Xylose enzyme method preparing method

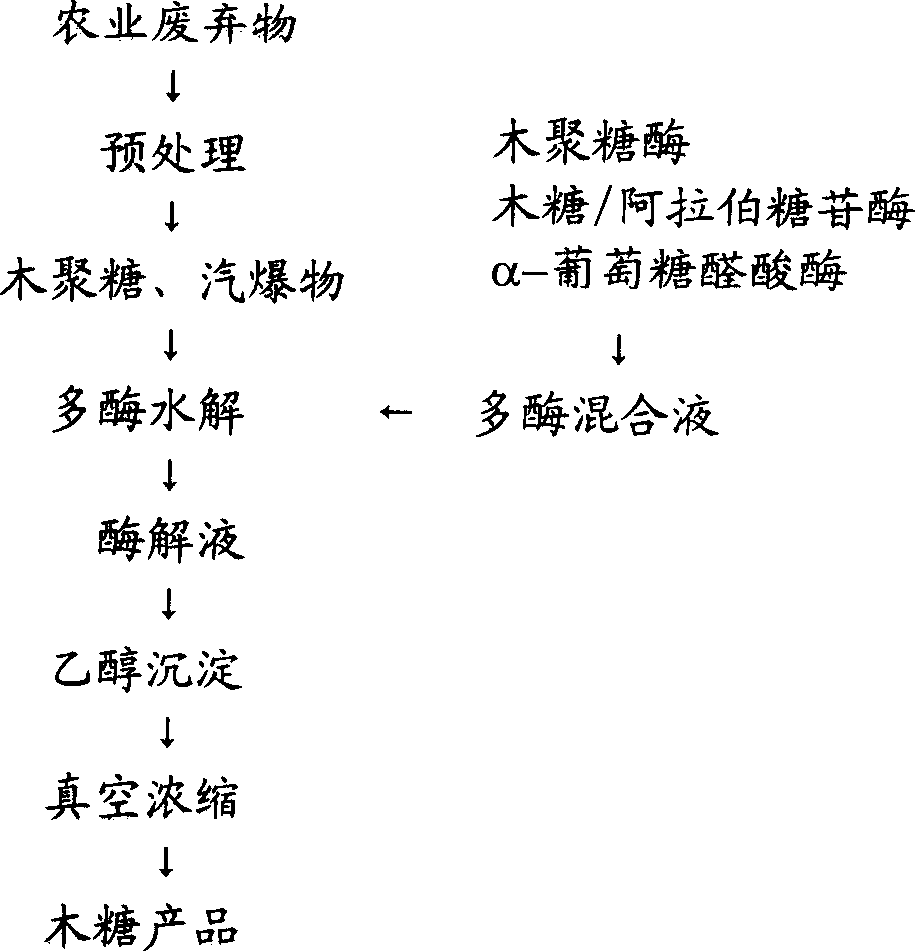

An enzymatic preparation and xylanase technology, applied in the preparation of xylose and the field of enzymatic preparation of xylose, can solve the problems of increased environmental protection burden, slow growth, low post-treatment efficiency, etc., and achieve important economic benefits and social benefits. Benefit, mild reaction conditions, mild effect conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of heat-resistant xylan degrading enzyme

[0032] Primers were designed according to the gene sequences of xylanase, xylosidase, arabinosidase and α-glucuronidase in Genbank,

[0033] Tm-xynB-N: 5'-CCGTTCCATGGACTACAGGATGTGC-3'

[0034] Tm-xynB-C: 5'-CCGCTCGAGCGGATATATCTTTTCTTCCCTT-3'

[0035] Tm-xyl-N: 5'-CATGCCATGGAACTGTACAGGGATC-3'

[0036] Tm-xyl-C: 5'-ATAAGAATGCGGCCGCCTCCTCGCAGGCTTCC-3'

[0037] Tm-aguA-N: 5'-GGAATTCCATATGAAAATATTACCTTCTGTGTTGAT-3'

[0038] Tm-aguA-C: 5'-CCC TCGAGTCTTTTCTTCTATCTTTTTCTCAG-3'

[0039] The genomic DNA of Thmotiga maritima was used as template for PCR amplification.

[0040] After inserting the PCR products of xylanase, xylose / arabinosidase and α-glucuronidase into plasmids pET-20b and pET-28a, respectively, the recombinant expression plasmids pET-20b-xynB, pET-28a-xyl and pET-28a-aguA.

[0041] 0.01 μg of recombinant expression plasmids pET-20b-xynB, pET-28a-xyl and pET-28a-aguA were electrotransformed into 50 μL E...

Embodiment 2

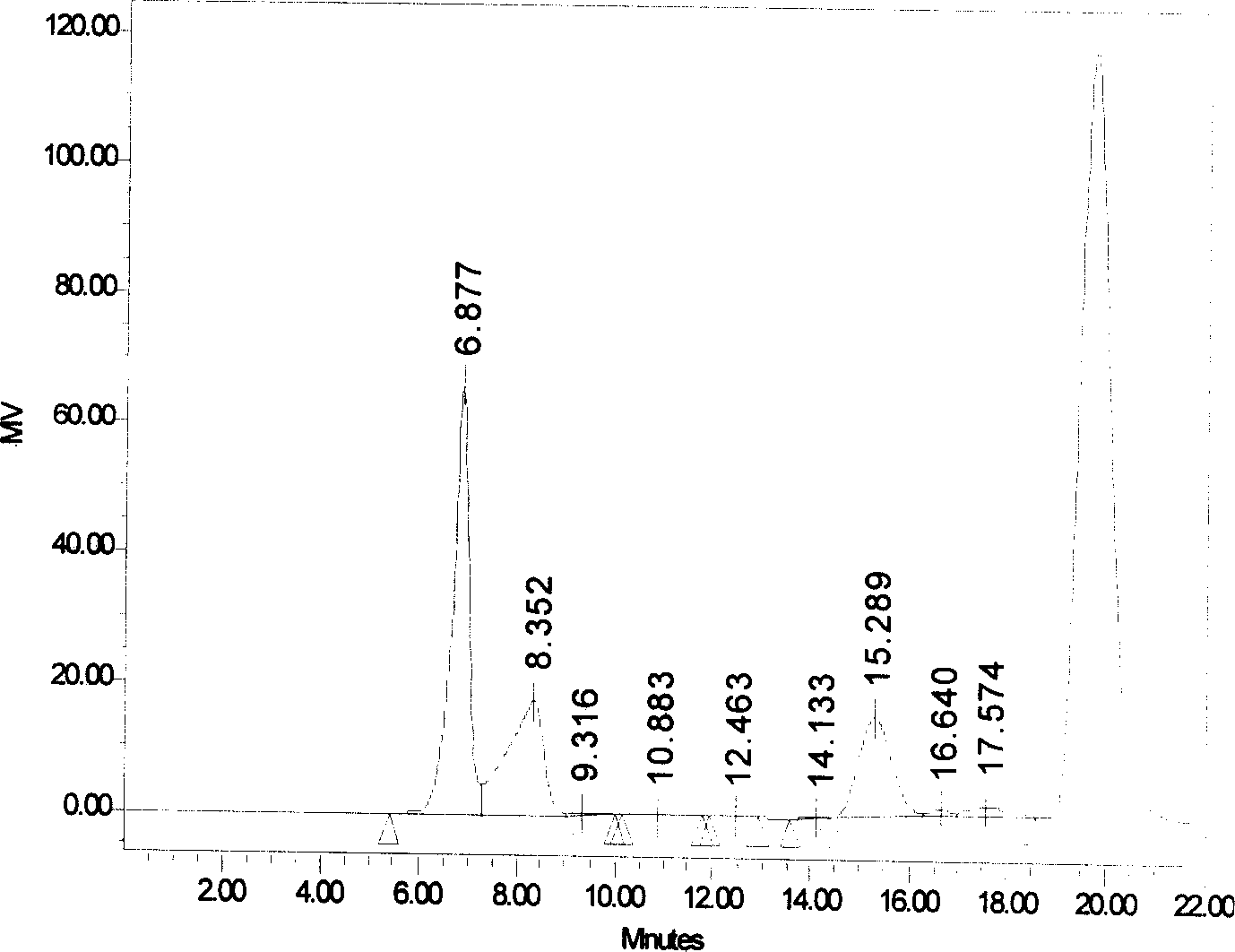

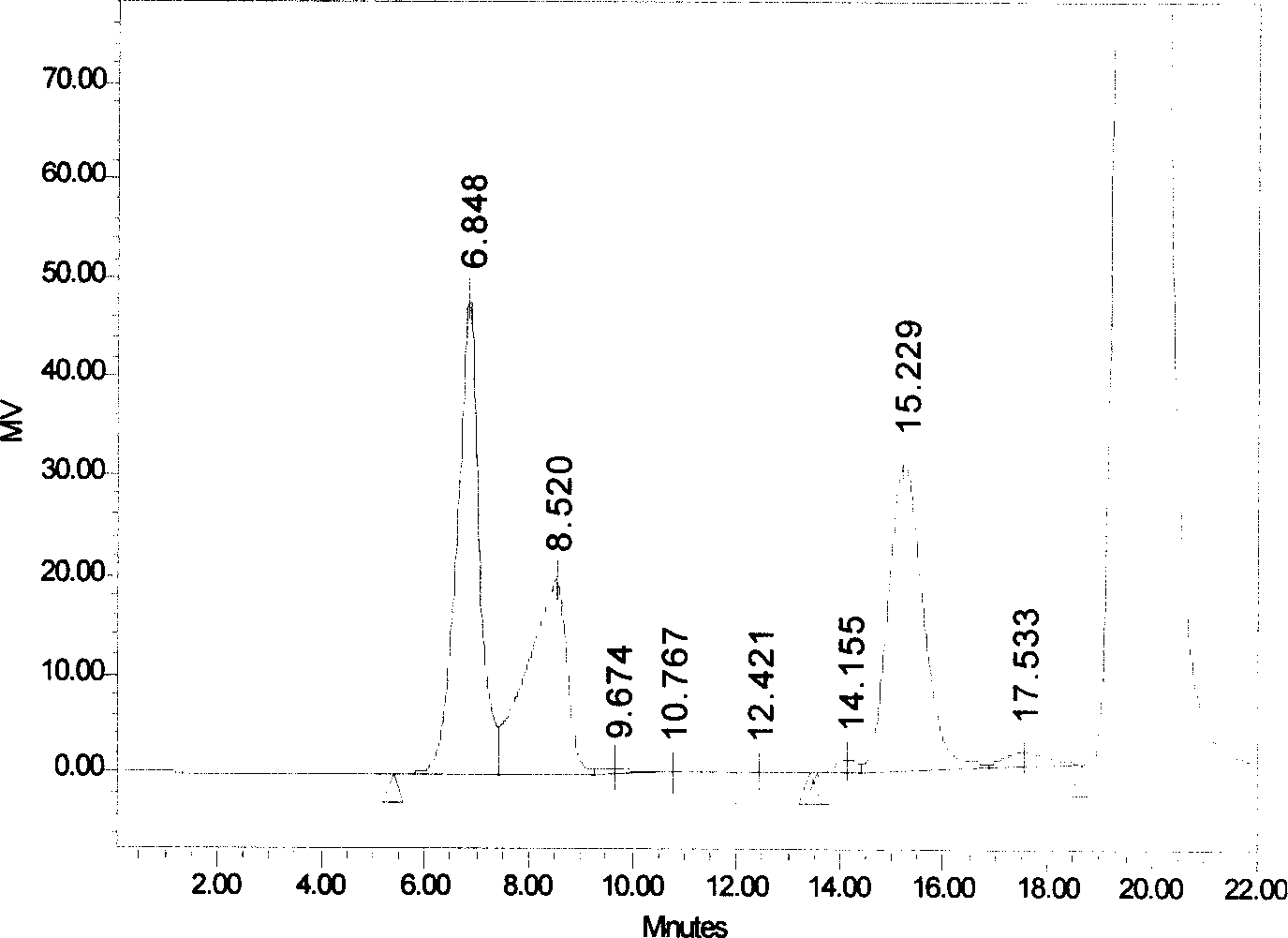

[0049] Embodiment 2: substantially the same as Example 1, the difference is that the xylan used is oat xylan, purchased from Sigma Company, and the ratio of xylan and multi-enzyme solution is 1: 10 (w / v), The obtained enzymolysis solution adopts HPLC detection to show that xylose content is more than twice as high as using xylanase and xylose / arabinosidase (see attached Figure 5 and Figure 4 Compare).

Embodiment 3

[0050] Embodiment 3: basically the same as Example 1, the difference is that the pretreated corn cob is used as raw material, and the specific operations are as follows:

[0051] (1) Raw material pretreatment

[0052] Take the air-dried corn cobs with a chopped diameter of about 3-20mm, soak them in clean water and then centrifuge to remove the water, add sodium hydroxide solution according to the solid-to-liquid ratio of 7-10:1, and the final concentration is 1%-3%. Or extract at high temperature, then collect the filtrate and neutralize it to slightly acidic with acid, and then use 3 times the volume of ethanol to precipitate to obtain xylan.

[0053] (2) Adding xylanase, xylose / arabinosidase and α-glucuronidase to the buffer in sequence at an addition ratio of 1:1:0.75 to prepare a multi-enzyme mixture, wherein the amount of xylanase 20U / g, xylose / arabinosidase 20U / g and α-glucuronidase 15U / g, the ratio of xylan to multi-enzyme solution is 1:4 (w / v).

[0054] (3) While st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com