Method for preparing high-performance near-infrared perovskite thin film in air

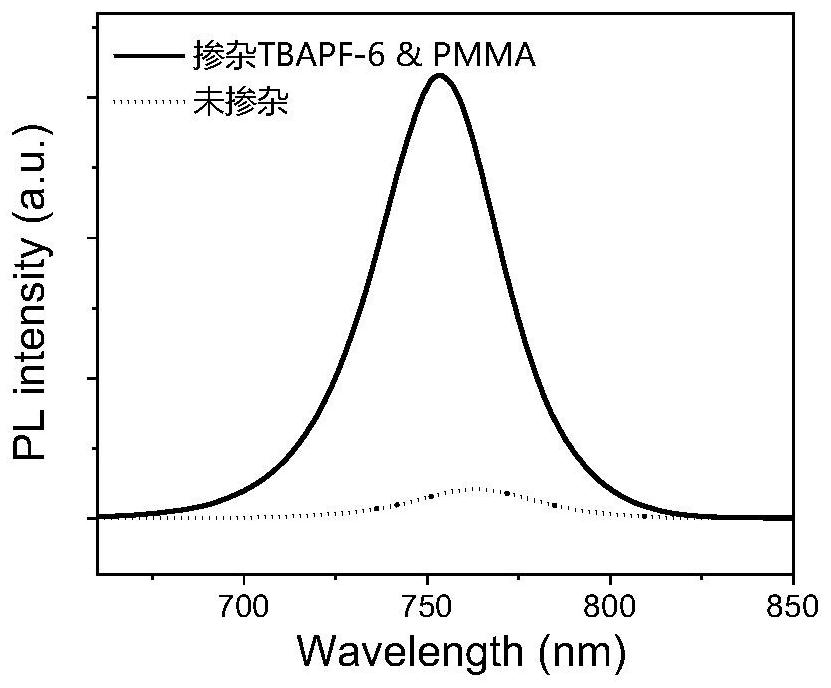

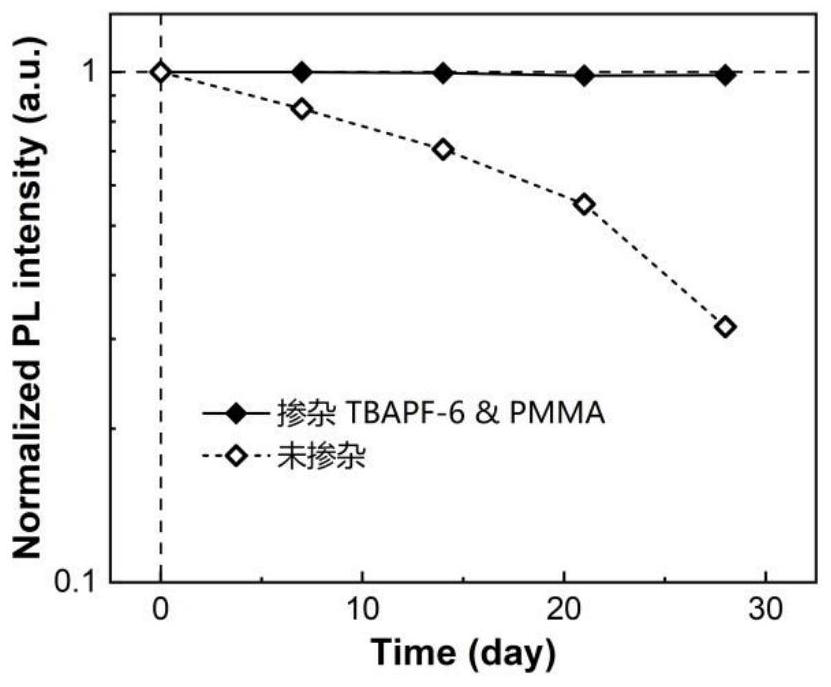

A technology of perovskite and perovskite precursor, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of increasing cost, reducing the stability of luminous efficiency, and poor stability of perovskite, achieving Good stability, increased fluorescence intensity, and high fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

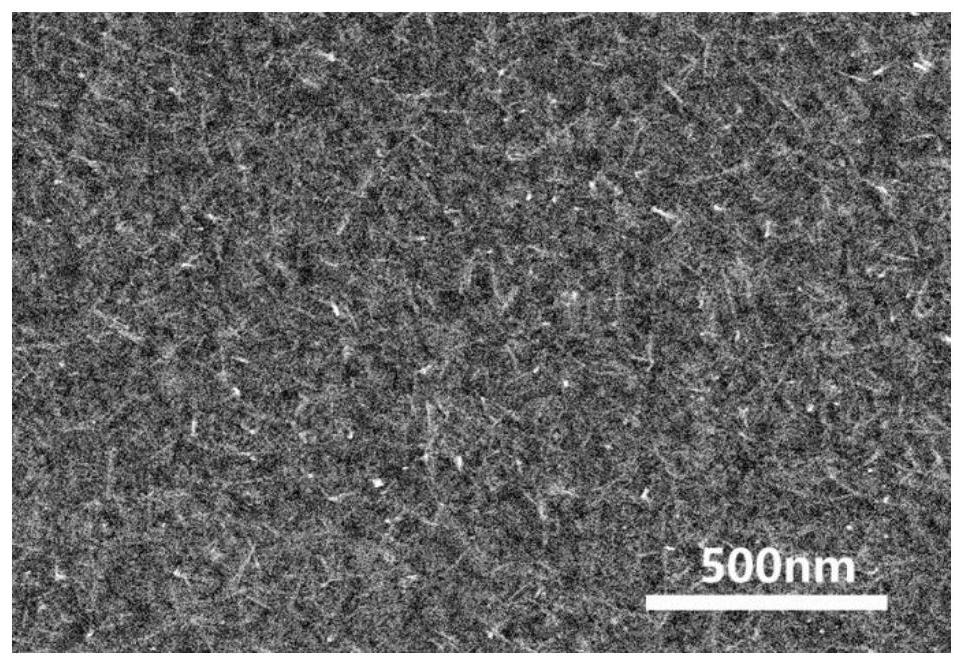

[0045] Embodiment 1: under the condition of air humidity 40%, prepare perovskite film as follows:

[0046] Step 1: Prepare a square p-type silicon substrate with a size of 1cm×1cm, clean it with RCA cleaning method, and then dry it.

[0047] The second step: 48mg of methylamine iodide (CH 3 NH 3 I,MAI) and 138mg of PbI 2 The powder was dissolved in a mixed solution of N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) at a volume ratio of 9:1, in which DMF was 635 μl and DMSO was 72 μl, and ultrasonically It dissolves rapidly, and the resulting methylamine lead iodide (CH 3 NH 3 PB 3 ,MAPbI 3 ) The concentration of the perovskite precursor solution is 0.3M.

[0048] Step 3: Add 0.5 mg of tetrabutylamine hexafluorophosphate (TBAPF-6) and 100 μl of 2% polymethyl methacrylate (PMMA) chlorobenzene solution into 1 ml of ethyl acetate, and stir by magnetic force Or ultrasonically mix them uniformly, and the doping concentrations of the obtained solutions are respectiv...

Embodiment 2

[0053] Embodiment 2: under the condition of air humidity 70%, prepare perovskite film as follows:

[0054] Step 1: Prepare a square ITO conductive glass substrate with a size of 1cm×1cm, clean it with RCA cleaning method, and then dry it.

[0055] The second step: 112mg of methyl ammonium bromide MABr and 367mg of PbBr 2 The powder was dissolved in a mixed solution of N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) at a volume ratio of 9:1, in which DMF was 635 μl and DMSO was 72 μl, and ultrasonically It dissolves quickly, and the resulting methylamine lead bromide (CH 3 NH 3 PbBr 3 ,MAPbBr 3 ) The concentration of the perovskite precursor solution is 1M.

[0056] Step 3: Add 0.5 mg of tetrabutylammonium hexafluorophosphate and 100 μl of 2% PMMA chlorobenzene solution into 1 ml of ethyl acetate, and mix them uniformly by magnetic stirring or ultrasound, and the doping concentration of the resulting solution They are: tetrabutylamine hexafluorophosphate 0.5mg / m...

Embodiment 3

[0061] Embodiment 3: all the other are identical with embodiment 1, and difference is: prepare perovskite film under the condition of air humidity 60%, p-type silicon substrate can be arbitrarily replaced by FTO conductive glass, n-type silicon, One of silicon dioxide, flexible substrates such as PET or PEN materials, or graphene, none of this substitution affected the final perovskite crystal formation. Figure 9 For undoped MAPbI deposited on different substrates 3 perovskite thin film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com