda of TK mixture quality 0.01 times, TK mixture Sodium lauryl sulphate with 0.03 times the mass of the material, water accounting for 60wt% of the total mass of the mixture (anatase titanium dioxide, potassium carbonate, additives and water), ball milled for 6 hours, and the mixture after ball milling was dried at 120°C for 8 hours Remove moisture, grind, and sieve with 100 mesh to obtain the mixed powder.

[0044] Pour the mixed powder into a crucible, put the crucible into a resistance furnace, heat it from 30°C to 930°C at 5°C / min, keep the temperature at 930°C for 4 hours, cool with the furnace, take out the sintered product, disperse it with water, filter, and dry Finally, ...

Embodiment 3

[0046] Metatitanic acid (TiO 2 ·nH 2 O) and potassium carbonate (K 2 CO 3 ) as raw material, first press TiO 2 / K 2 The molar ratio of O=3.3:1 Weigh the raw materials and mix them for 6 hours by ball milling at 300r / min to obtain the TK mixture; then add silicon carbide with 0.1 times the weight of the TK mixture, sodium polyacrylate with 0.03 times the weight of the TK mixture, and TK Carbomer 941 with 0.01 times the mass of the mixture, ethanol accounting for 60wt% of the total mass of the mixture (metatitanic acid, potassium carbonate, additives and ethanol), ball milled for 6 hours, dried at 120°C for 1 hour, ground, sieved through 100 mesh, Obtain mixed powder.

[0047] Pour the mixed powder into a crucible, put the crucible into a resistance furnace, heat it from 30°C to 1000°C at 5°C / min, keep the temperature at 1000°C for 8 hours, cool with the furnace, take out the sintered product, disperse it with water, filter, and dry Finally, the finished ultra-long potassi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com