A kind of heat dissipation coating and preparation method thereof

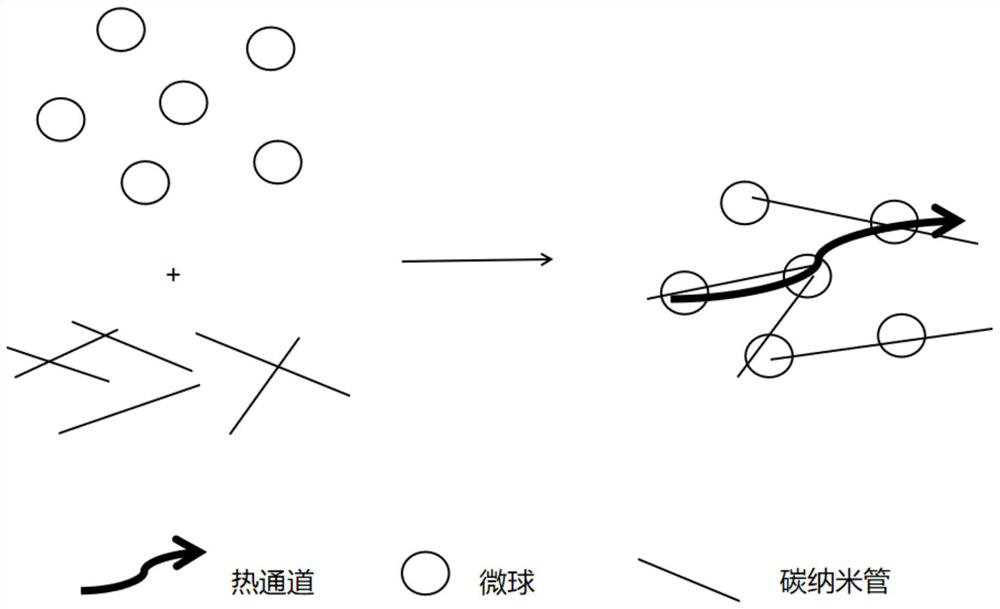

A technology for heat-dissipating coatings and oxides, used in anti-corrosion coatings, fire-resistant coatings, coatings, etc., to achieve the effect of increasing heat conduction channels, good mechanical properties, and high-density capillary phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The present embodiment provides a heat dissipation paint, which specifically includes the following steps:

[0058] S1. Preparation of metal oxide composite nano-ceramic powder: Dissolve 1g of titanium nitrate, 1g of aluminum nitrate and 2g of copper nitrate in 100g of water, add 15g of citric acid, heat to 60°C, evaporate the solvent for 2h to obtain a sol; then increase to 150 ℃, reduce the pressure to 0.01MPa, form a dry gel, take out, ignite the dry gel, grind it finely, and obtain the metal oxide composite nano-ceramic powder;

[0059]S2. Preparation of ferrite-wrapped metal oxide nano-ceramic powder: 10 g of the metal oxide composite nano-ceramic powder prepared in step S1 was uniformly dispersed in 50 g of an aqueous solution containing polyvinyl alcohol, and the content of polyvinyl alcohol was 2wt%, A suspension is obtained, heated to 40° C., and a solution of ferrous sulfate solution and ammonium bicarbonate is prepared. 50g ferrous sulfate solution was direc...

Embodiment 2

[0064] The present embodiment provides a heat dissipation paint, which specifically includes the following steps:

[0065] S1. Preparation of metal oxide composite nano-ceramic powder: Dissolve 1g of titanium nitrate, 3g of aluminum nitrate, and 4g of copper nitrate in 100g of water, add 25g of sodium citrate, heat to 80°C, evaporate the solvent for 4h to obtain a sol; then increase to 170℃, reduce the pressure to 0.1MPa to form a dry gel, take it out, ignite the dry gel, grind it finely, and obtain the metal oxide composite nano-ceramic powder;

[0066] S2. Preparation of ferrite-wrapped metal oxide nano-ceramic powder: 10 g of the metal oxide composite nano-ceramic powder prepared in step S1 was uniformly dispersed in 50 g of an aqueous solution containing polyvinyl alcohol, and the content of polyvinyl alcohol was 7wt%, A suspension is obtained, heated to 50° C., and a solution of ferrous sulfate solution and ammonium bicarbonate is prepared. 50g ferrous sulfate solution w...

Embodiment 3

[0071] The present embodiment provides a heat dissipation paint, which specifically includes the following steps:

[0072] S1. Preparation of metal oxide composite nano-ceramic powder: Dissolve 1g of titanium nitrate, 2g of aluminum nitrate, and 3g of copper nitrate in 100g of water, add 20g of citric acid, heat to 70°C, evaporate the solvent for 3h to obtain a sol; then increase to 160 ℃, reduce the pressure to 0.05MPa, form a dry gel, take out, ignite the dry gel, grind it finely, and obtain the metal oxide composite nano-ceramic powder;

[0073] S2. Preparation of ferrite-wrapped metal oxide nano-ceramic powder: 10 g of the metal oxide composite nano-ceramic powder prepared in step S1 is uniformly dispersed in 50 g of an aqueous solution containing polyvinyl alcohol, and the content of polyvinyl alcohol is 5wt%, A suspension is obtained, heated to 45° C., and a solution of ferrous sulfate solution and ammonium bicarbonate is prepared. 50g ferrous sulfate solution was direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com