Titanium-based gradient lead dioxide composite electrode material for copper electrodeposition and preparation method thereof

A technology of lead dioxide and composite electrodes, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of affecting interface conductivity, small internal stress, and low porosity, so as to prolong service life, improve conductivity, and ease The effect of electrowinning distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

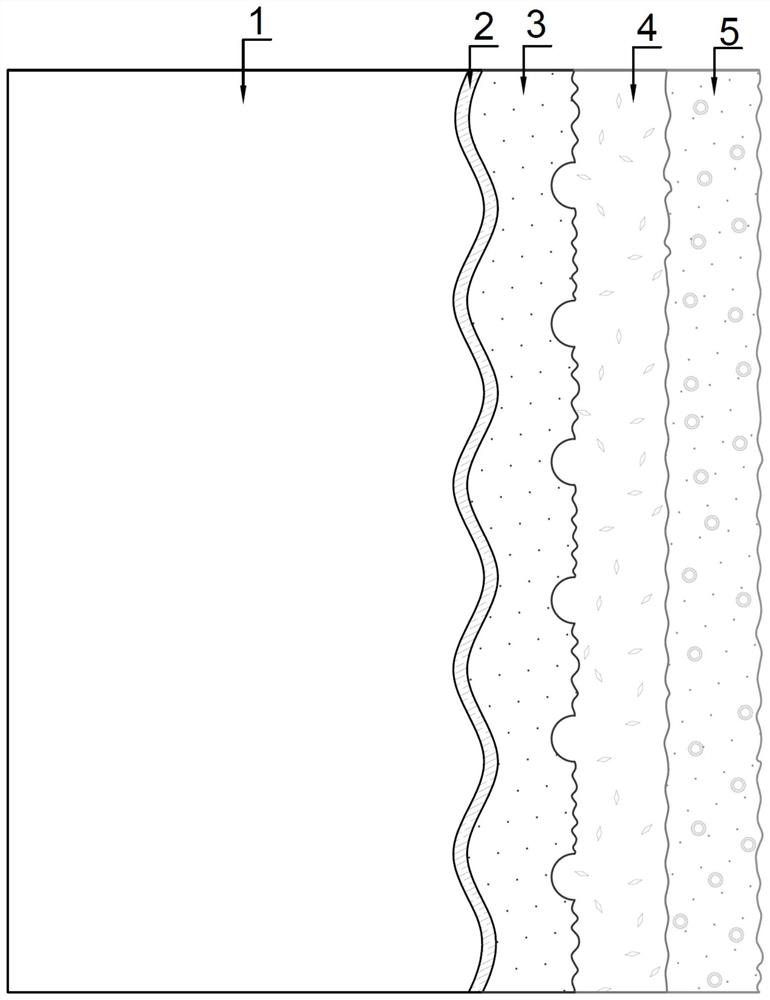

[0070] Embodiment 1: the titanium-based gradient lead dioxide composite electrode material used for copper electrowinning in this embodiment, the molar ratio of metal Sn, Ru, Ta and Zr in the bottom layer Sn-Ru-Ta-ZrOx oxide is 70:5 respectively: 12:13; middle layer β-PbO 2 -Nano SnO 2 SnO in 2 The mass content is 1.0wt.%; transition layer α-PbO 2 -The mass content of copper-coated graphite powder in copper-coated graphite powder is 2.2wt.%; the active layer β-PbO 2 -nano-ZrN-cobalt-coated hollow glass microspheres have a mass content of 1.2wt.% of nano-ZrN particles, and the content of cobalt-coated hollow glass microspheres is 2.0wt.%;

[0071] Sn-Ru-Ta-ZrOx oxide layer thickness is 4μm, β-PbO 2 -Nano SnO 2 The thickness of the middle layer is 200μm, α-PbO 2 - Copper-coated graphite powder transition layer thickness is 300μm, β-PbO 2 - The thickness of the active layer of nano-ZrN-cobalt-coated hollow glass microspheres is 600 μm;

[0072] β-PbO 2 -Nano SnO 2 Nano-...

Embodiment 2

[0093] Embodiment 2: the titanium-based gradient lead dioxide composite electrode material used for copper electrowinning in this embodiment, the molar ratio of metal Sn, Ru, Ta and Zr in the bottom layer Sn-Ru-Ta-ZrOx oxide is 50:10 respectively: 20:20; middle layer β-PbO 2 -Nano SnO 2 SnO in 2 The mass content is 0.1wt.%; transition layer α-PbO 2 -The mass content of copper-coated graphite powder in copper-coated graphite powder is 1.0wt.%; the active layer β-PbO 2 -nano-ZrN-cobalt-coated hollow glass microspheres have a mass content of nano-ZrN particles of 0.6wt.%, and the content of cobalt-coated hollow glass microspheres is 0.5wt.%.

[0094] Sn-Ru-Ta-ZrOx oxide layer thickness is 0.5μm, β-PbO 2 -Nano SnO 2 The thickness of the intermediate layer is 100 μm, α-PbO 2 - Copper-coated graphite powder transition layer thickness is 100μm, β-PbO 2 - The thickness of the active layer of nano ZrN-cobalt-coated hollow glass microspheres is 100 μm;

[0095] β-PbO 2 -Nano Sn...

Embodiment 3

[0108] Embodiment 3: the titanium-based gradient lead dioxide composite electrode material used for copper electrowinning in this embodiment, the molar ratio of metal Sn, Ru, Ta and Zr in the bottom layer Sn-Ru-Ta-ZrOx oxide is 90:1 respectively: 5:4; middle layer β-PbO 2 -Nano SnO 2 SnO in 2 The mass content is 1.5wt.%; transition layer α-PbO 2 -The mass content of copper-coated graphite powder in copper-coated graphite powder is 3.2wt.%; the active layer β-PbO 2 - The nano-ZrN-cobalt-coated hollow glass microspheres have a mass content of 1.8wt.% of the nano-ZrN particles, and the content of the cobalt-coated hollow glass microspheres is 5.0wt.%;

[0109] Sn-Ru-Ta-ZrOx oxide layer thickness is 8μm, β-PbO 2 -Nano SnO 2 The thickness of the middle layer is 500μm, α-PbO 2 - Copper-coated graphite powder transition layer thickness is 400μm, β-PbO 2 - The thickness of the active layer of nano-ZrN-cobalt-coated hollow glass microspheres is 1000 μm;

[0110] β-PbO 2 -Nano ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com