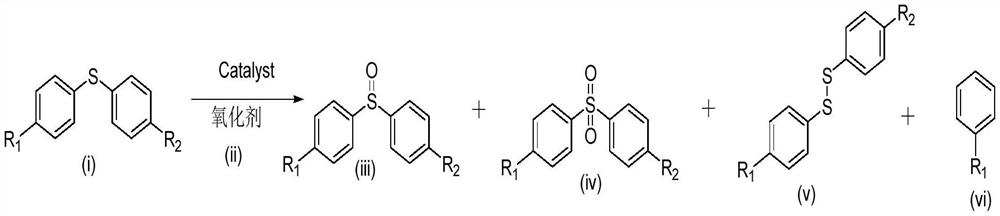

Synthetic method for preparing diphenyl sulfoxide-containing compound through electrochemical catalytic oxidation

A diphenyl sulfoxide, catalytic oxidation technology, applied in electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of long reaction time, low conversion rate, unsuitable for industrial production, etc., to achieve improved conversion rate, low energy Consumption, improve the effect of atomic utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

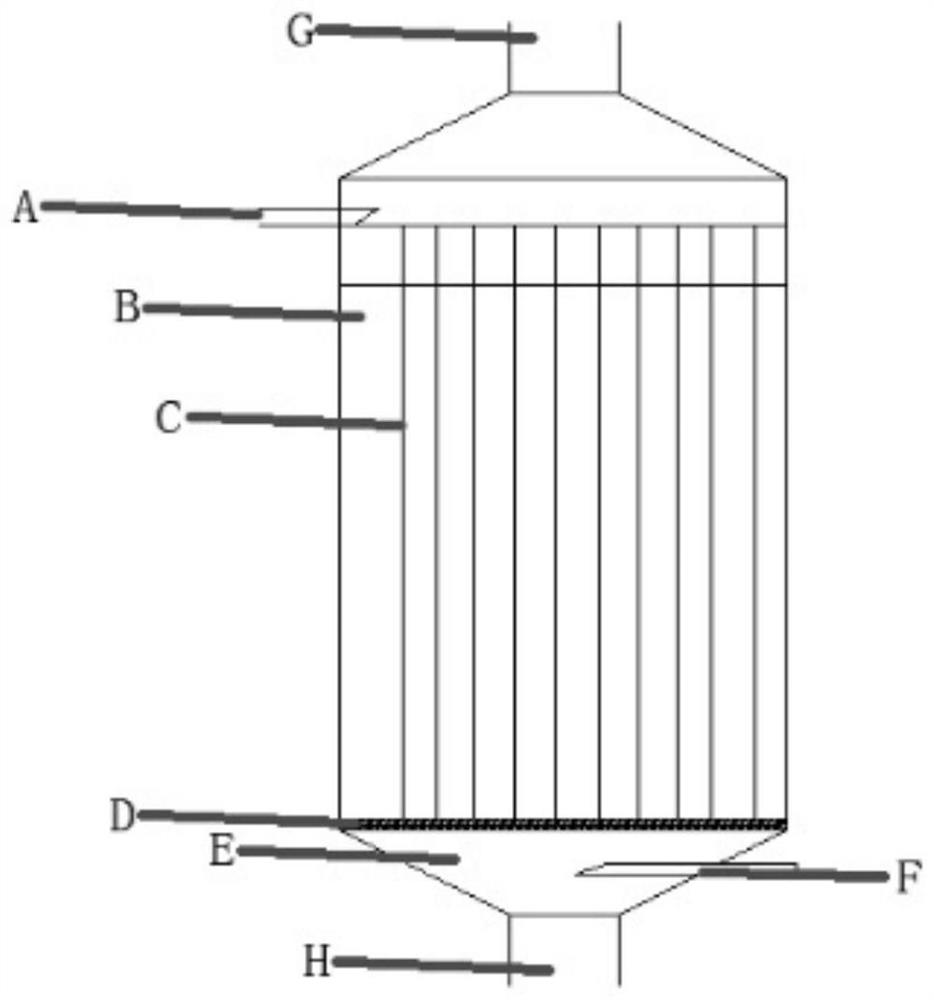

[0061] The electrochemical catalytic oxidation of the present embodiment prepares the synthetic method that contains diphenyl sulfoxide compound, reaction equipment such as figure 1 middle:

[0062] 1) A is the substrate (i) solution, and the substrate is dissolved in an organic solvent, wherein the organic solvent is: methanol, ethanol, isopropanol, ethyl acetate, isopropyl acetate, tert-butyl acetate, sec-butyl acetate One of ester, dimethyltetrahydrofuran, tetrahydrofuran, acetonitrile, acetone, butanone, cyclohexanone, tert-butyl methyl ether, ethylene glycol monomethyl ether, ethylene glycol dimethyl ether, anisole, NMP, toluene or Several kinds. Preference is given to acetonitrile, methanol, dichloromethane, acetone and small amounts of catalysts.

[0063] The oxidant is: one or more of hydrogen peroxide, sodium hypochlorite, sodium chlorobromide, oxygen, ozone, air, peroxide, and potassium dichromate. Preferably hydrogen peroxide, oxygen, sodium hypochlorite, air;

...

Embodiment 2

[0090] The electrochemical catalytic oxidation of this embodiment prepares the synthetic method of containing diphenyl sulfoxide compound, and equipment is the same as embodiment 1, and only difference is, A in the figure is feed inlet: substrate is 10% diphenyl sulfide For the methanol solution of ether, 10% refers to the mass ratio of the substrate weight to the solvent, F is the inlet of the mixed gas, and the mixed gas is air. Enter the electrochemical device at a gas velocity of 1.0 m / s. Electrode C is the graphite anode electrode of DC power supply, adjust the appropriate voltage, under the action of the mixed gas, the oxygen content is reduced from 18%-21% (volume) to 13%-15% (volume), and the single oxygen consumption is 30%, finally collect the reaction solution and add a reducing agent such as: sodium thiosulfate, sodium dithionite, sodium sulfite, potassium sulfite, sodium borohydride, etc.) to quench the reaction, and the reaction solution HPLC detection: Agilent 1...

Embodiment 3

[0092]

[0093]The electrochemical catalytic oxidation of the present embodiment prepares the synthetic method of the compound containing diphenyl sulfoxide, and the equipment is used in Example 1. The only difference is that A in the figure is the feed port: the substrate is diphenyl sulfide Methanol solution, where the substrate concentration needs to be controlled within the concentration range of 3-20%, the substrate concentration is the mass ratio of the substrate to the solvent, F is the inlet of the mixed gas, and the mixed gas is oxygen and nitrogen. Enter the electrochemical device at a gas velocity of 0.1 m / s. Electrode C is a graphite anode electrode of DC power supply, adjust the appropriate voltage, under the action of the mixer, the oxygen content is reduced from 80%-82% (volume) to 28-51% (volume), and the single oxygen consumption is 37.5 %, the final mobile phone reaction solution was added a reducing agent to quench the reaction, and the reaction solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com