Immobilized Metallic Nanoparticles as Unique Materials for Therapeutic and Biosensor Applications

a technology of metallic nanoparticles and unique materials, applied in the direction of animal cells, powder delivery, packaged goods, etc., can solve the problems of lack of flexibility and controllability of the process, the fabrication process is not highly suitable for practical biomedical applications, and the manufacturing process has several limitations to be used for practical applications. , to achieve the effect of cost-effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

[0157]The present disclosure demonstrates the development of mild and cost effective methods to immobilize metallic nanoparticles on polymeric or metallic substrates.

[0158]Metal Substrates

[0159]A metal substrate may be a metal or a metal film. In one aspect, the metal or metal film is titanium. In another aspect, the metal is one described below.

[0160]Metallic Nanoparticles

[0161]The present invention includes nanoparticles comprising metals and composites including, but not limited to, various metals including gold (Au), silver (Ag), platinum (Pt), aluminum (Al), nickel (Ni), iron (Fe), palladium (Pd), titanium (Ti), scandium (Sc), vanadium (V), chromium (Cr), magnesium (Mg), manganese (Mn), cobalt (Co), copper (Cu), zinc (Zn), yttrium (Y), zirconium (Zr), niobium (Nb), molybdenum (Mo), technetium (Tc), ruthenium (Ru), cadmium (Cd), lutetium (Lu), hafnium (Hf), tungsten (W), rhenium (Re), osmium (Os), iridium (Ir), tantalum (Ta), rhodium (Rh), rare-earth metals ytterbium (Yb), lanth...

example 1

A. Development of Nanostructured Metal Surfaces Containing Silver Nanoparticles

[0367]Surface Modification of Titanium Metal by Surface Etching Followed by Silver Nanoparticle Formation

[0368]Titanium thin films were procured from Good Fellow Inc. The metal film was cut into 1×1 cm. square samples for surface modification. The samples were washed with acetone, 1% triton followed by mild sonication in distilled water.

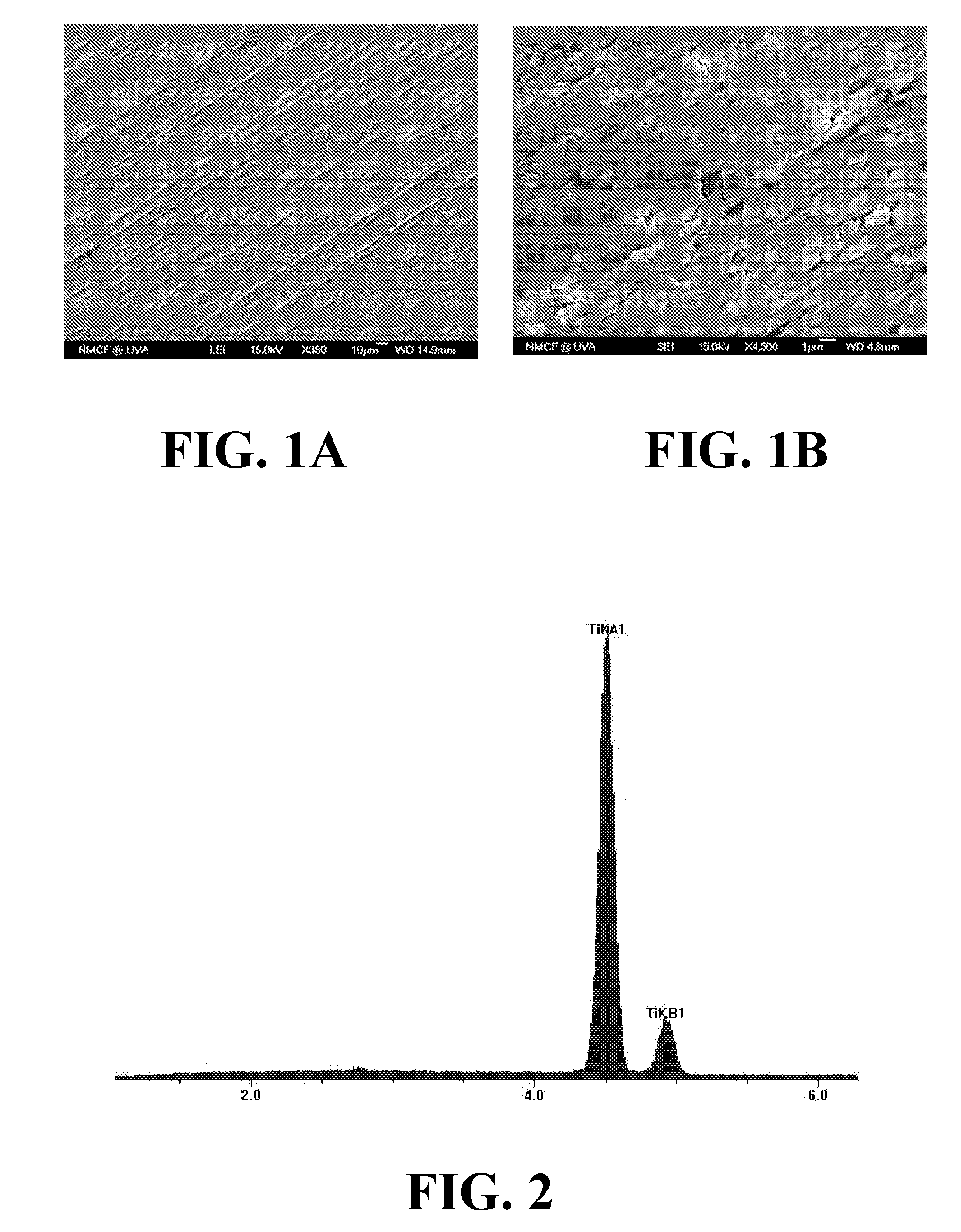

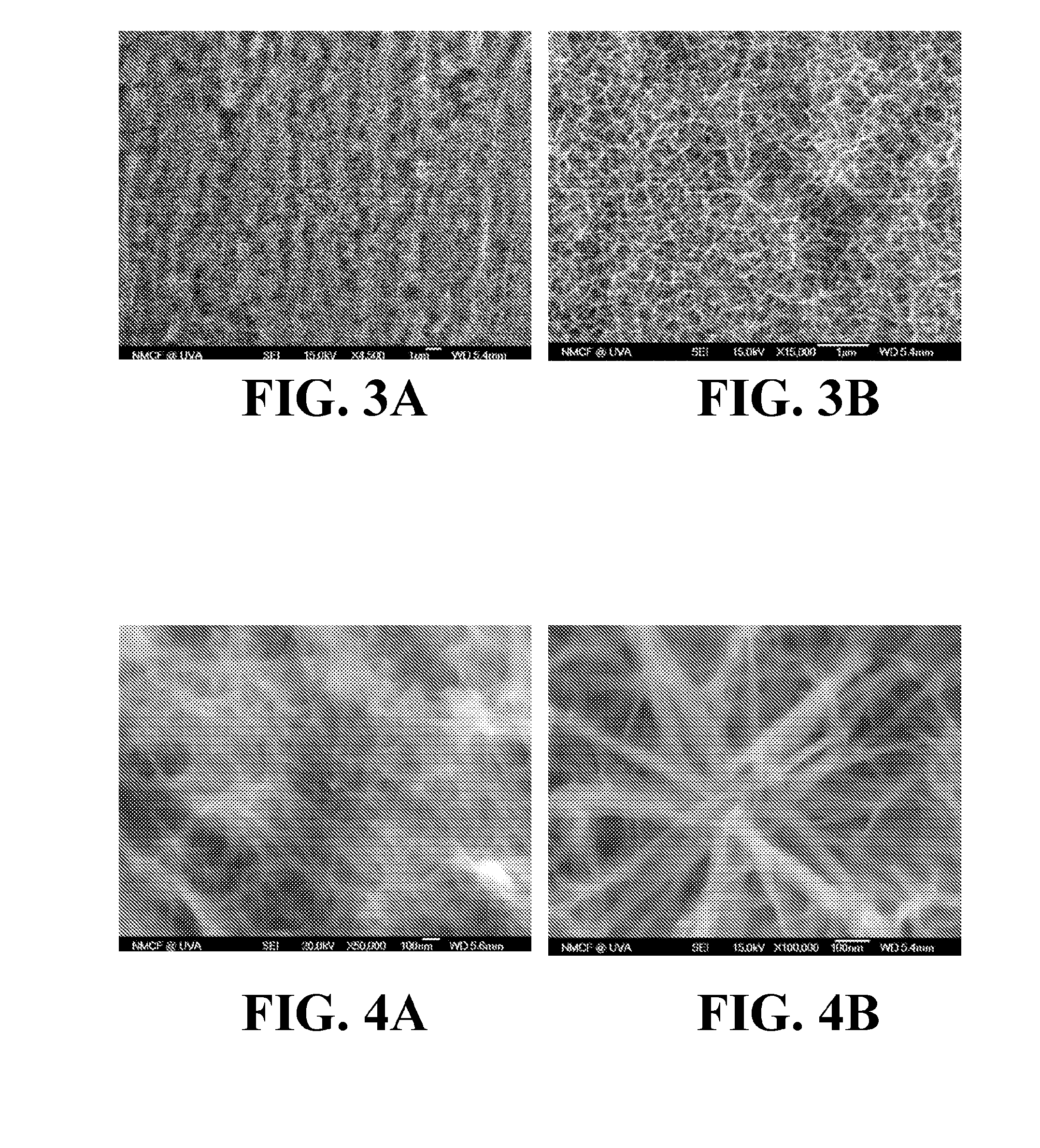

[0369]The morphology of the metal surfaces, both before and after surface modifications, was evaluated using secondary electron imaging (SEI) in a JEOL 6700F scanning electron microscope (SEM). The elemental composition of the modified surface was evaluated using energy dispersive spectroscopy (PGT Light Element Detector running Spirit software).

[0370]FIG. 1 shows images of scanning electron micrographs of unmodified titanium sample indicating the morphology. FIG. 2 shows the elemental composition of the unmodified metal film indicating that the surface is composed solely ...

example 2

Preparation of PluroGel-Silver Particle Composites

[0388]Procedure 1: 30 mg of Silver in 9.5 mL of Neat PluroGel.

[0389]2 mL of PluroGel was aliquoted and stirred using a magnetic stirrer at 4° C. in an icebath. 0.01 gm of silver nitrate powder was then added to PluroGel. The color of the solution instantly turned to yellow. The solution was stirred for another 2-5 minutes to form the silver nanoparticle-PluroGel composite mixture. The solution showed phase transition (liquid to solid) when heated to 37° C. in a water bath.

[0390]Procedure 2: 30 mg of Silver Solution in 9.5 mL of Neat PluroGel

[0391]2 mL of PluroGel was aliquoted and stirred using a magnetic stirrer at 4° C. in an icebath. 10 μL of 10% solution of silver nitrate in water was then added to PluroGel. The color of the solution instantly turned to yellow. The solution was stirred for another 2-5 minutes to form the silver particle-PluroGel composite mixture. The solution showed phase transition (liquid to solid) when heated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com