Preparation method of oxygenation membrane with anticoagulant coating, catheter and intubation tube

A coating and oxygenation technology, applied in catheters, coatings, anticoagulant treatment, etc., can solve the problems of difficult to build a coating with high blood compatibility, and achieve the prolongation of thromboplastin time, firm adhesion, and reaction Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

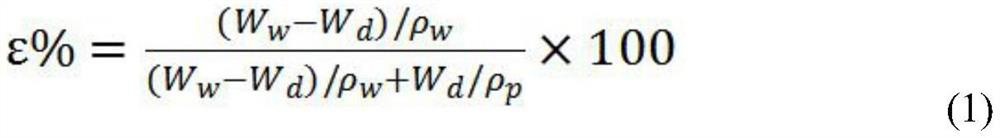

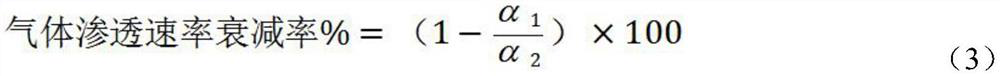

[0053] Step 1, put 11wt% polyvinyl chloride resin, 10wt% polyethylene glycol (molecular weight 4000) and 79wt% solvent dimethylacetamide into the spinning kettle, stir at 60°C for 10 hours to dissolve evenly, and let it stand for defoaming After 4 hours, it was extruded together with the core liquid (aqueous solution of 70 wt% dimethylacetamide) through an inserted tubular spinning nozzle, and entered into a coagulation bath water tank. At a spinning and drafting speed of 50 m / min, polyvinyl chloride hollow fiber membranes were spun, washed with water, and dried at room temperature directly to obtain polyvinyl chloride oxygenated membrane substrates. The inner diameter of the polyvinyl chloride oxygenated membrane substrate is 200 μm, the wall thickness is 40 μm, and the gas permeation rate is 35 mL / min cm 2 ·bar, the water penetration pressure is 0.52MPa, the maximum pore size measured by ethanol bubble point method is 0.05μm, and the porosity is 83%.

[0054] Step 2: On the...

Embodiment 2

[0062] Step 1. Put 21wt% polyvinylidene fluoride-chlorotrifluoroethylene resin, 10wt% polyethylene glycol (molecular weight 400) and 69wt% solvent N-methylpyrrolidone into the spinning kettle, stir at 90°C for 6 hours to dissolve After standing for 4 hours for defoaming, it is extruded together with the core liquid (70wt% N-methylpyrrolidone aqueous solution) through the inserted tubular spinning nozzle and enters the coagulation bath water tank. At a spinning and drawing speed of 45 m / min, polyvinylidene fluoride-chlorotrifluoroethylene hollow fiber membranes were spun, washed with water and dried at room temperature directly to obtain polyvinylidene fluoride-chlorotrifluoroethylene oxygenated membrane bases material. The inner diameter of the polyvinylidene fluoride-chlorotrifluoroethylene oxygenated membrane substrate is 200 μm, the wall thickness is 40 μm, and the gas permeation rate is 100 mL / min cm 2 ·bar, the water penetration pressure is 0.32MPa, the maximum pore size...

Embodiment 3

[0069] On the inner surface of the polyvinyl chloride catheter or cannula prepared by the conventional plastic extrusion method, a solution of tetraethylenepentamine solution with a concentration of 2mol / L is passed through, and the temperature is 60°C, and the reaction time is kept for 8 hours, and then deionized Rinse the inner surface of the catheter or cannula with water, then pass through a citric acid aqueous solution with a concentration of 0.8 mol / L, and keep the reaction time at room temperature for 8 hours.

[0070] The bovine serum albumin adsorption rate of the catheter or cannula is less than 0.5%, and the hemolysis rate is less than 0.3%. After citric acid graft modification, the APTT value was 2.9 times that of the blank control group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com