Carbon nitride membrane composite material modified by black phosphorus/ metal organic framework, and preparation method thereof and application in waste gas treatment

a carbon nitride and composite material technology, applied in the field of functional materials, can solve the problems of difficult regeneration, air pollution, air pollution, etc., and achieve the effects of simple preparation method, easy availability of raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0048]The specific steps of preparing porous carbon nitride are as follows:

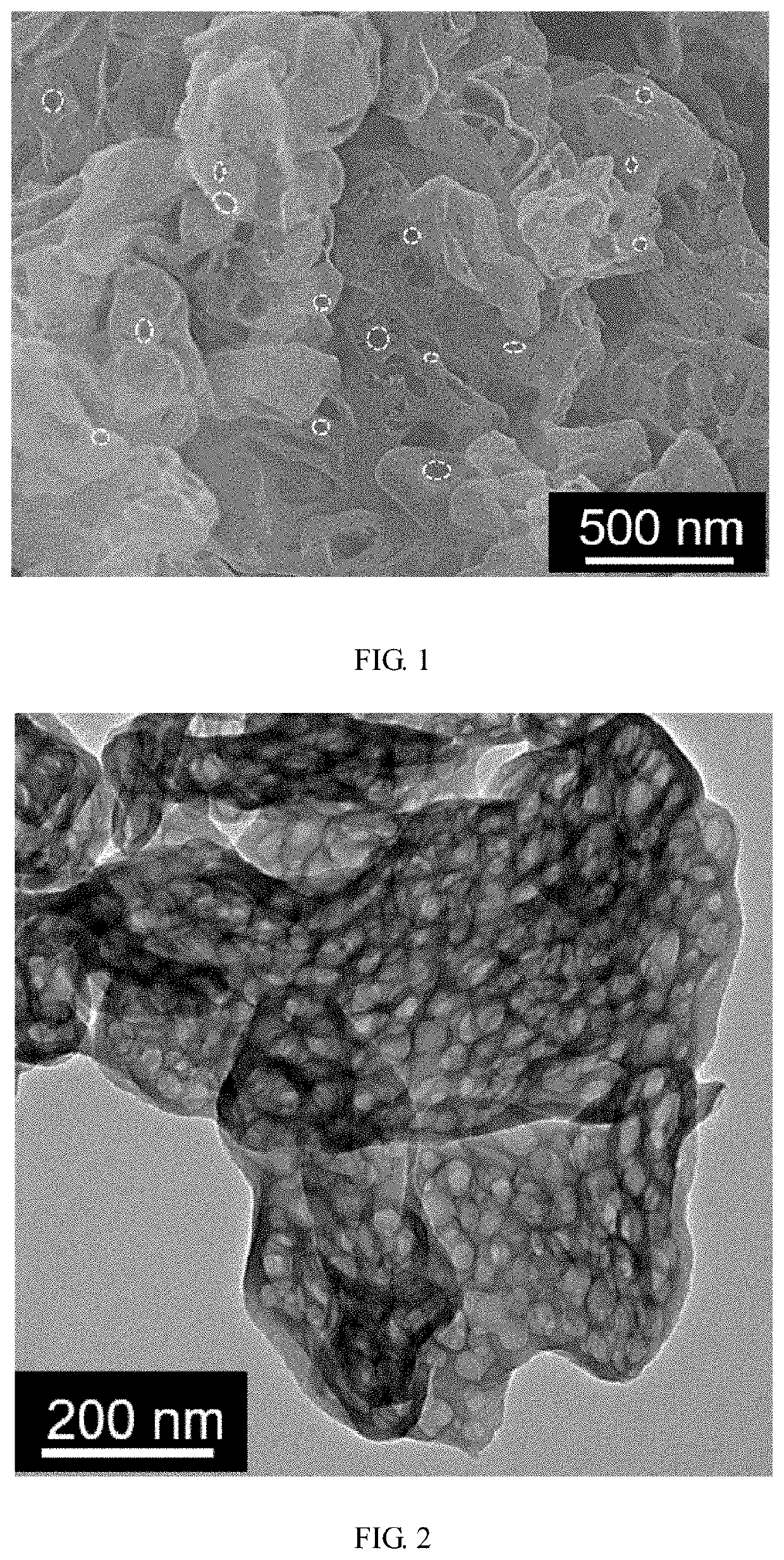

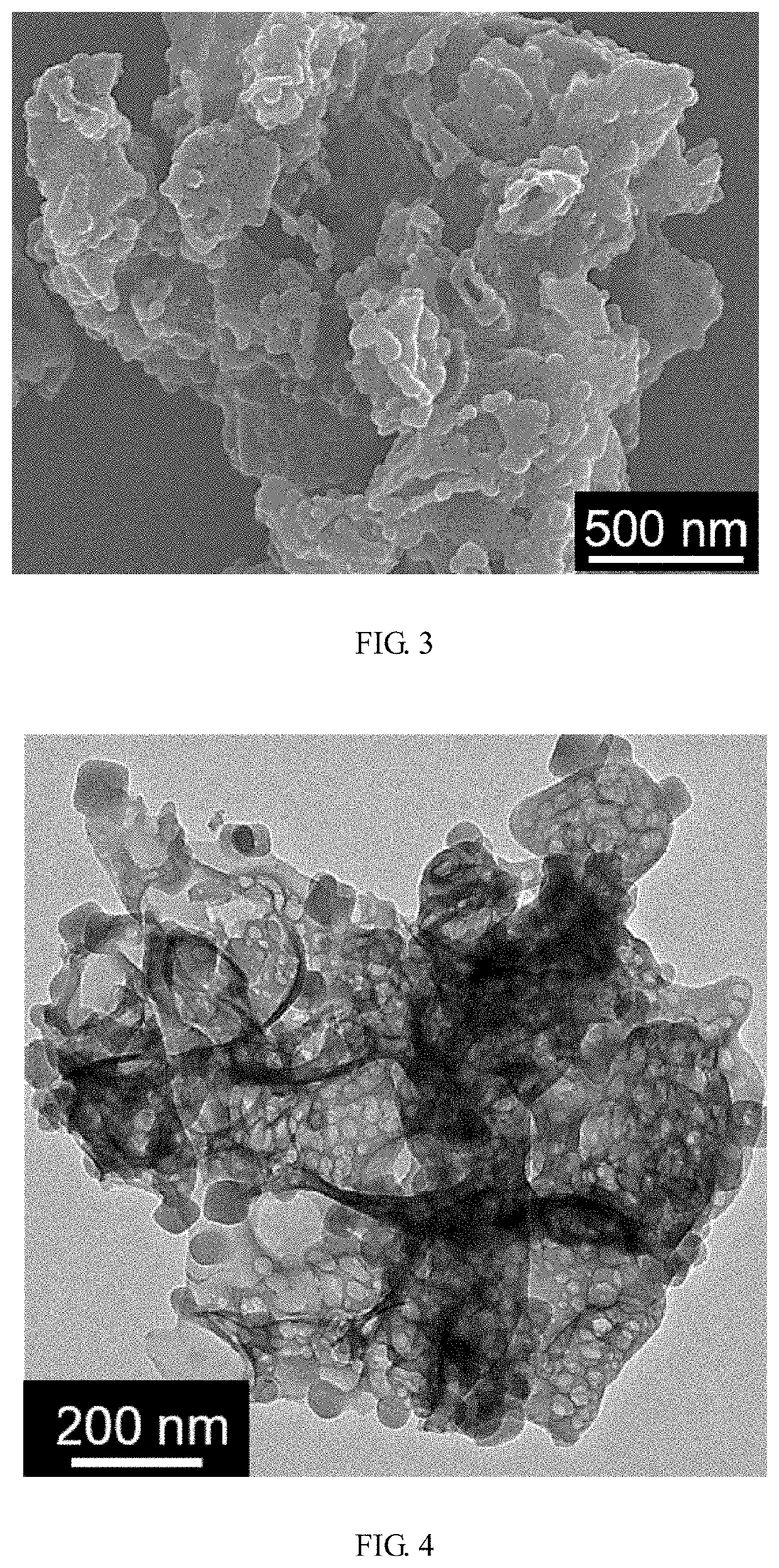

[0049]10 g of urea is placed in a porcelain crucible, and 15 mL of water is added, placed in a muffle furnace, heated to 400° C. at a heating rate of 10° C. per minute, and calcined for 1 hour. Then, the temperature is further raised to 450° C., the heating rate is 10° C. per minute, and calcination is continued for 1 hour to obtain a pale yellow porous carbon nitride nanosheet, which is ground into a powder; and FIG. 1 and FIG. 2 are the SEM and TEM images of porous carbon nitride respectively.

[0050]The preparation of porous carbon nitride modified by MOFs is as follows:

[0051]First, the porous carbon nitride nanosheet is subjected to surface carboxylation modification, and 0.05 g of porous carbon nitride and 0.6 g of succinic anhydride are dispersed to 25 mL of N, N-dimethylformamide, then stirred at room temperature for 12 hours and then washed with deionized water and ethanol for three times respectively.

[...

embodiment 2

[0057]Photocatalytic degradation of nitric oxide gas, the specific steps are as follows:

[0058]A batch reactor (2.2 liters in volume) containing one quartz glass is used for the photocatalytic degradation of nitric oxide; 50 mg of carbon nitride membrane composite material modified by black phosphorus / metal organic framework (MOF) is placed in the batch reactor, the door is closed, the reactor is evacuated, the flow rate of high purity air (1 liter) and nitric oxide (concentration of 10 ppm) is adjusted so that the flow rate of the mixed gas is 1.2 liters per minute. After the concentration of nitrogen oxide concentration stabilized at 600 ppb for fifteen minutes, a xenon light is turned on to initiate the photo degradation reaction. The carbon nitride membrane composite material modified by black phosphorus / metal organic framework (MOF) photocatalyst can be recycled many times, with good stability, after 5 times of recycling, it still have a good catalytic effect. FIG. 8 is the effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com