Preparation method of platinum-based synergistic catalyst with structure coupling effect

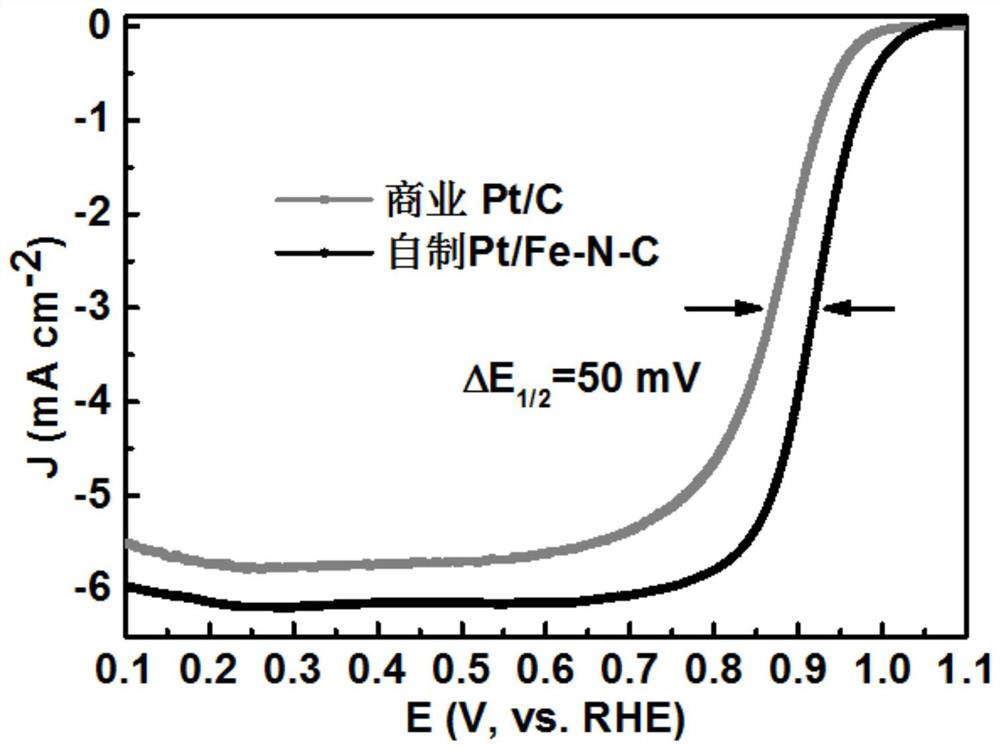

A coupling effect and catalyst technology, applied in the field of electrocatalysis, can solve the problems that the catalytic activity and durability cannot meet the large-scale commercial application of fuel cells, and the cost of cathode platinum carbon oxygen reduction electrocatalyst is high, achieving excellent industrialization prospects, electrocatalysis Excellent catalytic performance, highlighting the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

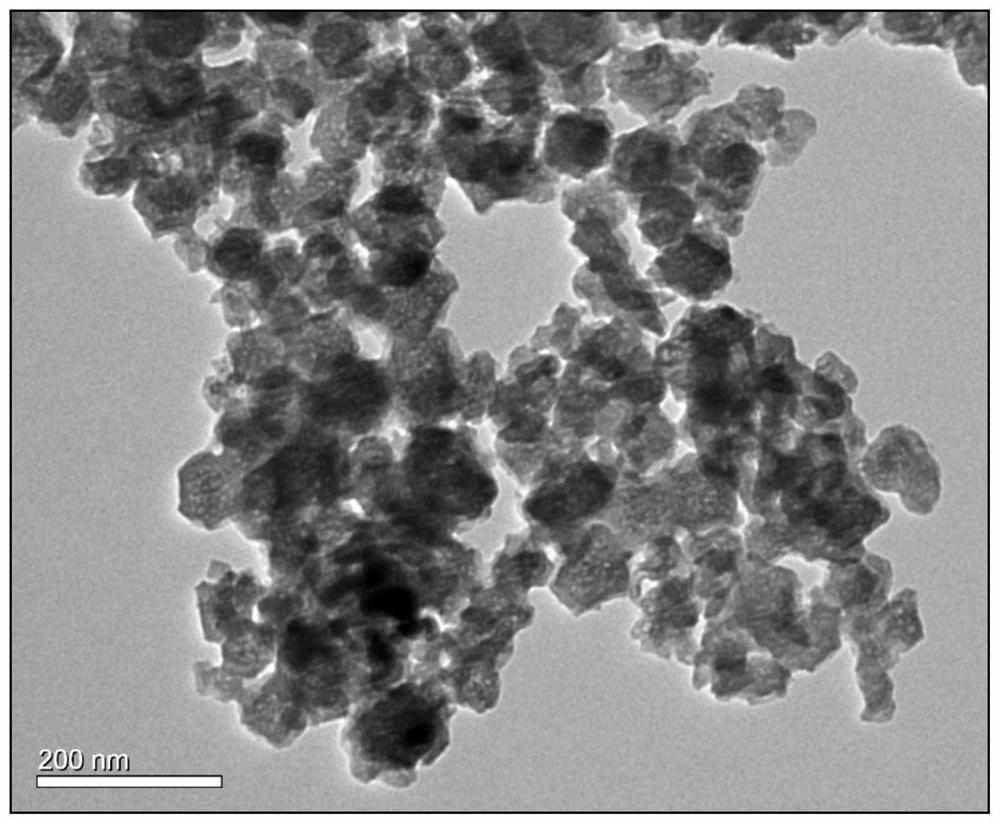

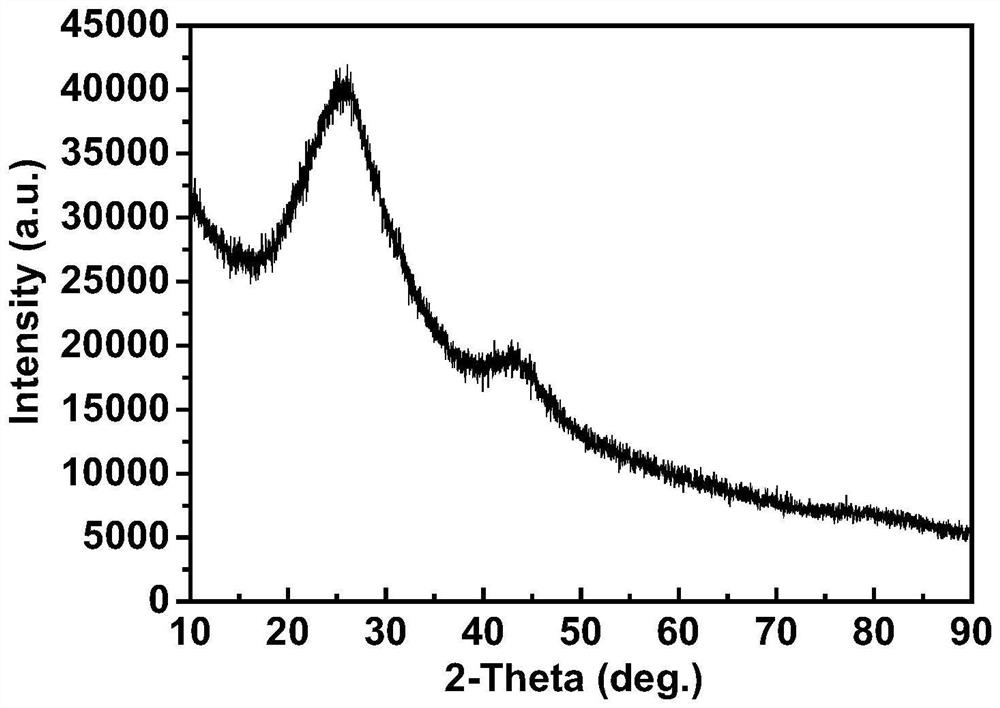

[0042] 3.0 grams of zinc nitrate, 0.1 gram of ferric chloride, and 0.5 gram of sodium acetate were dissolved in 0.3 liters of methanol and ultrasonicated for 10 minutes, then stirred at 500 rpm for 10 minutes to form a uniformly dispersed solution A. Dissolve 8 g of dimethylimidazole in 0.5 liter of methanol, sonicate for 10 minutes and then stir at 500 rpm for 10 minutes to form a uniformly dispersed solution B. Solutions A and B were mixed and stirred at 500 rpm for 12 hours at room temperature. After the stirring, the synthesized product was collected by centrifugation at 9000 rpm, and washed three times with methanol solution at a centrifugation speed of 8000 rpm for 5 minutes. Put the finally obtained precipitate into freeze-drying equipment for 12 hours to freeze-dry, then grind the freeze-dried powder and put it into an alumina crucible, and finally carry out carbonization and pyrolysis at 900°C for 2 hours under the protection of nitrogen gas, and put After carbonizat...

Embodiment 2

[0044] 5.0 grams of polyoxyethylene polyoxypropylene block copolymer, 10.0 grams of dopamine hydrochloride, 2.0 grams of bithiophene and 50.0 milligrams of ammonium molybdate were dissolved in the mixed solution of 2.0 liters of methanol and water (volume ratio 1:1), with 500 It was stirred at rpm for 1 hour, then 50.0 ml of trimethylbenzene was added, and stirring was continued for 1 hour. Finally, 5 ml of ammonia water was added and stirred at 500 rpm for 12 hours. After stirring, the synthesized product was collected by centrifugation at 10,000 rpm for 10 minutes, and washed three times with a mixed solution of water and ethanol at a centrifugation speed of 8,000 rpm for 10 minutes. Put the finally obtained precipitate into freeze-drying equipment for 12 hours to freeze-dry, then grind the freeze-dried powder and put it into an alumina crucible, and finally carry out carbonization and pyrolysis at 900°C for 3 hours under the protection of nitrogen gas, and put After carbon...

Embodiment 3

[0046] Disperse 1.5 grams of polyethylene glycol p-isooctylphenyl ether and 60 mg of nickel nitrate in 1.8 liters of aqueous solution, stir at 500 rpm for 1 hour, then add 24 milliliters of aniline and 15 milliliters of pyrrole, and continue stirring for 1 hour to form Solution A. Dissolve 10 g of ammonium persulfate in 0.2 liter of water, and stir at 500 rpm for 0.5 hour to form solution B. Solution B was slowly added to solution A, and stirred in an ice-water bath at a speed of 300 rpm for 12 hours. After the end, the synthetic product was collected by centrifugation at 8000 rpm for 10 minutes, and washed three times with a mixed solution of water and ethanol (volume ratio 1:1). The centrifugation speed was 8000 rpm and the centrifugation time was 10 minutes. Put the finally obtained precipitate into freeze-drying equipment for 12 hours to freeze-dry, then grind the freeze-dried powder and put it into an alumina crucible, then carry out carbonization and pyrolysis at 800°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com