Imprint product and method for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of poly(1,1,2-trifluoro-2-trifluoromethyl-3,5-cyclopentylene ethylene)

[0167]A tetrahydrofuran solution of 5,5,6-trifluoro-6-(trifluoromethyl)bicyclo[2.2.1]hept-2-ene (100 g) and 1-hexene (268 mg) was mixed with a tetrahydrofuran solution of Mo (N-2,6-Pri2C6H3) (CHCMe2Ph) (OCMe(CFA2)2 (70 mg), and ring-opening metathesis polymerization was carried out at 70° C. The olefin moiety of the polymer thus obtained was subjected to a hydrogenation reaction using palladium alumina (5 g) at 160° C., and thus a tetrahydrofuran solution of poly(1,1,2-trifluoro-2-trifluoromethyl-3,5-cyclopentylene ethylene) was obtained.

[0168]The solution was added to methanol, and a white polymer was separated by filtration and was dried. Thus, 99 g of a polymer was obtained. The hydrogenation rate was 100%, the weight average molecular weight (Mw) was 127,000, the molecular weight distribution (Mw / Mn) was 1.70, and the glass transition temperature was 109° C. The fluorine atom content rate was 52.3% b...

example 2

Synthesis of poly(1,1,2-trifluoro-2-trifluoromethyl-3,5-cyclopentylene ethylene)

[0170]The synthesis was carried out in the same manner as in Example 1, except that the catalyst was changed to Mo(N-2,6-Pri2C6H3)(CHCMe2Ph)(OBut)2 (50 mg), and thus poly(1,1,2-trifluoro-2-trifluoromethyl-3,5-cyclopentylene ethylene) was obtained (98 g). The hydrogenation rate was 100%, the weight average molecular weight (Mw) was 83,000, the molecular weight distribution (Mw / Mn) was 1.73, and the glass transition temperature was 108° C. The fluorine atom content rate was 52.3% by mass.

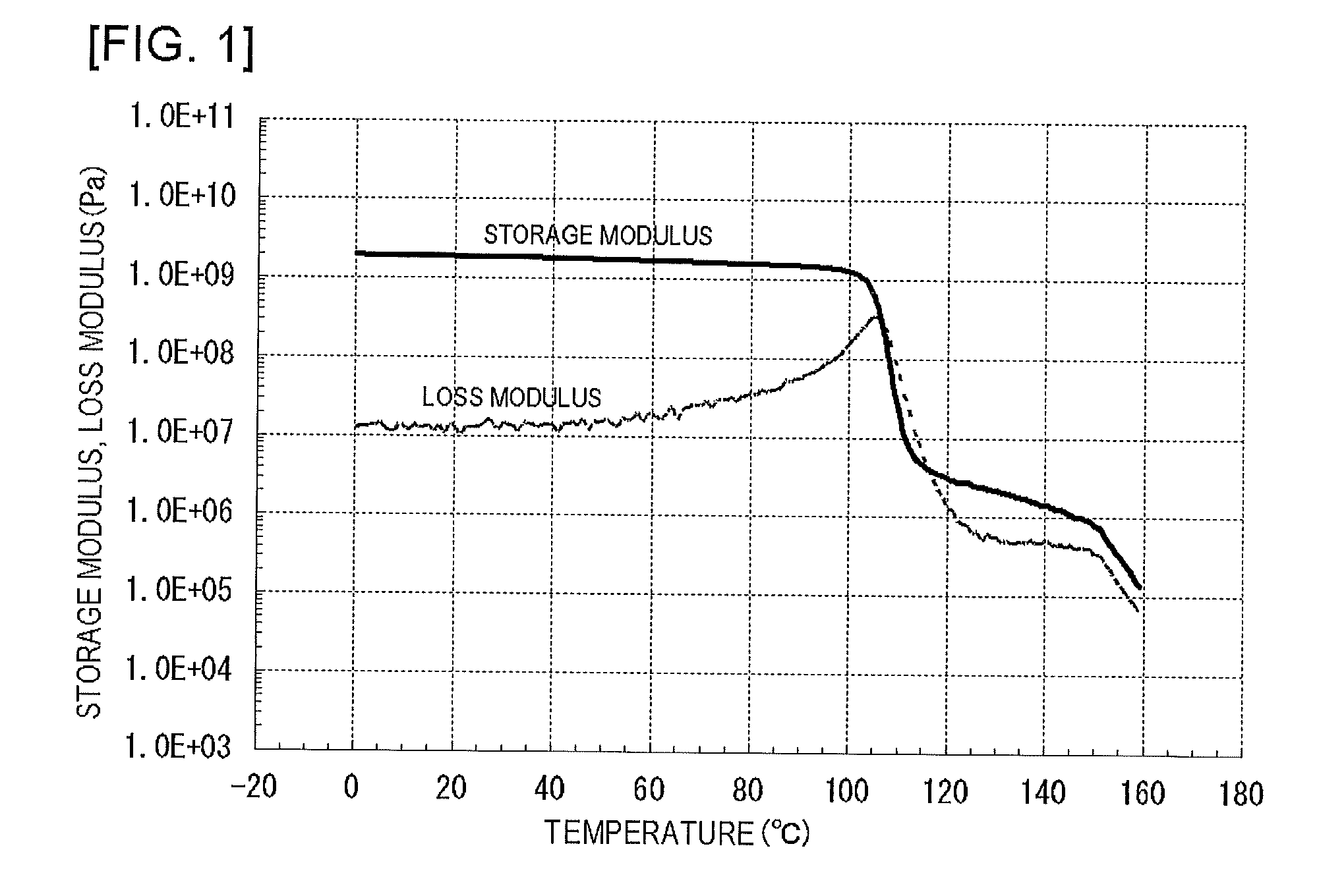

[0171]Subsequently, a powder of the hydrogenated polymer thus obtained was treated by heat pressing, and thus a heat pressed sheet having a thickness of 0.37 mm was produced. From the results of the dynamic mechanical analysis by tensile mode carried out, it was found that a flat region of variation in storage modulus or loss modulus in the range of temperature which is not less than the glass transition temperature lies i...

example 3

Synthesis of poly(1,2-difluoro-1-trifluoromethyl-2-perfluoroethyl-3,5-cyclopentylene ethylene)

[0172]The synthesis was carried out in the same manner as in Example 1, except that the monomer was changed to 5,6-difluoro-5-trifluoromethyl-6-perfluoroethylbicyclo[2.2.1]hep t-2-ene (50 g), and the catalyst was changed to Mo (N-2,6-Pri2C6H3) (CHCMe2Ph) (OBut)2 (17 mg), and thus poly(1,2-difluoro-1-trifluoromethyl-2-perfluoroethyl-3,5-cyclopentylene ethylene) was obtained (49 g). The hydrogenation rate was 100%, the weight average molecular weight (Mw) was 95,000, the molecular weight distribution (Mw / Mn) was 1.52, and the glass transition temperature was 110° C. The fluorine atom content rate was 59.7% by mass.

[0173]Subsequently, a powder of the hydrogenated polymer thus obtained was treated by heat pressing, and thus a heat pressed sheet having a thickness of 0.37 mm was produced. From the results of the dynamic mechanical analysis by tensile mode carried out, it was found that a flat re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com