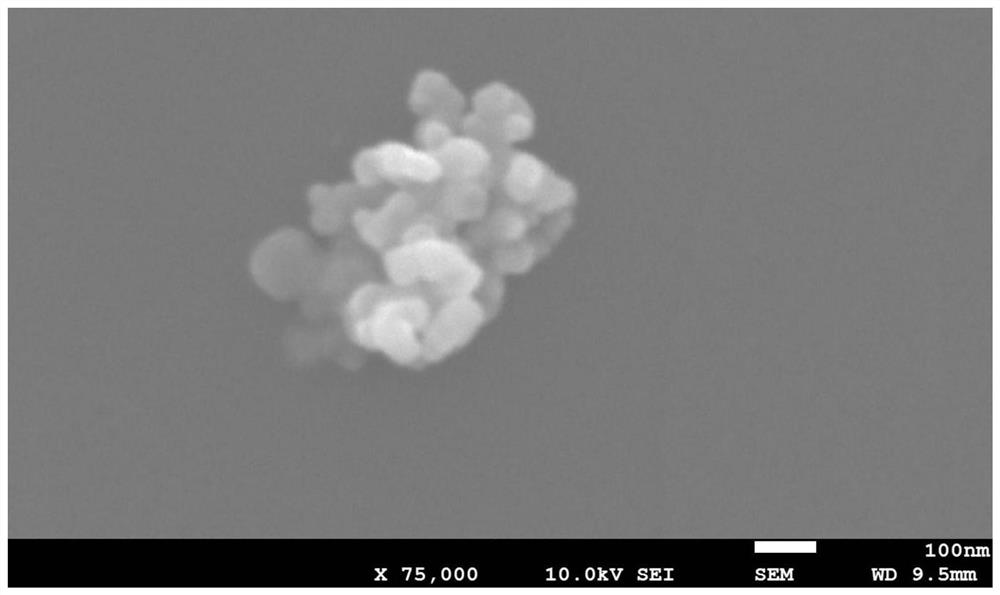

Superfine scandium oxide as well as preparation method and application thereof

A technology of scandium oxide and scandium oxalate, which is applied in the field of material chemistry, can solve the problems of long process flow and small specific surface area of scandium oxide, and achieve the effects of high specific surface area, suppression of uneven particle size, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] As described in the background art, the existing methods for preparing scandium oxide have the problems of long process flow and small specific surface area of scandium oxide. In order to solve the above-mentioned technical problems, the application provides a method for preparing ultrafine scandium oxide, the preparation method comprising: in the presence of microwaves and anionic surfactants, the soluble salt solution containing scandium is subjected to precipitation reaction with a precipitant to obtain Scandium oxalate precipitation, the precipitating agent is oxalic acid or oxalate; the scandium oxalate precipitation is roasted to obtain ultrafine scandium oxide; anionic surfactants include but not limited to sulfate ester surfactants and / or sulfonate lipid surfactants .

[0022] Taking oxalate as an example, the reaction principle of the above preparation method is as follows:

[0023] sc 3+ +C 2 o 4 2- →S C2 (C 2 o 4 ) 3

[0024] S C2 (C 2 o 4 ) 3...

Embodiment 1

[0039] Under the condition of reaction temperature 90 ℃, 600W microwave radiation, the scandium chloride solution of 1.0mol / L and anion surface active agent (the weight ratio of sodium lauryl sulfate and sodium dodecylsulfonate are 1:2 ) mixing, the consumption of anionic surfactant is 0.2g / L, obtains mixed solution; Then under the first stirring rate of 450r / min, according to scandium ion and precipitant molar ratio is 1:2, to above-mentioned mixed solution Add a precipitant (oxalic acid) dropwise. After the precipitating agent is added, the product system of the precipitation reaction is continuously stirred for 30 min at the second stirring speed of 200 r / min, and the reaction ends.

[0040] After aging the product system of the precipitation reaction at 90° C. for 60 min, the obtained product system was centrifuged, washed three times with ethanol and pure water respectively, and the obtained precipitate was placed in a vacuum drying oven. Drying treatment at 100°C for 18...

Embodiment 2

[0042] Under the microwave radiation condition of reaction temperature 70 ℃, 500W, the scandium chloride solution of 0.5mol / L and anionic surface active agent (the weight ratio of sodium lauryl sulfate and sodium dodecylsulfonate are 1:2 ) mixed, the consumption of anionic surfactant is 0.2g / L, obtains mixed solution; Then under the first stirring rate of 300r / min, according to scandium ion and precipitant molar ratio is 1:3 in above-mentioned mixed solution Slowly add the precipitant (ammonium oxalate) dropwise. After the precipitating agent is added, the product system of the precipitation reaction is continuously stirred for 60 min at the second stirring rate of 100 r / min, and the reaction ends.

[0043] After aging the product system of the precipitation reaction at 70° C. for 180 min, the obtained product system was subjected to suction filtration, washed three times with ethanol and water respectively, and the obtained precipitate was placed in a vacuum drying oven. Dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com