Antimicrobial semiconductor coating layer with detection effect and preparation method and application thereof

An anti-microbial and semiconductor technology, used in coatings, metal material coating processes, pharmaceutical formulations, etc., to avoid the use of antibiotics, achieve antimicrobial activity, and high antibacterial efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] Another aspect of the present invention provides a method for preparing a semiconductor coating, comprising the steps of:

[0071] 1) epoxy groups are formed on the surface of the substrate;

[0072] 2) Generate semiconductor nano-arrays on the epoxy base by hydrothermal method or anodic oxidation method;

[0073] 3) Decorate the metal nanoparticles on the surface of the semiconductor nanoarray.

[0074] In some specific embodiments of the present invention, the method for forming epoxy groups on the surface of the substrate is to react the substrate with a silane coupling agent, preferably γ-(2,3-glycidoxy)propyltrimethoxysilane, Get epoxy. The epoxy group can make the semiconductor nano-array contact more closely with the substrate, thereby strengthening the electron transfer process and improving the antibacterial effect.

[0075] In some specific embodiments of the present invention, the method of generating zinc oxide semiconductor nano-arrays on the epoxy group...

Embodiment 1

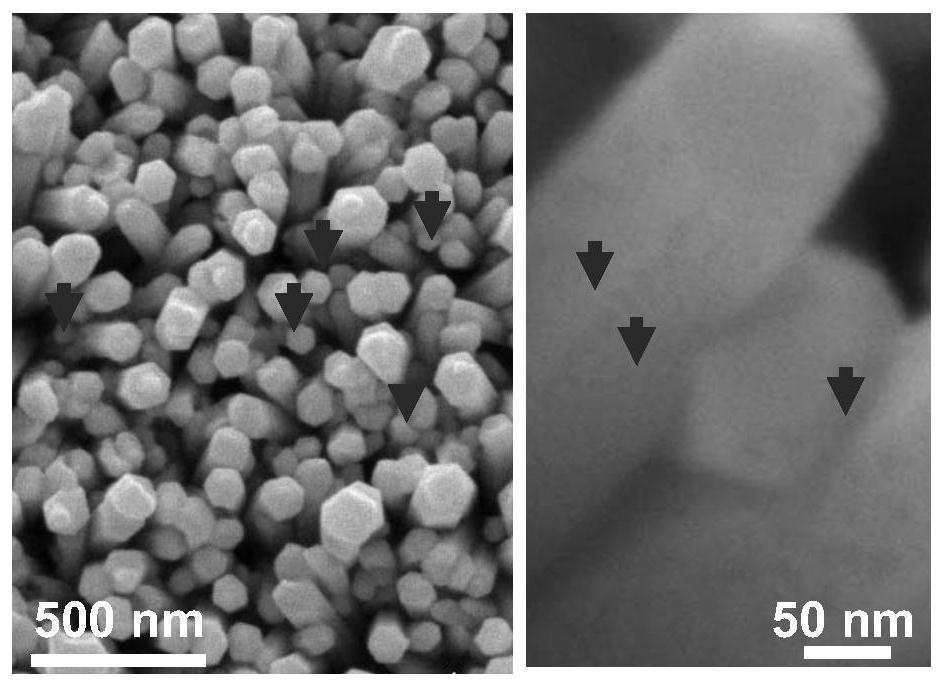

[0104] The titanium alloy is processed into cuboids with a length, width and height of 30 mm, 30 mm and 0.5 mm respectively, which are polished and polished, and then ultrasonically cleaned in acetone, ethanol and water for 10 minutes, and dried with nitrogen for later use. Soak the above titanium alloy material in NaOH aqueous solution (10M) for 2h, and react with KH-560 (2% v / v) for 10h to form epoxy functional groups. Then prepare Zn(CH 3 COO) 2 2H 2 A methanol solution of O (10 mM) and NaOH (30 mM), pipetting 10 μL was dropped onto the sample surface and treated at 120° C. for 5 min and repeated three times to prepare a seed layer. Next, the above samples were placed in a mixed aqueous solution of cyclohexamethylenetetramine (50 mM) and zinc acetate hexahydrate (50 mM), and subjected to hydrothermal treatment at 96° C. for 10-12 h to form ZnO nanorod semiconductors. After the reaction, the sample was rinsed with 5 mL of water for 2 min and dried with nitrogen. The nano...

Embodiment 2

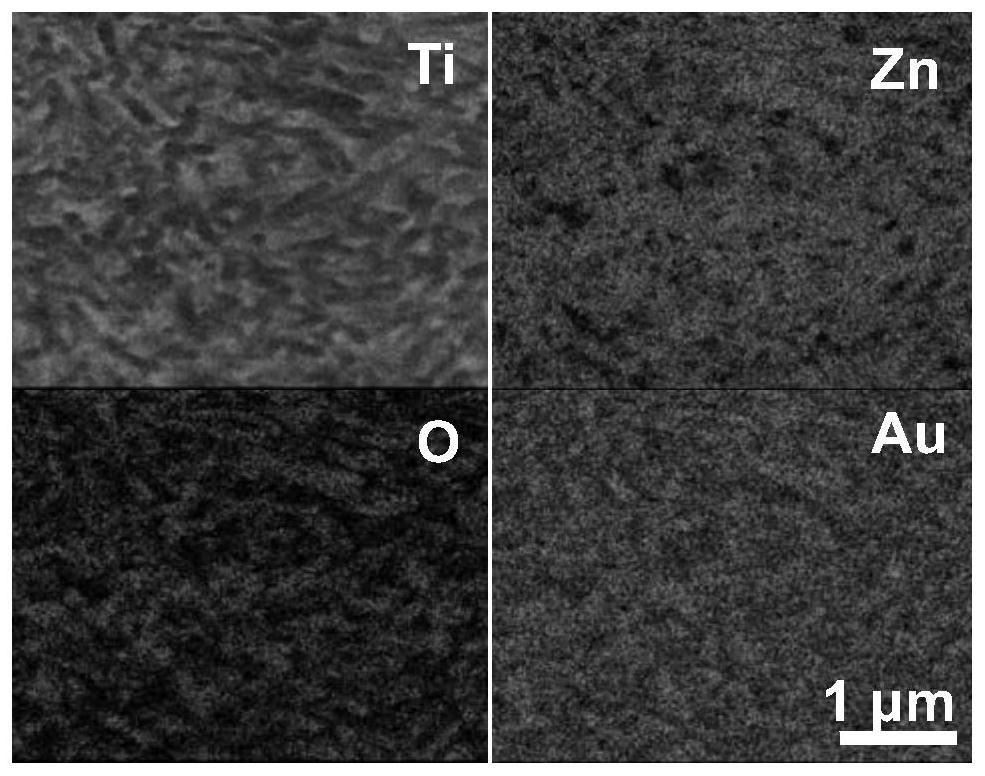

[0106] The surface of the sample treated in Example 1 was analyzed for elemental content. Energy Spectrum ( Figure 1b ) shows that zinc, oxygen, gold, and titanium elements are evenly distributed on the surface of the sample, indicating that the zinc oxide coating and gold nanoparticles are evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com