Method for preparing rutile nano titanium dioxide

A nano-titanium dioxide, rutile phase technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of small particle size, long sedimentation time, hard agglomeration, etc., to prevent the growth of crystal grains, avoid agglomeration and sticking. The effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 2g of cyclodextrin to 100ml of ethanol / water mixed solvent containing 0.8g / L lecithin, and fully disperse it under the action of ultrasonic waves; then use concentrated hydrochloric acid to adjust the pH value of the dispersion to 1.1; the concentration is 0.5mol / L of titanium tetrachloride aqueous solution is slowly added to the above dispersion liquid, under the action of ultrasonic waves with a frequency of 30KHz and a power of 250W, drip ammonia water with a concentration of 30%, and react at room temperature for 1.5 hours; after standing for 2 hours, carry out Filtrate, wash, and calcinate the obtained filter cake at 700° C. for 1 hour to obtain milky white powdery rutile nano-titanium dioxide with a particle size of 9.5 nm.

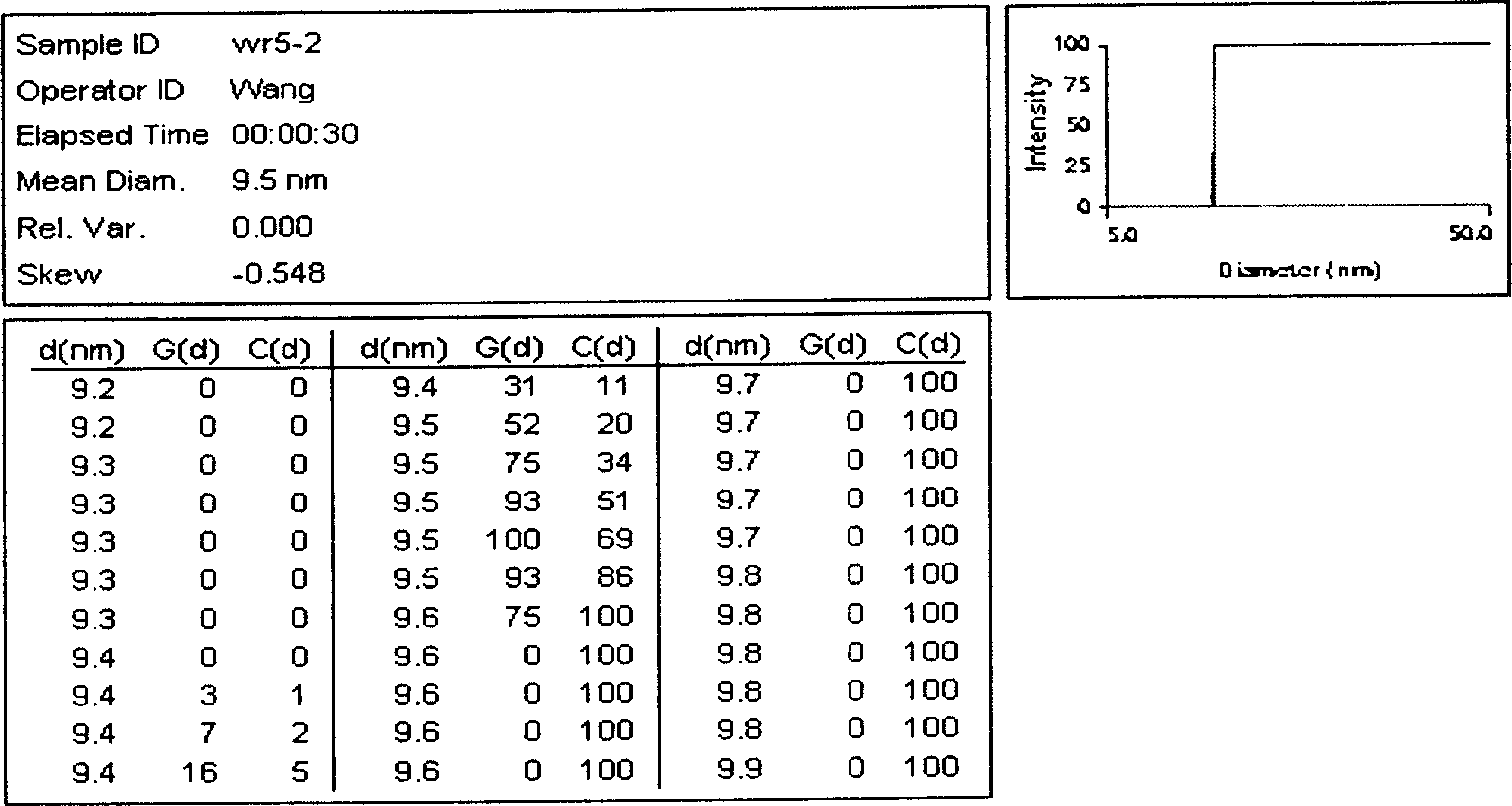

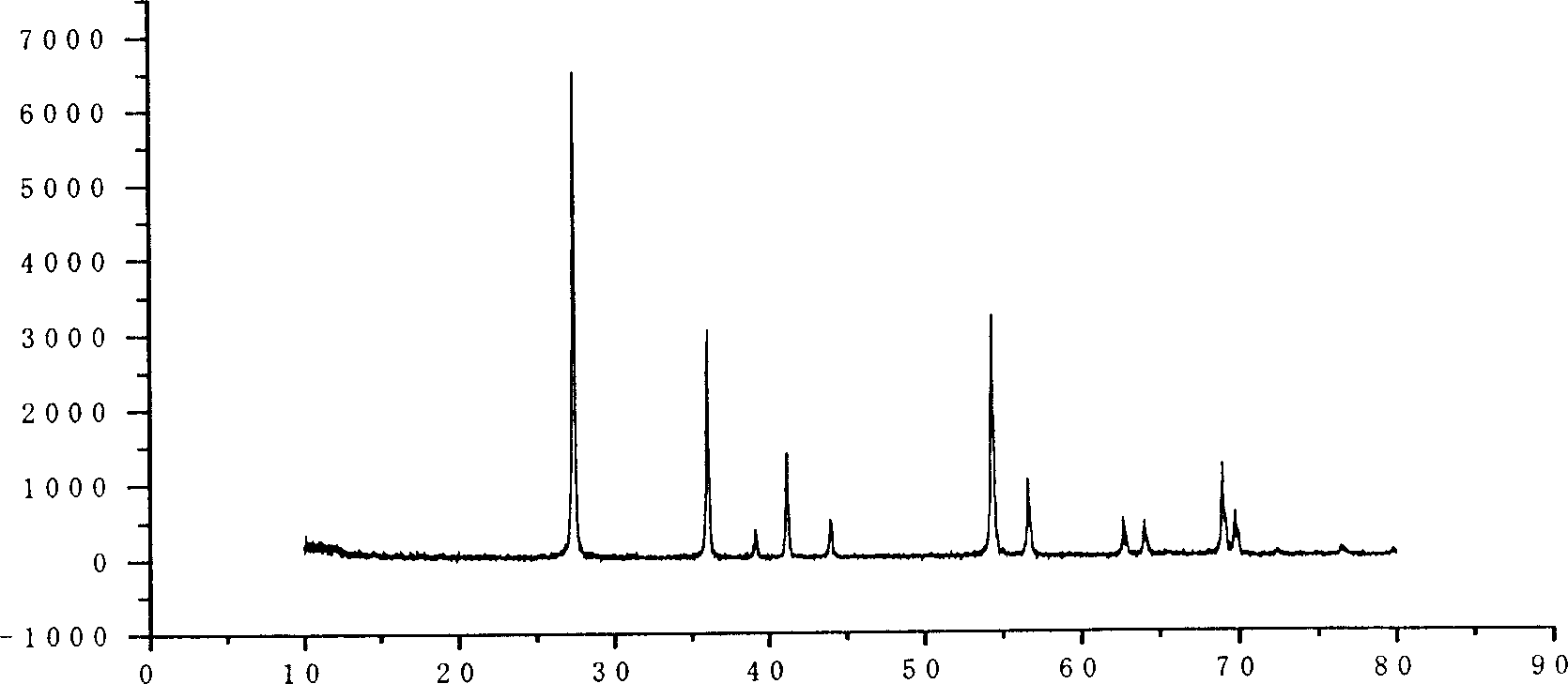

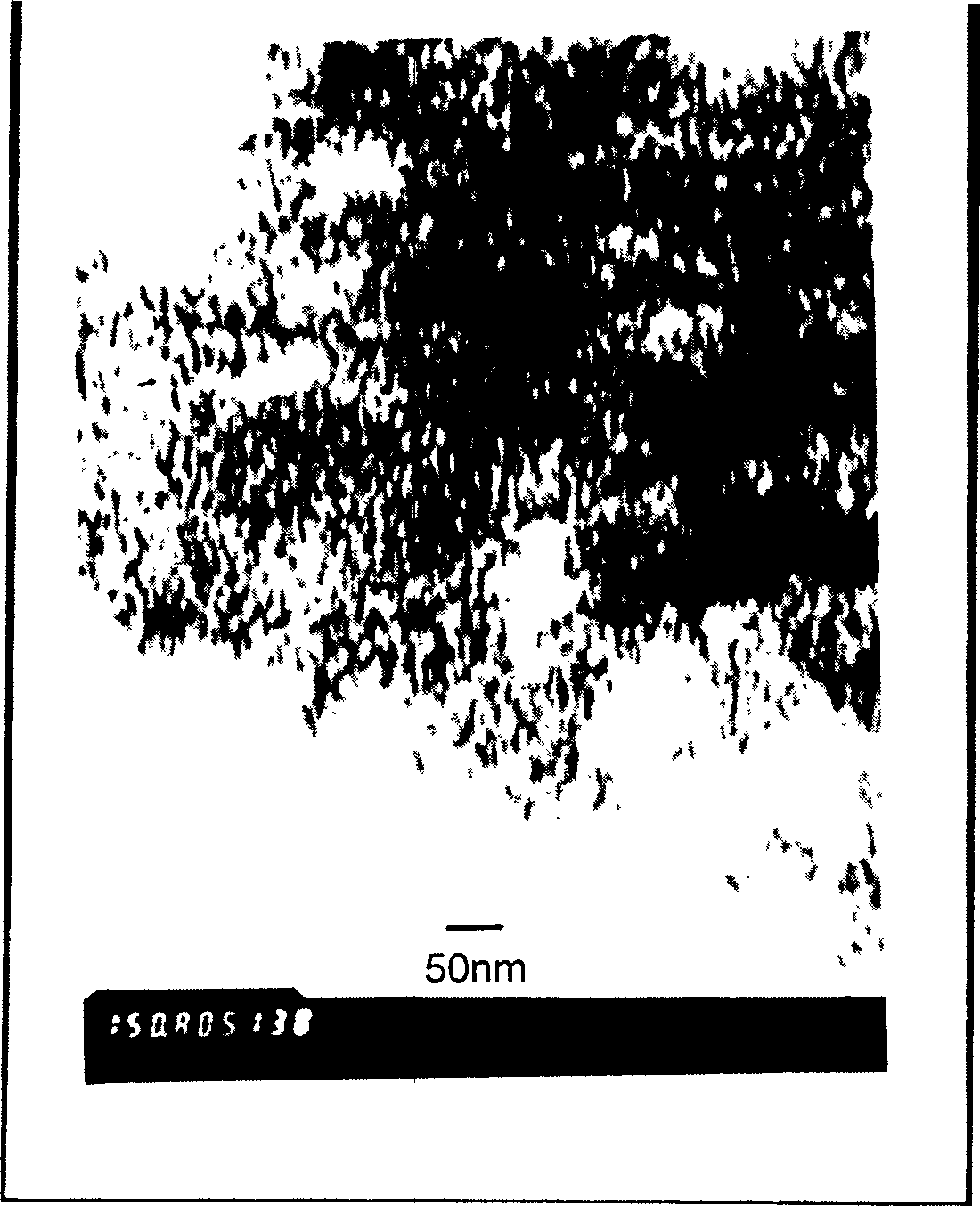

[0024] See attached figure 1 , from the analysis results of the laser particle size analyzer, it can be seen that the rutile phase nano-titanium dioxide powder prepared by the preparation method described in Example 1 has an average part...

Embodiment 2

[0028] Add 2g of modified lignosulfonate to 150ml of ethanol / cyclohexane / water mixed solvent containing EDTA 2.0g / L, fully disperse the carrier under the action of ultrasonic waves, and then adjust the dispersion with concentrated hydrochloric acid The pH value of the solution is 1.5, and the butyl titanate aqueous solution with a concentration of 1.5mol / L is slowly added to the above dispersion liquid, and under the action of ultrasonic waves with a frequency of 30KHz and a power of 300W, ammonia water with a concentration of 30% is added dropwise, and other The steps are the same as in Example 1 to obtain 19.5nm milky white powdery rutile nano-titanium dioxide.

Embodiment 3

[0030] Add 1g of carbon powder and 1g of starch to 150ml of ethanol / cyclohexane / water mixed solvent containing citric acid 2.0g / L, fully disperse it under the action of ultrasonic waves, and then use concentrated nitric acid to adjust the pH value of the dispersion to 1.0 , slowly add titanium tetrachloride aqueous solution with a concentration of 0.5 mol / L to the above dispersion liquid, under the action of ultrasonic waves with a frequency of 30KHz and a power of 250W, add ammonia water with a concentration of 30% dropwise, and react at room temperature for 1.5 hours , let stand for 2 hours, then filter and wash, and calcinate the filter cake at 700°C for 1 hour to obtain 24.5nm milky white powdery rutile nano-titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com