Preparation method of spinelle lithium titanate for lithium secondary battery negative electrode material

A lithium secondary battery and lithium halite titanate technology, which is applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of short reaction time, low heat treatment temperature, and low bulk density, and achieve the expansion of production scale and preparation Simple process and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] TiO 2 , LiOH·H 2 O and LiCl were mixed evenly at a molar ratio of 1.25:1:1.25, then transferred to a crucible, placed in a muffle furnace, and calcined at 1200 °C for 16 hours in an air atmosphere, and then naturally cooled to room temperature with the furnace, and the sample was taken out. Repeated washing with distilled water to remove excess Cl - and Li + , until the AgNO 3 The solution does not precipitate out. The washed samples were baked in a vacuum oven at 100° C. for 24 hours to obtain lithium titanate powder. The morphology of the product is octahedral structure observed by field emission scanning electron microscope (SEM), the particle size is 90-100 μm, and it is detected as pure phase spinel Li by X-ray powder diffraction (XRD). 4 Ti 5 o 12 .

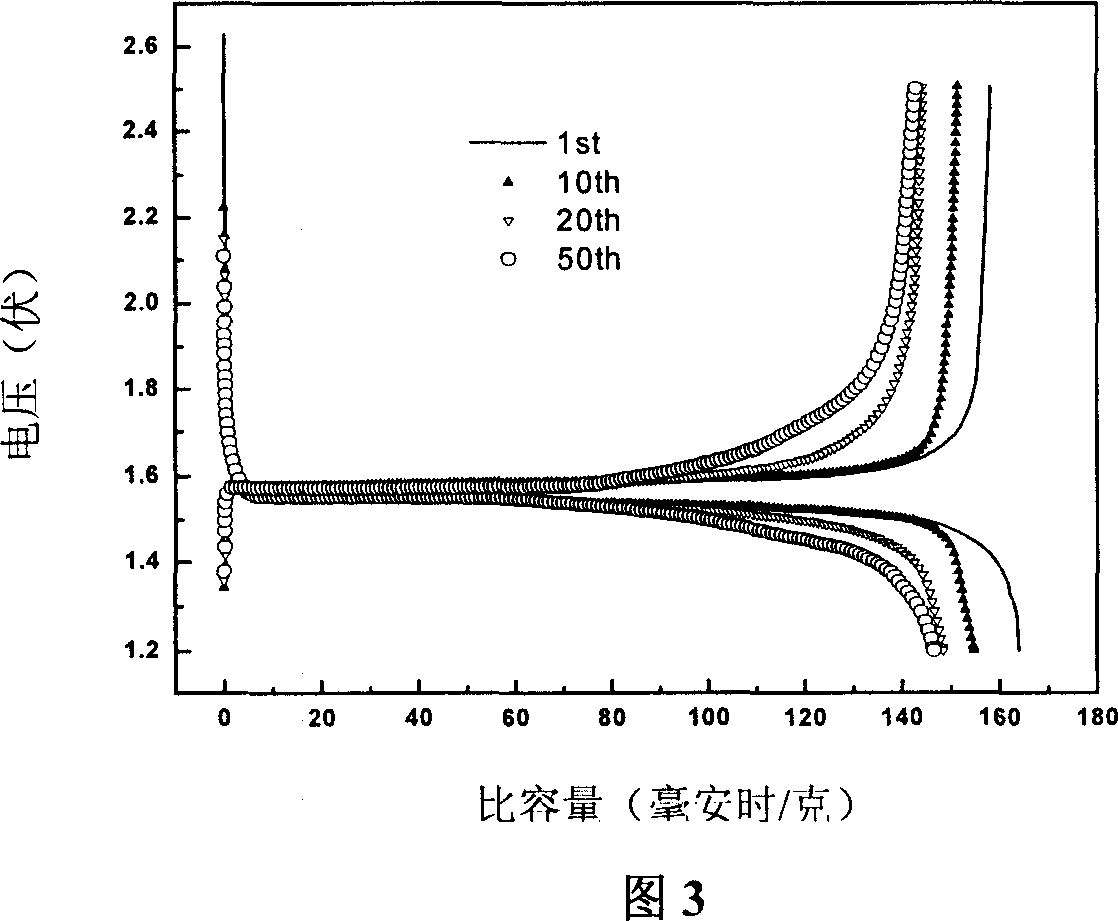

[0020] The synthesized Li 4 Ti 5 o 12 , acetylene black and binder are mixed evenly in a mass ratio of 8:1:1, and coated on aluminum foil. After drying in a vacuum oven at 55°C for 24 hours, the pressed s...

Embodiment 2

[0022] TiO 2 , LiOH·H 2 O and LiCl were mixed uniformly at a molar ratio of 1.25:1:25, then transferred to a crucible, placed in a muffle furnace, and calcined at 500 °C for 6 hours in an air atmosphere, then cooled naturally to room temperature with the furnace, and the sample was taken out. Repeated washing with distilled water to remove excess Cl - and Li + , until the AgNO 3 The solution does not precipitate out. The washed sample was baked in a vacuum oven at 80° C. for 24 hours to obtain lithium titanate powder. The morphology of the product is octahedral structure observed by field emission scanning electron microscope, the particle size is 50-60nm, and it is detected as pure phase spinel Li by X-ray powder diffraction. 4 Ti 5 o 12 .

[0023] The preparation of the pole piece, the assembly of the experimental battery and the electrochemical performance test are the same as in Example 1. The current density is 0.07mA / cm 2 , the first charge-discharge efficiency...

Embodiment 3

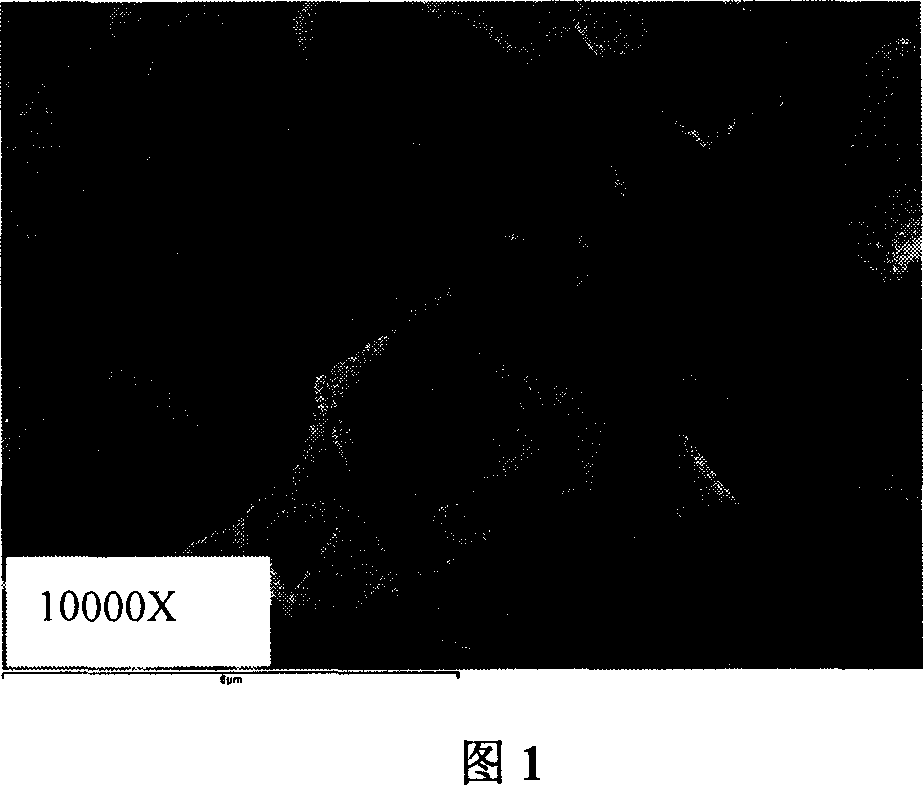

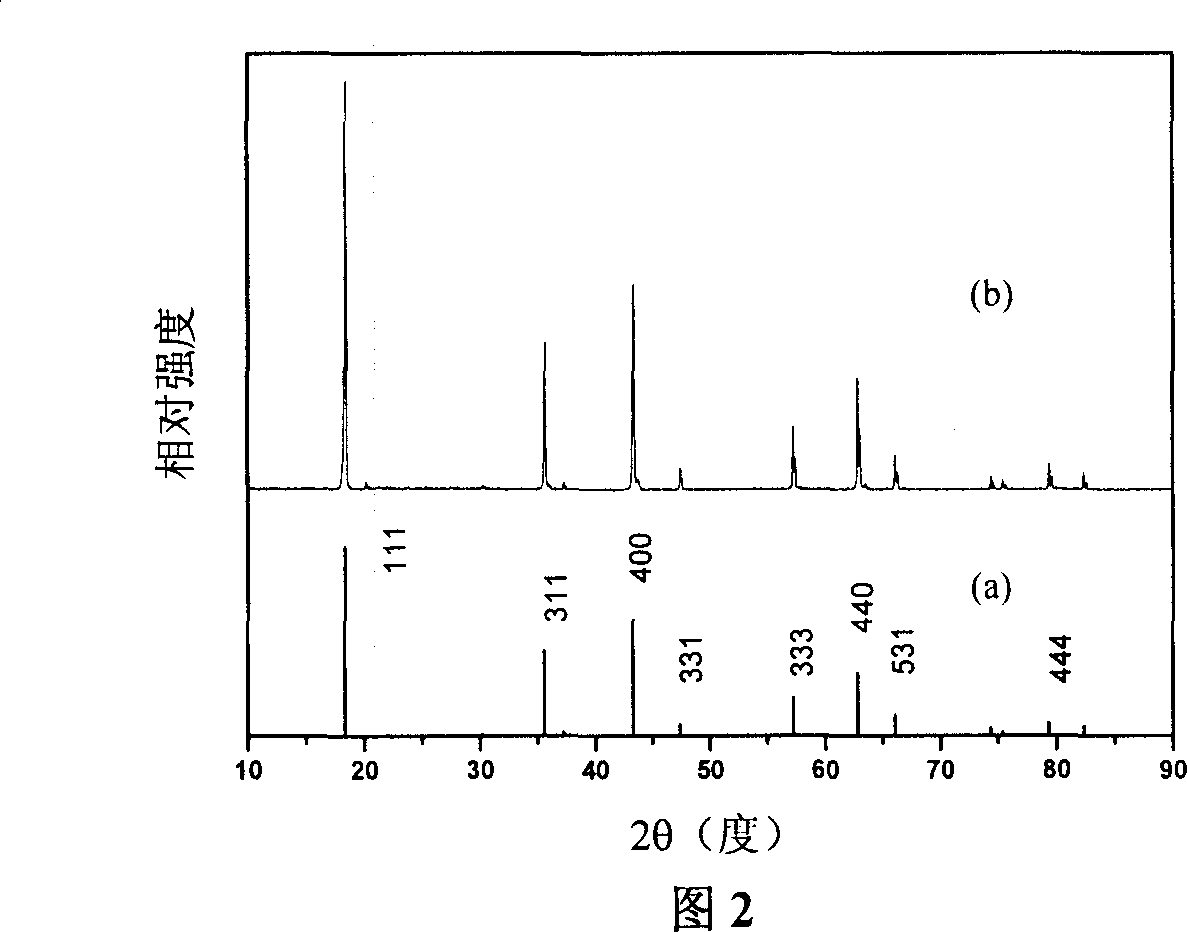

[0025] TiO 2 , LiOH·H 2 O and binary low-temperature molten salt 0.59LiCl-0.41KCl were mixed evenly in a molar ratio of 1.25:1:10, then transferred to a crucible, placed in a muffle furnace, and calcined at 800°C for 8 hours in an air atmosphere, and then The furnace was naturally cooled to room temperature, and the samples were taken out. Repeated washing with distilled water to remove excess Cl - and Li + , until the AgNO 3 The solution does not precipitate out. The washed samples were baked in a vacuum oven at 100° C. for 24 hours to obtain lithium titanate powder. The morphology of the product was observed by a field emission scanning electron microscope as an octahedral structure with a particle size of 1-3 μm, as shown in Figure 1 . Detected as pure phase spinel Li by X-ray powder diffraction 4 Ti 5 o 12 , see Figure 2.

[0026] The preparation of the pole piece, the assembly of the experimental battery and the electrochemical performance test are the same as i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com