Patents

Literature

34results about "PIc I-O input output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

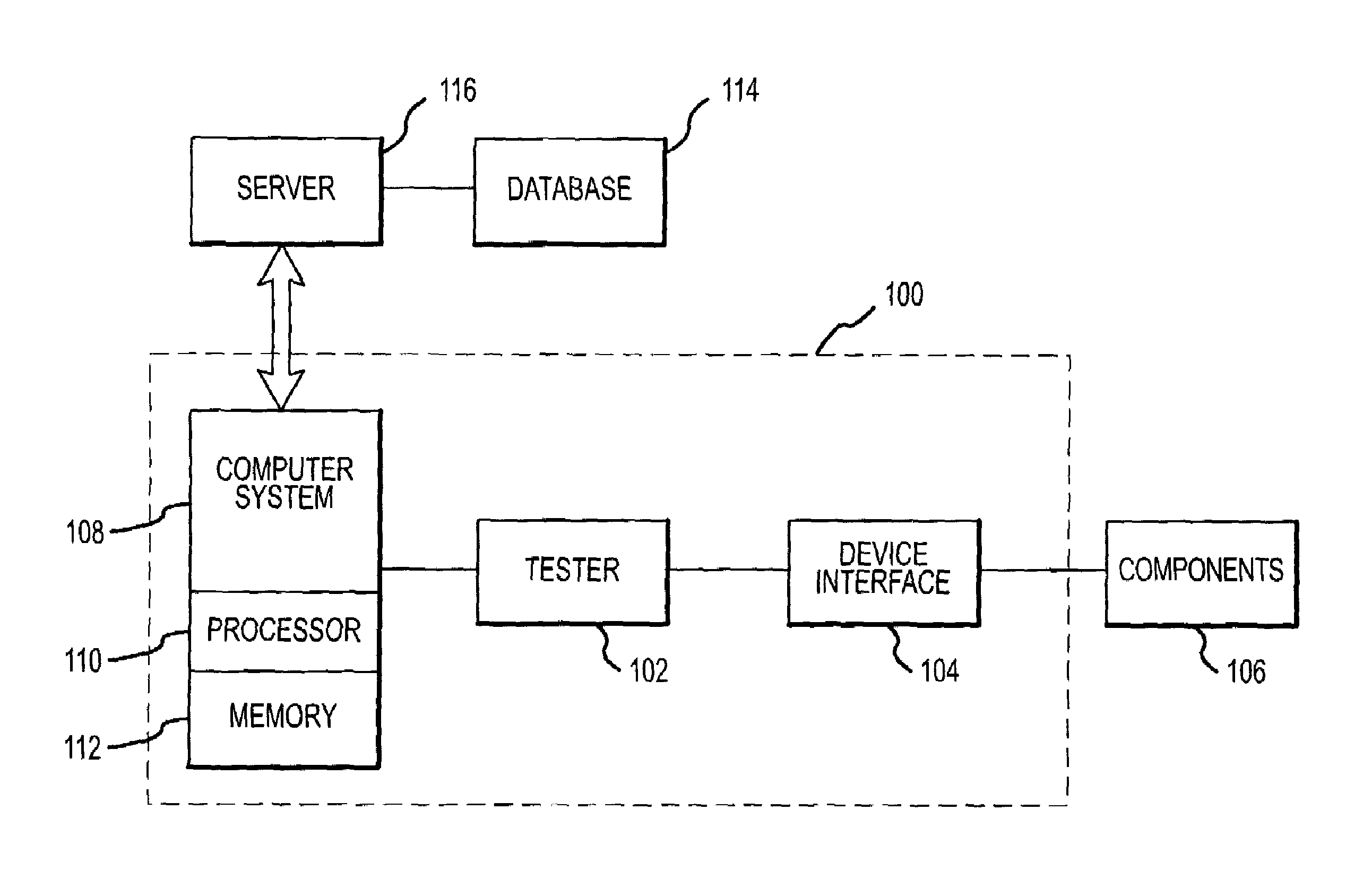

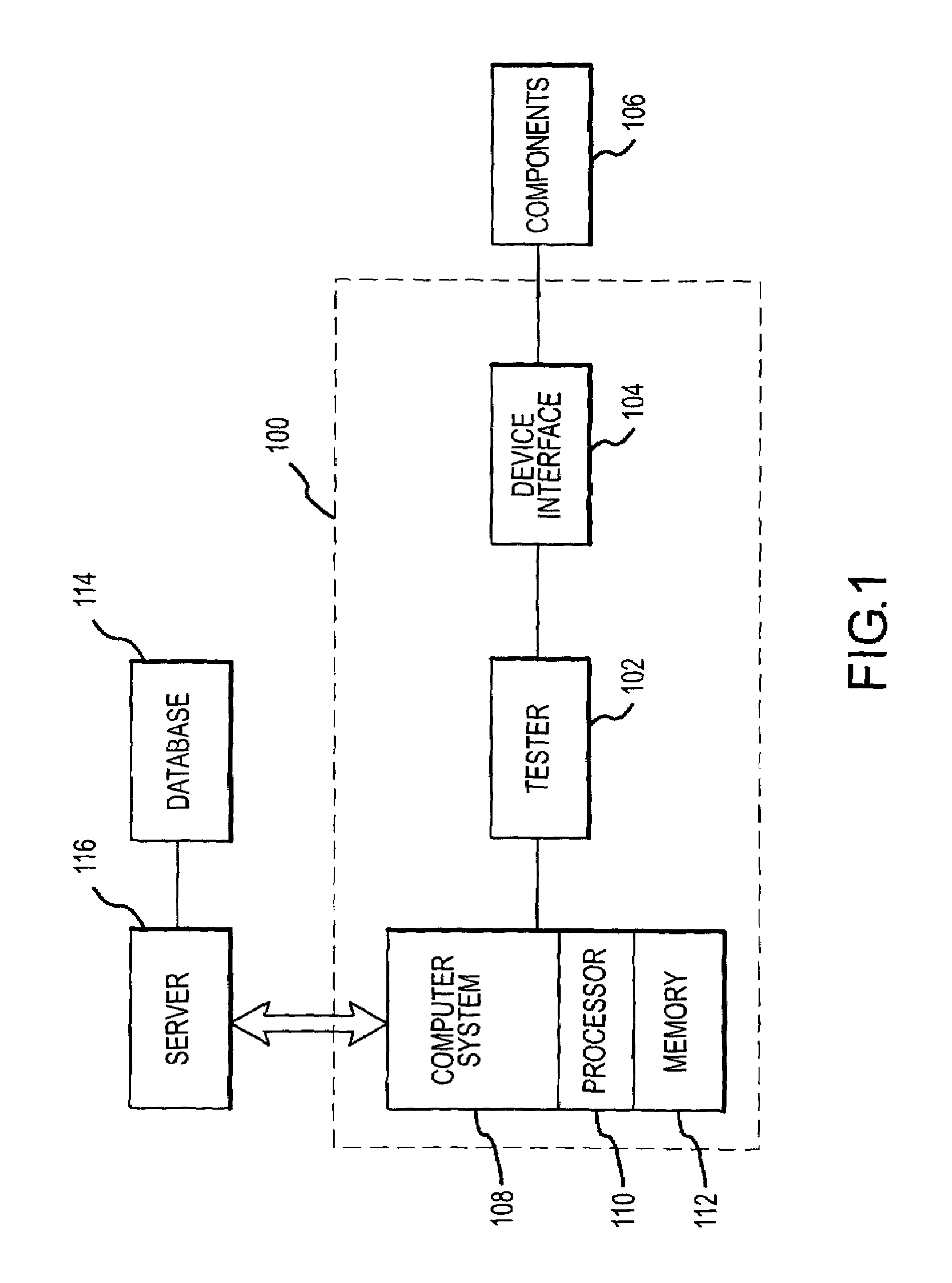

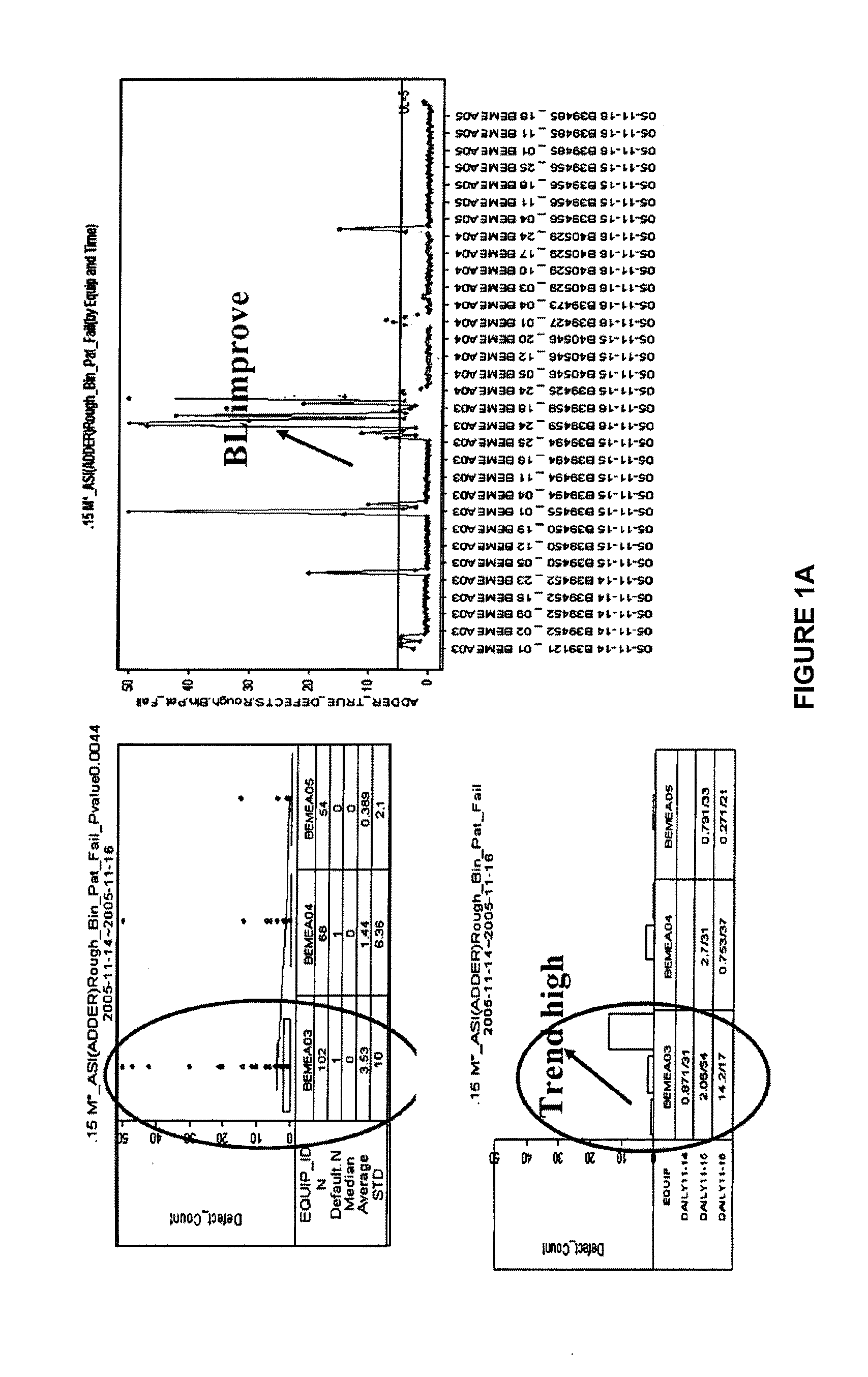

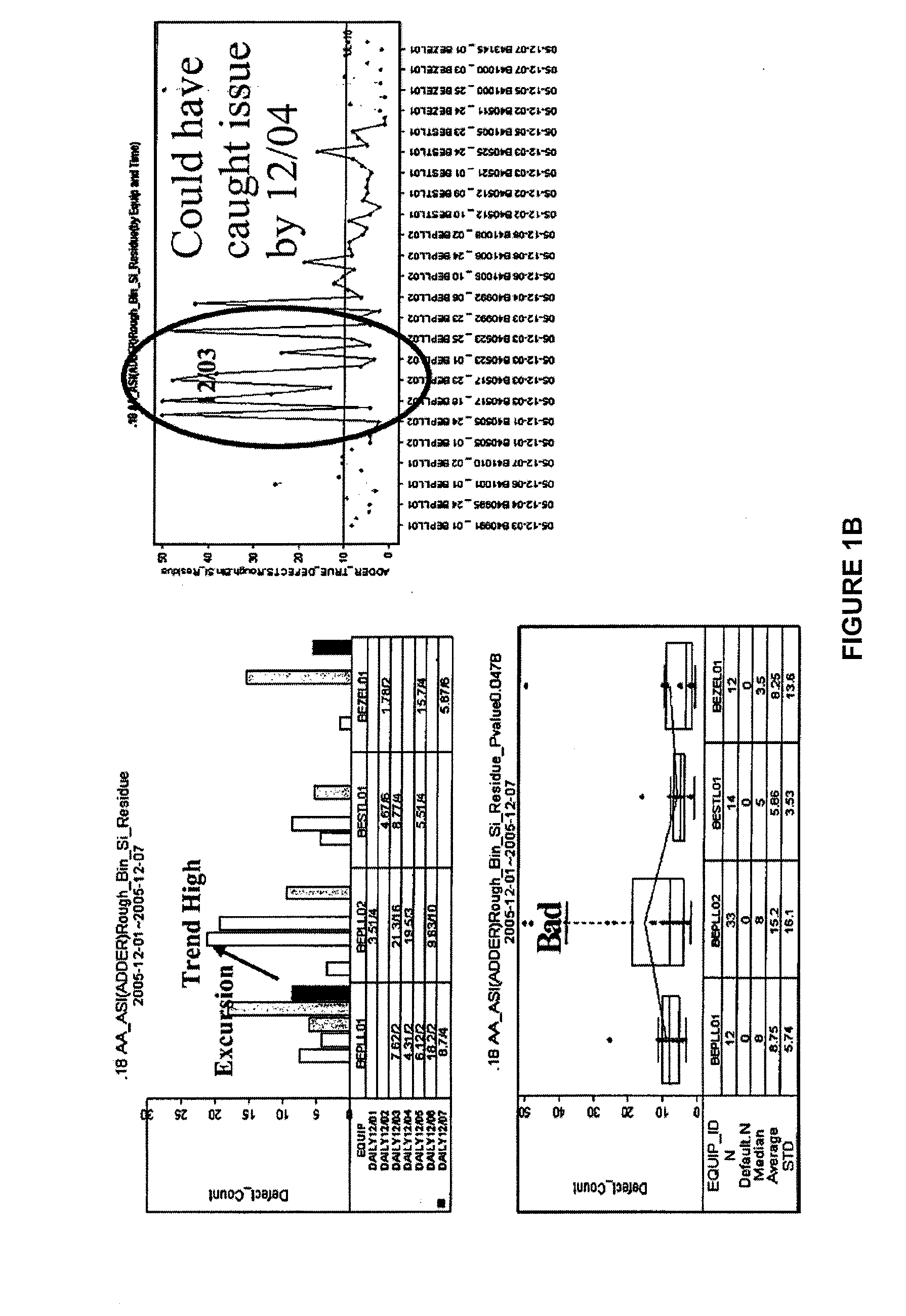

Methods and apparatus for data analysis

InactiveUS20050278597A1Semiconductor/solid-state device testing/measurementElectronic circuit testingData analysisTest data

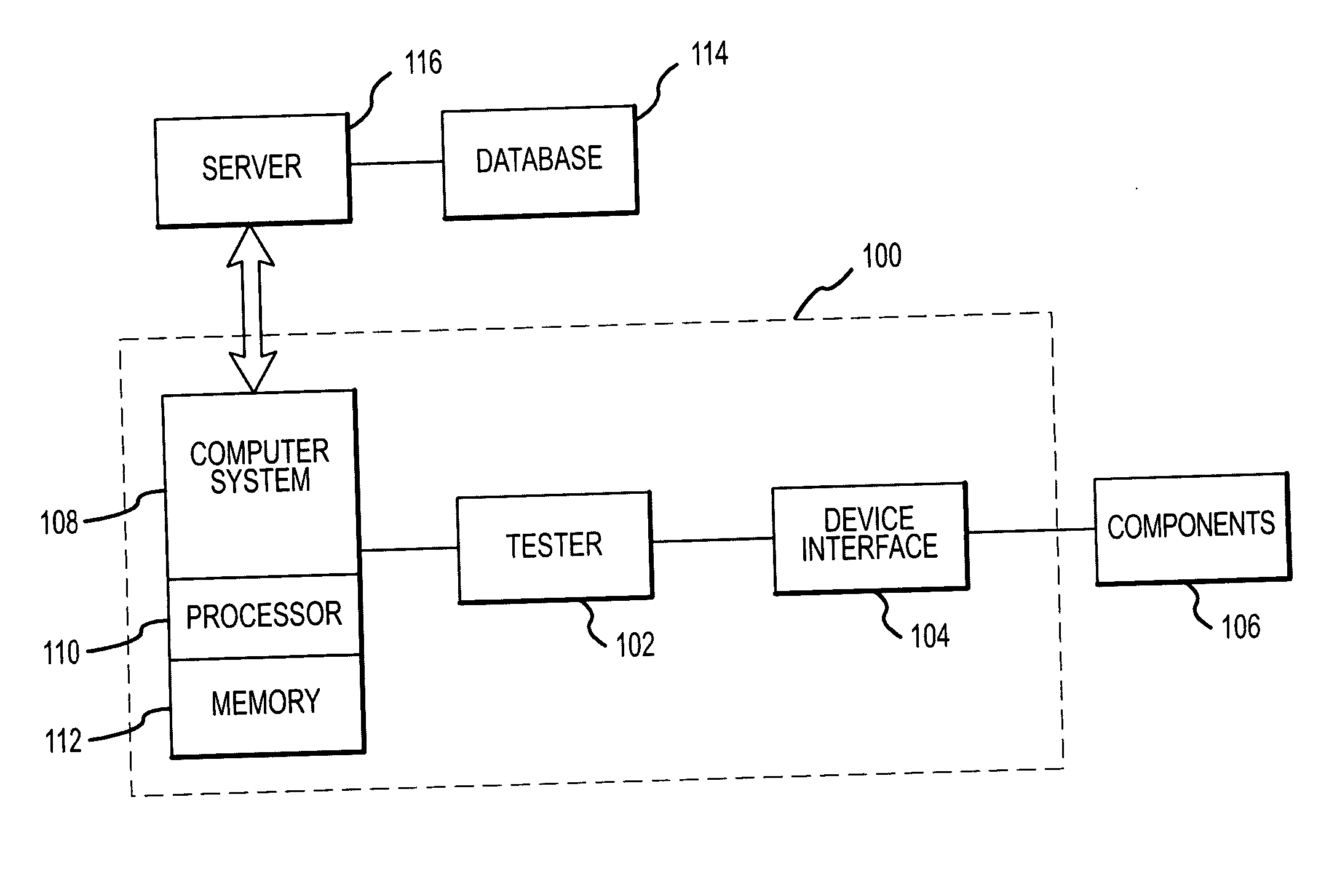

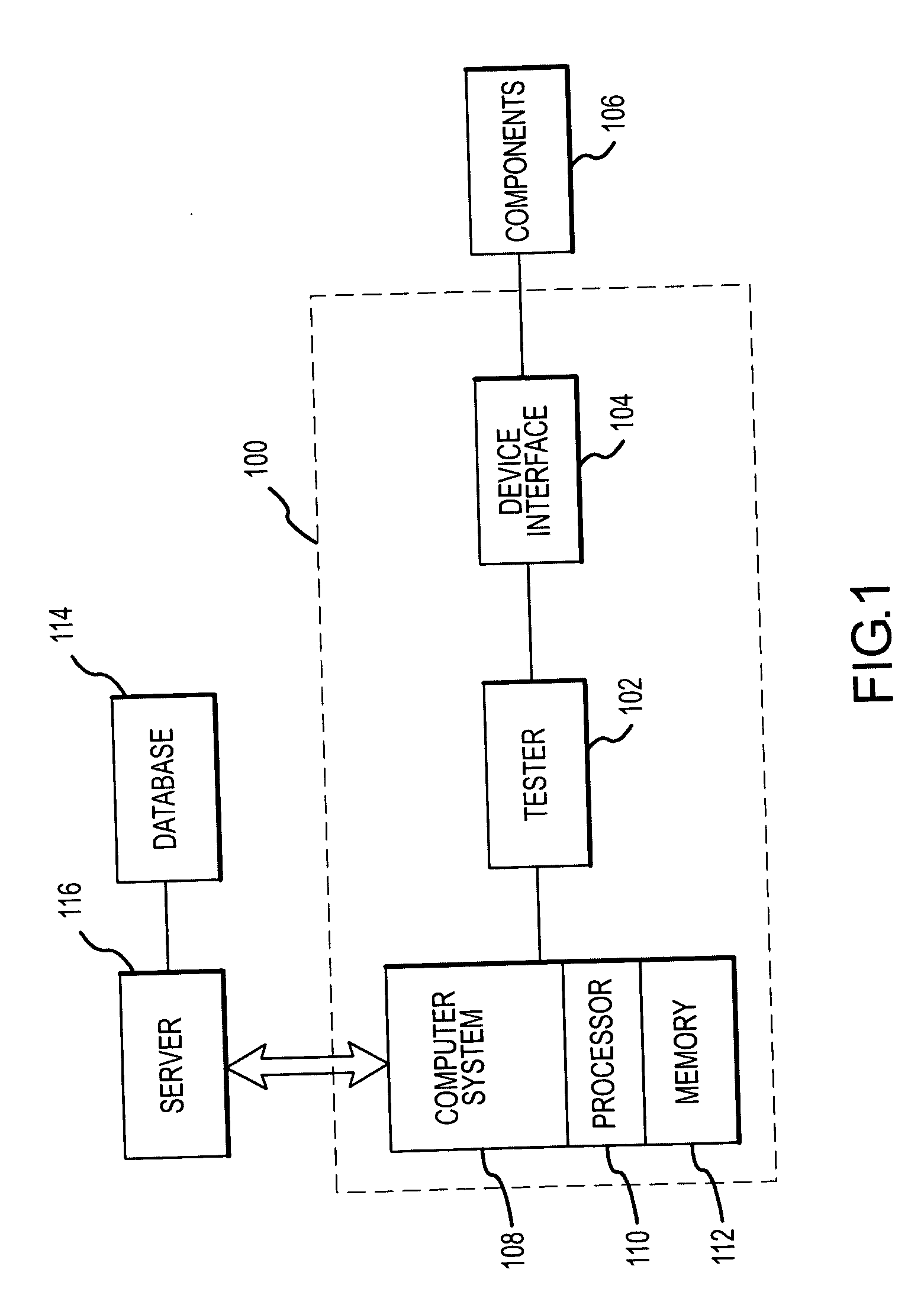

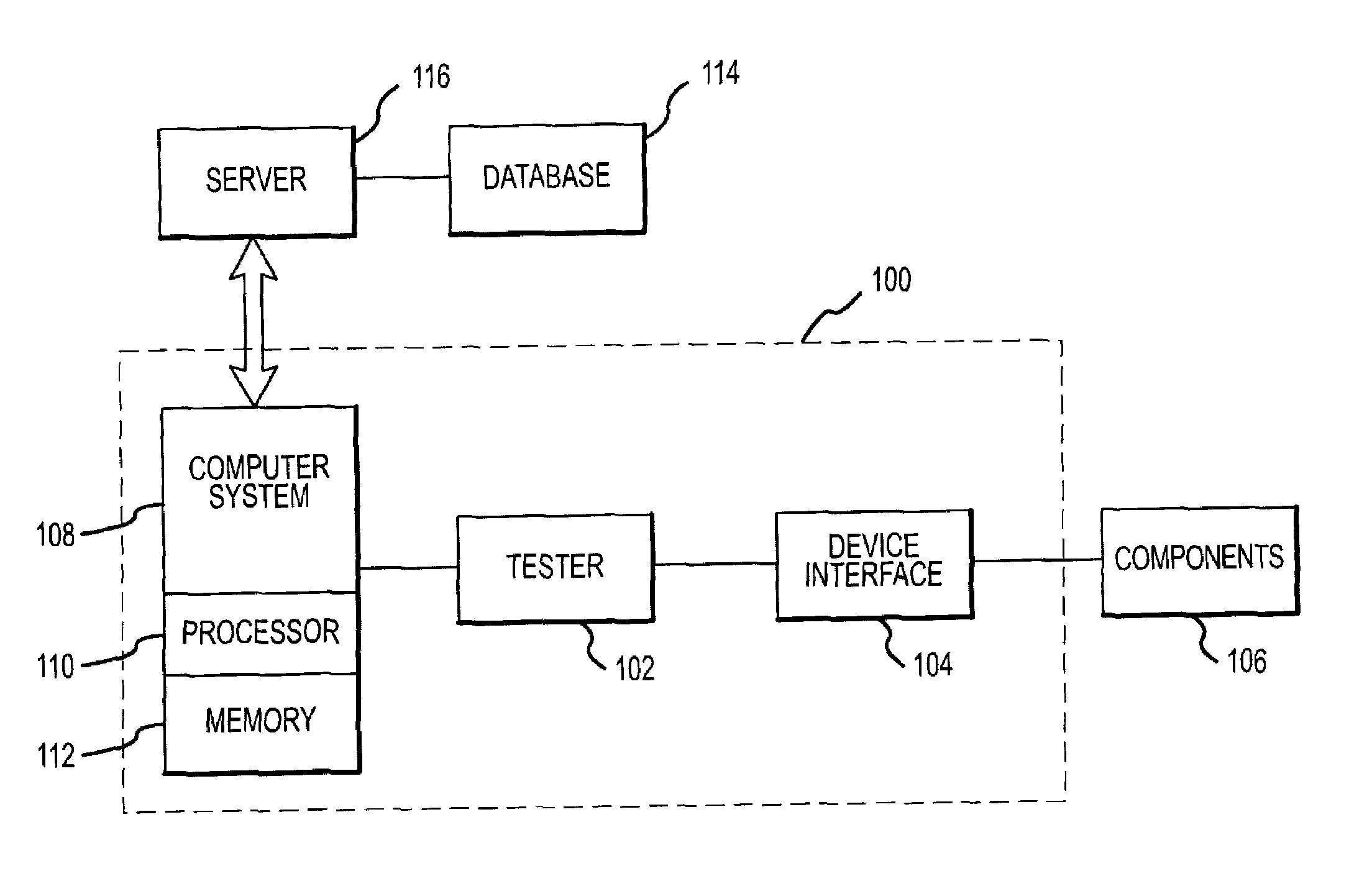

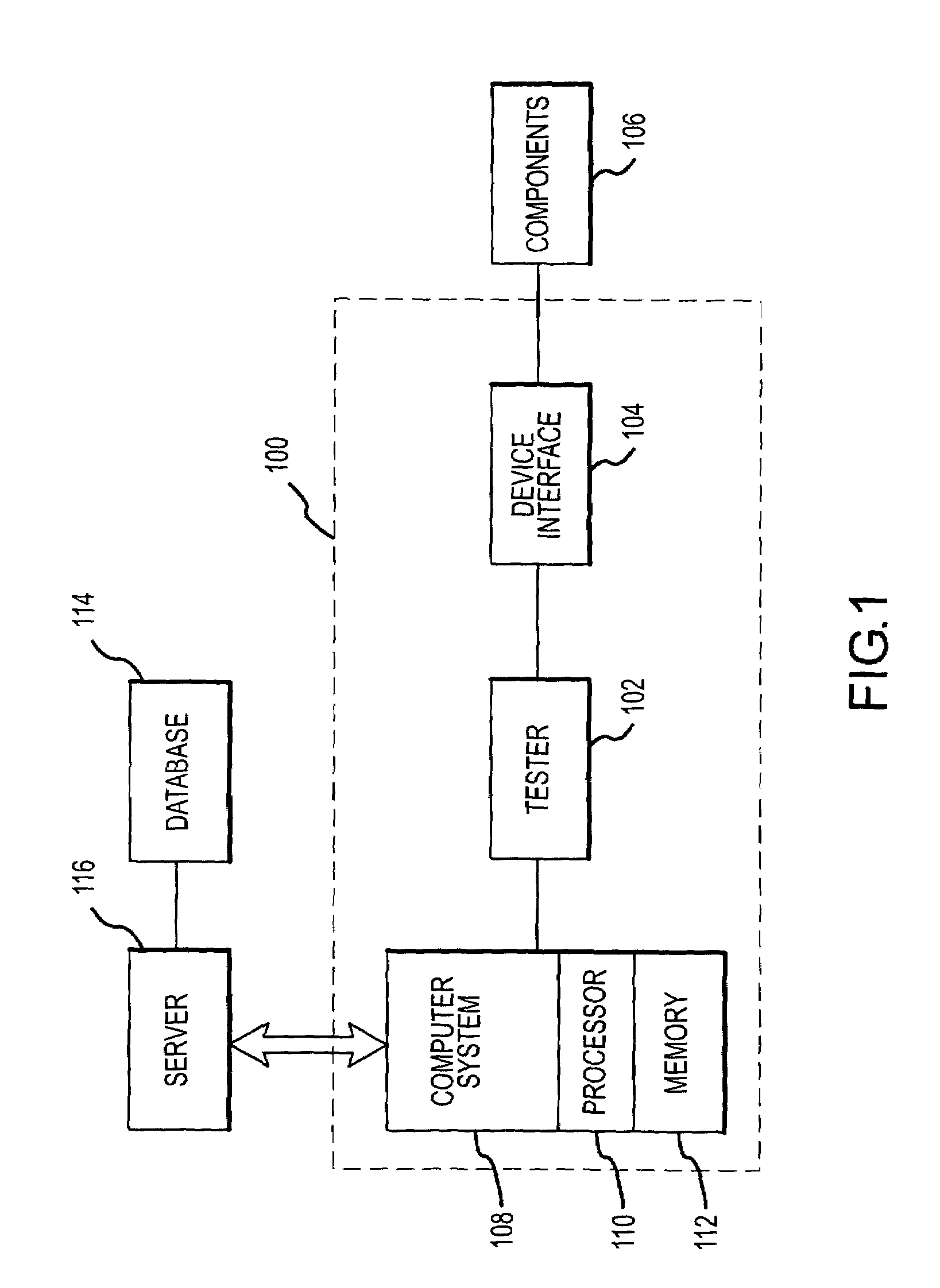

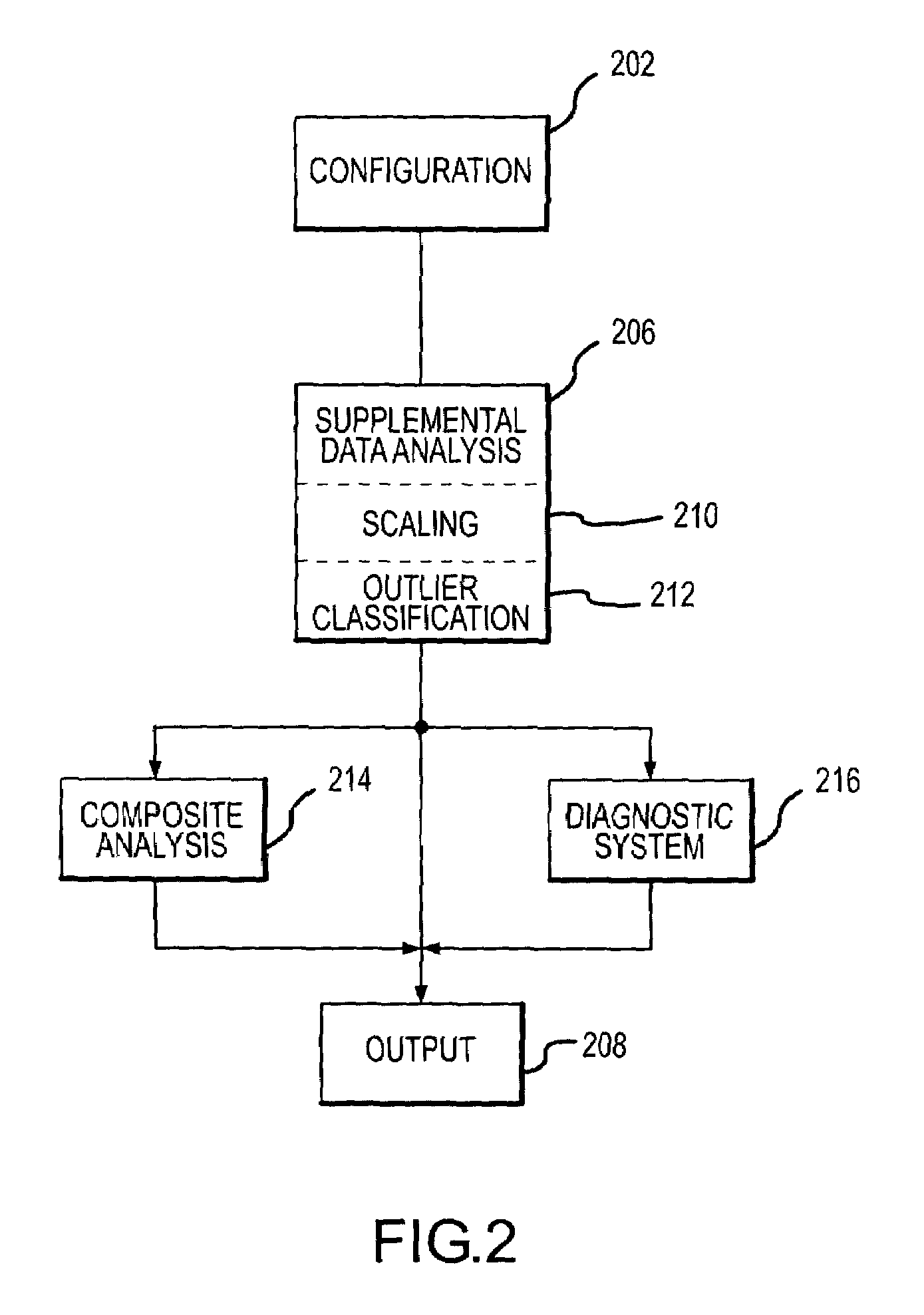

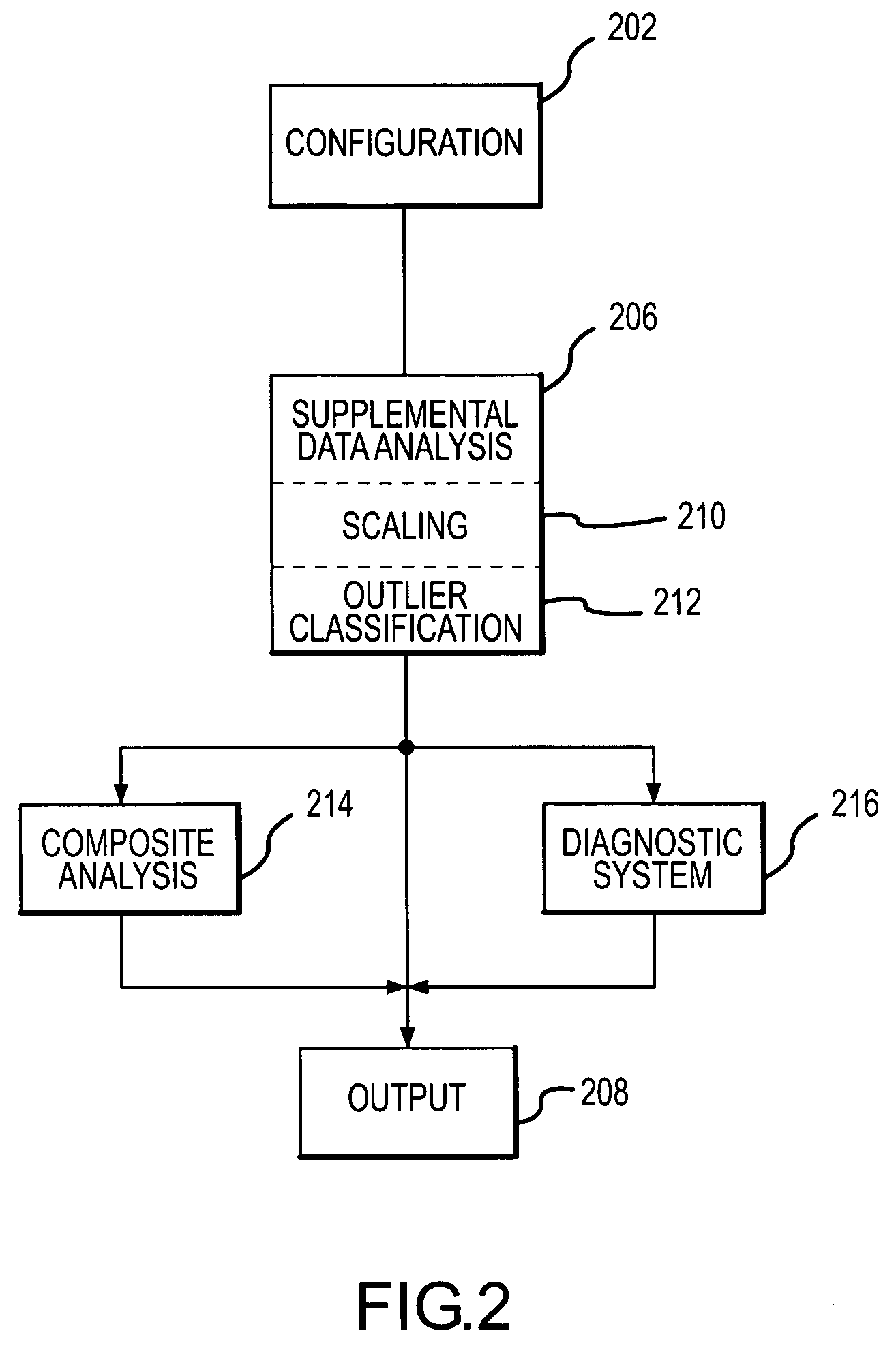

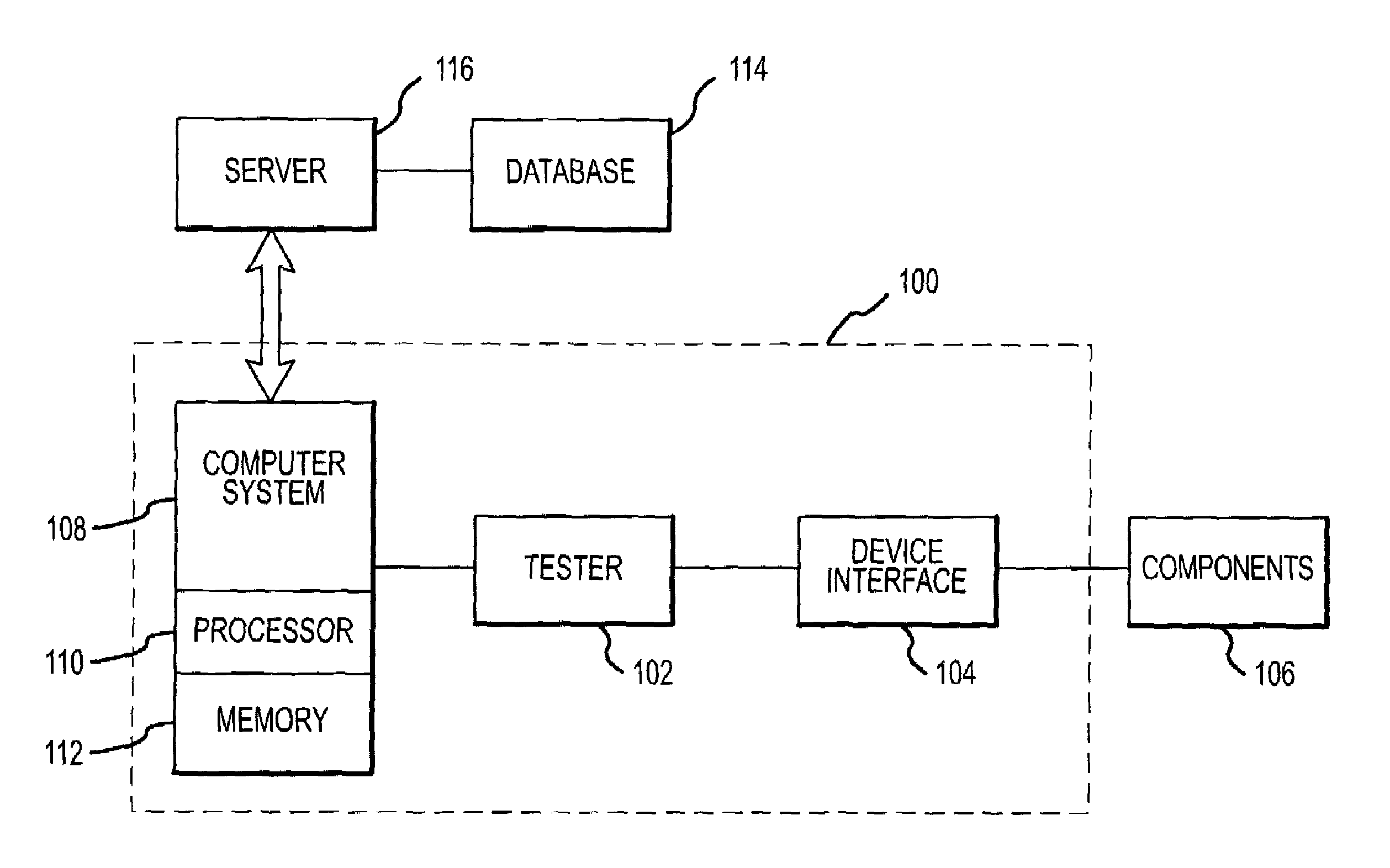

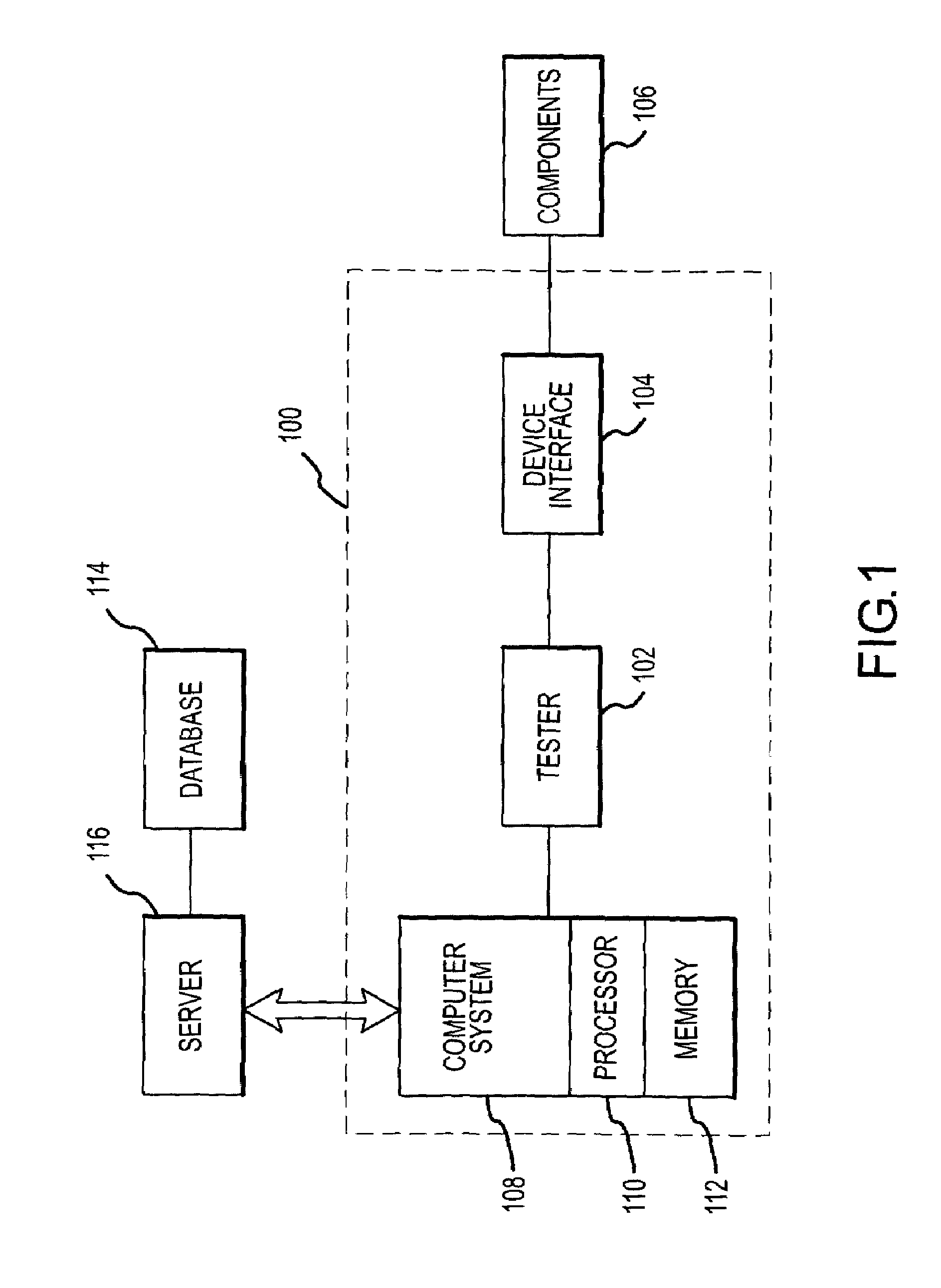

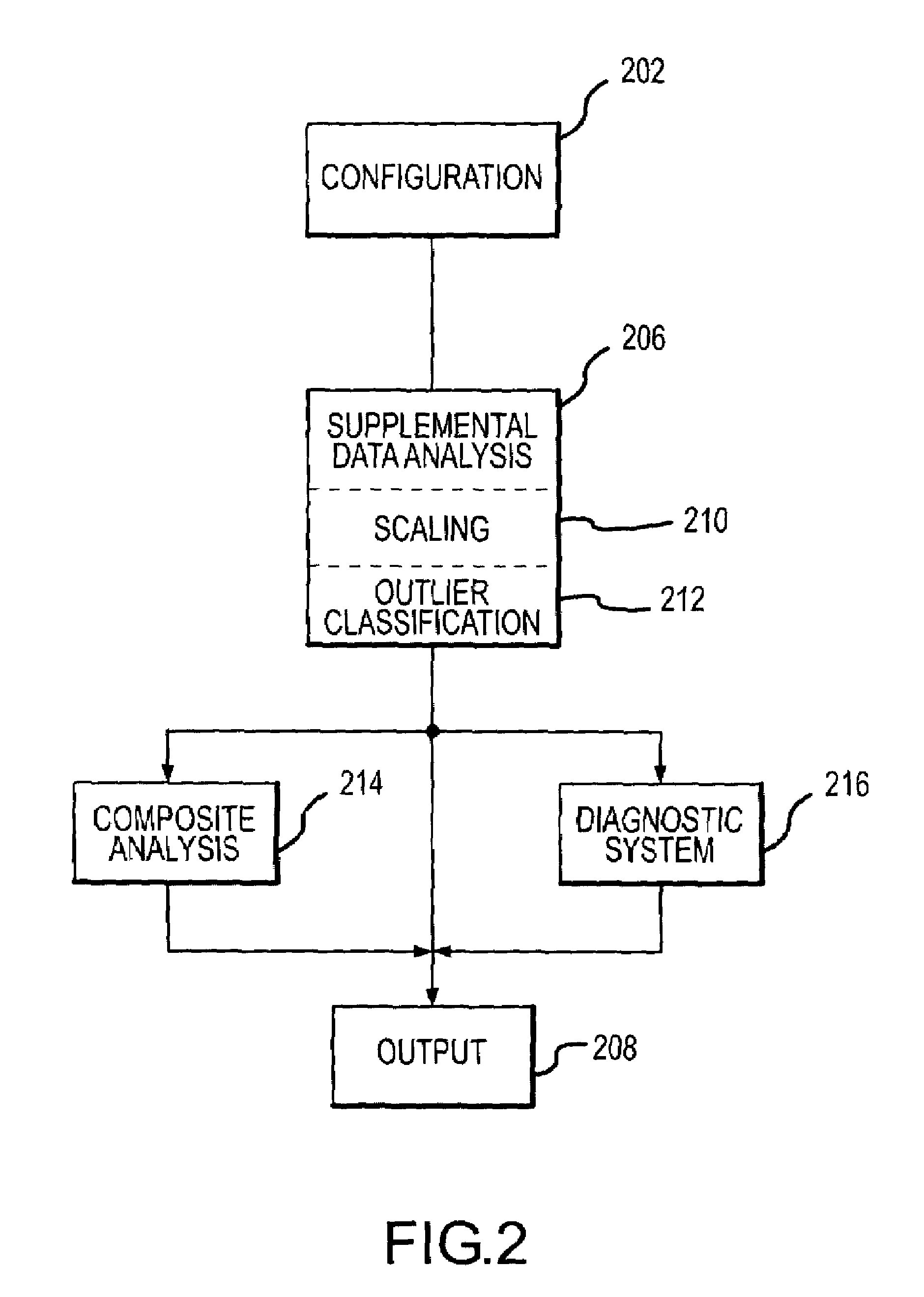

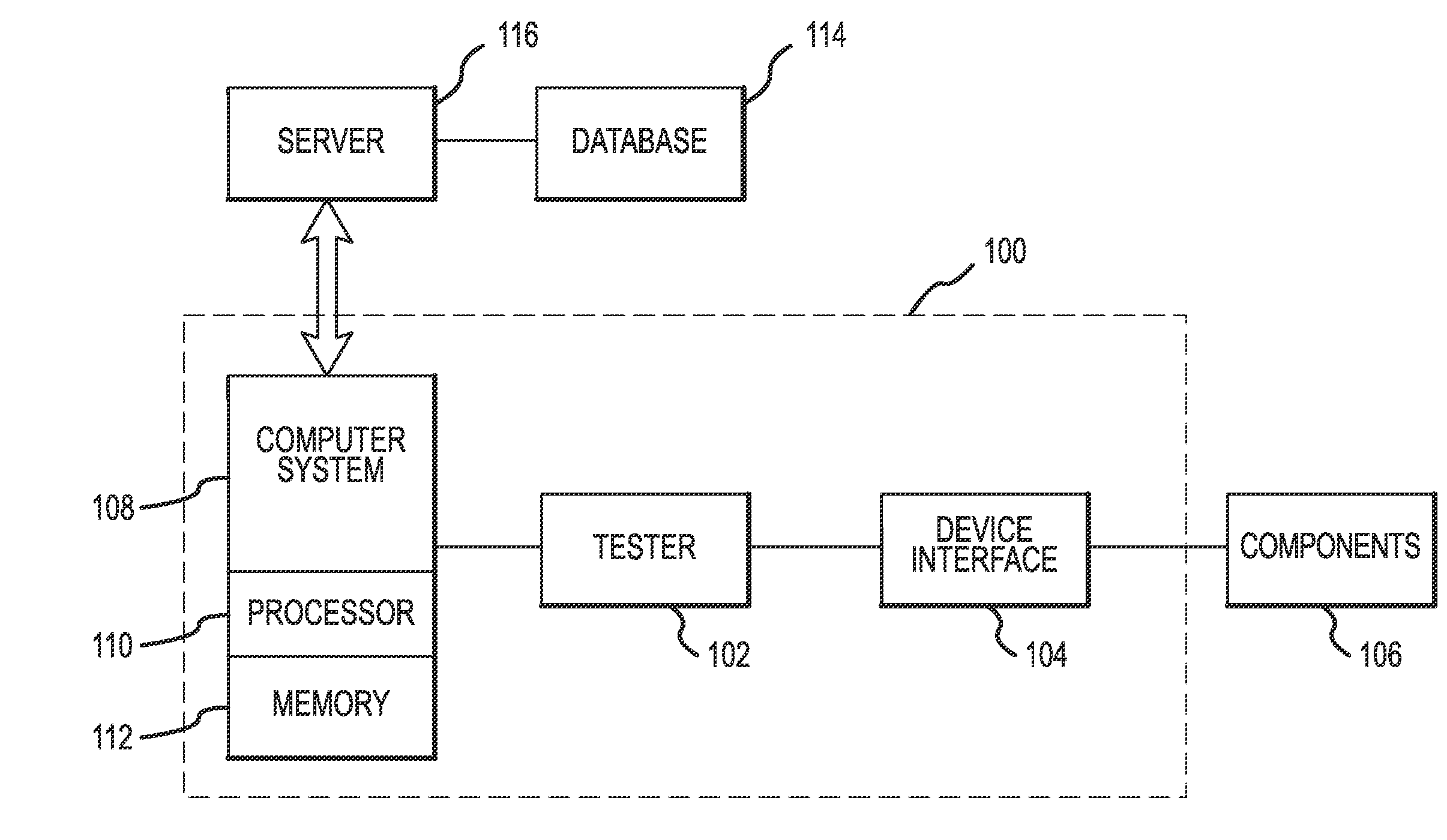

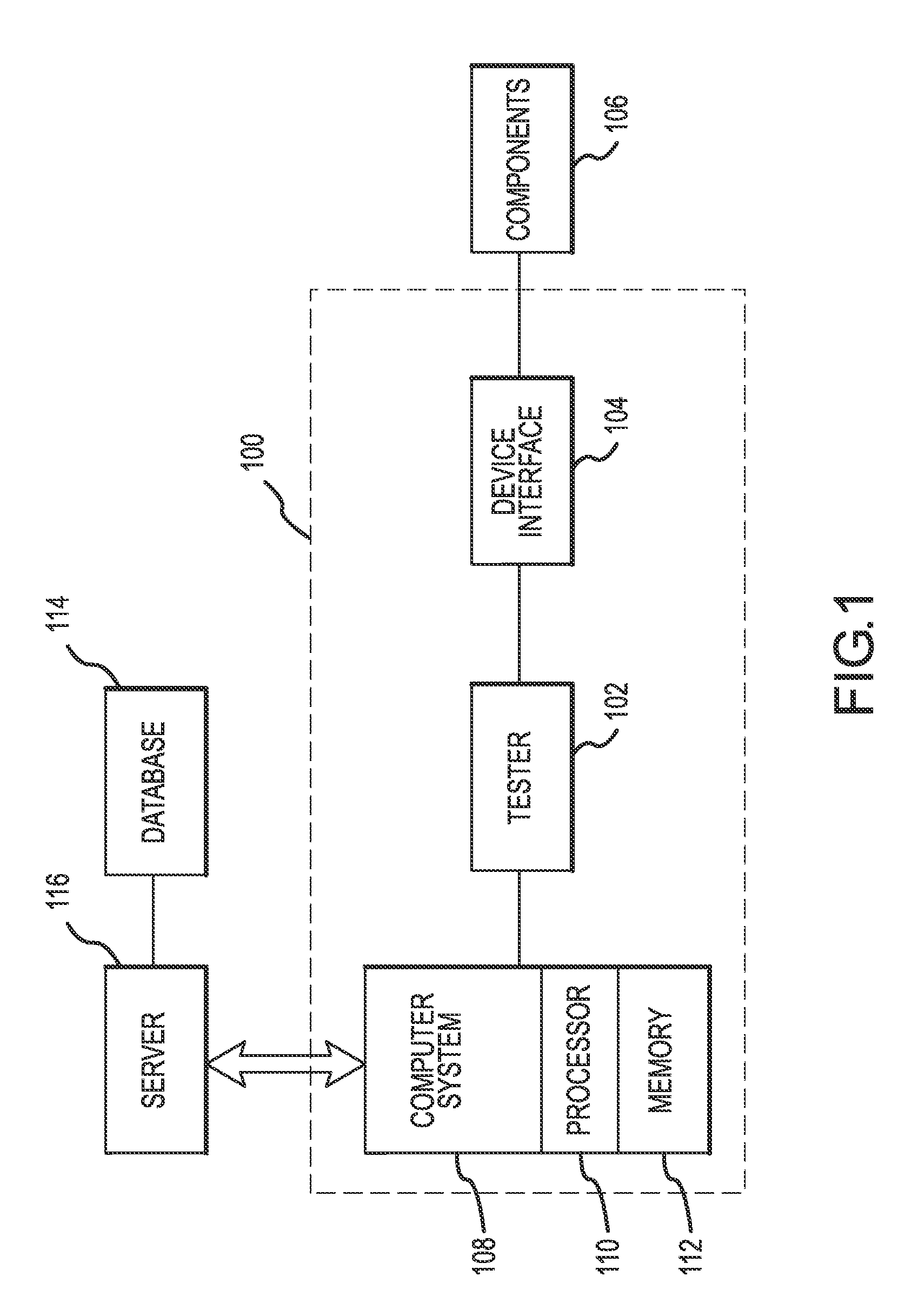

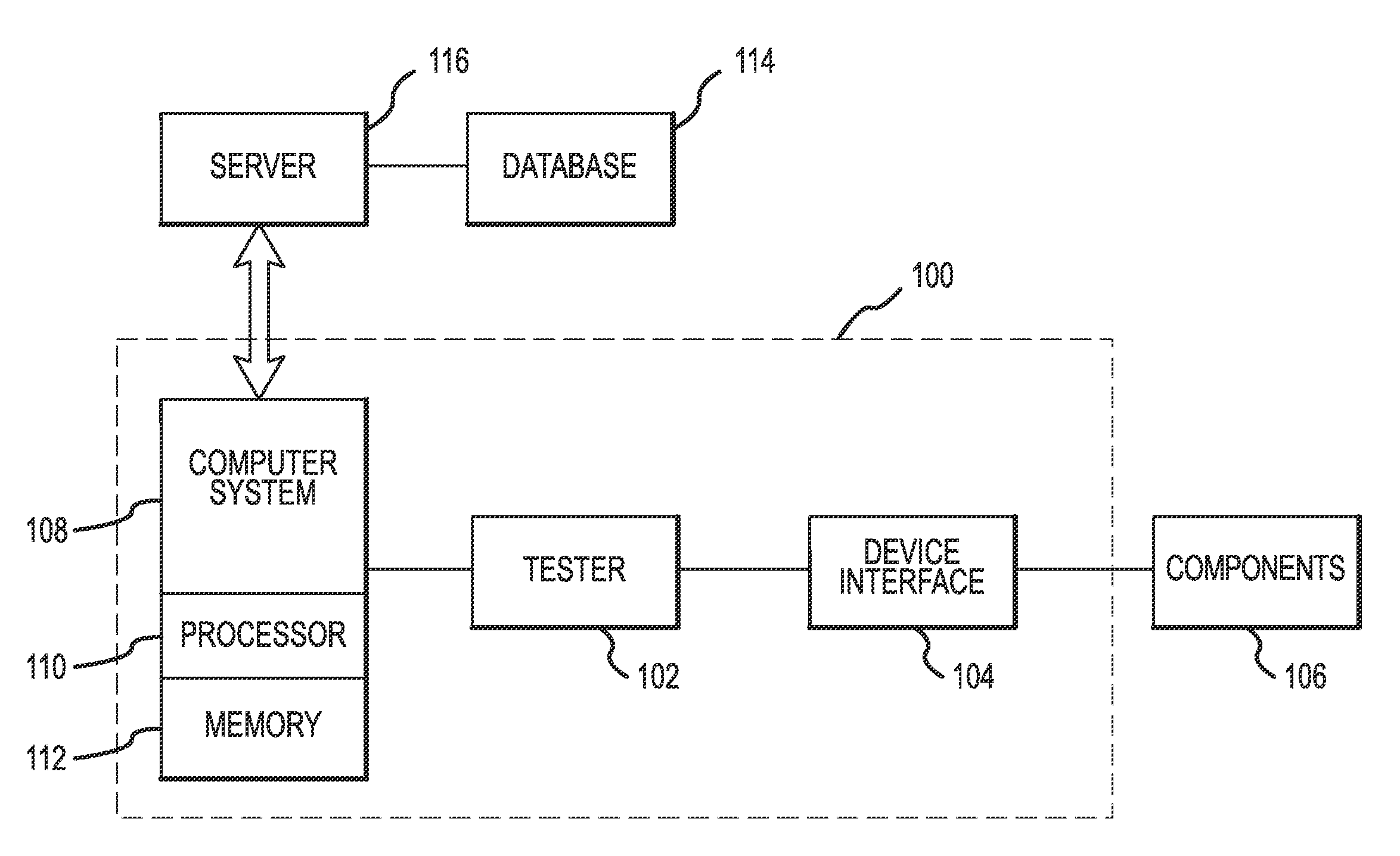

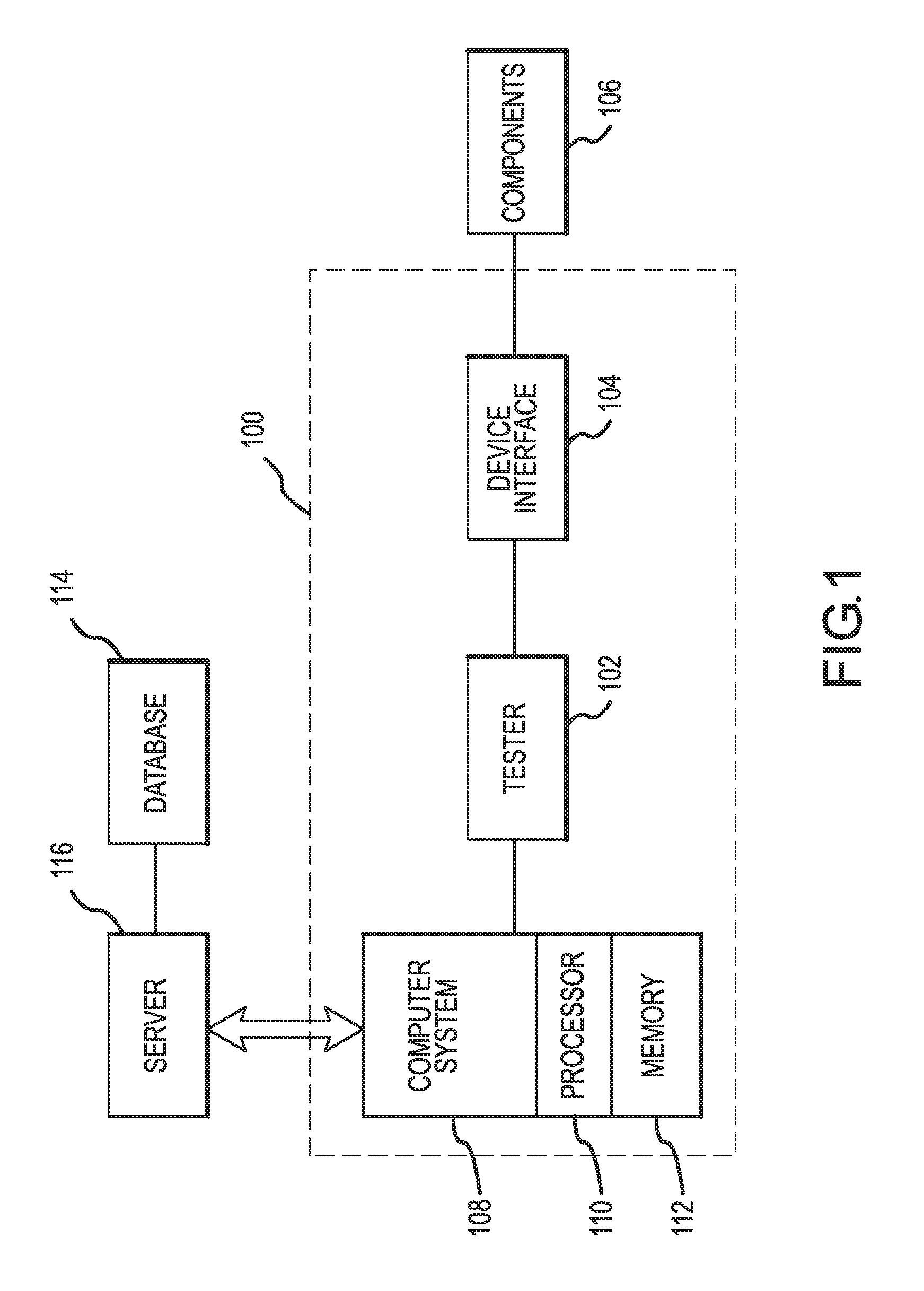

A method and apparatus for data analysis according to various aspects of the present invention is configured to automatically identify a characteristic of a component fabrication process guided by characteristics of the test data for the components.

Owner:IN DEPTH TEST

Methods and apparatus for data analysis

InactiveUS7356430B2Semiconductor/solid-state device testing/measurementElectronic circuit testingAutomatic test equipmentSemiconductor

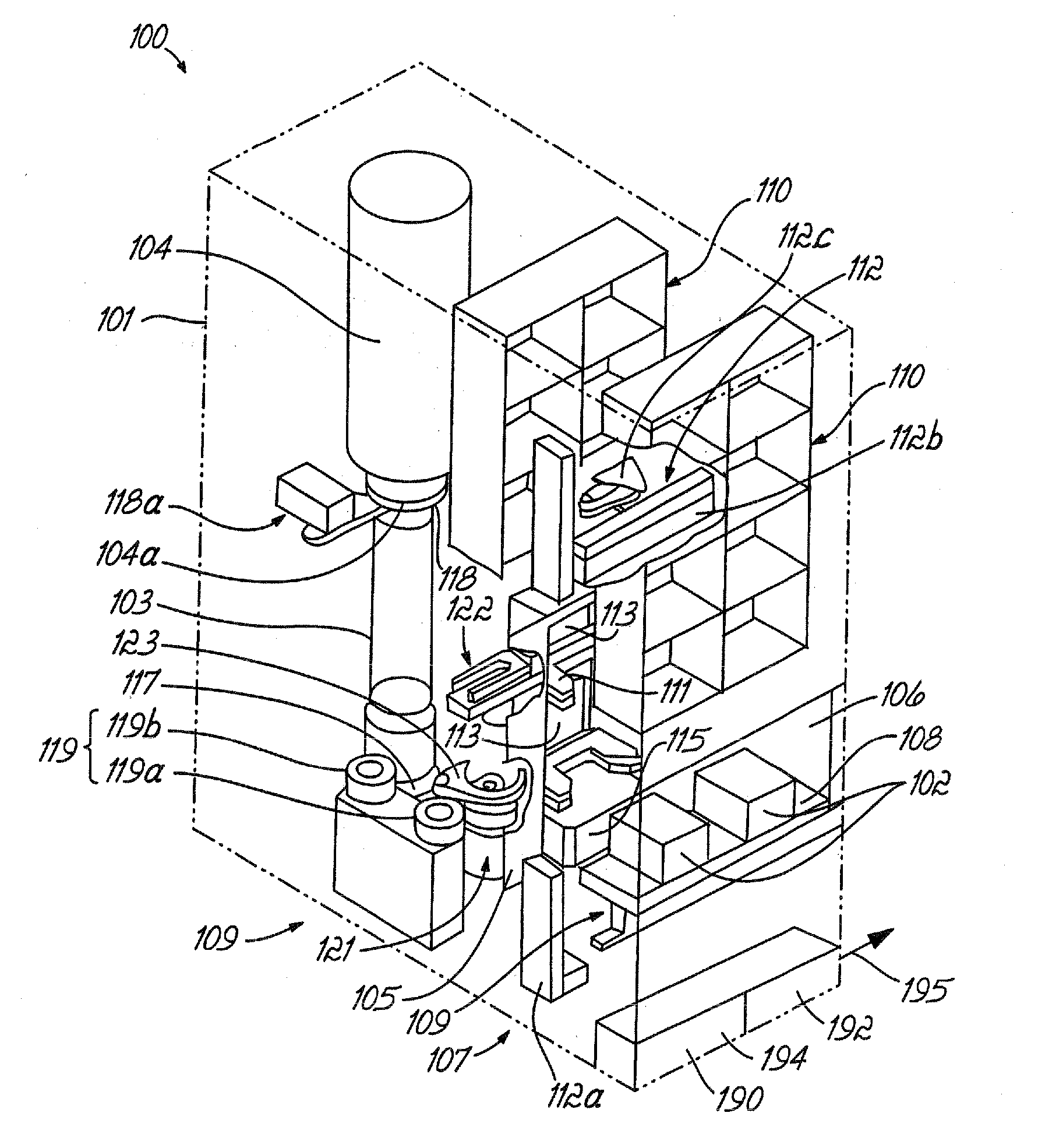

A method and apparatus for data analysis according to various aspects of the present invention is configured to automatically identify a characteristic of a component fabrication process guided by characteristics of the test data for the components. A method and apparatus according to various aspects of the present invention may operate in conjunction with a test system having a tester, such as automatic test equipment (ATE) for testing semiconductors.

Owner:IN DEPTH TEST

Methods and apparatus for data analysis

A method and apparatus for data analysis according to various aspects of the present invention is configured to automatically identify a characteristic of a fabrication process for components based on test data for the components.

Owner:IN DEPTH TEST

Methods and apparatus for data analysis

InactiveUS20110178967A1Detecting faulty hardware using neural networksSemiconductor/solid-state device testing/measurementMachine learningDiagnostic system

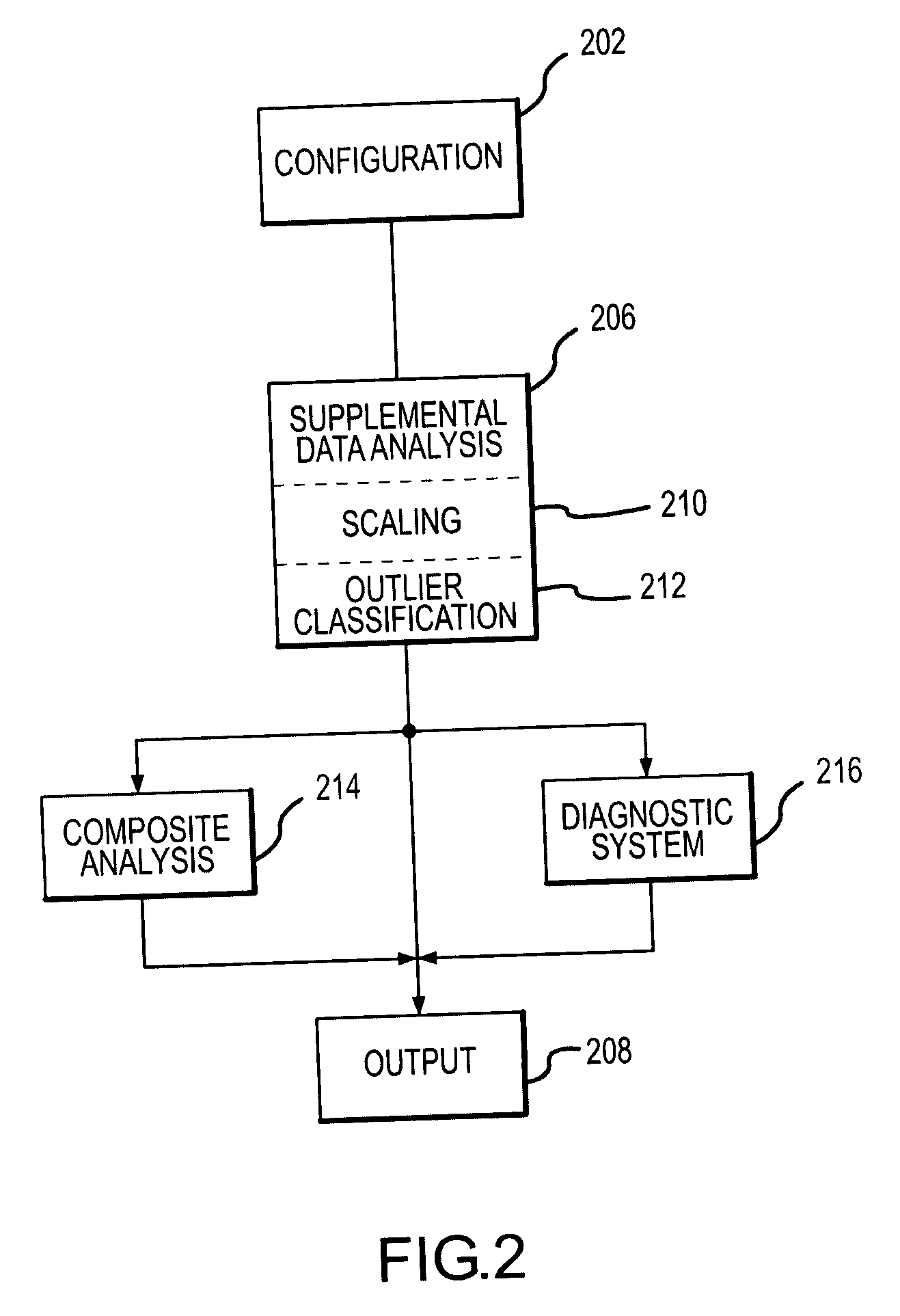

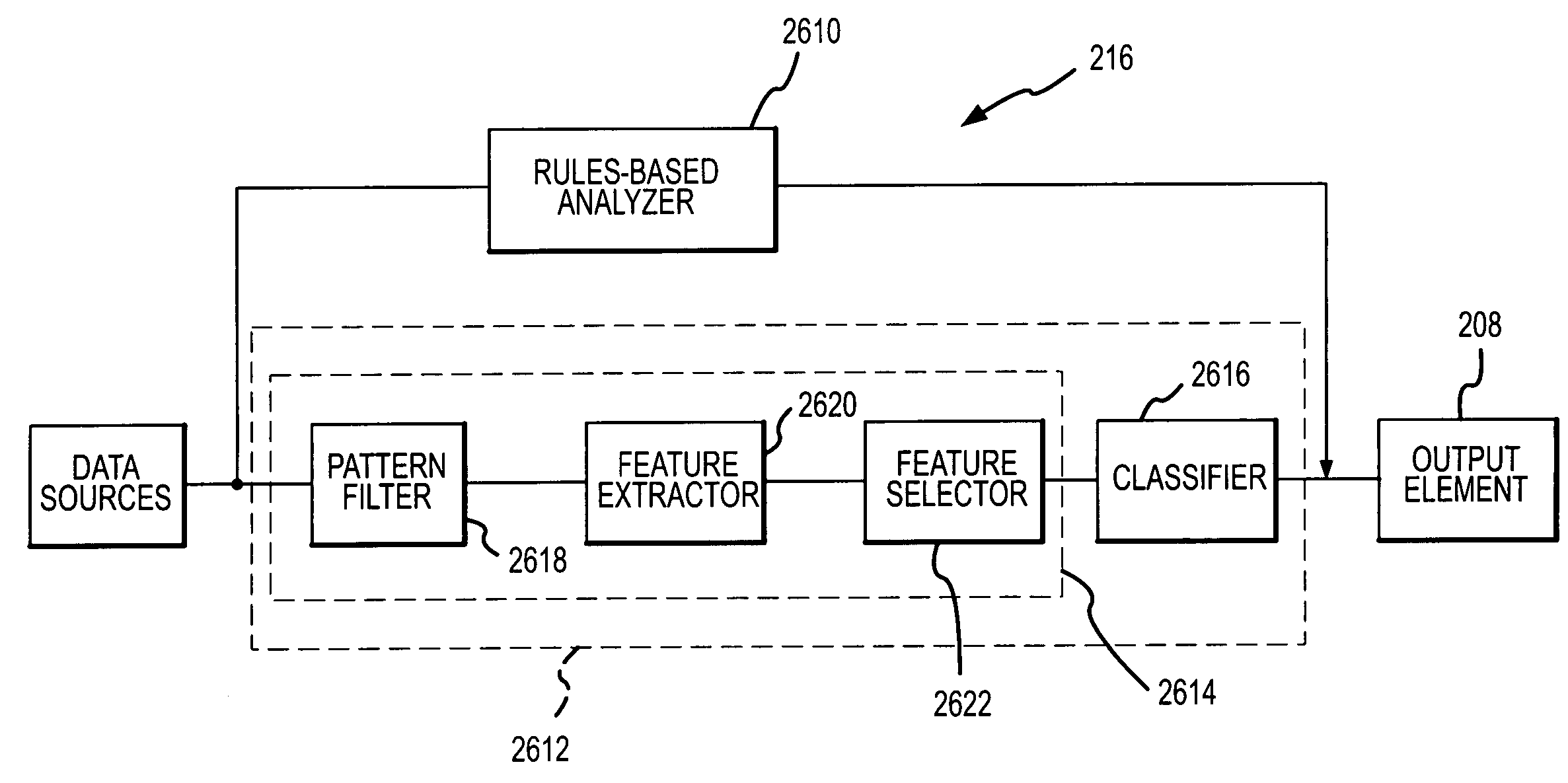

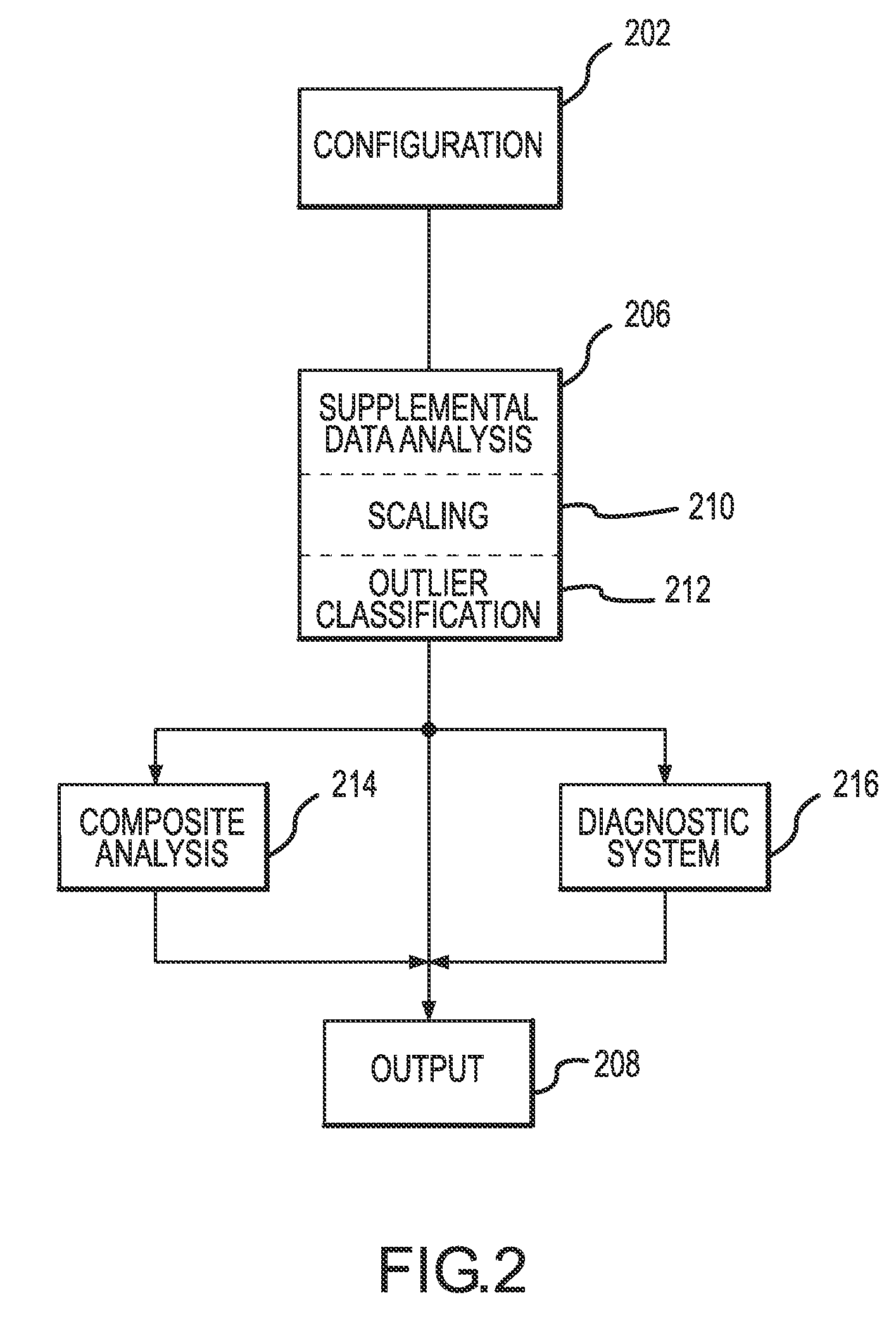

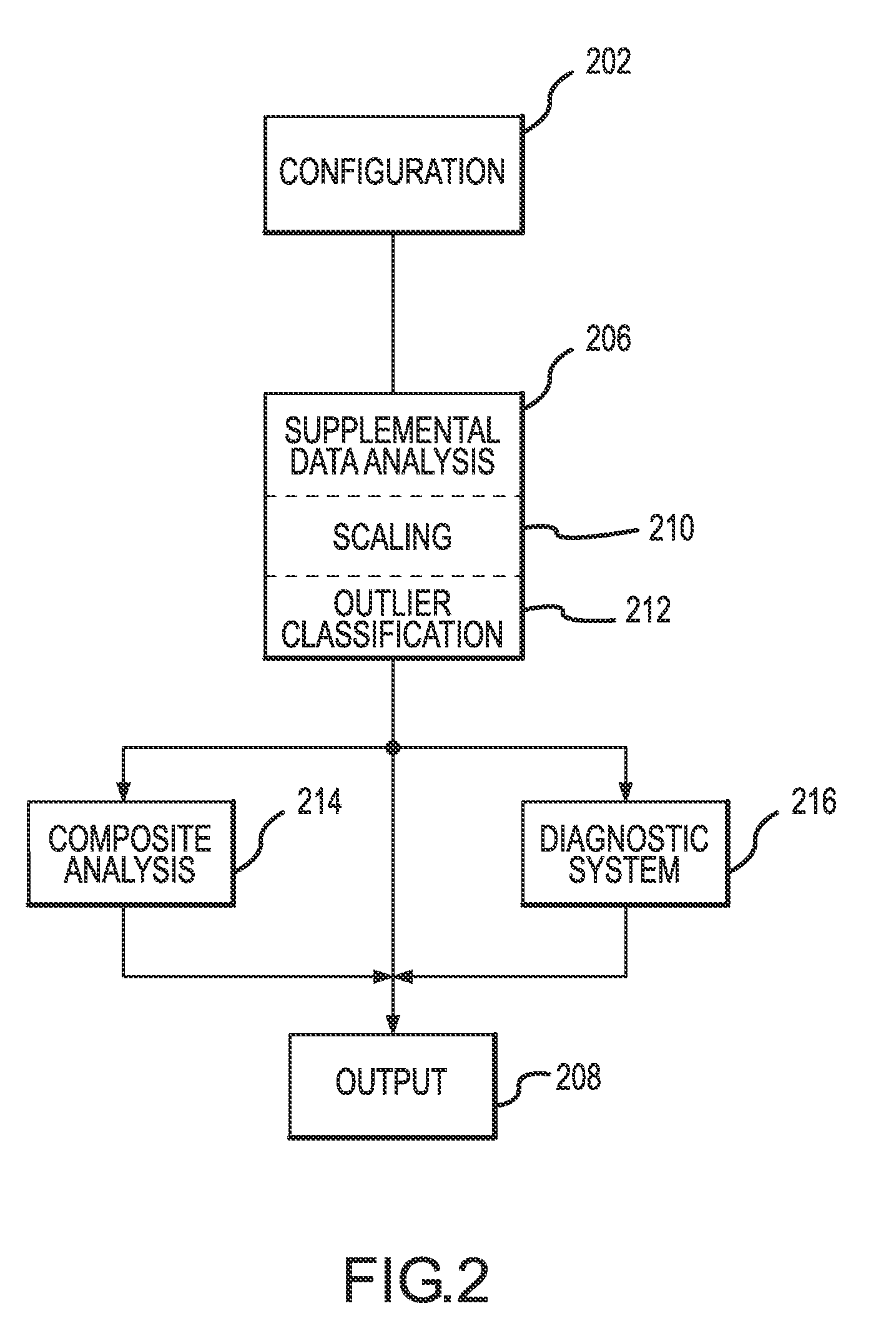

A method and apparatus for data analysis according to various aspects of the present invention is configured to test a set of components and generate test data for the components. A diagnostic system automatically analyzes the test data to identify a characteristic of a component fabrication process by recognizing a pattern in the test data and classifying the pattern using a neural network.

Owner:IN DEPTH TEST

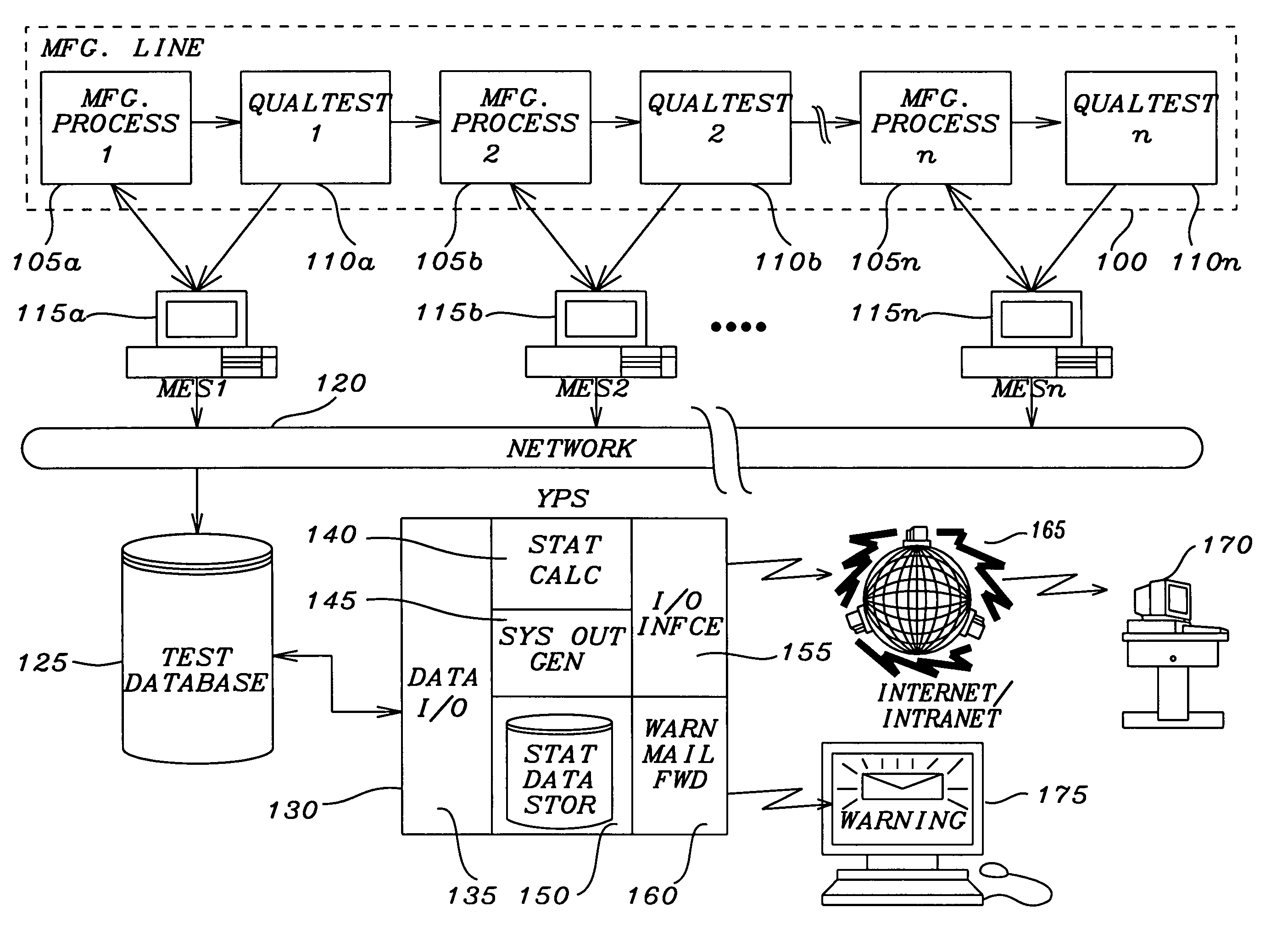

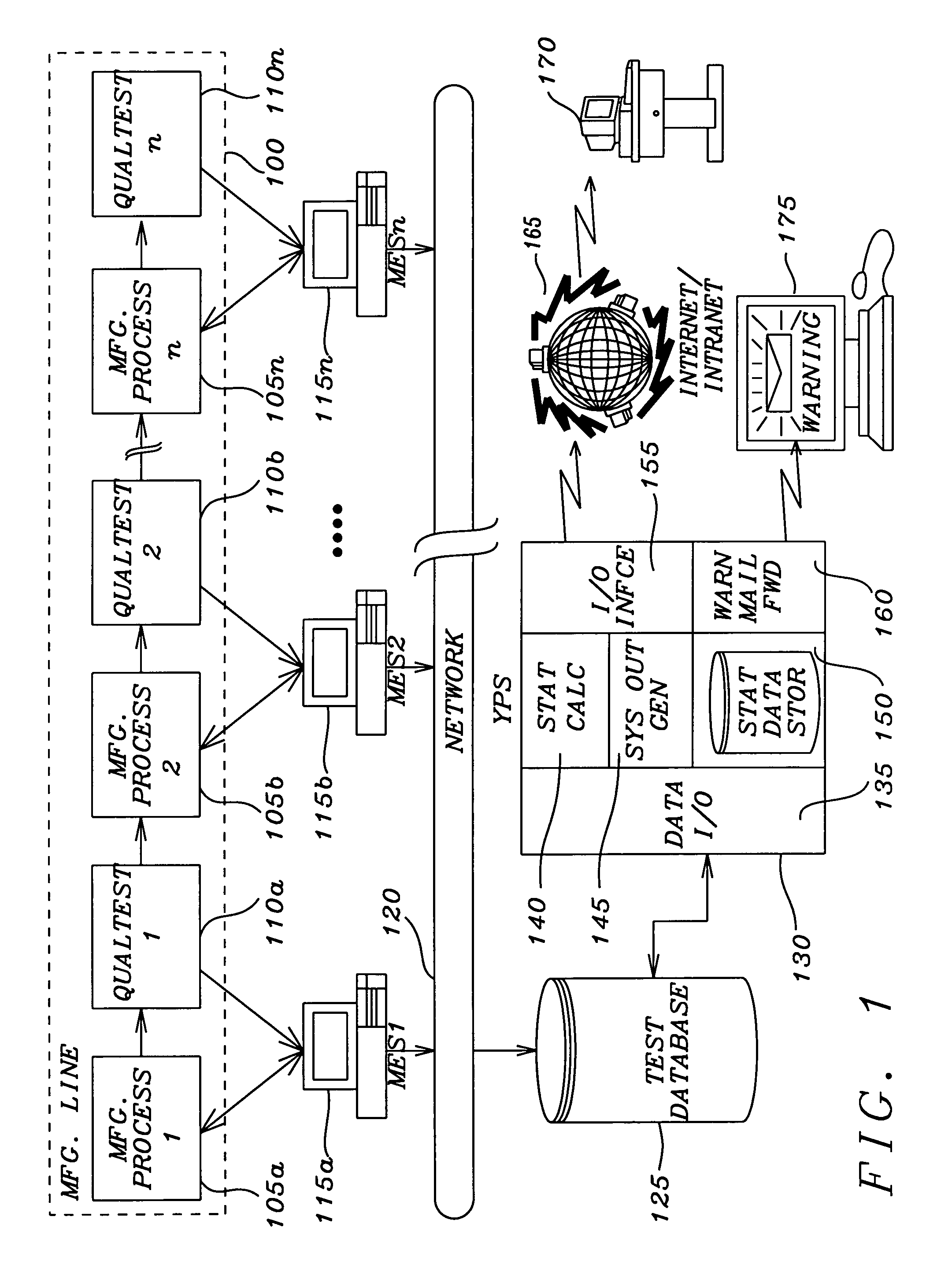

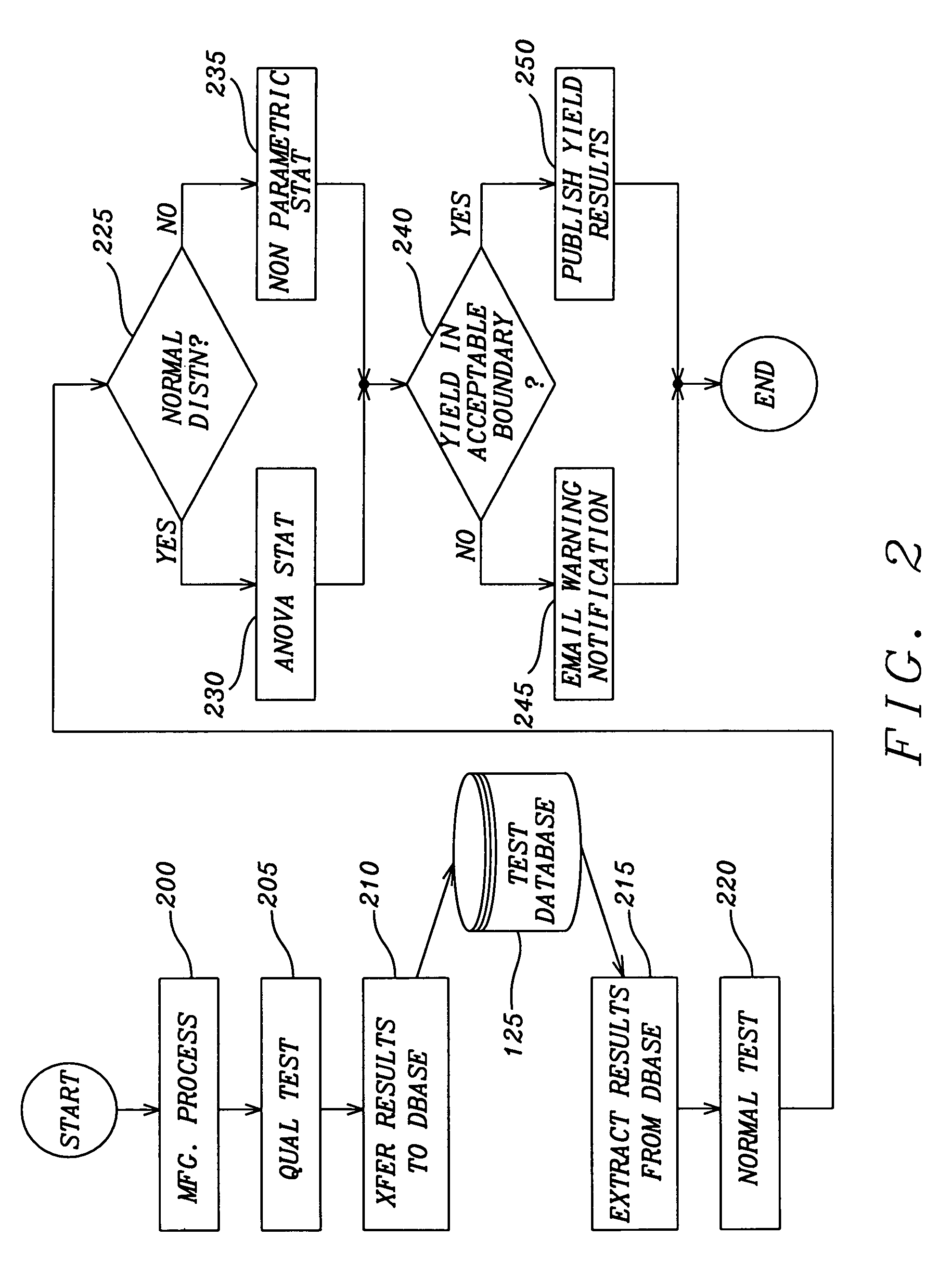

Yield patrolling system

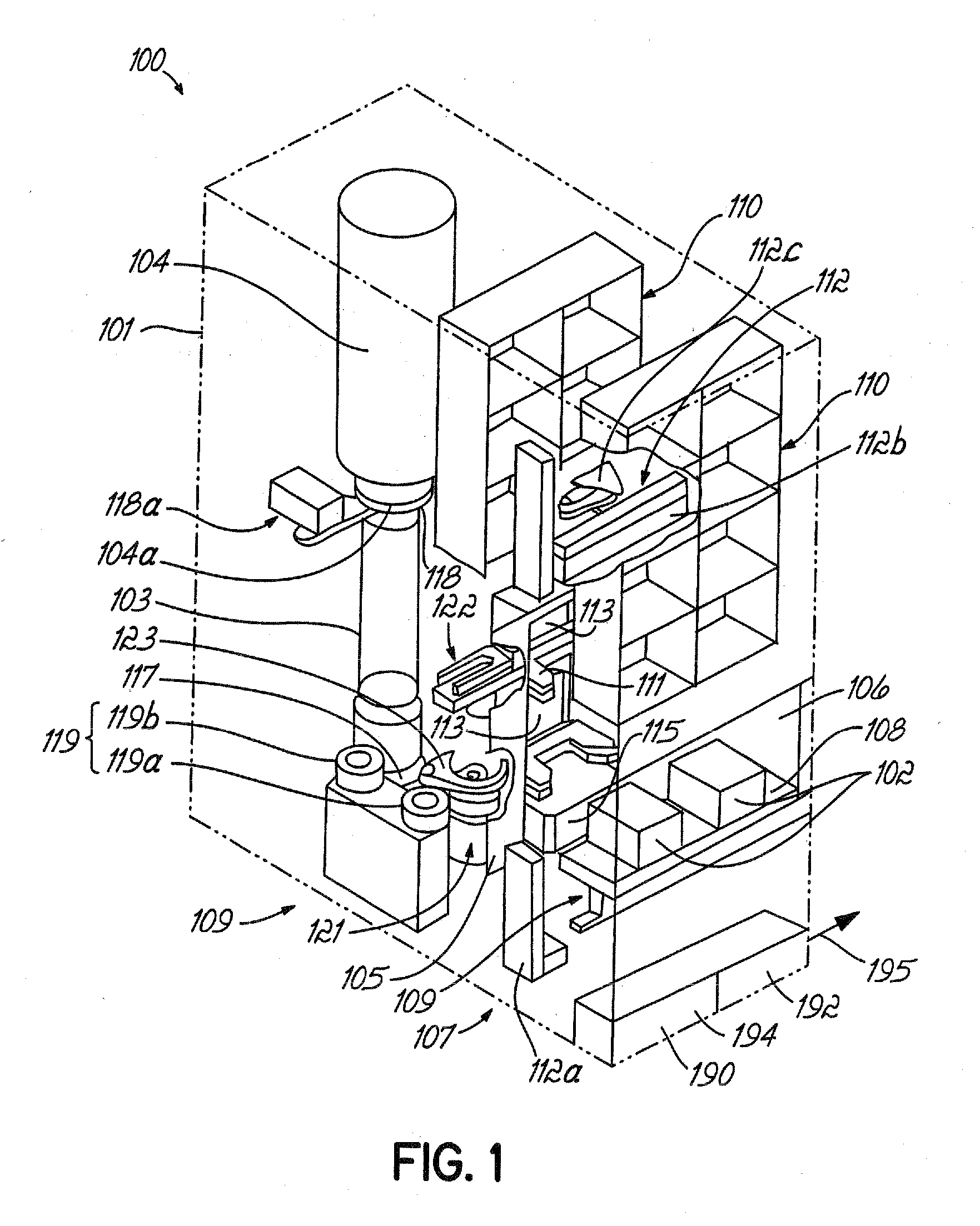

InactiveUS7117057B1Total factory controlSpecial data processing applicationsTest fixtureManufacturing line

A yield patrolling system, which monitors production yield of a manufacturing line, has at least one product measurement and test device. The product measurement and test device measures yield determining parameters of product at completion of process steps executed by equipment within the manufacturing line. The system further has a test database in communication with the product measurement and test device to receive and retain the measured yield determining parameters. A statistical calculator is in communication with the test database to receive the measured yield determining parameters. The statistical calculator then calculates from the measured yield determining parameters production yield statistics indicating an amount of the product being fabricated on the manufacturing line. A yield-warning device is in communication with the statistical calculator to receive the production yield statistics and to provide a yield warning alert to a responsible person indicating that the manufacturing line is not fabricating product with a sufficient yield. Further, a yield information interface receives a compilation of the production yield statistics for each process step from the statistical calculator.

Owner:TAIWAN SEMICON MANUFACTUTING

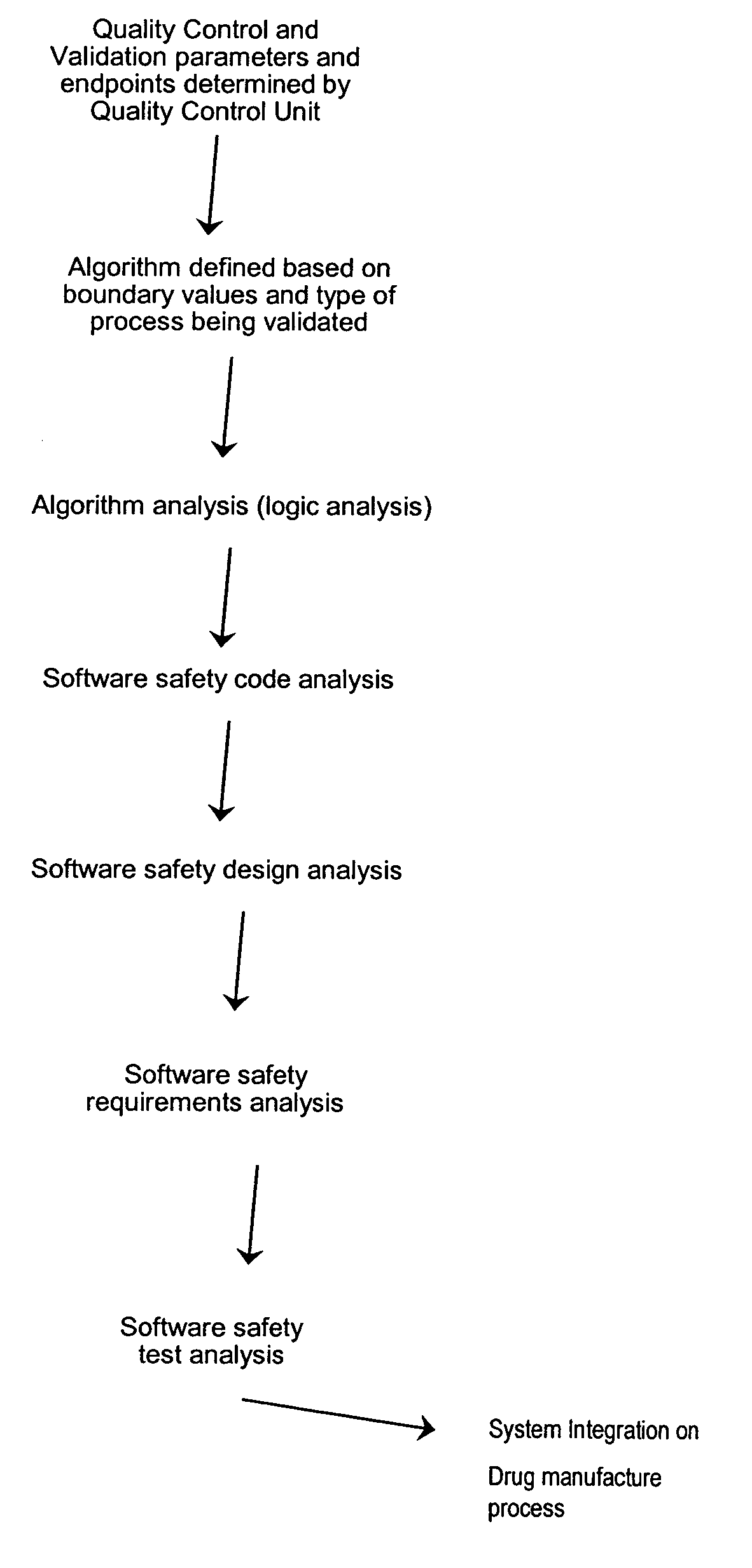

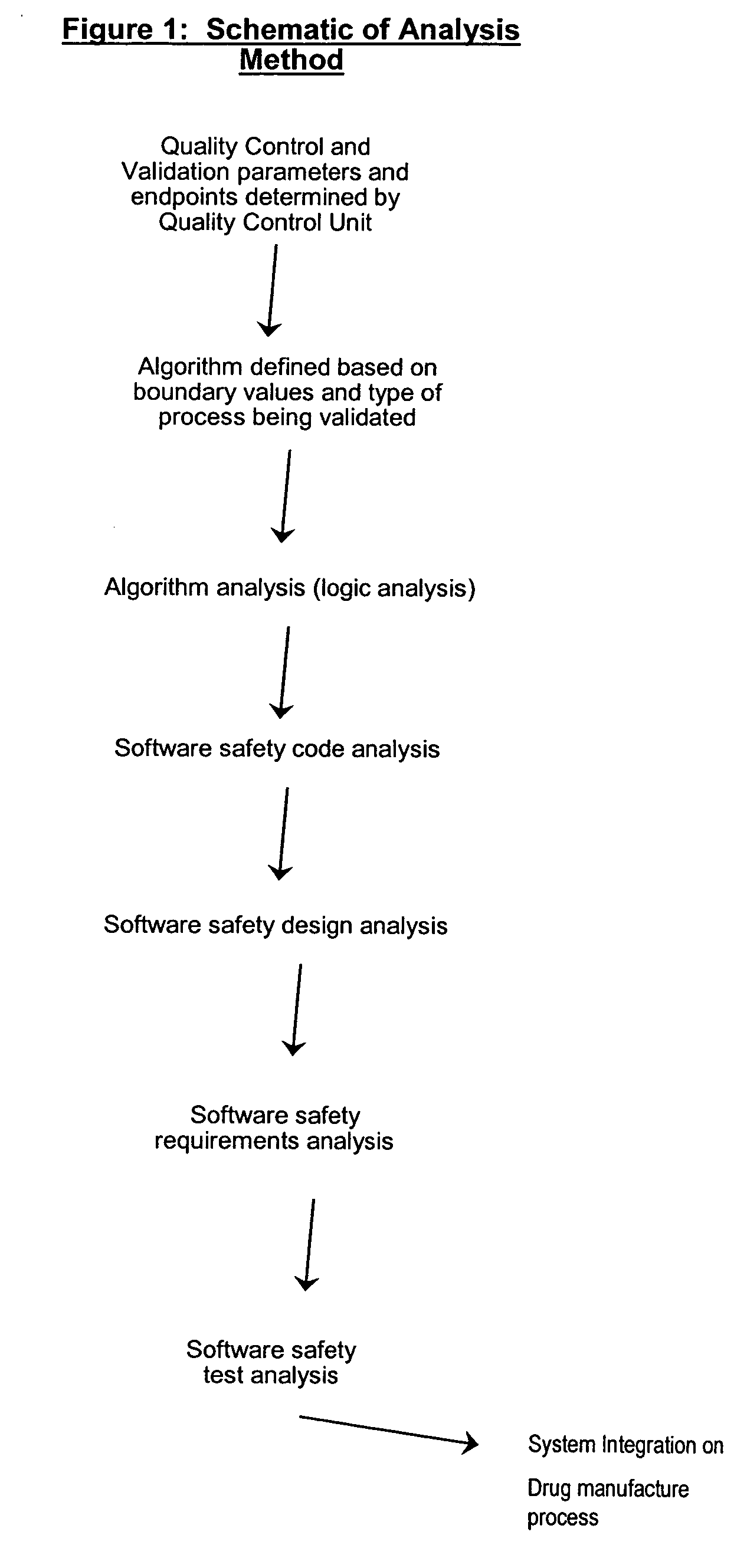

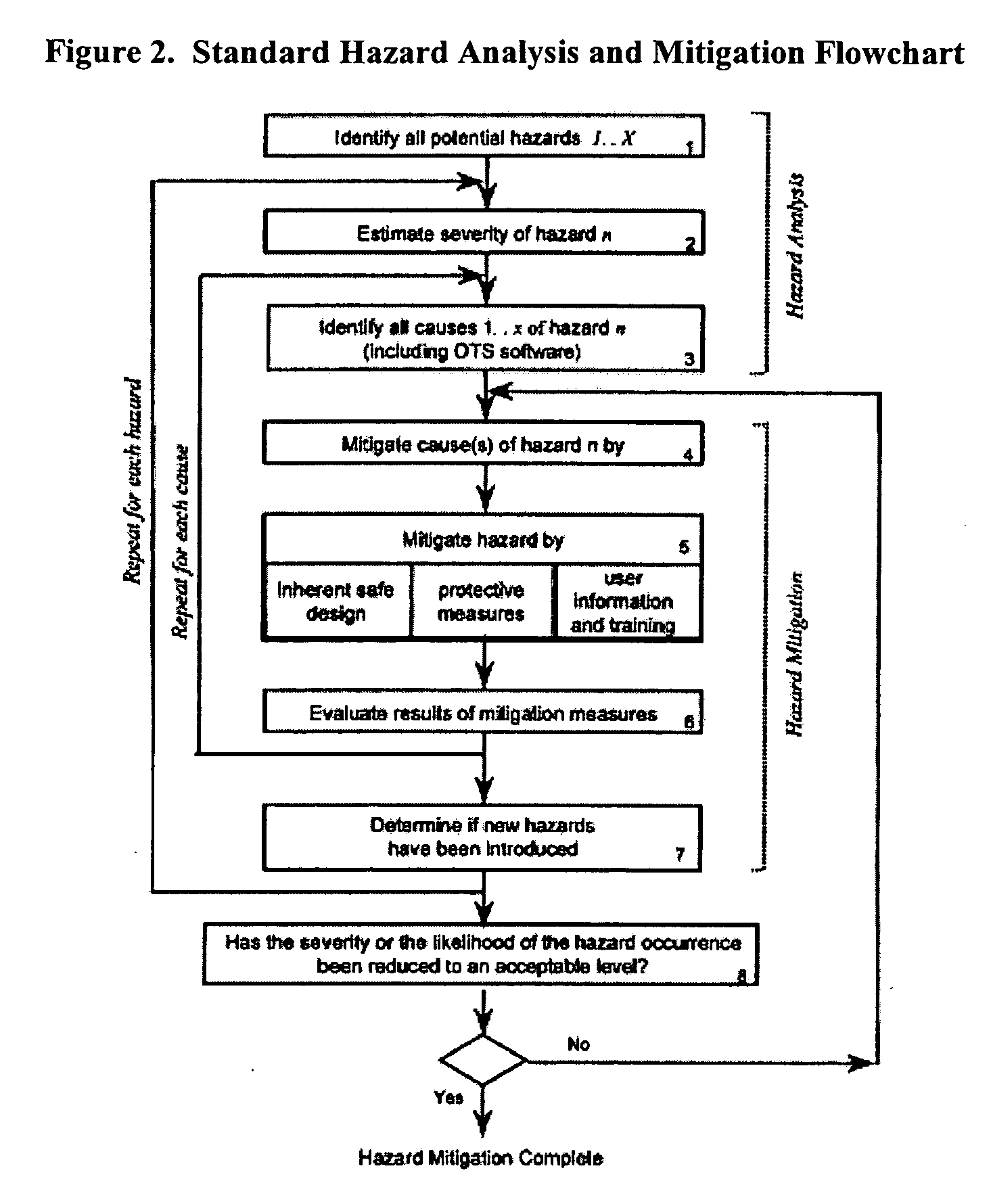

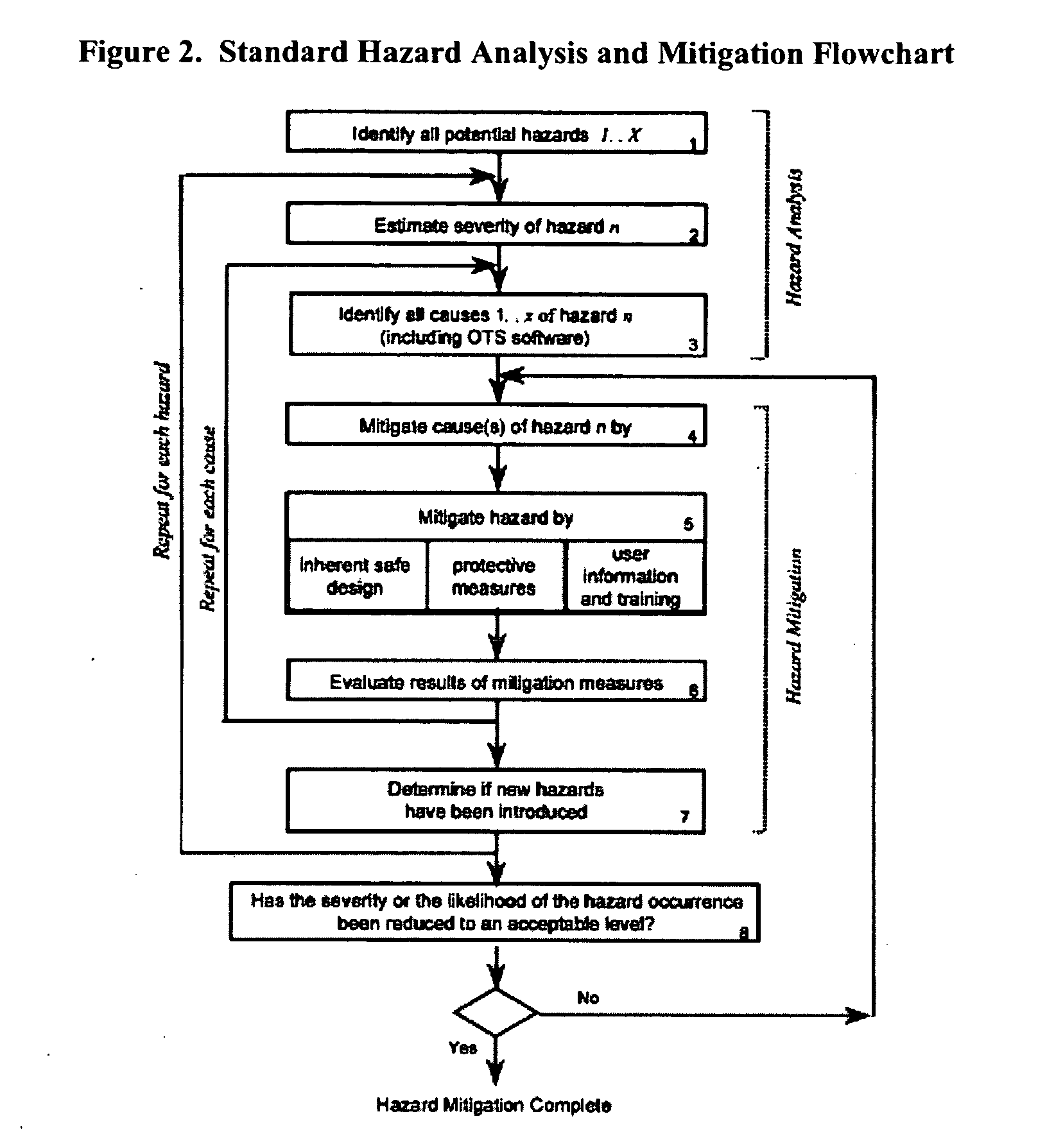

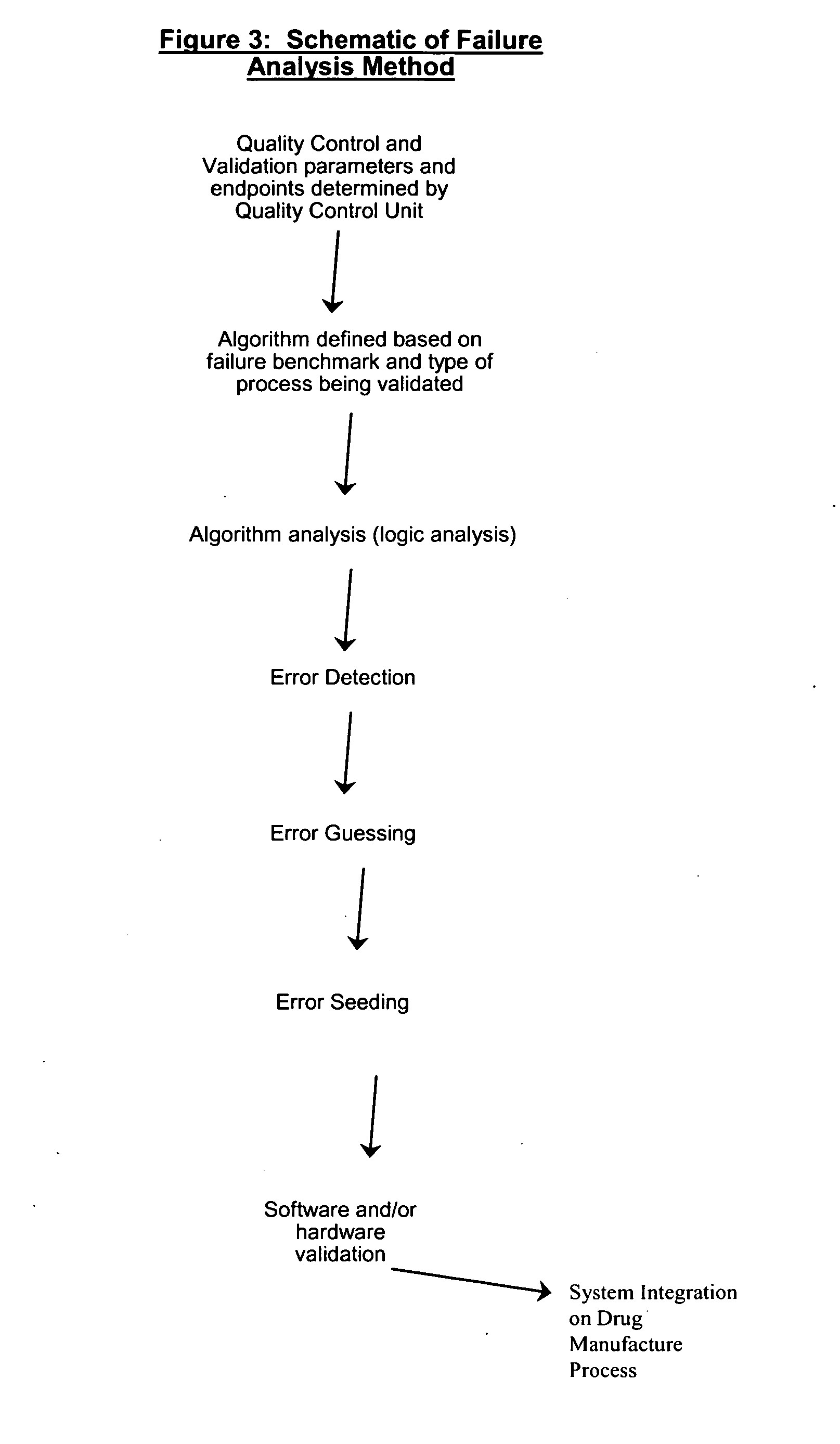

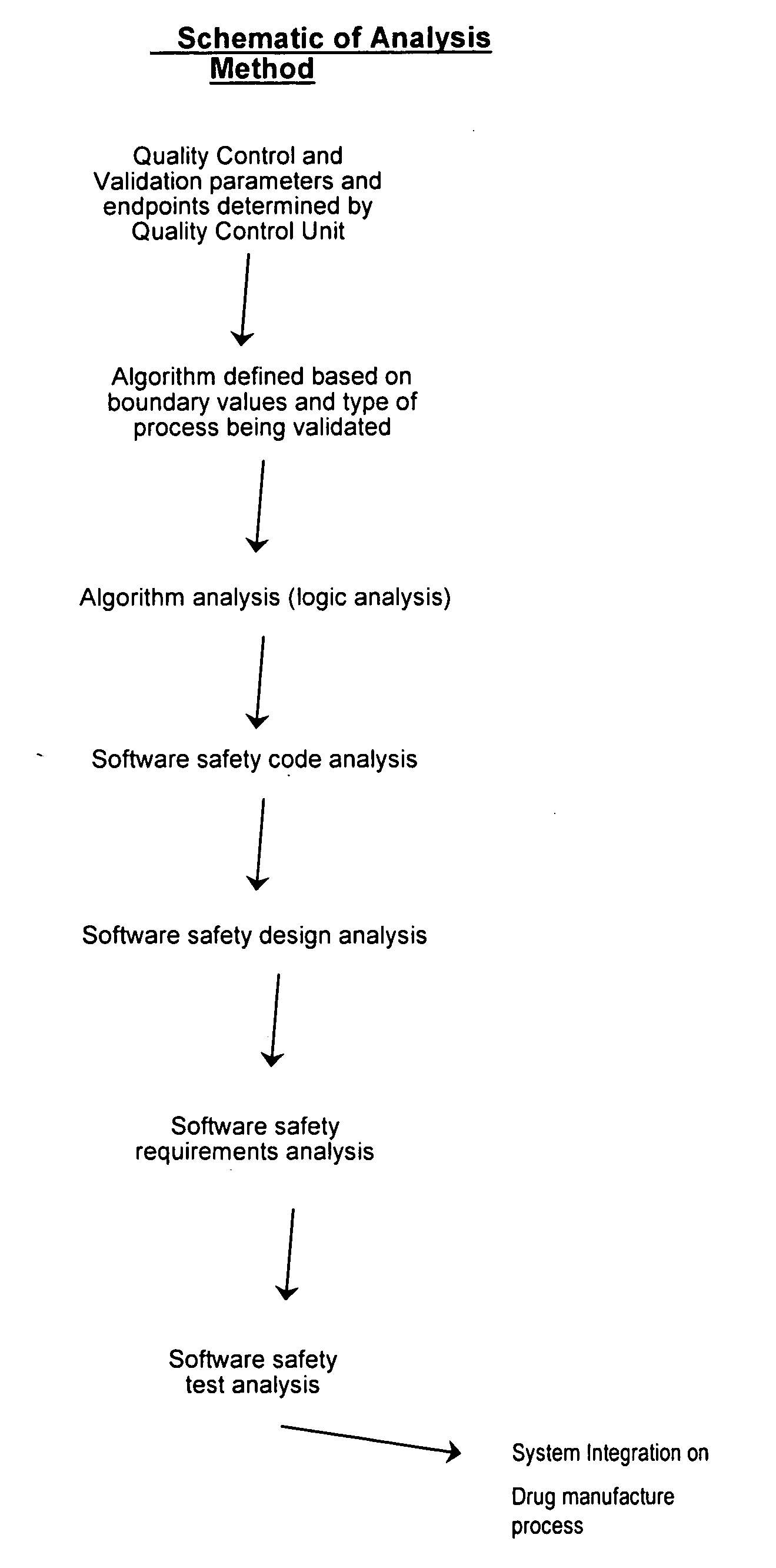

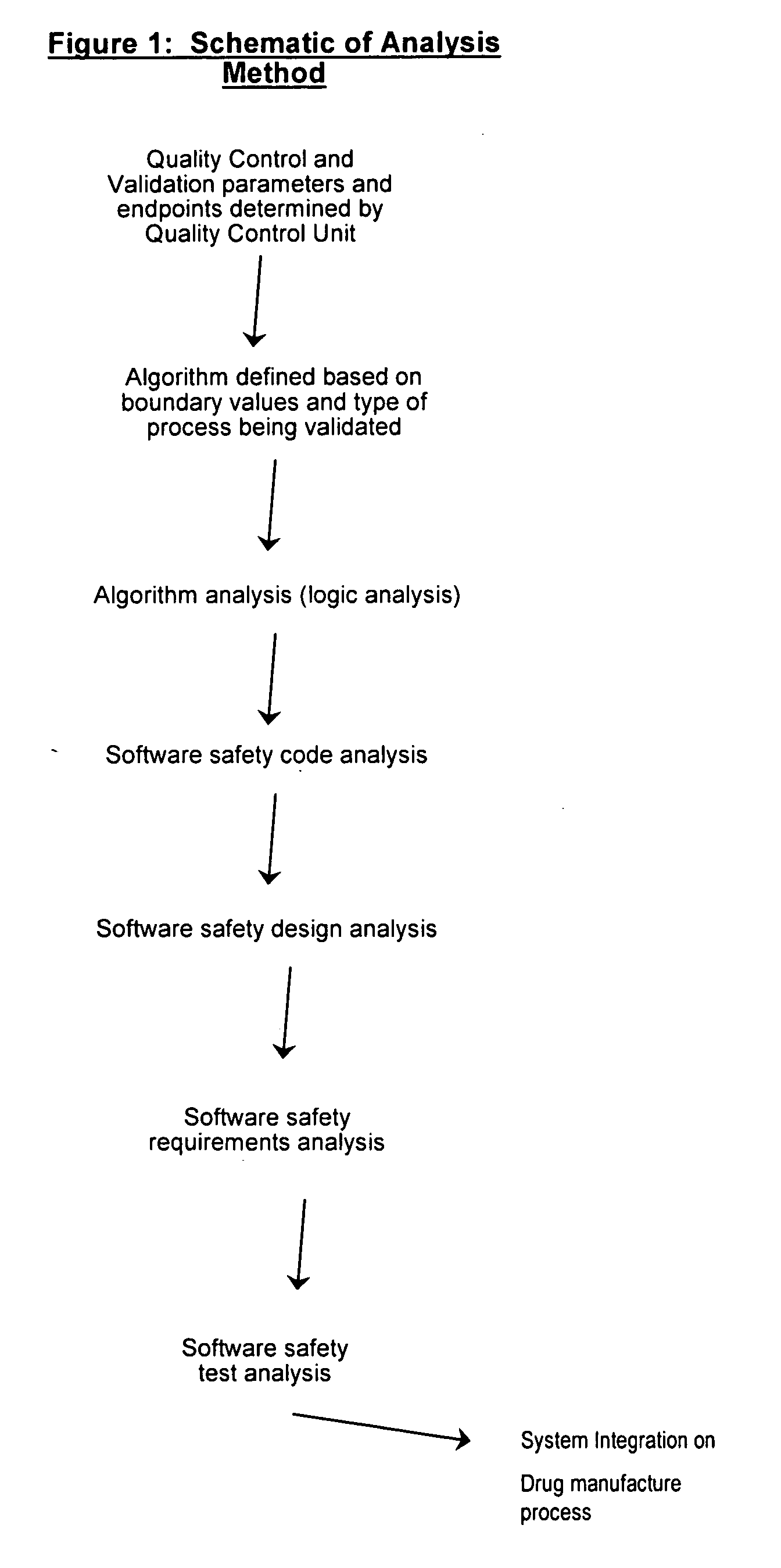

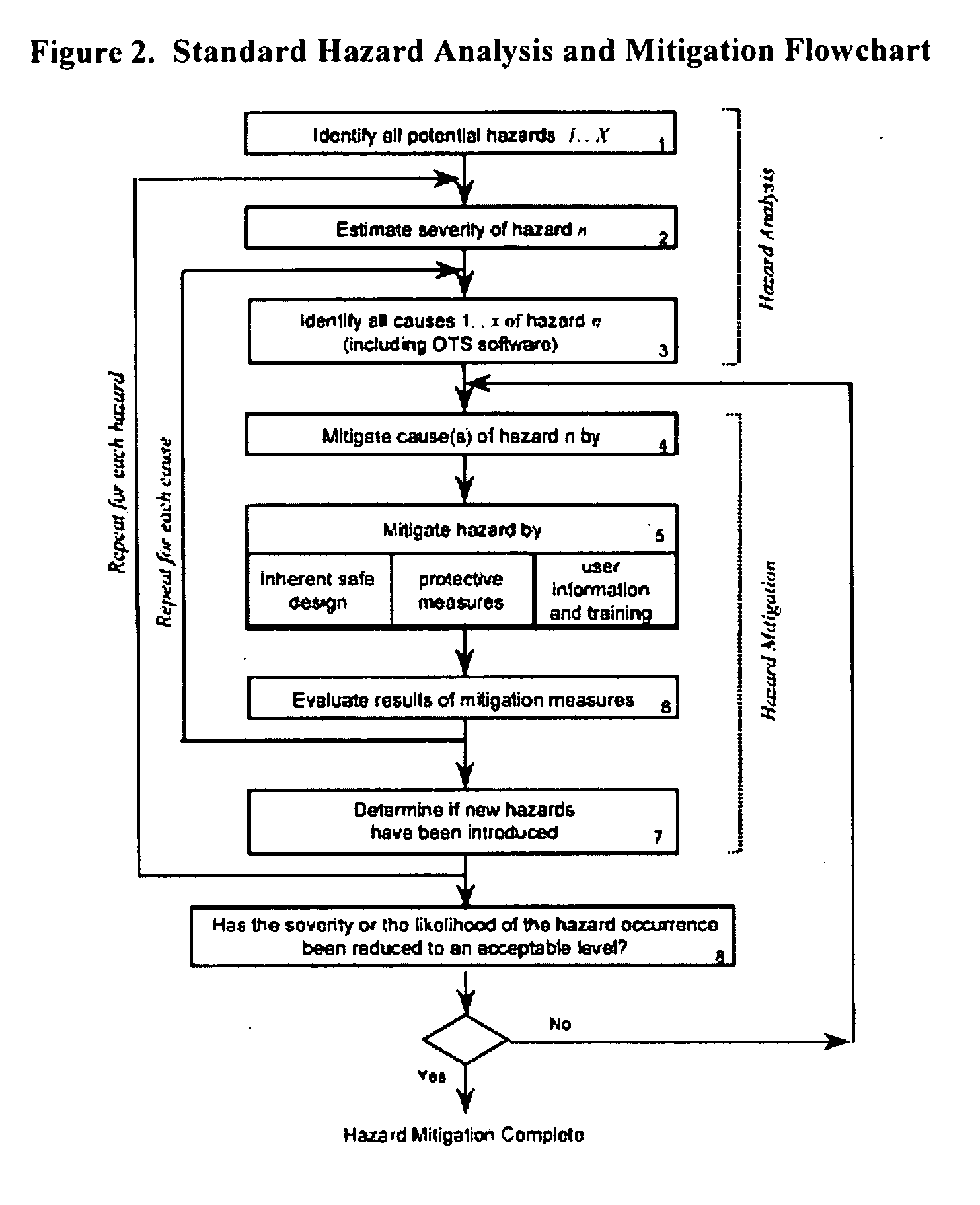

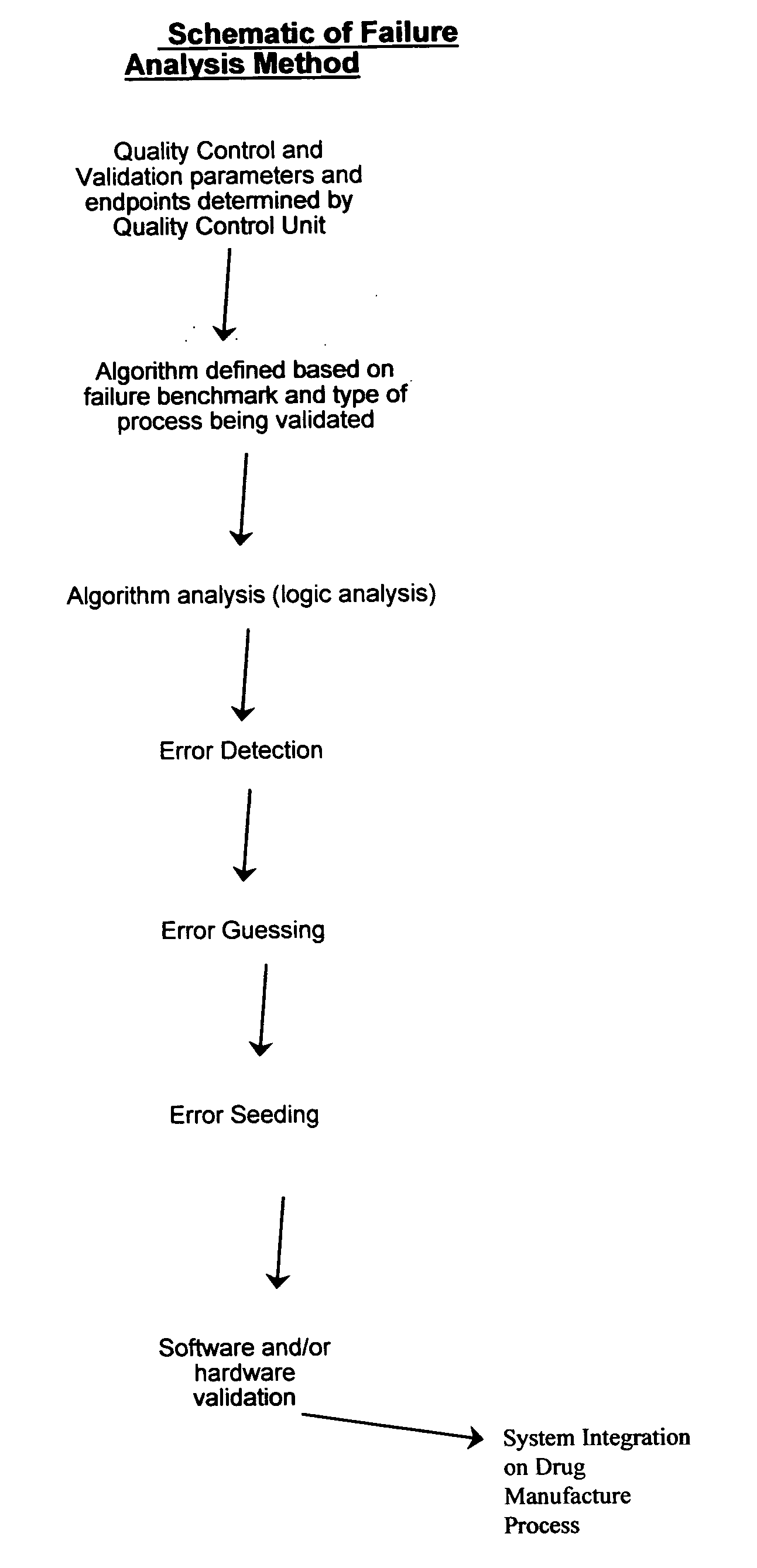

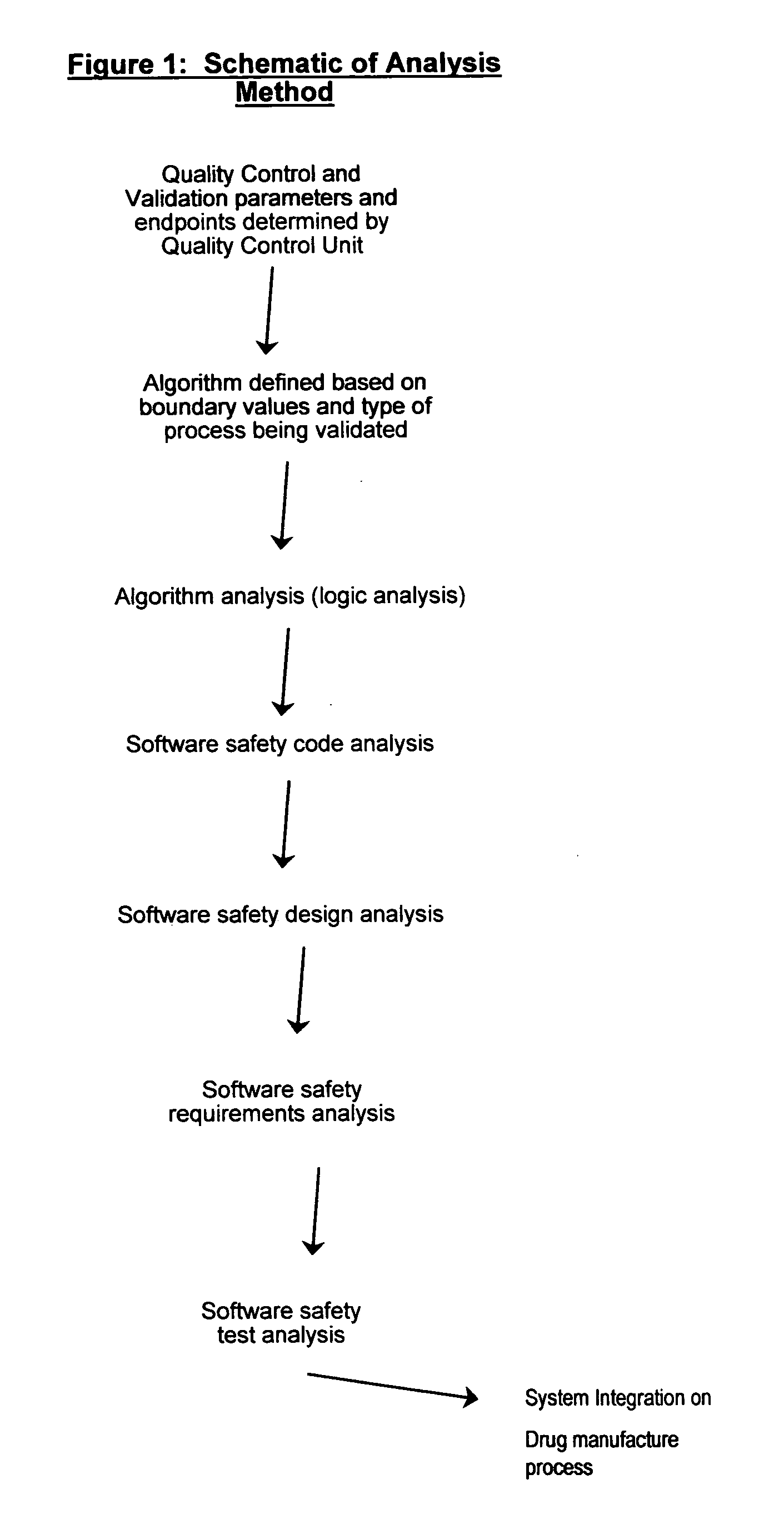

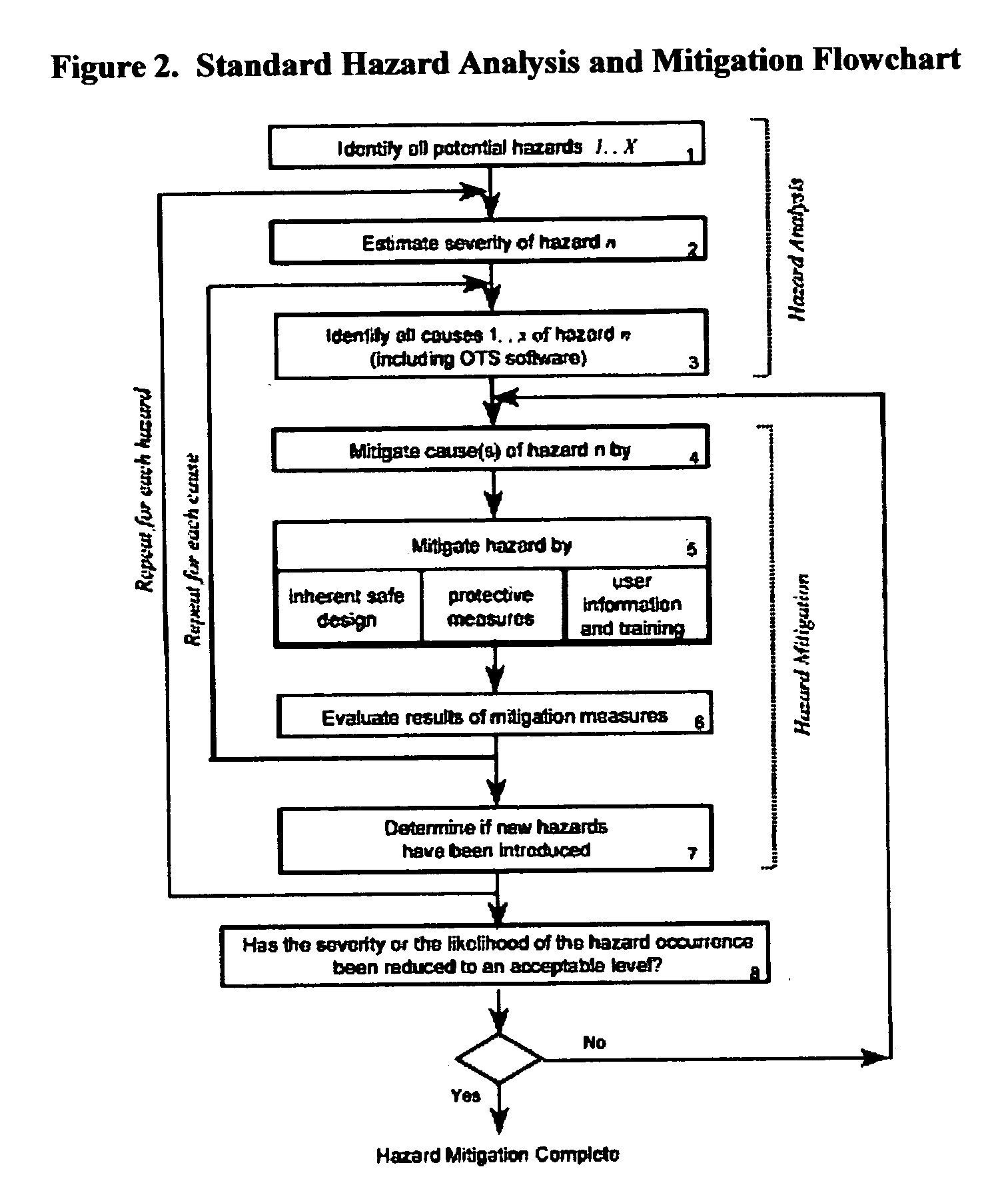

Methods, systems, and software program for validation and monitoring of pharmaceutical manufacturing processes

ActiveUS20050251278A1Testing/monitoring control systemsResourcesQuality assuranceSoftware engineering

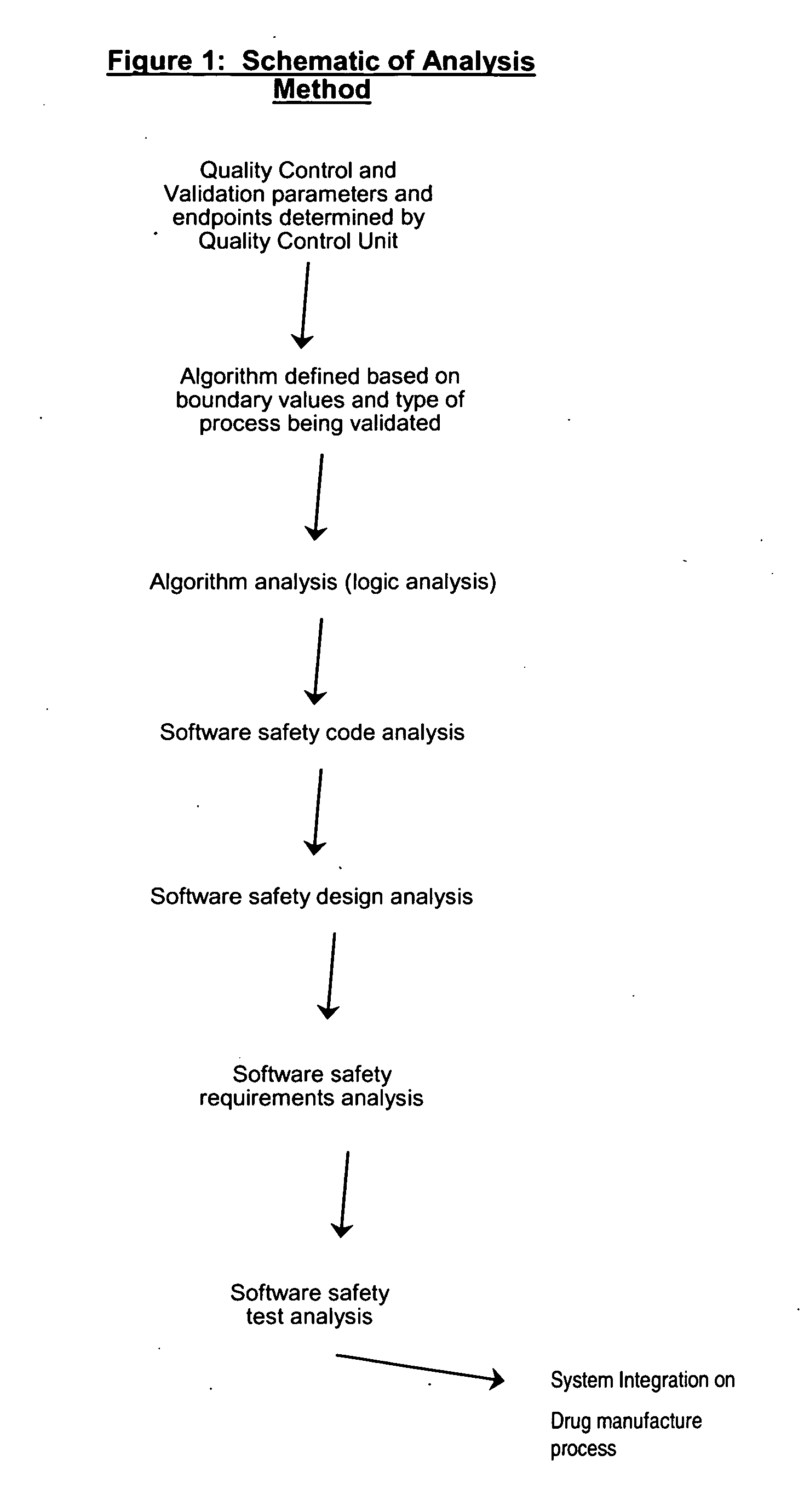

Methods, systems, and software program for validation of pharmaceutical manufacturing processes and quality assurance process are described and disclosed herein. Consequently, the methods provide a means to perform validation on an integrated level whereby the quality control unit can ensure data and product integrity and minimize cost.

Owner:SMP LOGIC SYST

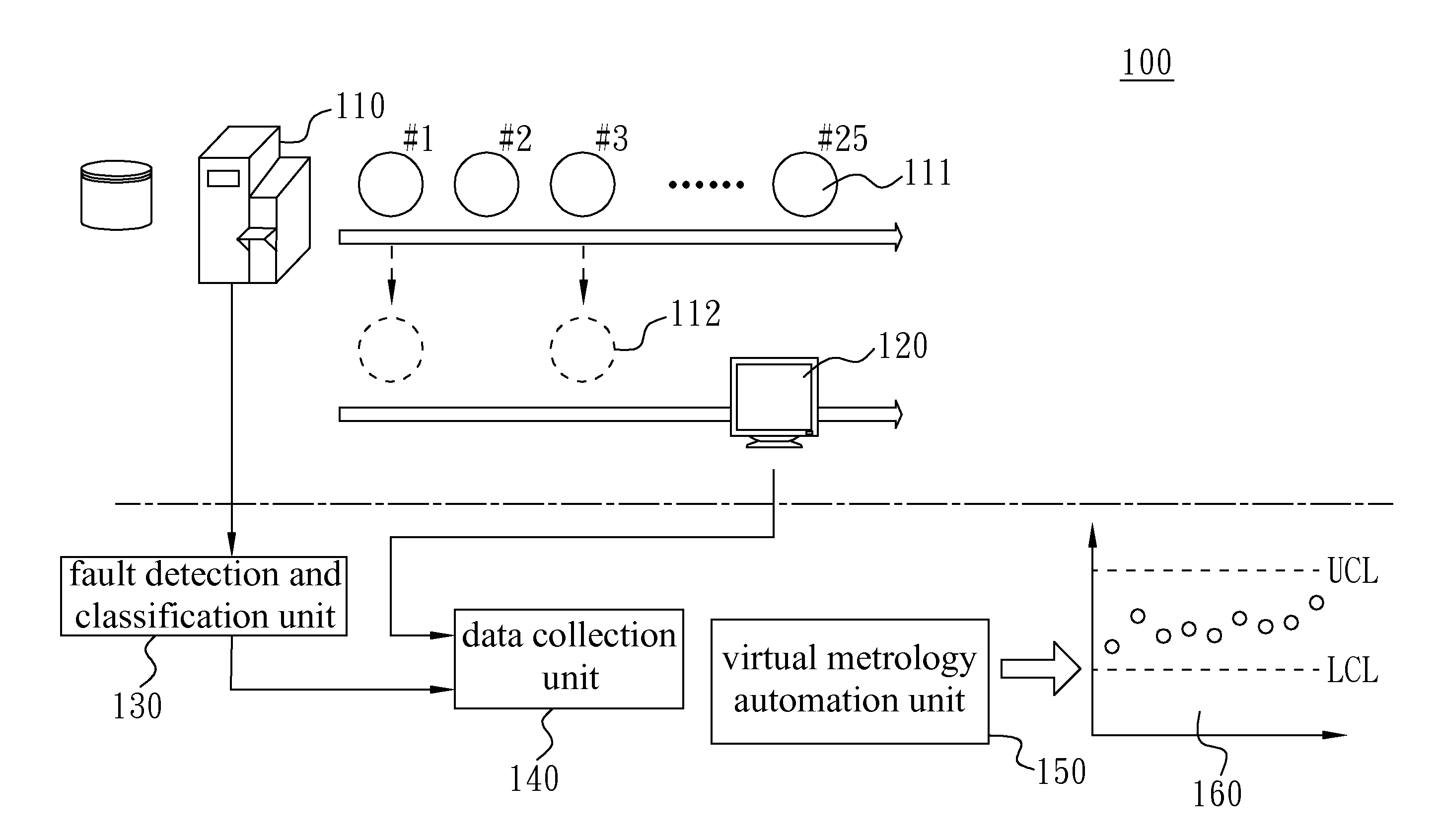

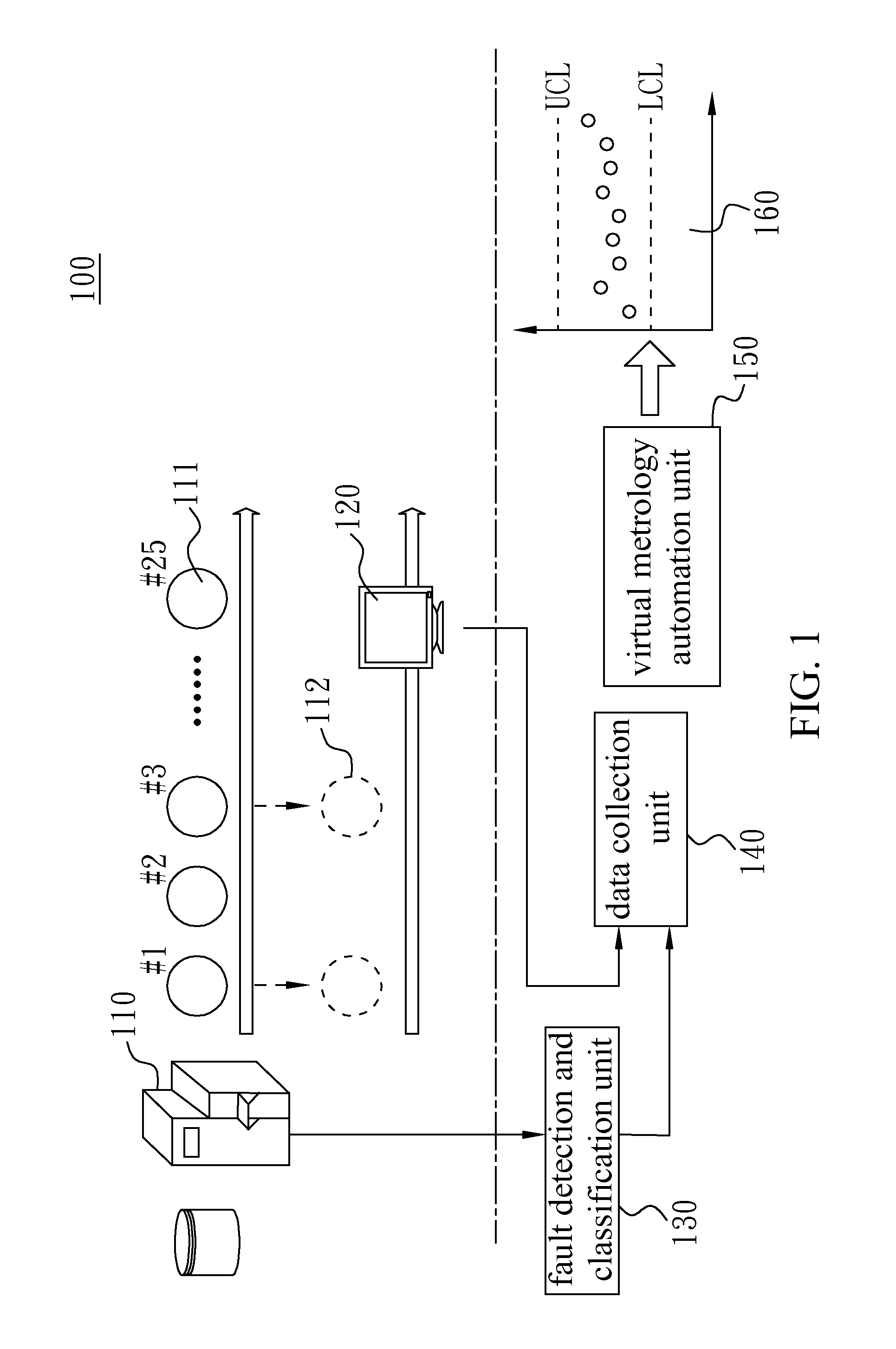

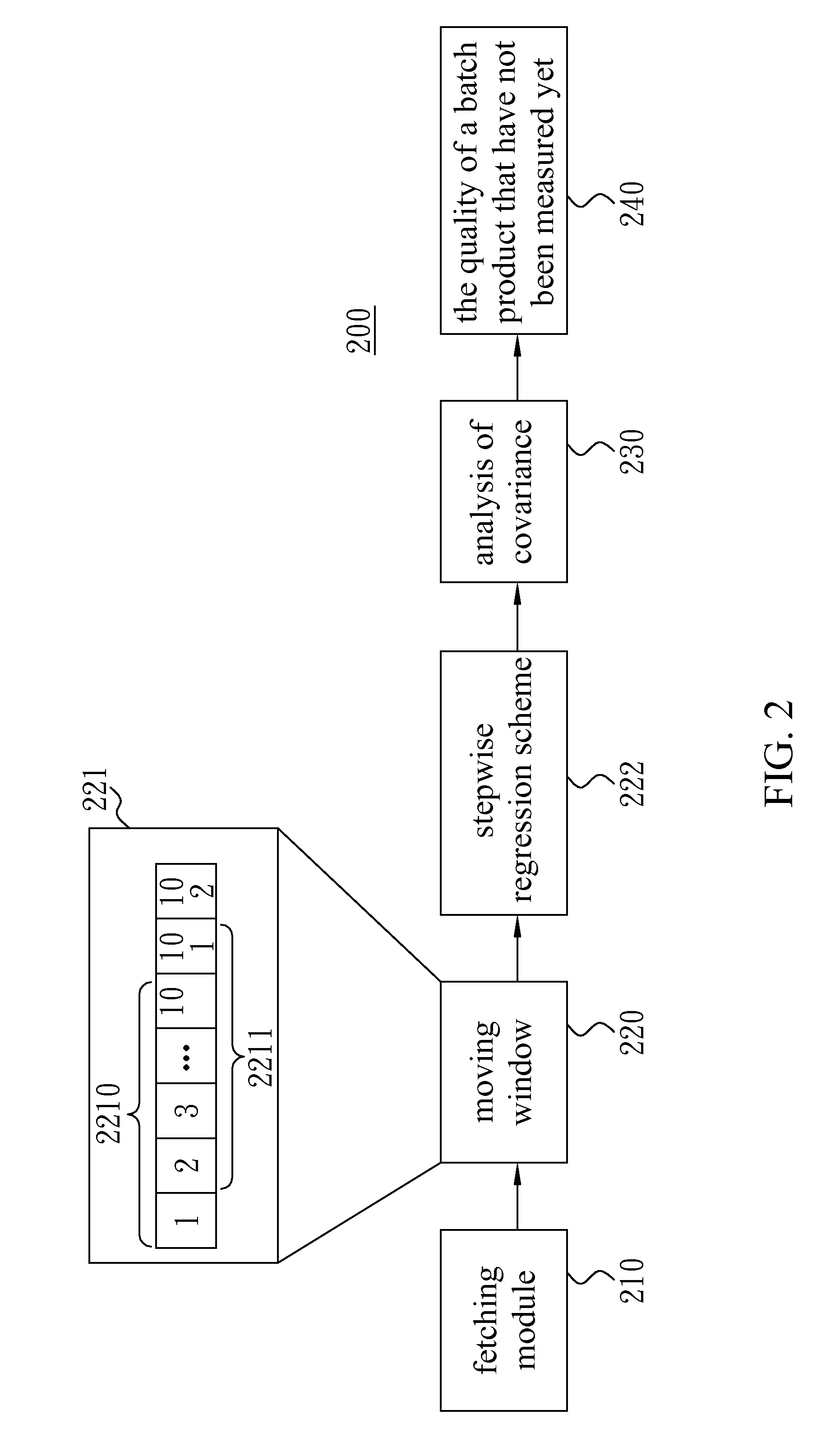

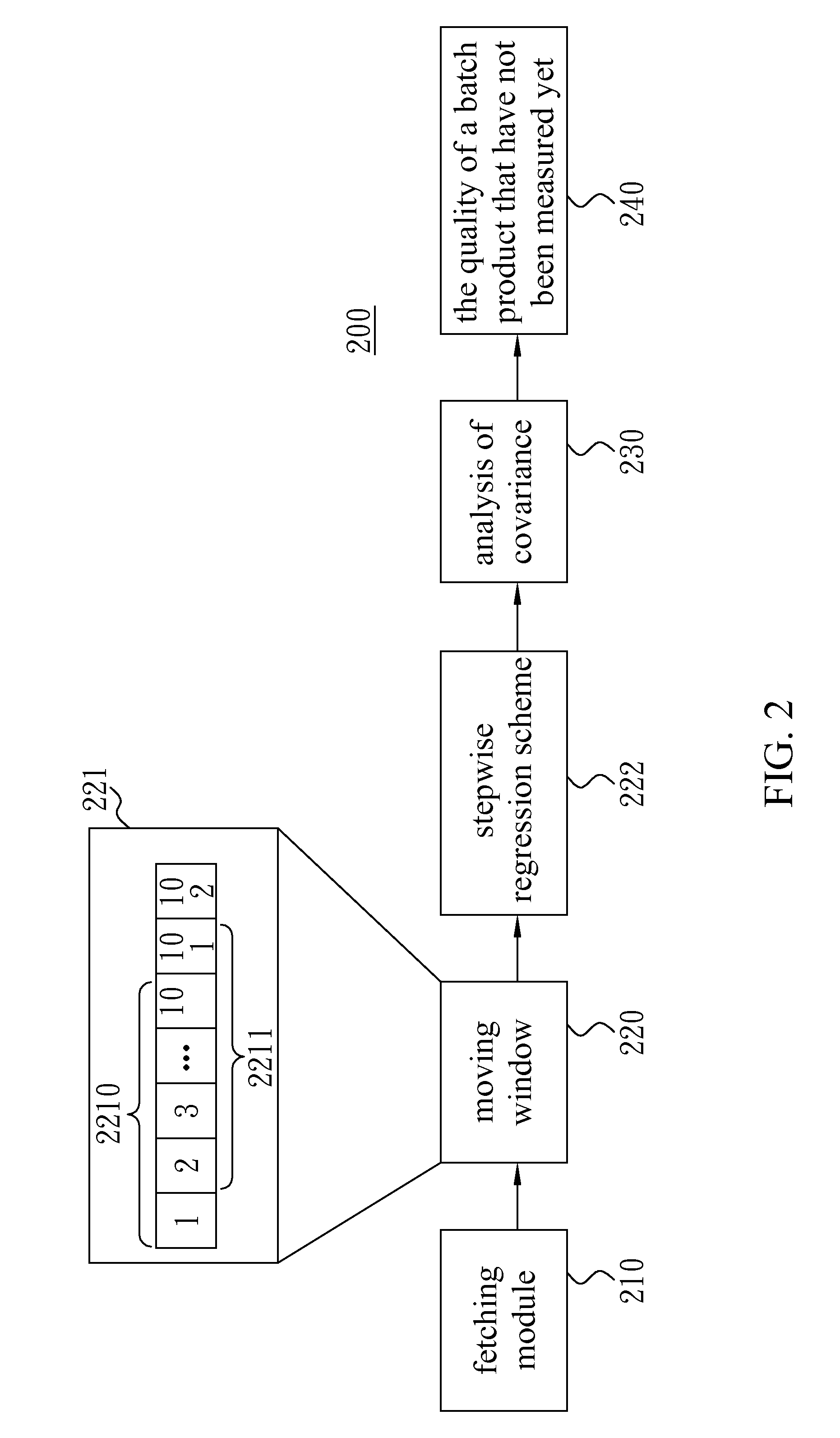

Process Quality Predicting System and Method Thereof

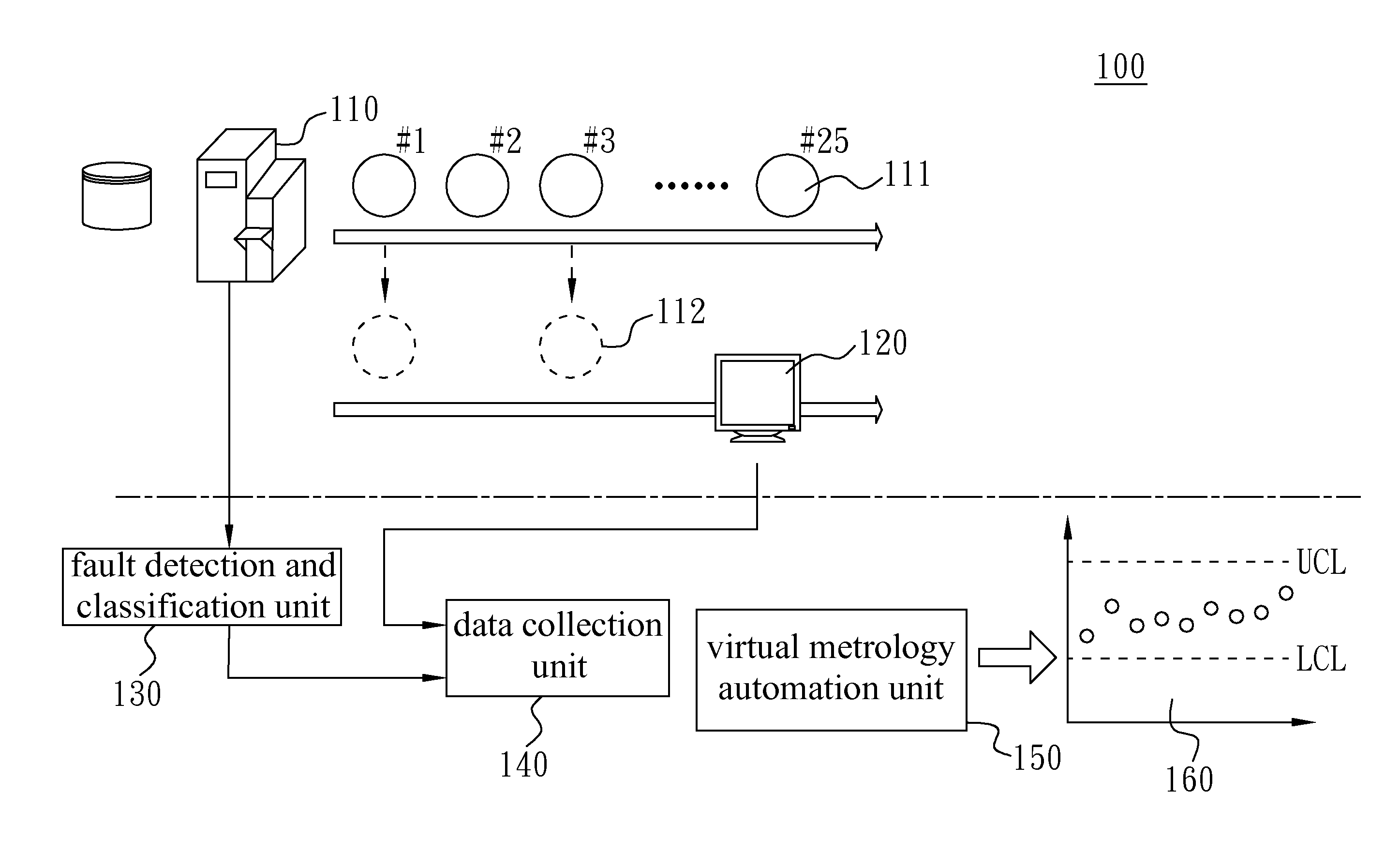

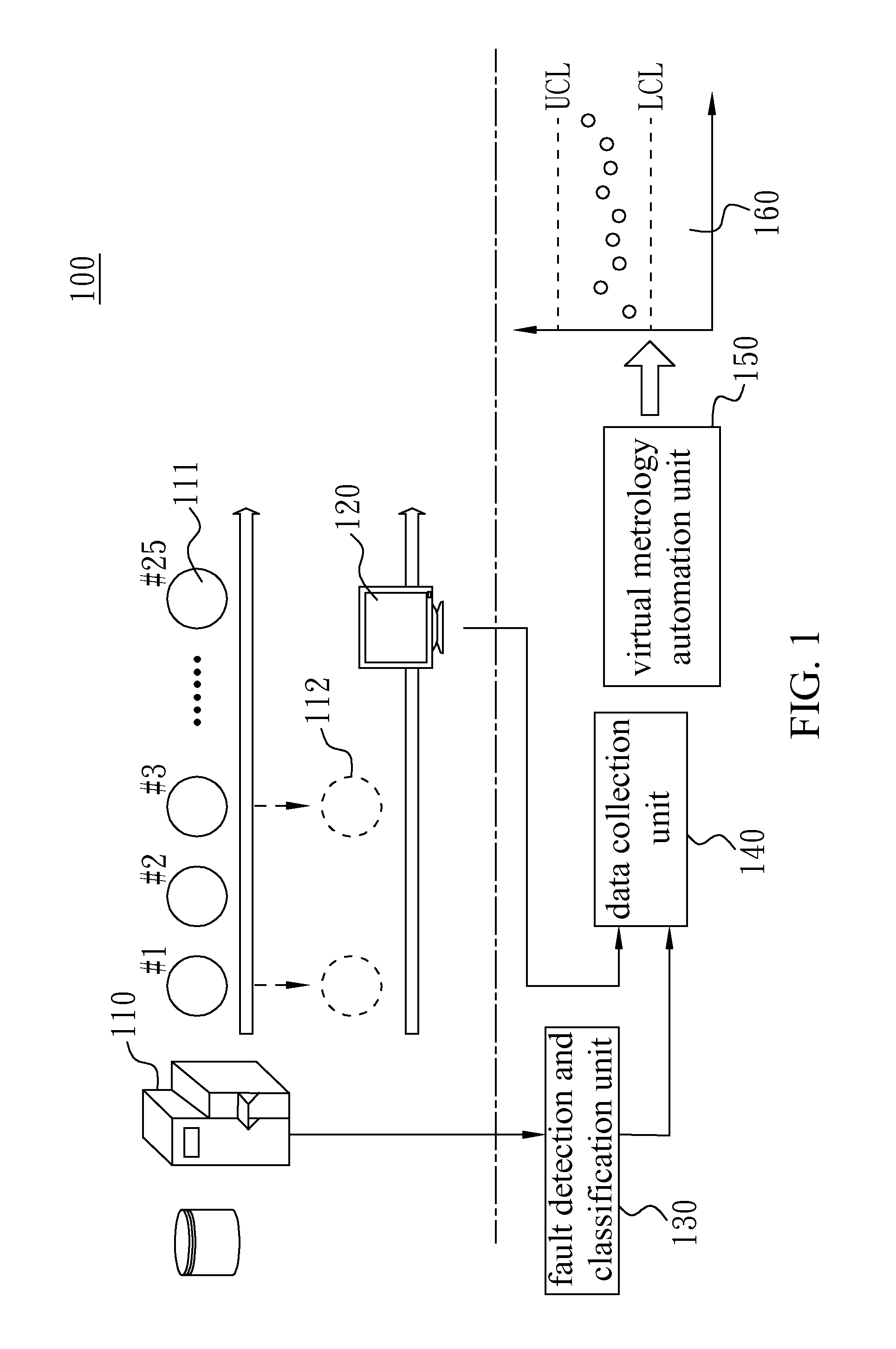

InactiveUS20110282480A1High precisionSpeed up the processTesting/monitoring control systemsComputation using non-denominational number representationProcess qualityMeasurement device

The invention discloses a process quality prediction system and a method thereof. When a processing apparatus performs a process on a target, the process is measured by a measurement apparatus to receive a process value. The process value and several previous quality data collected from the measurement apparatus are used to predict the quality of the product which is processing inline. The method is composed of a moving window, a stepwise regression scheme and an analysis of covariance (ANCOVA). The drift and shift of process are overcome by the moving window. A key variable set is selected by the stepwise regression scheme and a virtual model is identified by the analysis of covariance.

Owner:NATIONAL TSING HUA UNIVERSITY

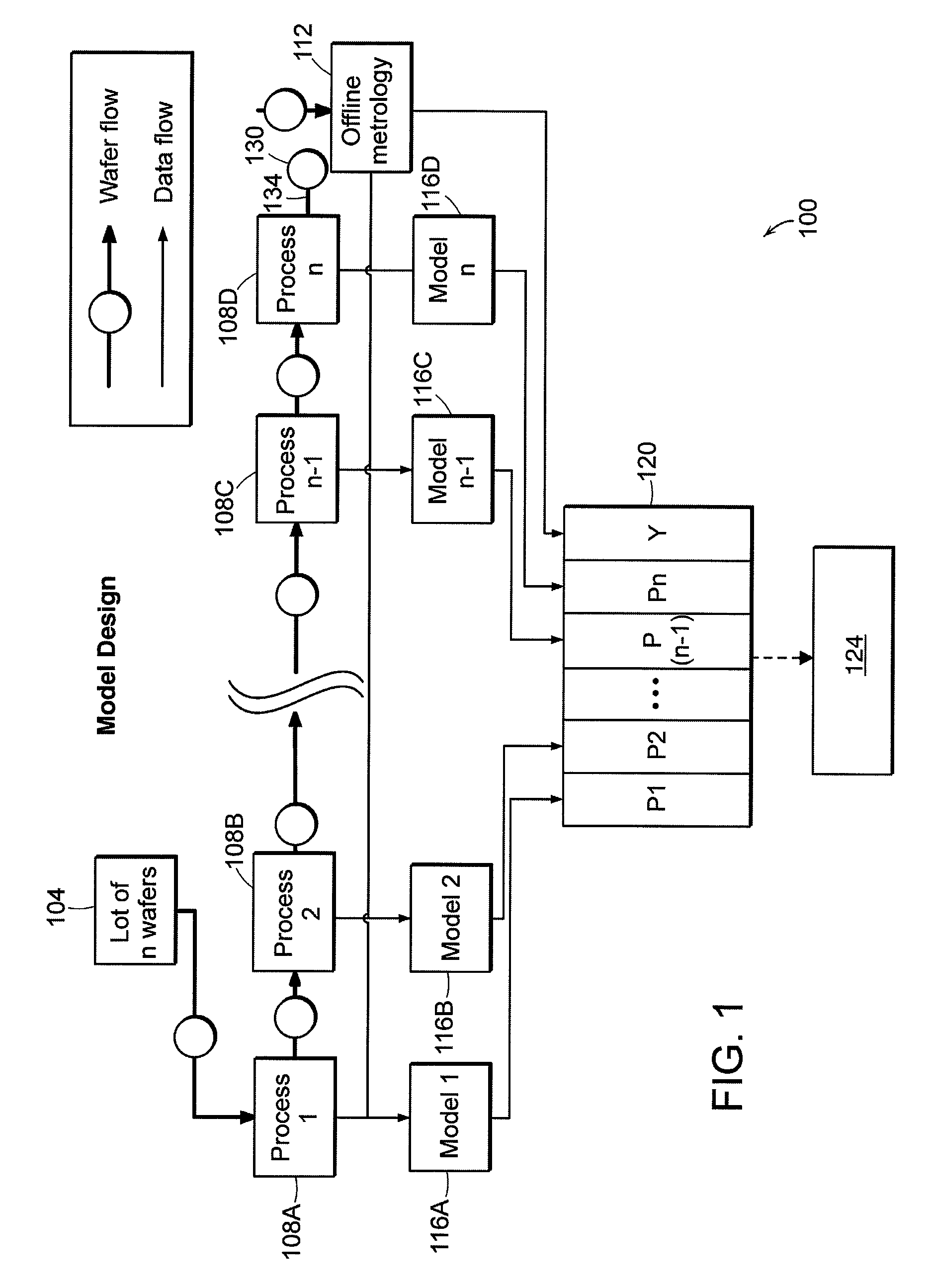

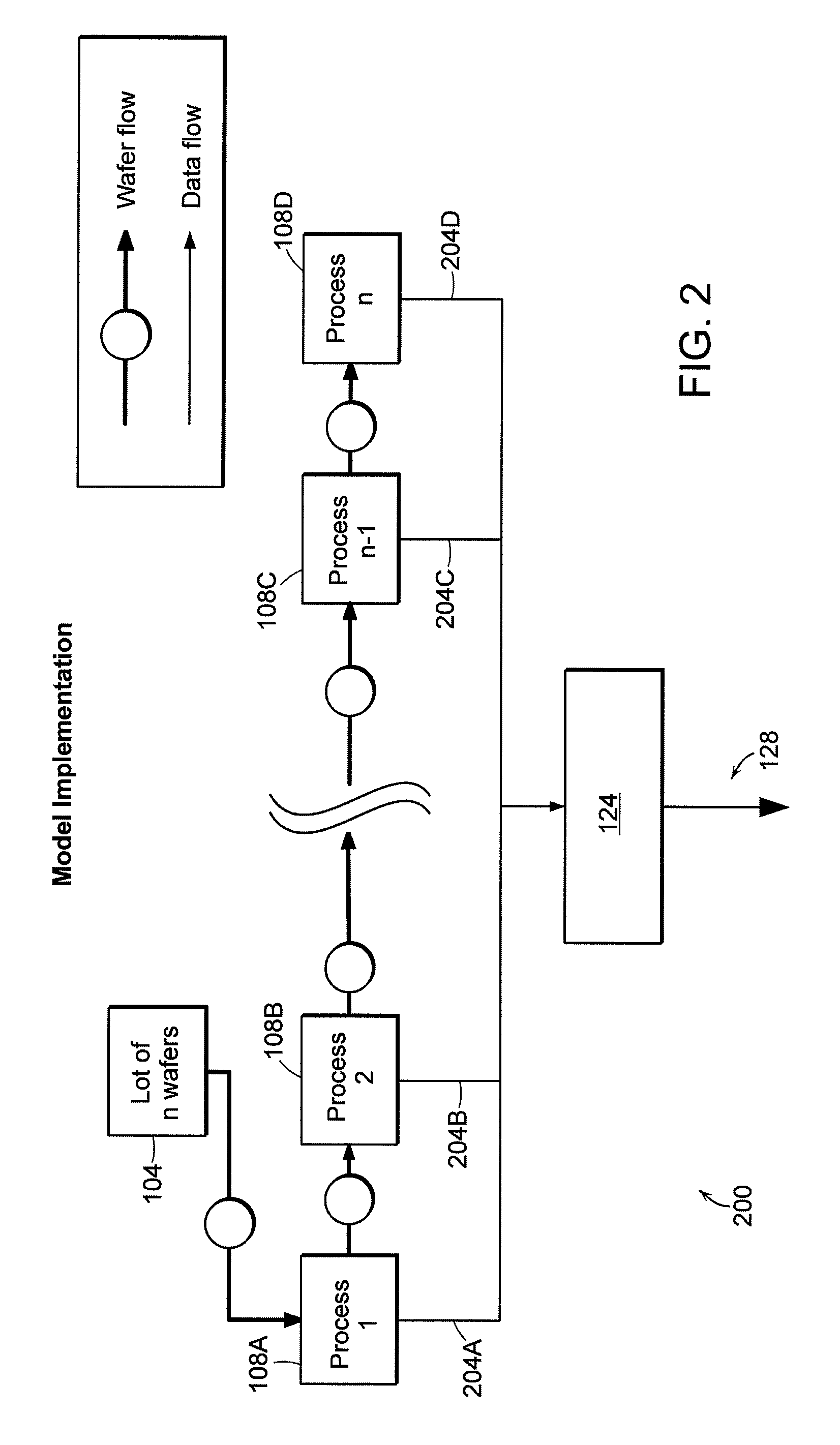

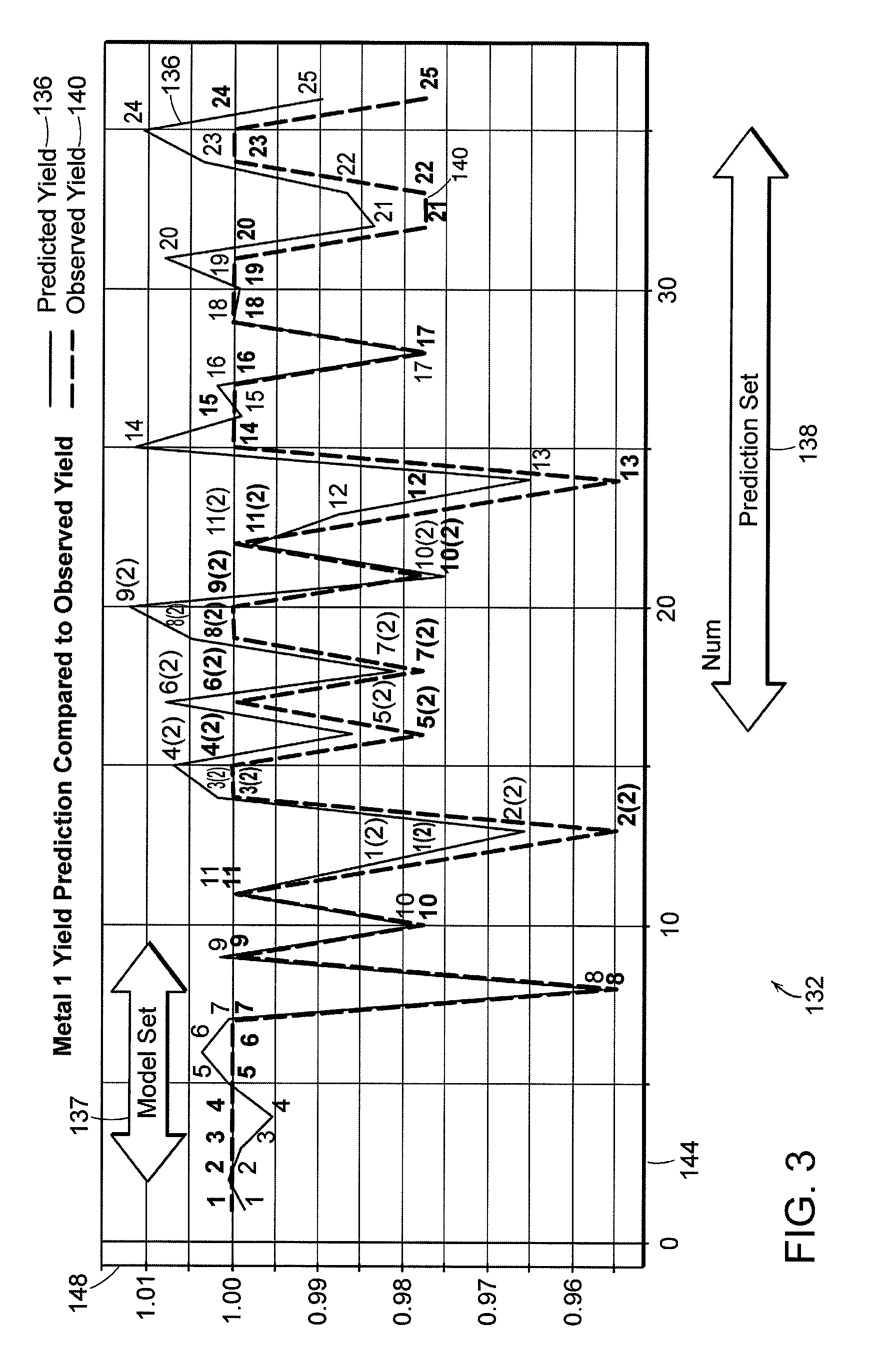

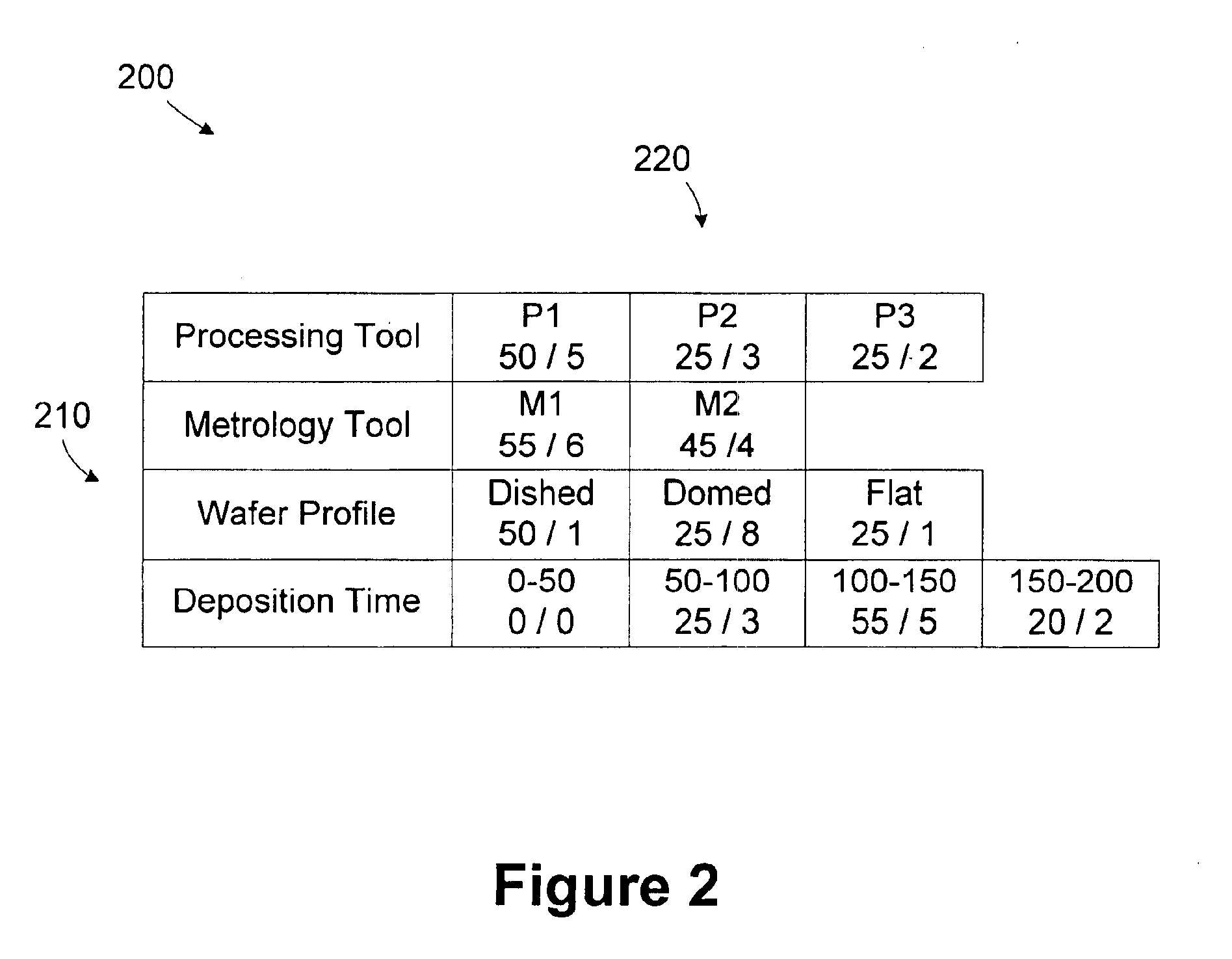

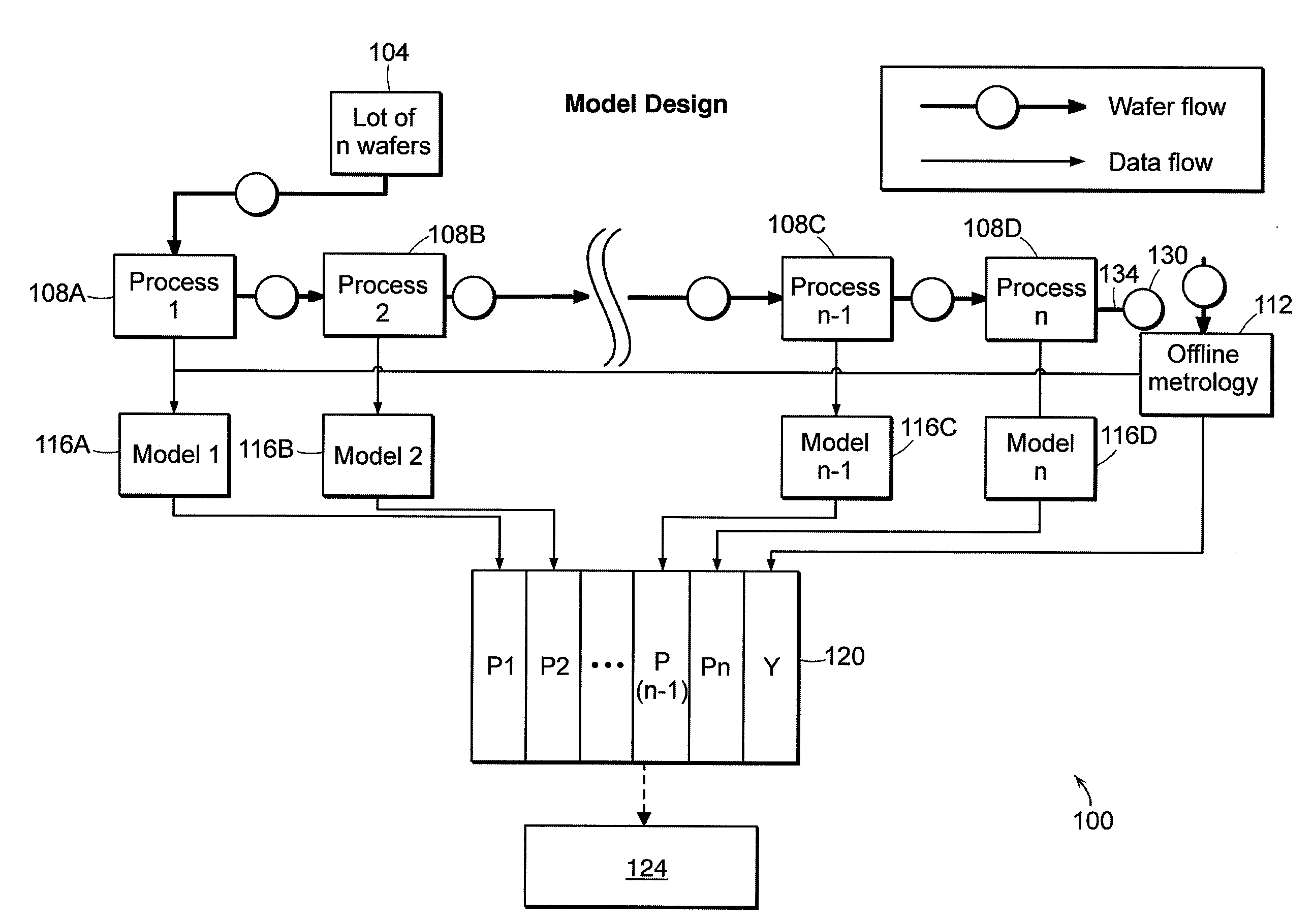

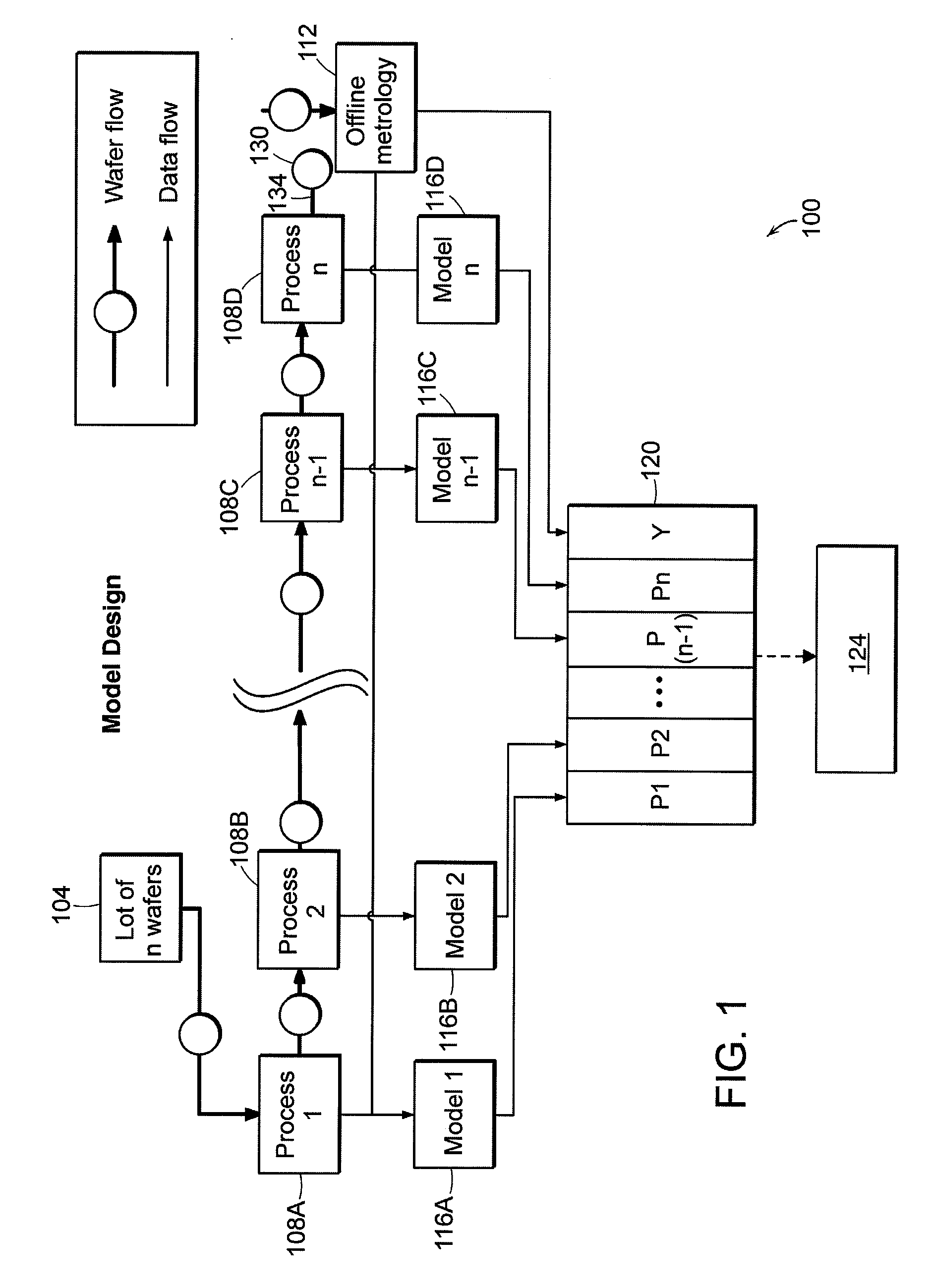

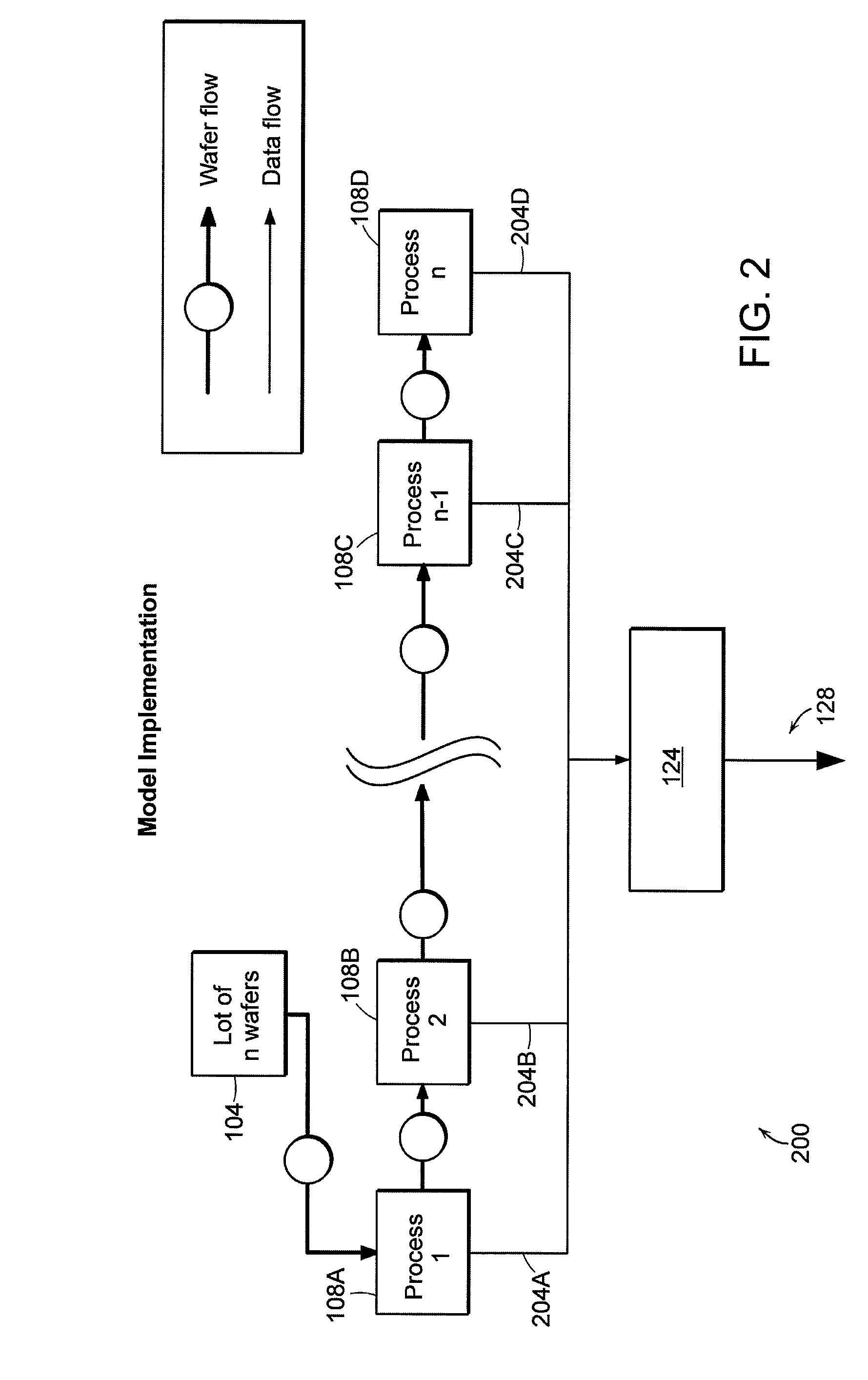

Process control using process data and yield data

ActiveUS7622308B2Semiconductor/solid-state device testing/measurementSimulator controlMetrologyMathematical model

A method for monitoring a manufacturing process features acquiring metrology data for semiconductor wafers at the conclusion of a final process step for the manufacturing process (“Step a”). Data is acquired for a plurality of process variables for a first process step for manufacturing semiconductor wafers (“Step b”). A first mathematical model of the first process step is created based on the metrology data and the acquired data for the plurality of process variables for the first process step (“Step c”). Steps b and c are repeated for at least a second process step for manufacturing the semiconductor wafers (“Step d”). An nth mathematical model is created based on the metrology data and the data for the plurality of process variables for each of the n process steps (“Step e”). A top level mathematical model is created based on the metrology data and the models created by steps c, d and e (“Step f”). The top level mathematical model of Step f is based on those process variables that have a substantial effect on the metrology data.

Owner:SARTORIUS STEDIM DATA ANALYTICS AB

Methods and apparatus for data analysis

InactiveUS20080189575A1Semiconductor/solid-state device testing/measurementElectronic circuit testingData analysisTest data

A method and apparatus for data analysis according to various aspects of the present invention is configured to automatically identify a characteristic of a component fabrication process guided by characteristics of the test data for the components.

Owner:TEST ADVANTAGE

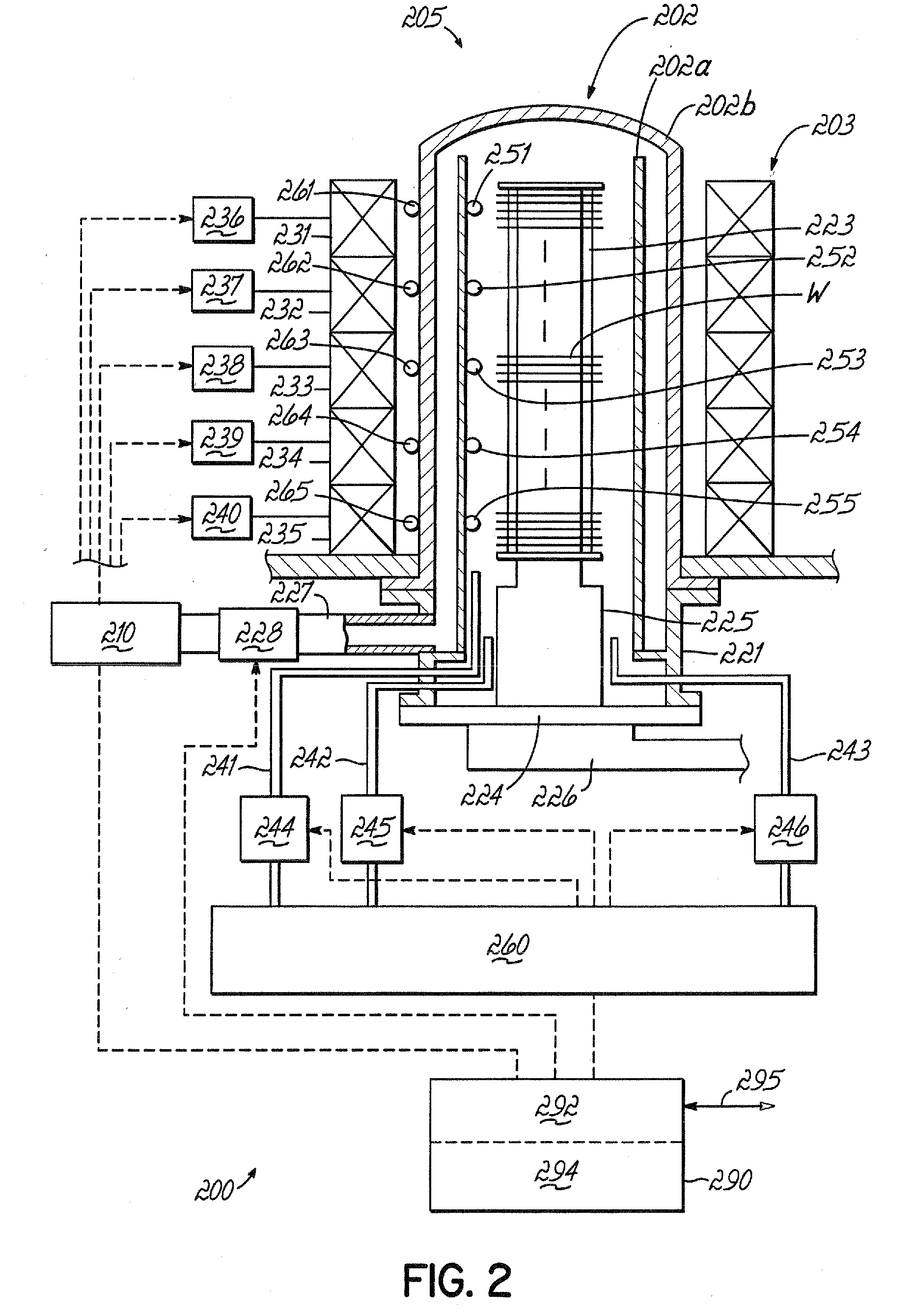

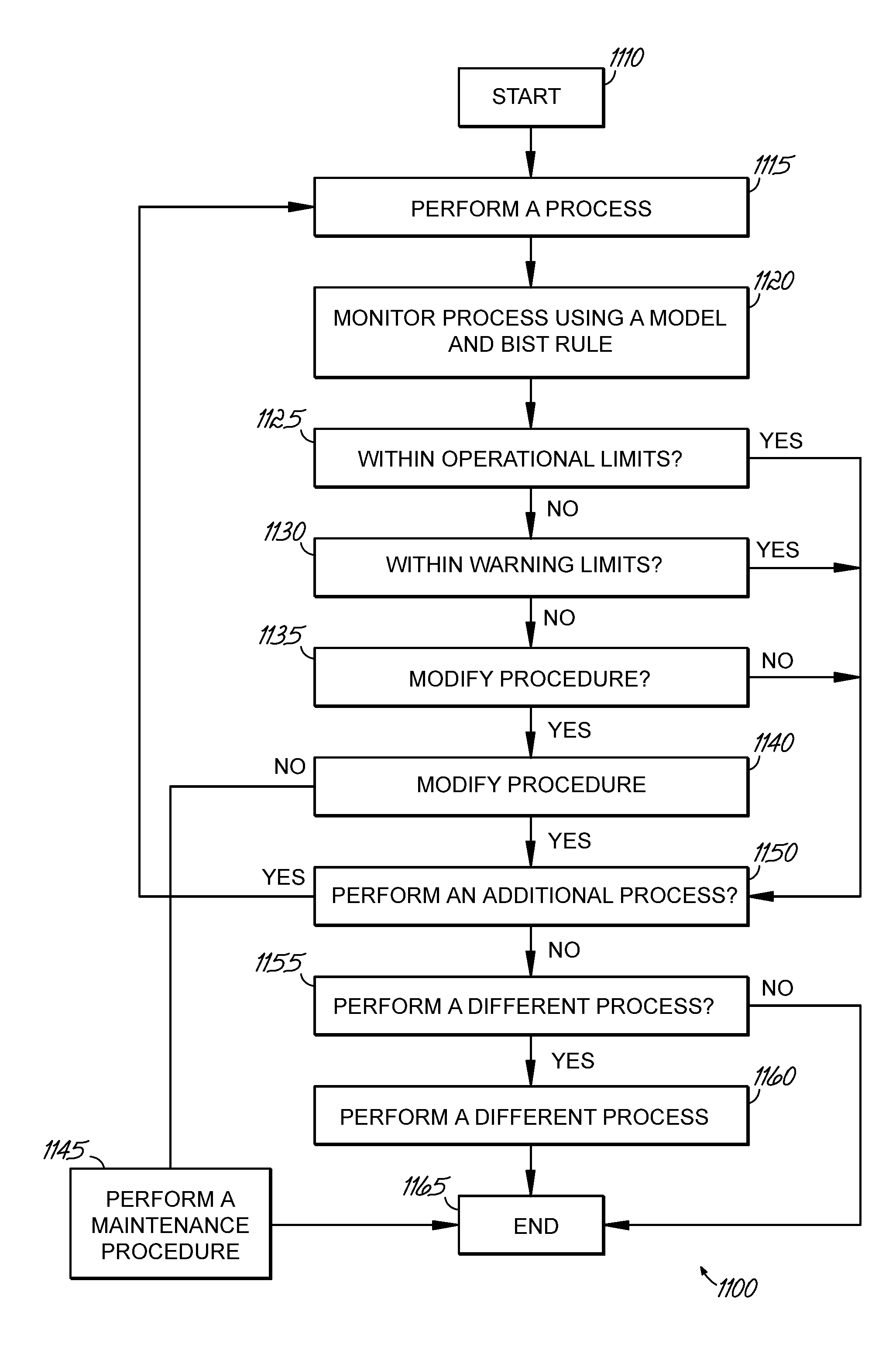

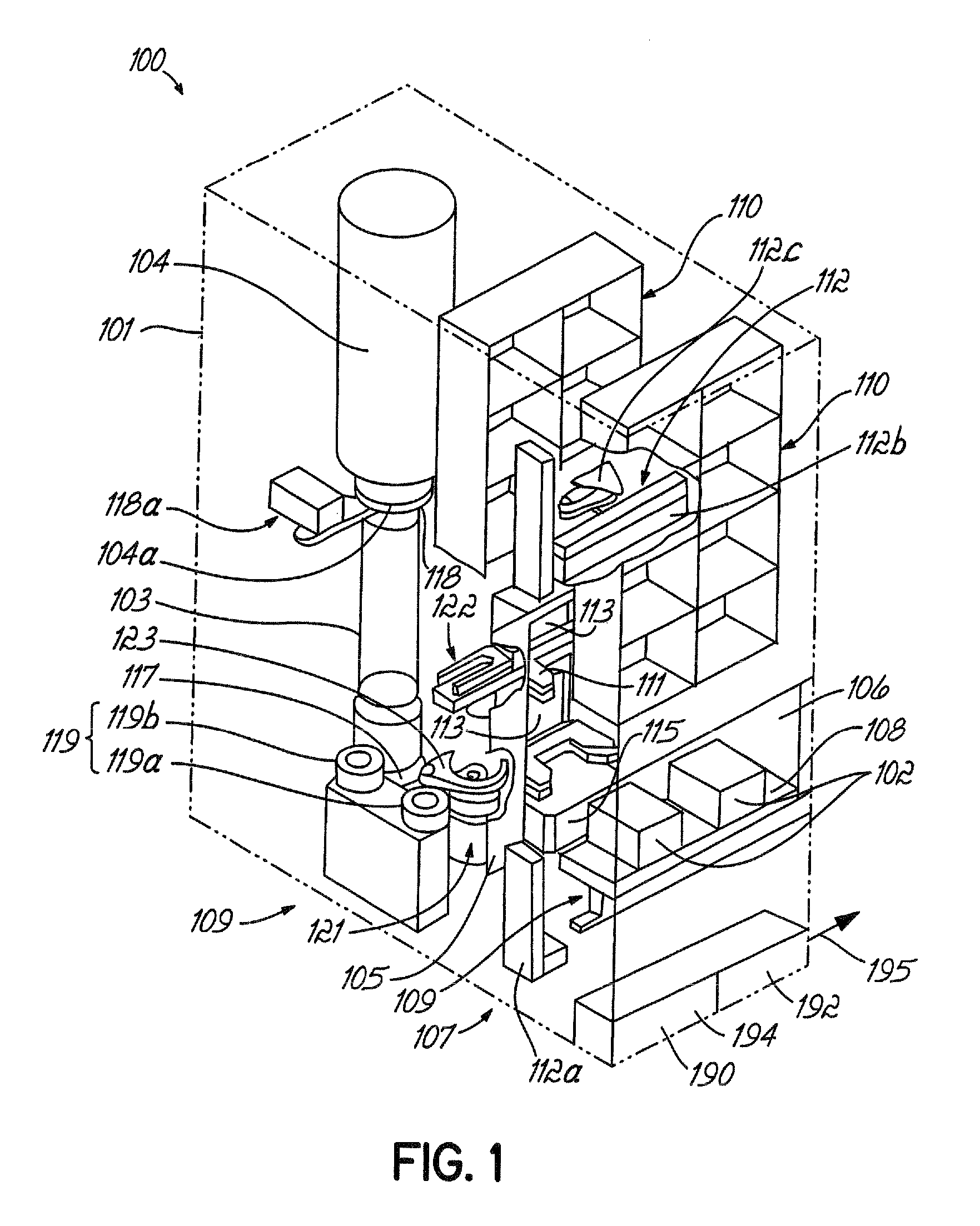

Monitoring a monolayer deposition (MLD) system using a built-in self test (BIST) table

InactiveUS20070234953A1Reduce pressureLower performance requirementsLiquid surface applicatorsSemiconductor/solid-state device testing/measurementDynamic modelsTime dynamics

A method of monitoring a processing system in real-time using low-pressure based modeling techniques that include processing one or more of wafers in a processing chamber; determining a measured dynamic process response for a rate of change for a process parameter; executing a real-time dynamic model to generate a predicted dynamic process response; determining a dynamic estimation error using a difference between the predicted dynamic process response and the expected process response; and comparing the dynamic estimation error to operational limits.

Owner:TOKYO ELECTRON LTD

Methods and Apparatus for Data Analysis

InactiveUS20160026915A1Detecting faulty hardware using neural networksSemiconductor/solid-state device testing/measurementData profilingMachine learning

A method and apparatus for data analysis according to various aspects of the present invention is configured to test a set of components and generate test data for the components. A diagnostic system automatically analyzes the test data to identify a characteristic of a component fabrication process by recognizing a pattern in the test data and classifying the pattern using a neural network.

Owner:IN DEPTH TEST

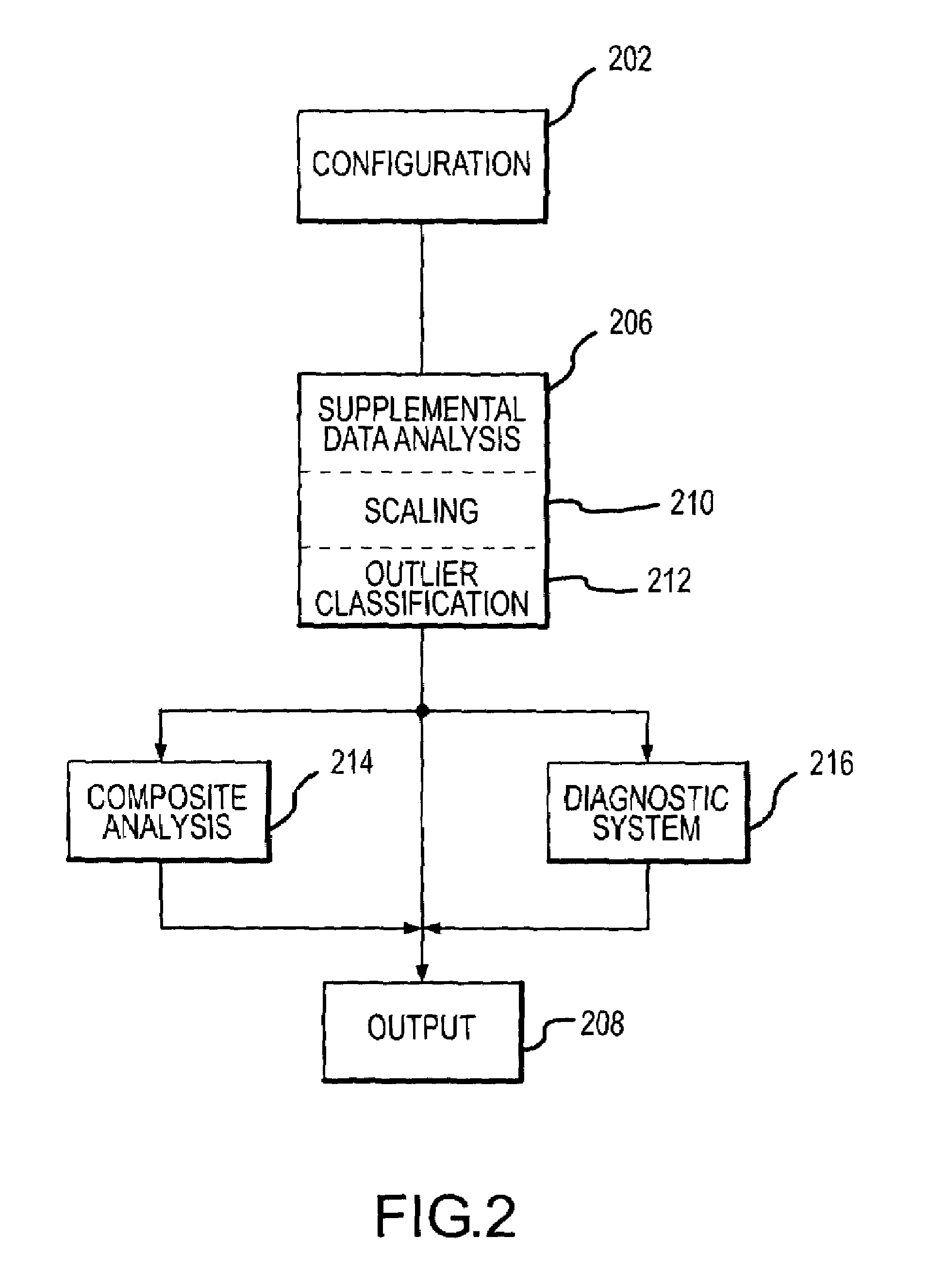

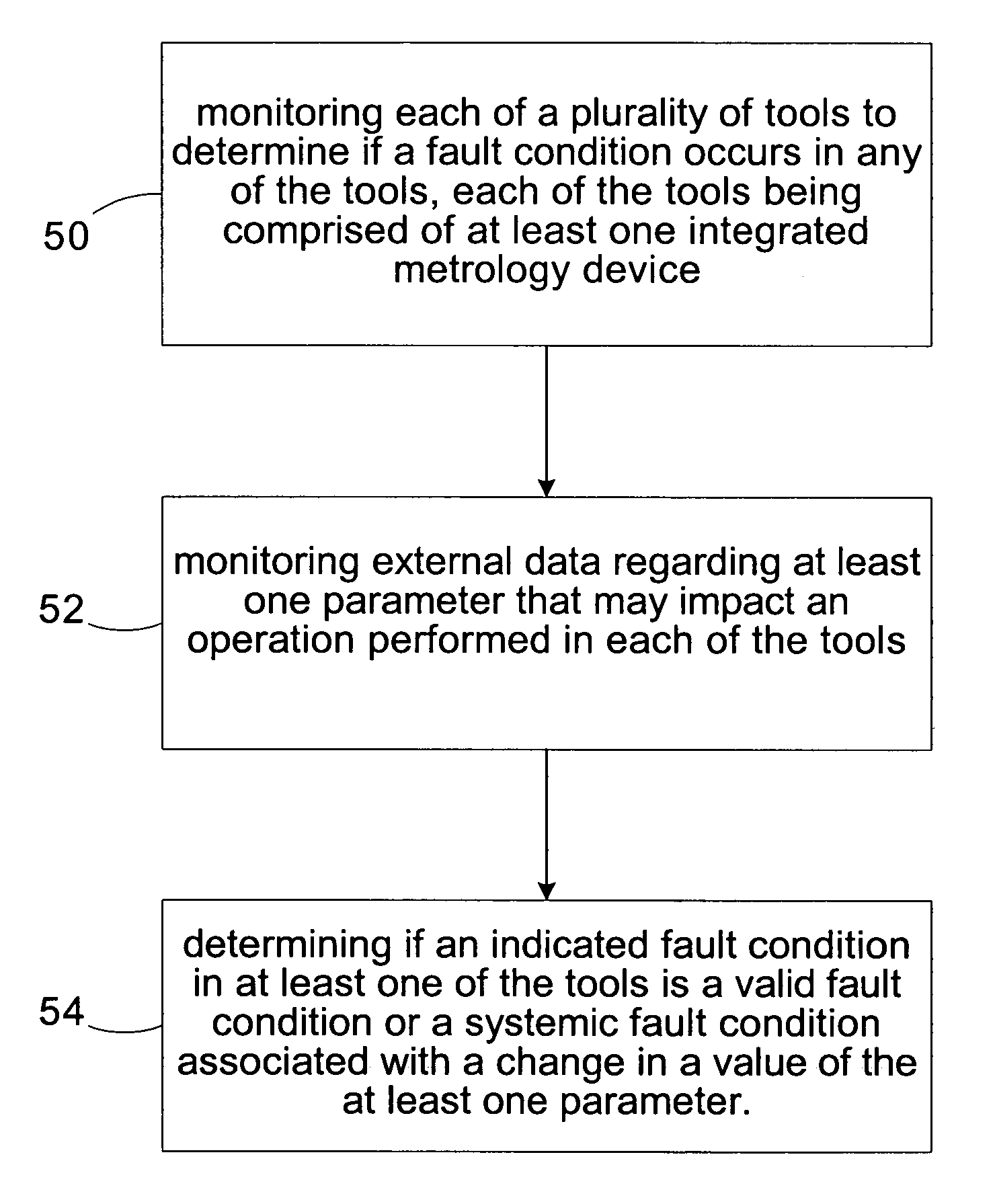

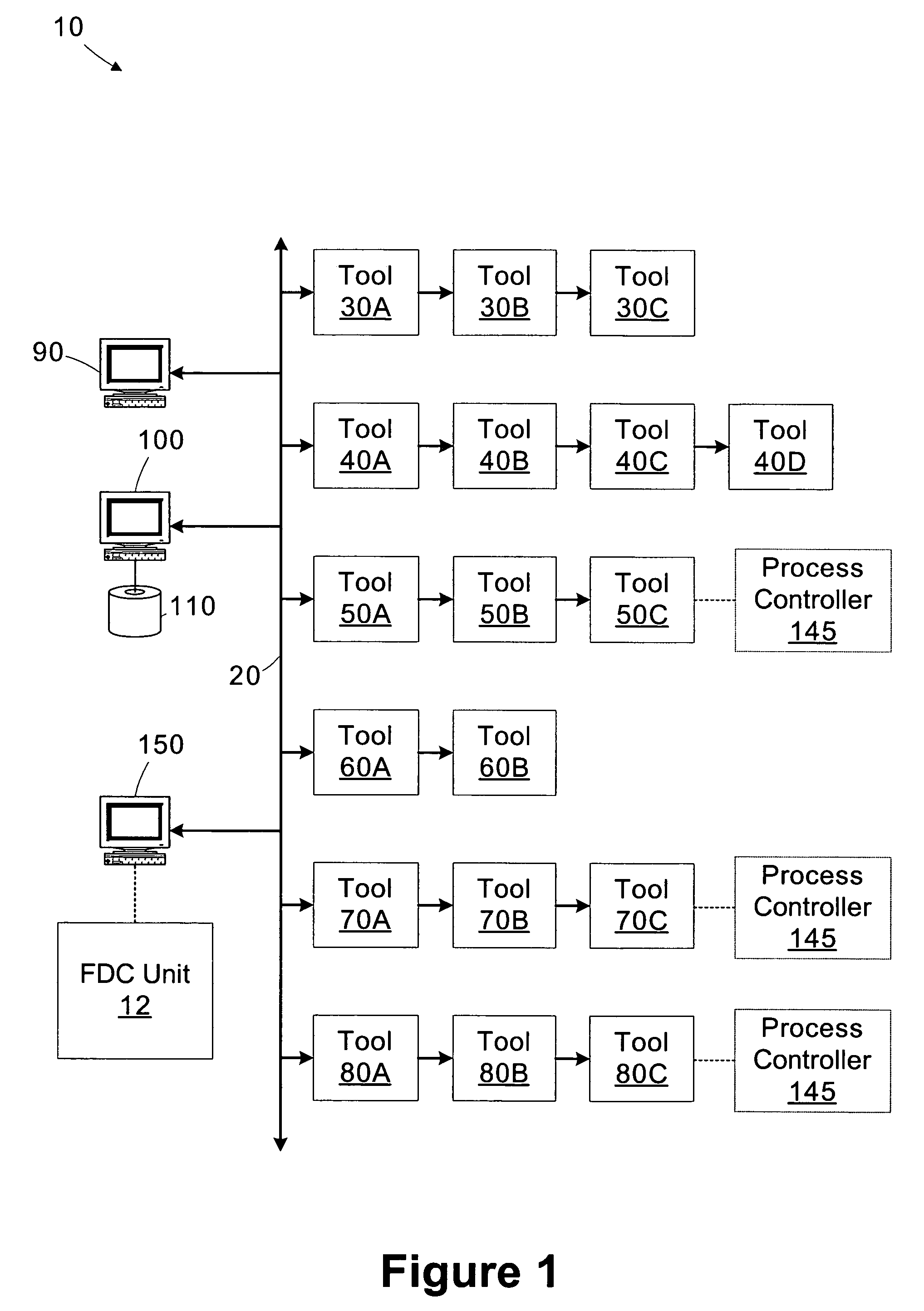

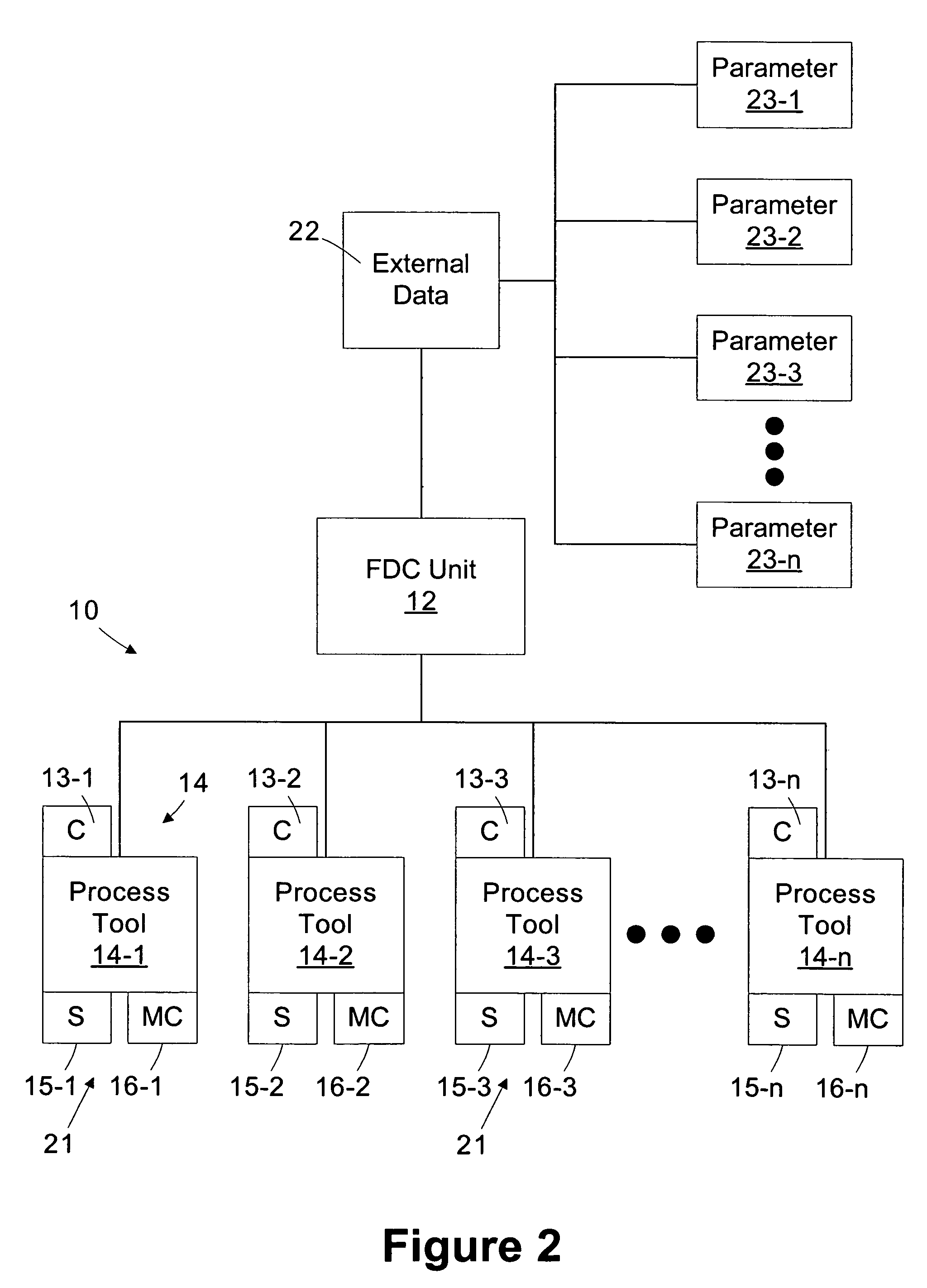

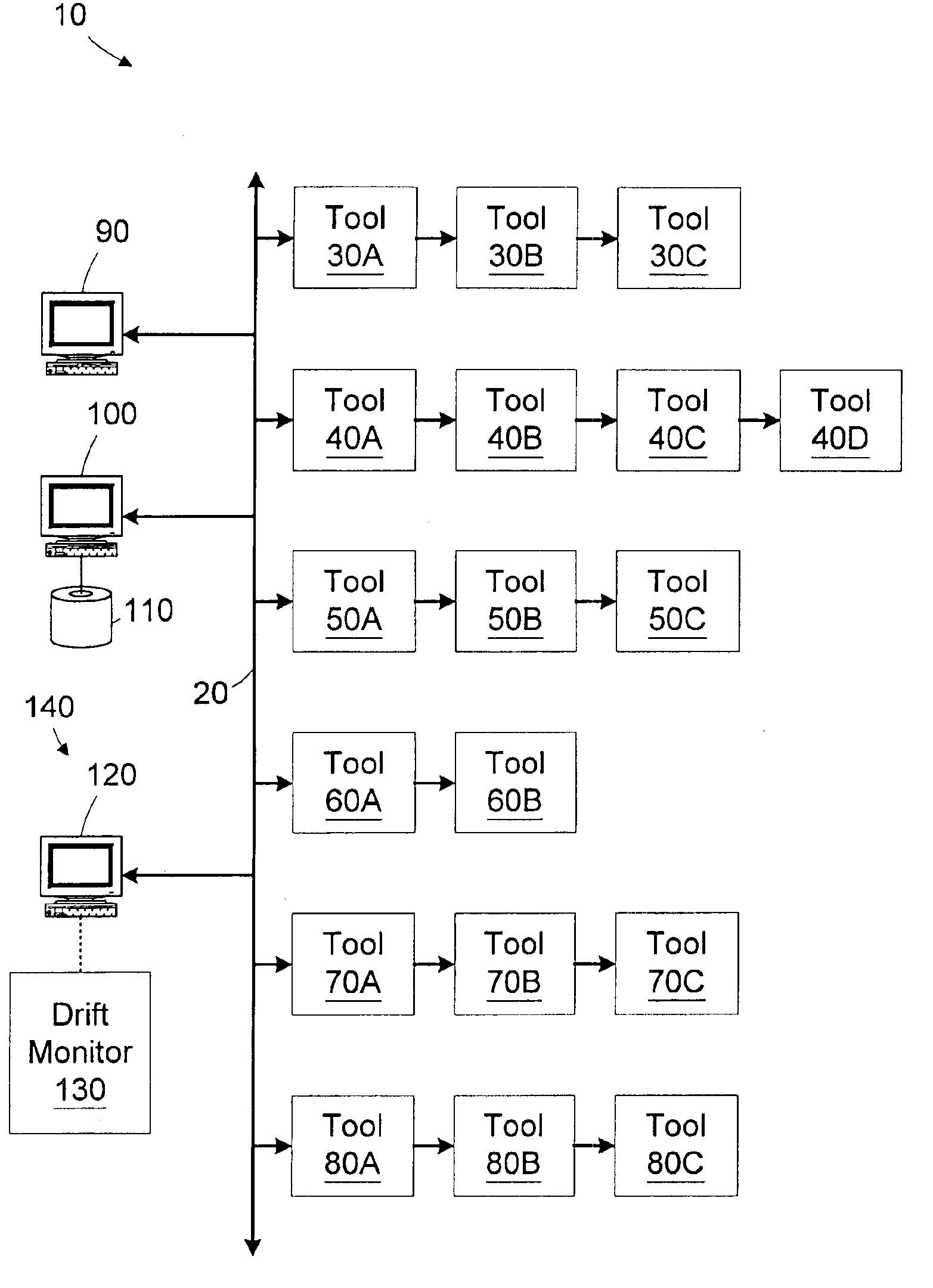

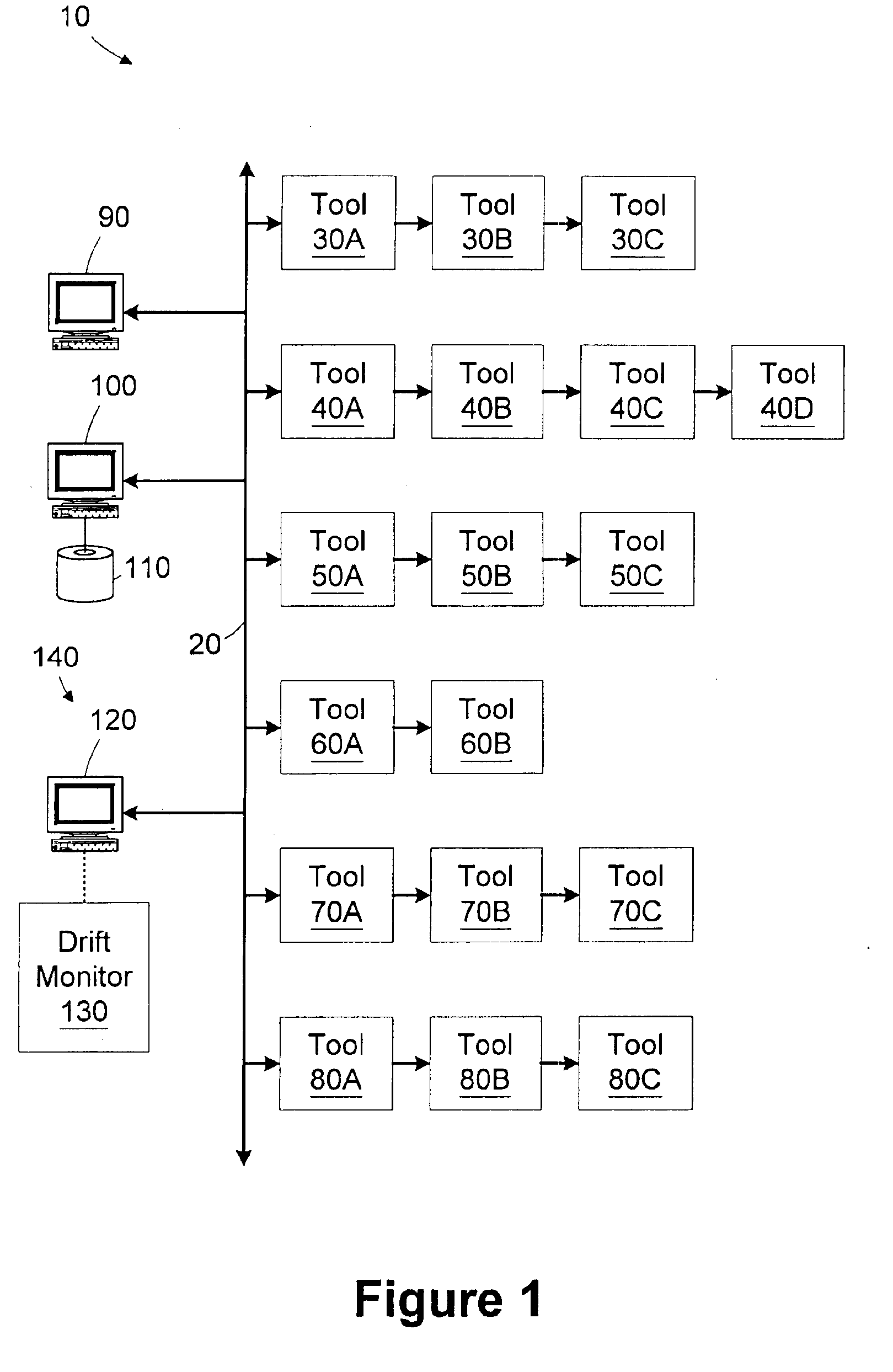

Method and apparatus for fault detection classification of multiple tools based upon external data

The present invention is generally directed to various methods and systems for fault detection control of multiple tools based upon external data. In one illustrative embodiment, the method includes monitoring each of a plurality of tools to determine if a fault condition occurs in any of the tools, each of the tools being comprised of at least one integrated metrology device, monitoring external data regarding at least one parameter that may impact an operation performed in each of the tools, and determining if an indicated fault condition in at least one of the tools is a valid fault condition or a systemic fault condition associated with a change in a value of the at least one parameter.

Owner:ADVANCED MICRO DEVICES INC

Methods and apparatus for data analysis

InactiveUS20100088054A1Semiconductor/solid-state device testing/measurementElectronic circuit testingComputer scienceData analysis

A method and apparatus for data analysis according to various aspects of the present invention is configured to automatically identify a characteristic of a component fabrication process guided by characteristics of the test data for the components.

Owner:TEST ADVANTAGE

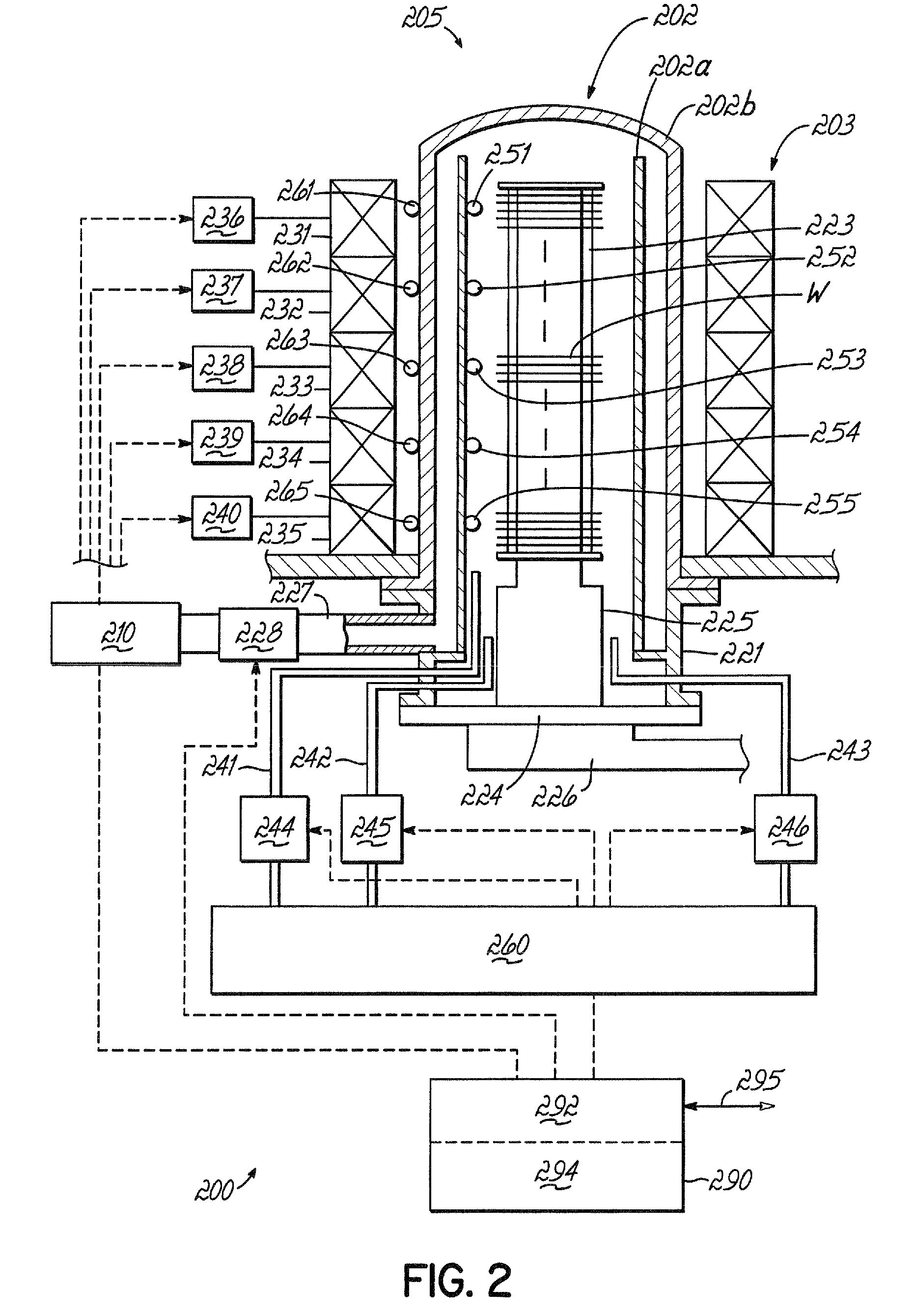

Manufacturing execution system for validation, quality and risk assessment and monitoring of pharmaceutical manufacturing processes

ActiveUS20080038833A1Quality improvementImprove productivityComponent separationDrug and medicationsManufacture execution systemQuality assurance

Manufacturing execution systems relating to methods, systems, and software program for validation of pharmaceutical manufacturing processes and quality assurance process are described and disclosed herein. Consequently, the methods provide a means to perform validation on an integrated level whereby the quality control unit can ensure data and product integrity and minimize cost.

Owner:SMP LOGIC SYST

Method and apparatus for distinguishing between sources of process variation

InactiveUS6901340B1Electric testing/monitoringSemiconductor/solid-state device manufacturingAmbient dataDatabase server

A method for distinguishing between sources of process variation includes processing a plurality of manufactured items in a process flow; storing a set of production environment data associated with each of the manufactured items; identifying manufactured items associated with a process drift; generating a plurality of characteristic threads based on the production environment data; comparing the characteristic threads for at least those manufactured items associated with the process drift; and determining at least one potential cause for the process drift based on the comparison of the characteristic threads. A manufacturing system for distinguishing between sources of process variation is also provided. The manufacturing system includes a plurality of tools for processing manufactured items in a process flow, a database server, and a drift monitor.

Owner:ADVANCED MICRO DEVICES INC

Process Control Using Process Data and Yield Data

ActiveUS20090228247A1Semiconductor/solid-state device testing/measurementSimulator controlMetrologyMathematical model

A method for monitoring a manufacturing process features acquiring metrology data for semiconductor wafers at the conclusion of a final process step for the manufacturing process (“Step a”). Data is acquired for a plurality of process variables for a first process step for manufacturing semiconductor wafers (“Step b”). A first mathematical model of the first process step is created based on the metrology data and the acquired data for the plurality of process variables for the first process step (“Step c”). Steps b and c are repeated for at least a second process step for manufacturing the semiconductor wafers (“Step d”). An nth mathematical model is created based on the metrology data and the data for the plurality of process variables for each of the n process steps (“Step e”). A top level mathematical model is created based on the metrology data and the models created by steps c, d and e (“Step f”). The top level mathematical model of Step f is based on those process variables that have a substantial effect on the metrology data.

Owner:SARTORIUS STEDIM DATA ANALYTICS AB

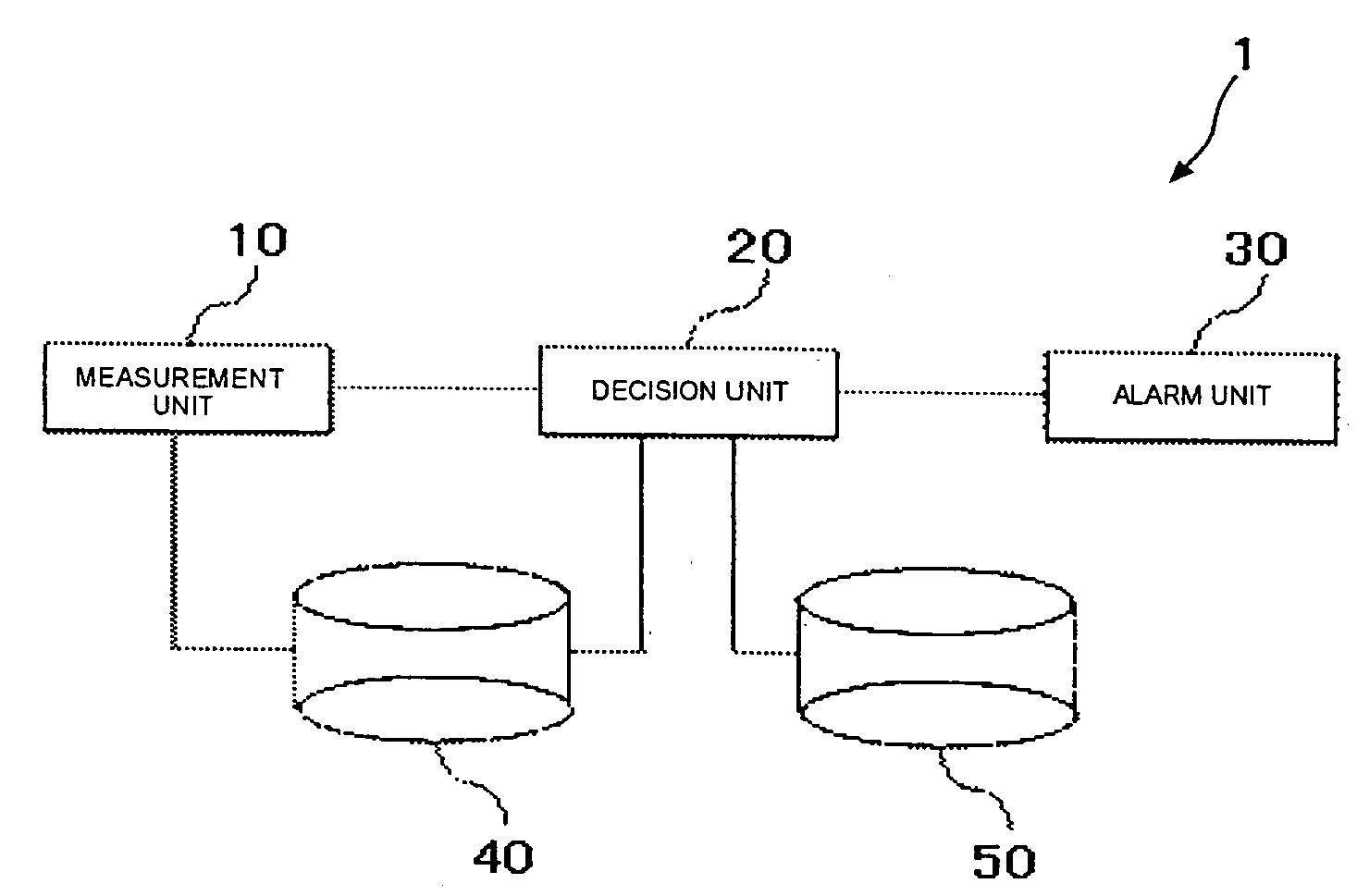

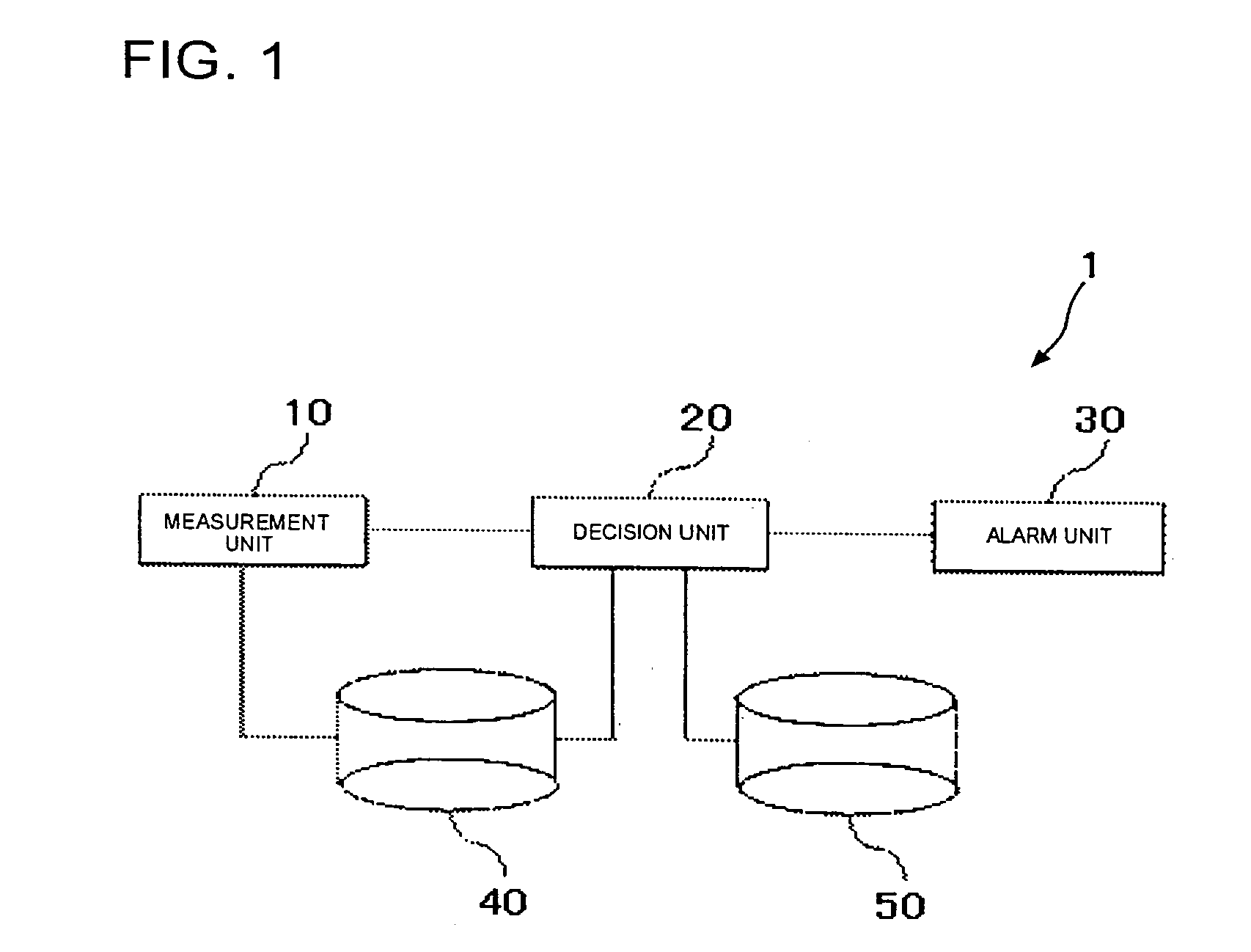

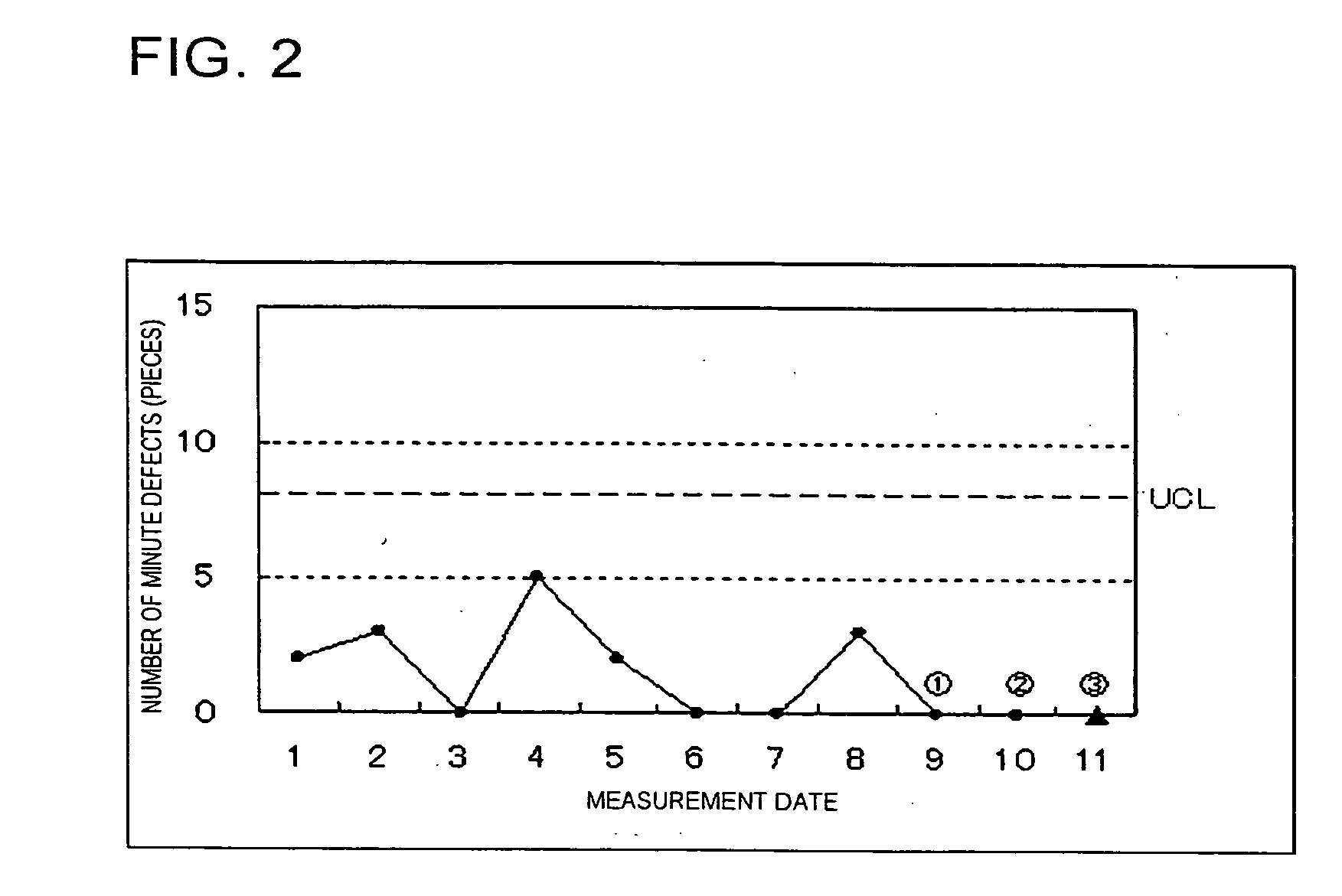

Abnormality detection system and method of detecting abnormality

ActiveUS20070203603A1High detection sensitivityInhibitionTesting/monitoring control systemsElectrical testingAnomaly detectionEngineering

An abnormality detection system includes a measurement unit, a decision unit, an alarm unit, and storage units, and serves to detect the abnormality in a control characteristic value of a plurality of products manufactured on the same production line. The decision unit receives the control characteristic value stored in the storage unit, and decides whether an abnormality exists, based on that value. More specifically, the decision unit decides that the control characteristic value is abnormal when, with respect to m (m is a natural number) pieces of the products that are consecutively manufactured, an absolute value of a difference in control characteristic value between each of the products and another manufactured immediately before the former is equal to or less than a predetermined constant.

Owner:RENESAS ELECTRONICS CORP +1

Manufacturing execution system for validation, quality and risk assessment and monitoring of pharamaceutical manufacturing processes

ActiveUS20070032897A1Quality improvementImprove productivityDrug and medicationsTechnology managementManufacture execution systemQuality assurance

Manufacturing execution systems relating to methods, systems, and software program for validation of pharmaceutical manufacturing processes and quality assurance process are described and disclosed herein. Consequently, the methods provide a means to perform validation on an integrated level whereby the quality control unit can ensure data and product integrity and minimize cost.

Owner:SMP LOGIC SYST

Monitoring a monolayer deposition (MLD) system using a built-in self test (BIST) table

InactiveUS7519885B2Liquid surface applicatorsSemiconductor/solid-state device testing/measurementDynamic modelsBuilt-in self-test

Owner:TOKYO ELECTRON LTD

Methods, systems, and software program for validation and monitoring of pharmaceutical manufacturing processes

ActiveUS20060271227A1Testing/monitoring control systemsResourcesQuality assuranceSoftware engineering

Methods, systems, and software program for validation of pharmaceutical manufacturing processes and quality assurance process are described and disclosed herein. Consequently, the methods provide a means to perform validation on an integrated level whereby the quality control unit can ensure data and product integrity and minimize cost.

Owner:SMP LOGIC SYST

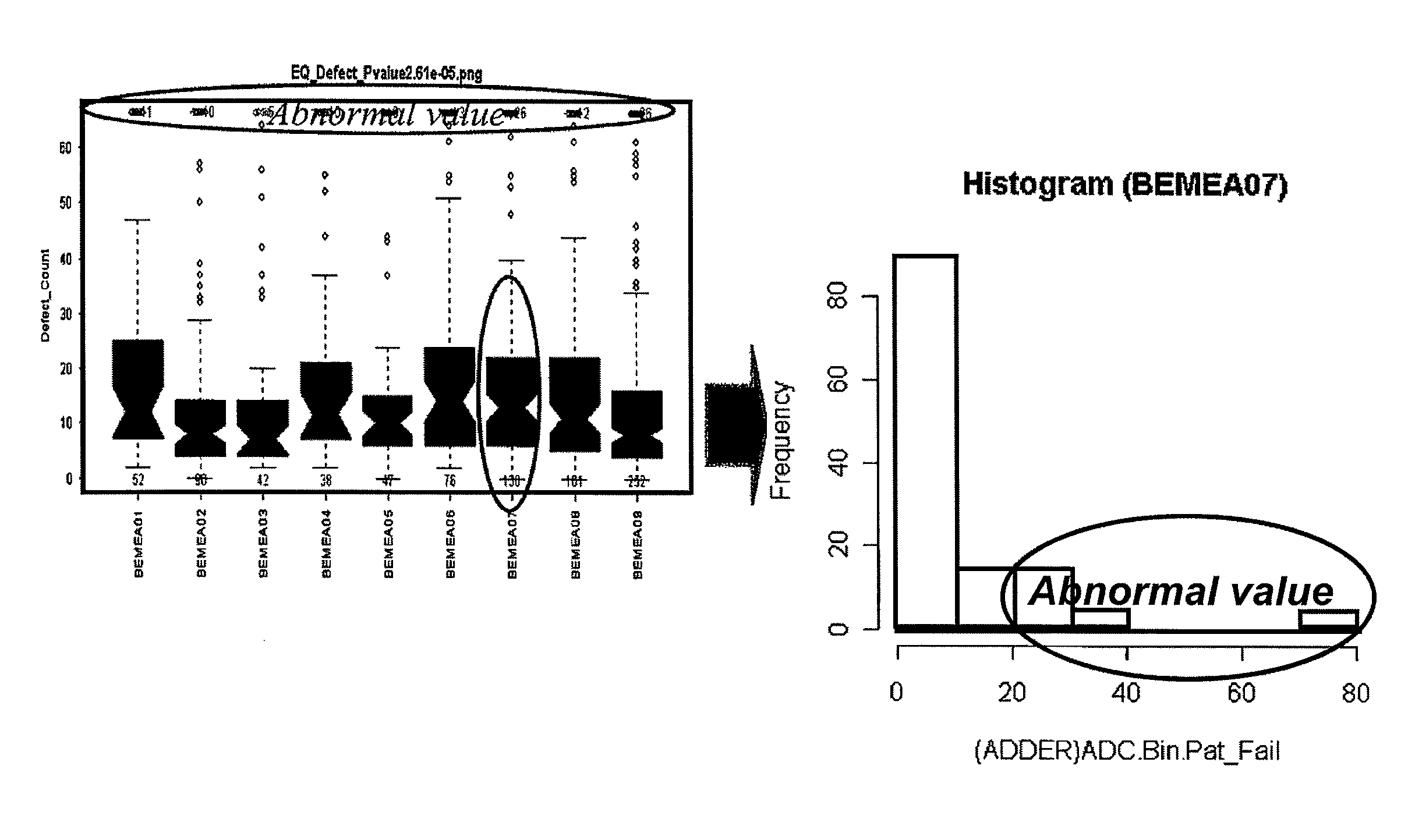

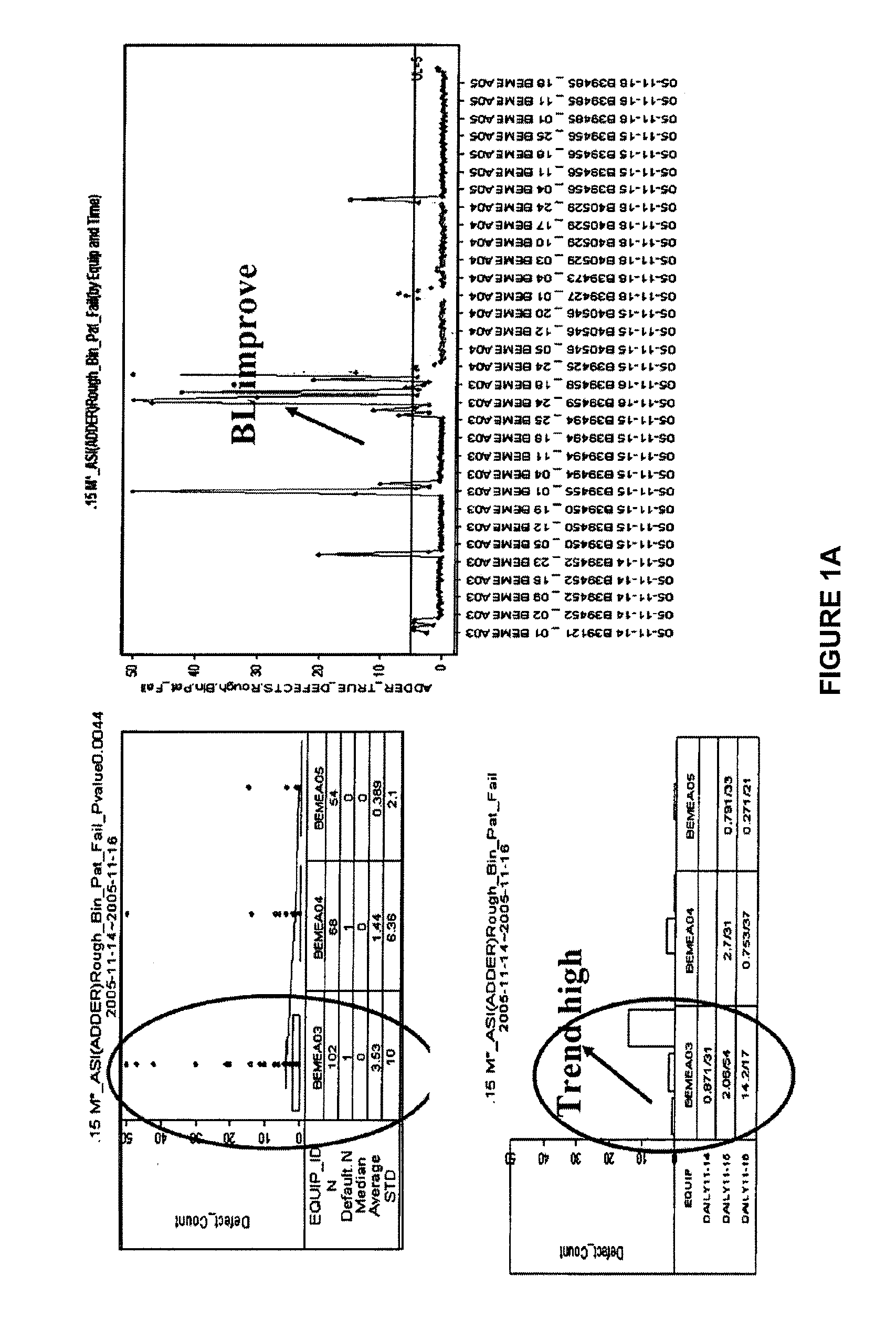

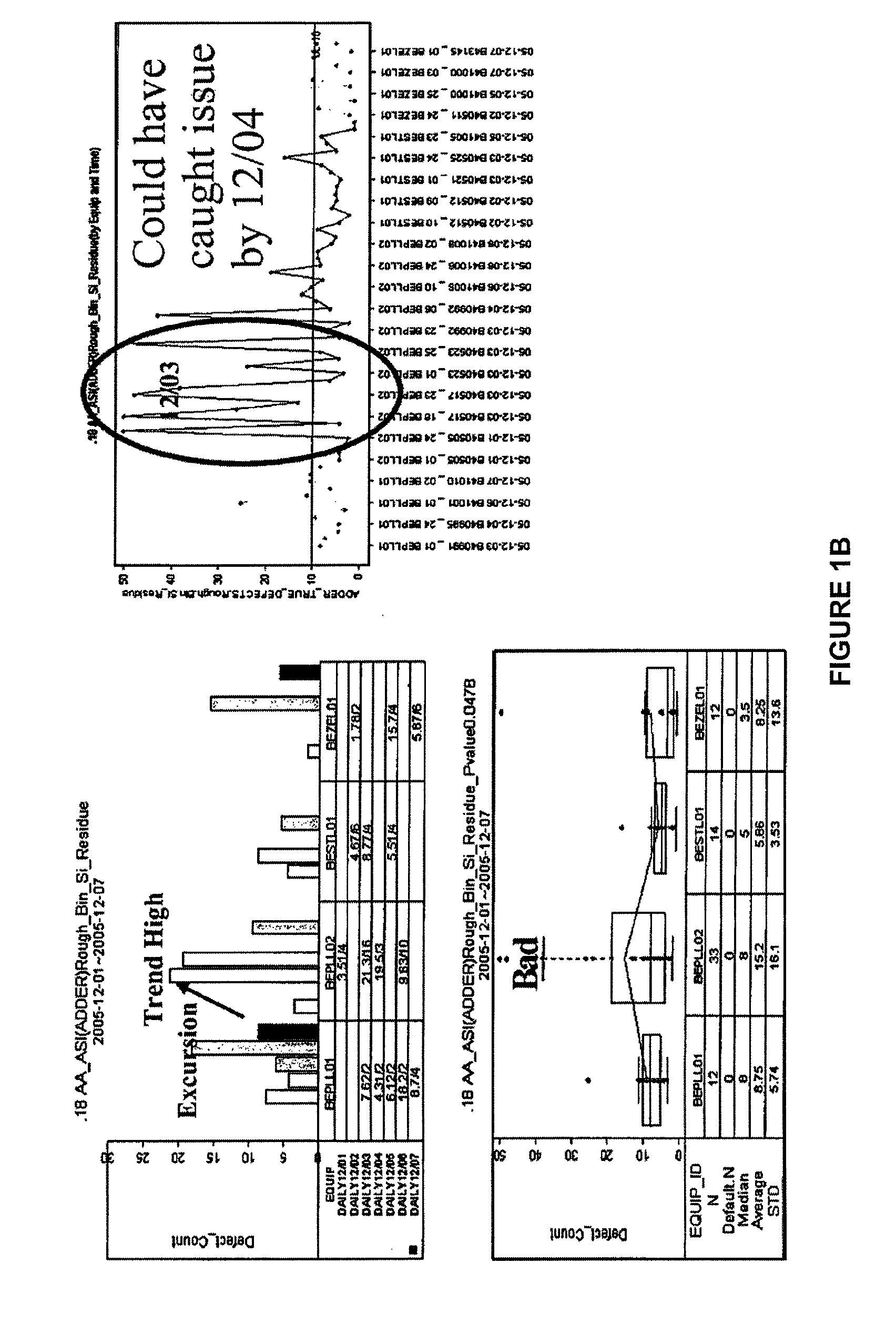

Method and system for defect detection in manufacturing integrated circuits

ActiveUS7991497B2Fast and automated solutionSemiconductor/solid-state device testing/measurementFuzzy logic based systemsEngineeringSemiconductor

Owner:SEMICON MFG INT (SHANGHAI) CORP

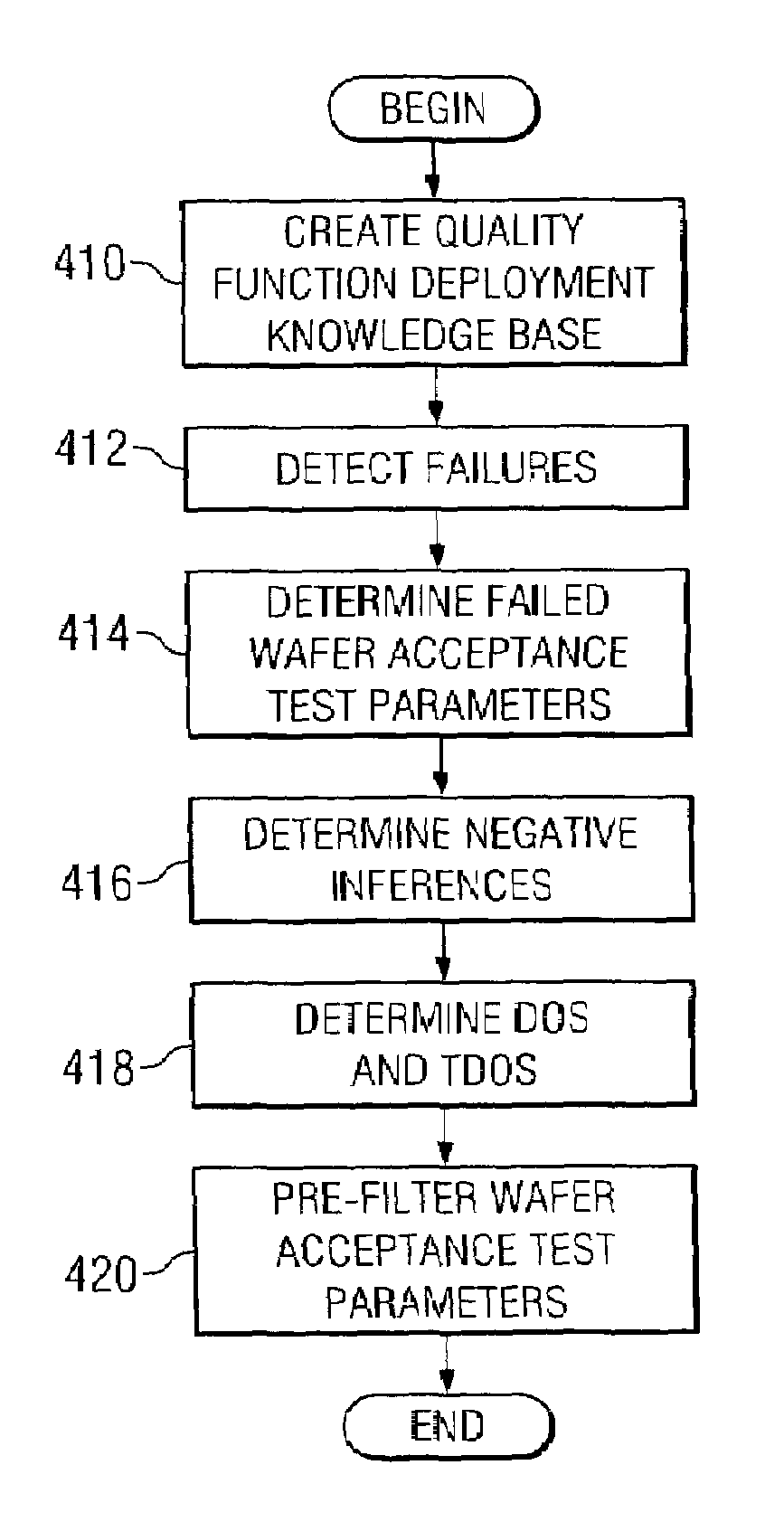

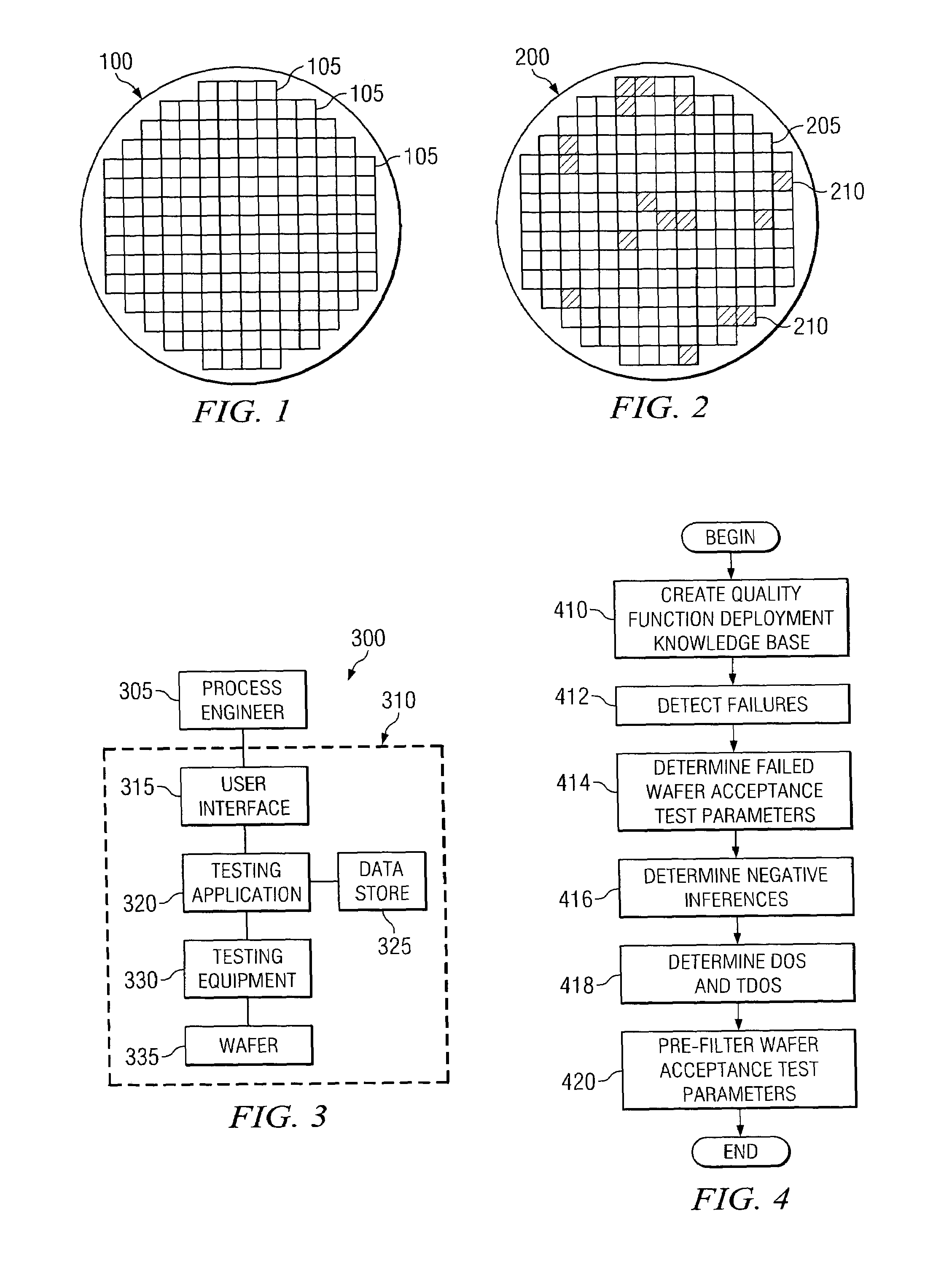

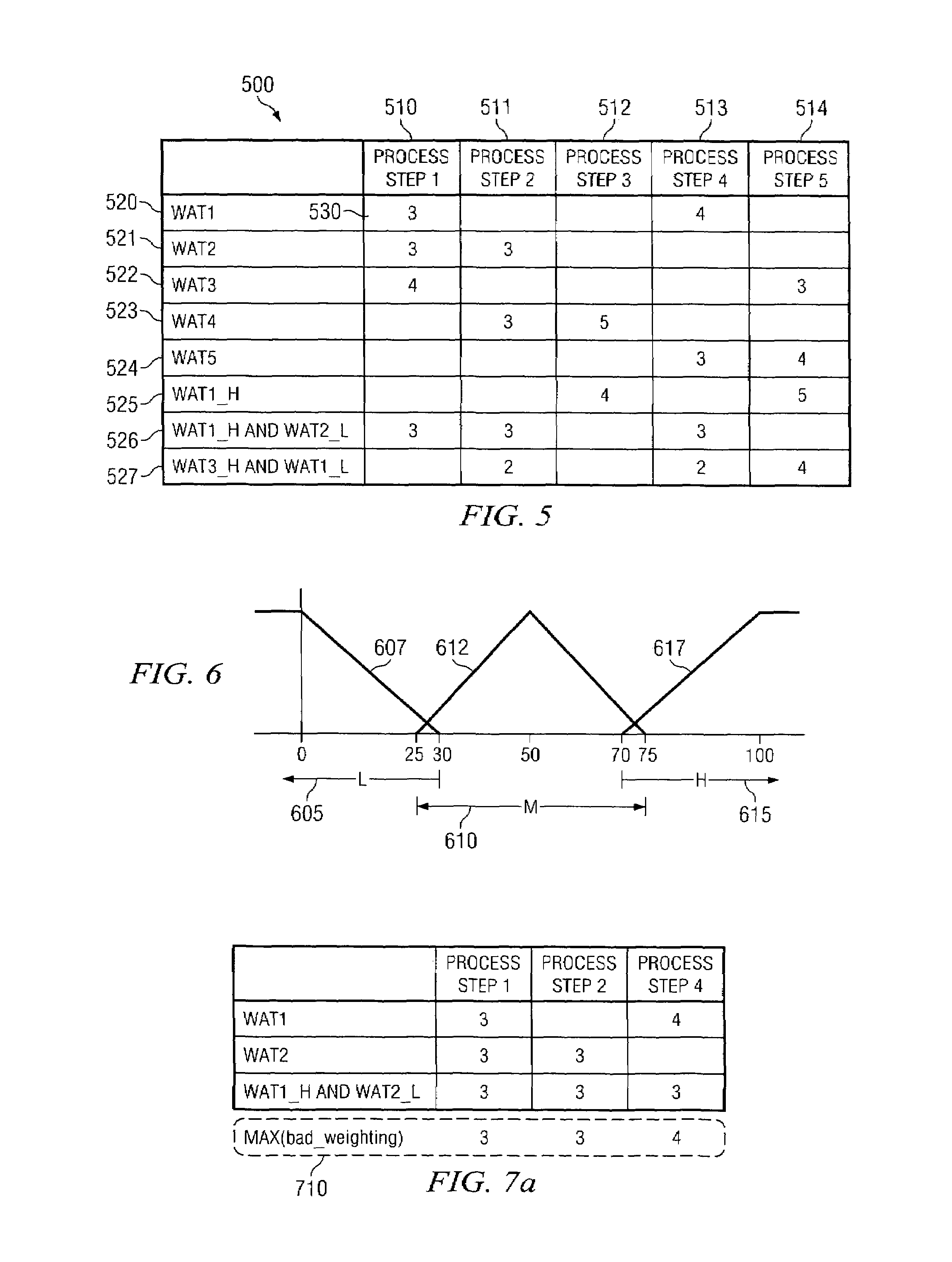

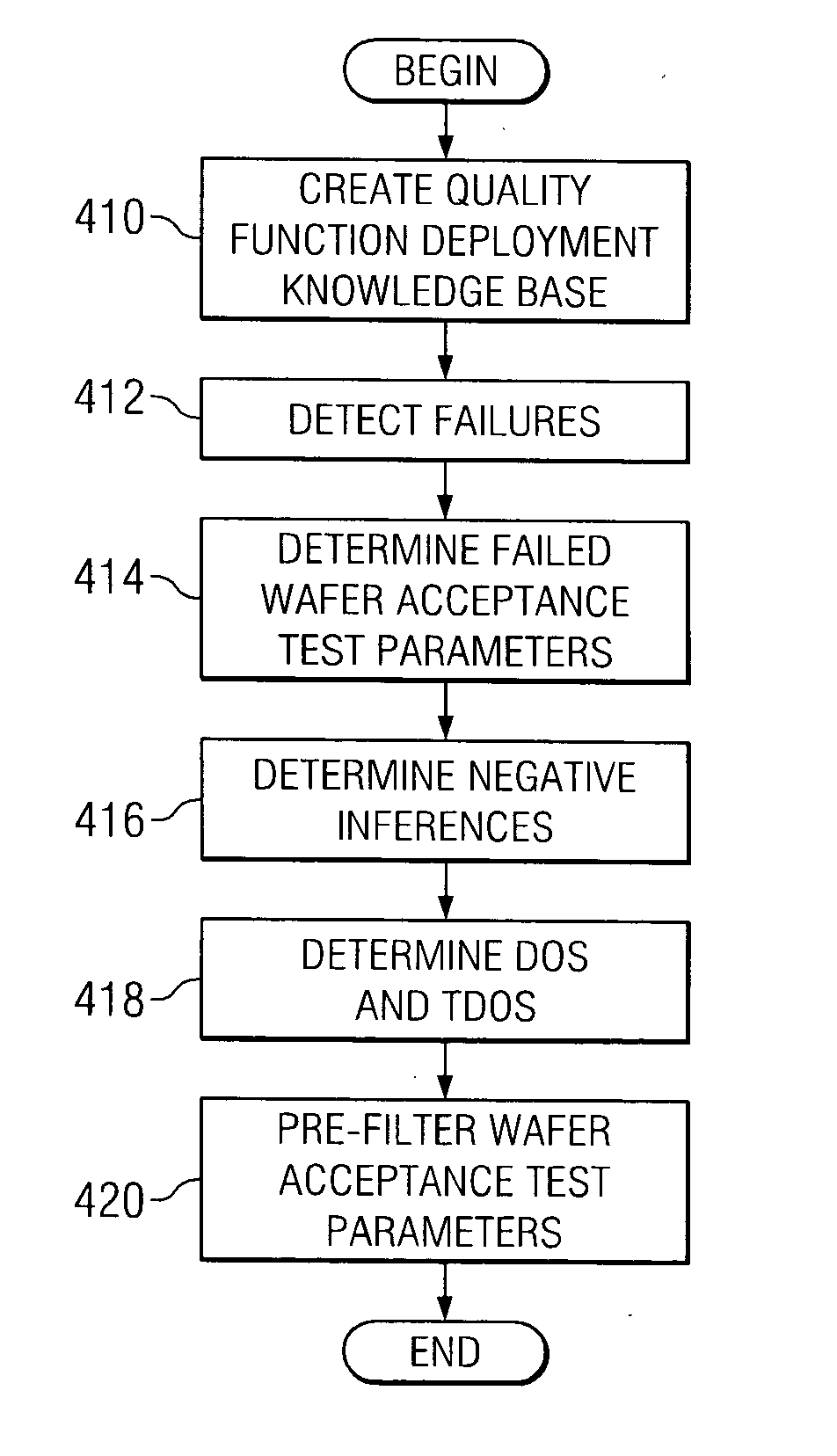

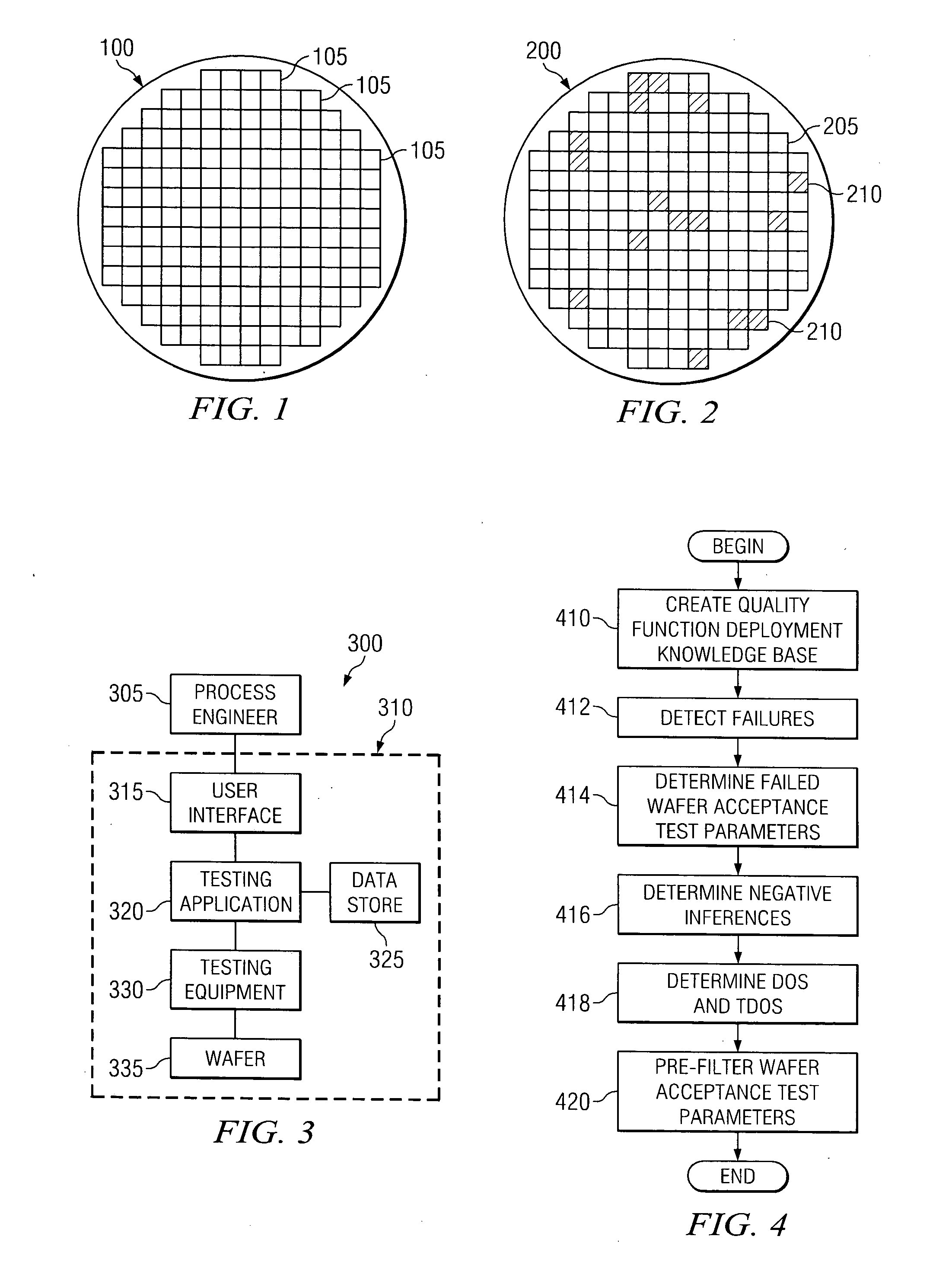

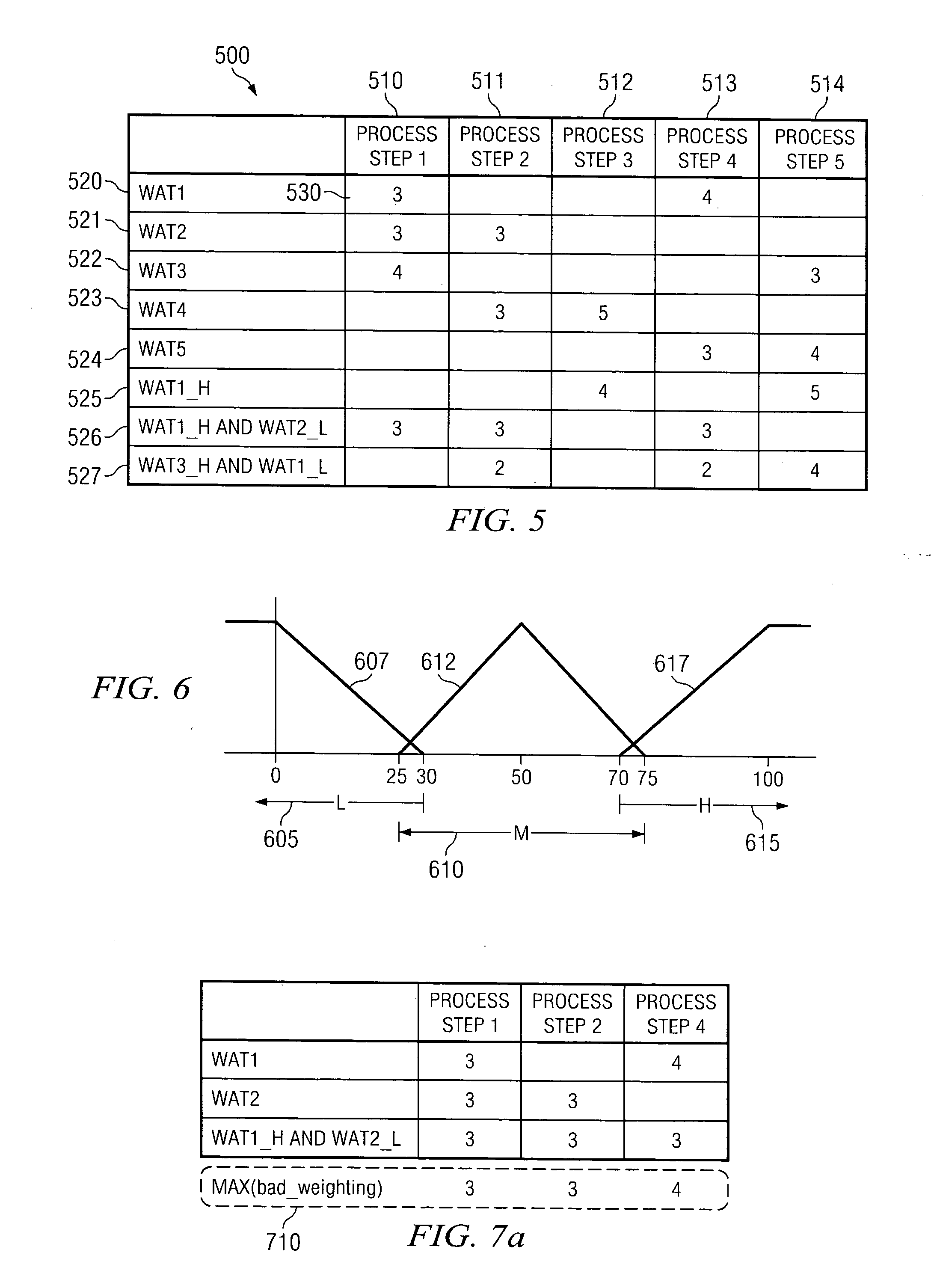

Fuzzy reasoning model for semiconductor process fault detection using wafer acceptance test data

InactiveUS7035770B2Easy to createEasy maintenanceDigital computer detailsNuclear monitoringFuzzy reasoningData system

System and method for detecting suspicious process faults. A preferred embodiment comprises determining a strength relationship between wafer acceptance test (WAT) parameters and process steps. The strength relationships indicate the affect of a failed process step on the value of a WAT parameter. Thus, if a WAT parameter is not within the parameters set in the WAT, then the suspicious process steps that caused the failure are the process steps that had a strength relationship with the failed WAT parameter. Furthermore, in a preferred embodiment, negative inferences are determined and utilized to determine a degree of suspiciousness. The degree of suspiciousness is used to determine a total degree of suspiciousness.

Owner:TAIWAN SEMICON MFG CO LTD

Process quality predicting system and method thereof

InactiveUS8452441B2Increase productionPredictive performanceTesting/monitoring control systemsComputation using non-denominational number representationProcess qualityQuality data

The invention discloses a process quality prediction system and a method thereof. When a processing apparatus performs a process on a target, the process is measured by a measurement apparatus to receive a process value. The process value and several previous quality data collected from the measurement apparatus are used to predict the quality of the product which is processing inline. The method is composed of a moving window, a stepwise regression scheme and an analysis of covariance (ANCOVA). The drift and shift of process are overcome by the moving window. A key variable set is selected by the stepwise regression scheme and a virtual model is identified by the analysis of covariance.

Owner:NATIONAL TSING HUA UNIVERSITY

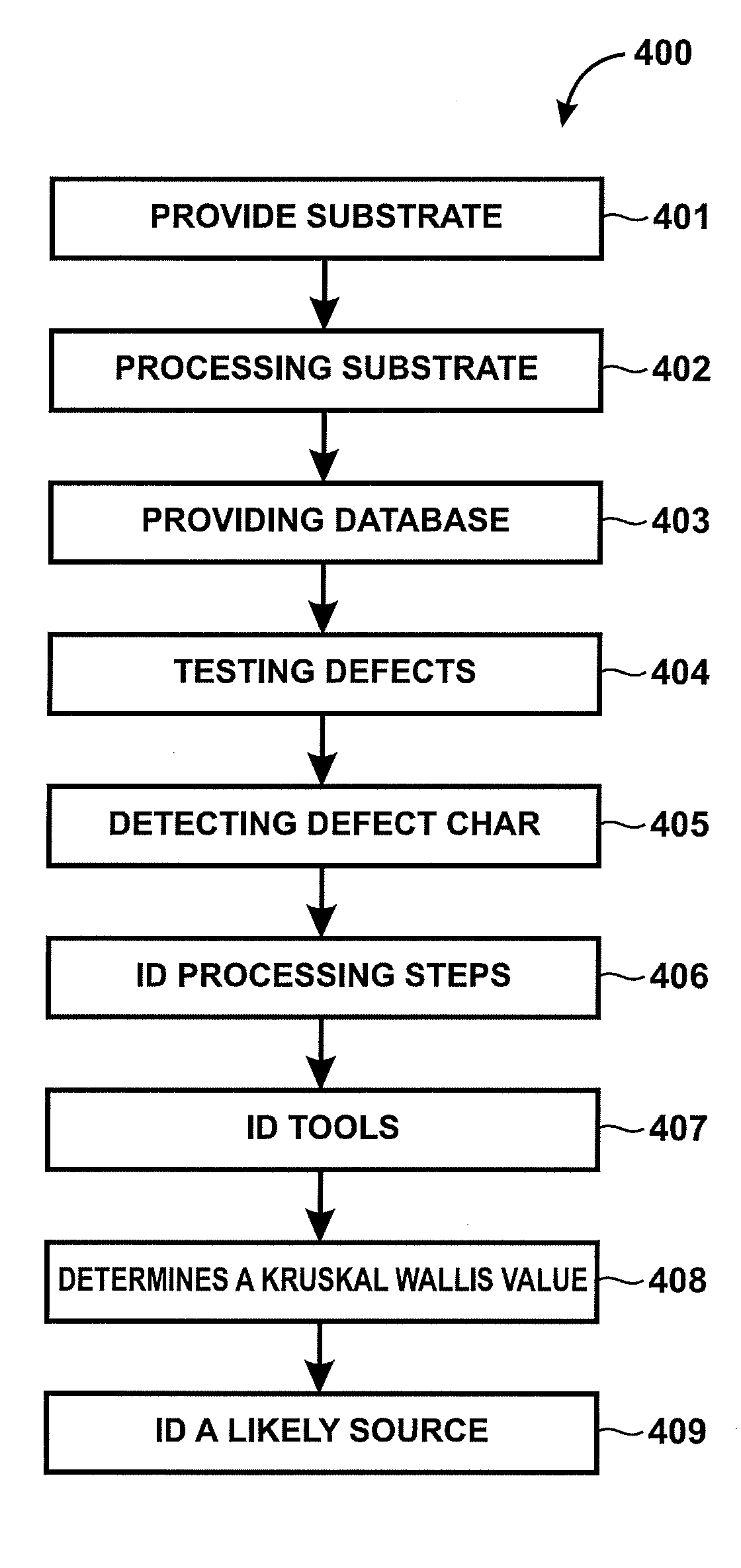

Method and system for defect detection in manufacturing integrated circuits

ActiveUS20100004775A1Fast and automated solutionSemiconductor/solid-state device testing/measurementFuzzy logic based systemsEngineeringSemiconductor

Method and system for defect detection in manufacturing integrated circuits. In an embodiment, the invention provides a method for identifying one or more sources for possible causing manufacturing detects in integrated circuits. The method includes a step for providing a plurality of semiconductor substrates. The method includes a step for processing the plurality of semiconductor substrates in a plurality of processing steps using a plurality of processing tools. The method additionally includes a step for providing a database, which includes data associated with the processing of the plurality of semiconductor substrates. The method further includes a step for testing the plurality of semiconductor wafers after the processing of the plurality of semiconductor substrates. Additionally, the method includes a step for detecting at least one defect characteristic associated with the plurality of the semiconductor substrates that have been processed. Moreover, the method includes a step for identifying a set of processing steps. For example, the set of processing step are possibly associated with the defect characteristic.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Fuzzy reasoning model for semiconductor process fault detection using wafer acceptance test data

InactiveUS20050137736A1Easy to createEasy maintenanceElectric testing/monitoringSemiconductor/solid-state device manufacturingFuzzy reasoningData system

System and method for detecting suspicious process faults. A preferred embodiment comprises determining a strength relationship between wafer acceptance test (WAT) parameters and process steps. The strength relationships indicate the affect of a failed process step on the value of a WAT parameter. Thus, if a WAT parameter is not within the parameters set in the WAT, then the suspicious process steps that caused the failure are the process steps that had a strength relationship with the failed WAT parameter. Furthermore, in a preferred embodiment, negative inferences are determined and utilized to determine a degree of suspiciousness. The degree of suspiciousness is used to determine a total degree of suspiciousness.

Owner:TAIWAN SEMICON MFG CO LTD

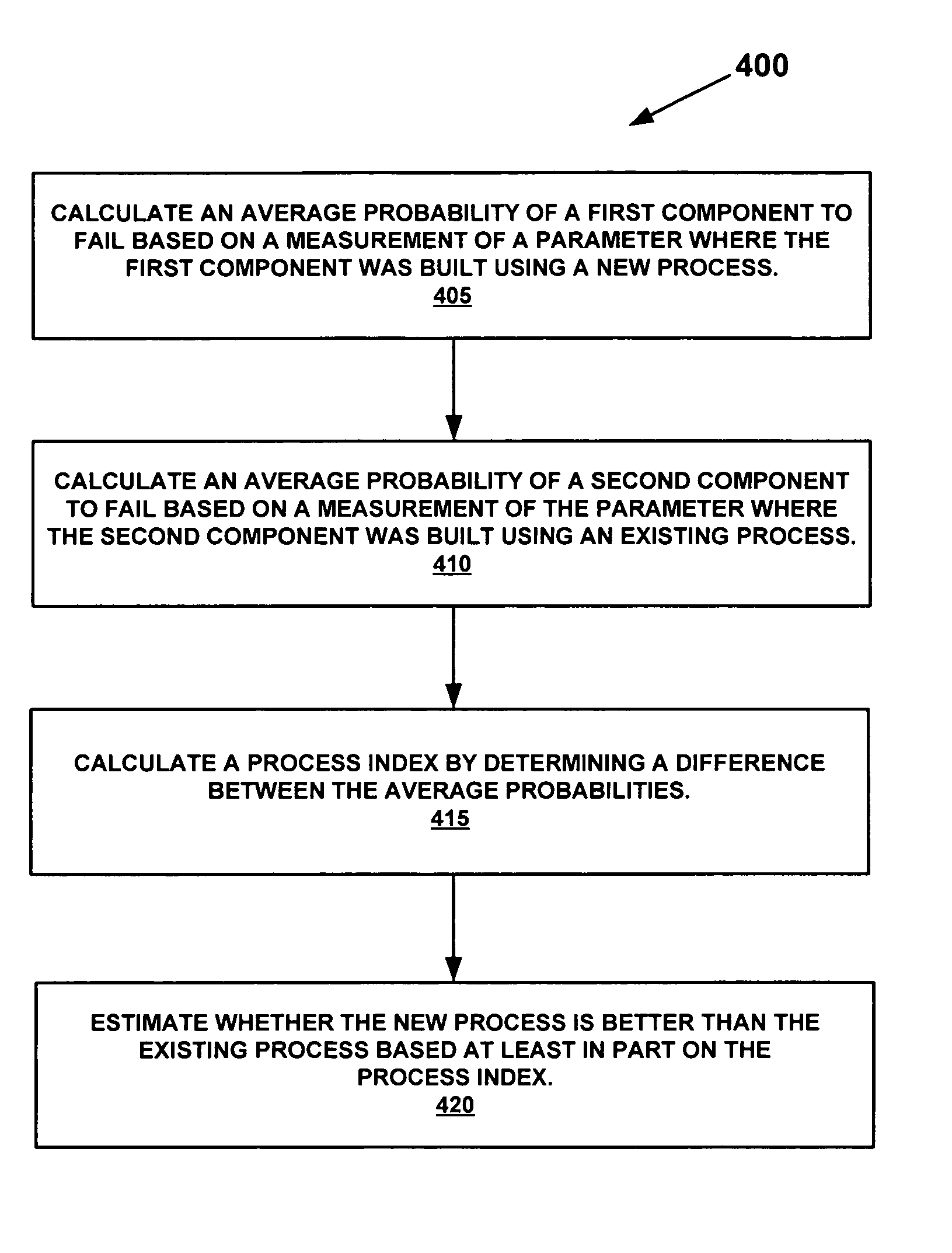

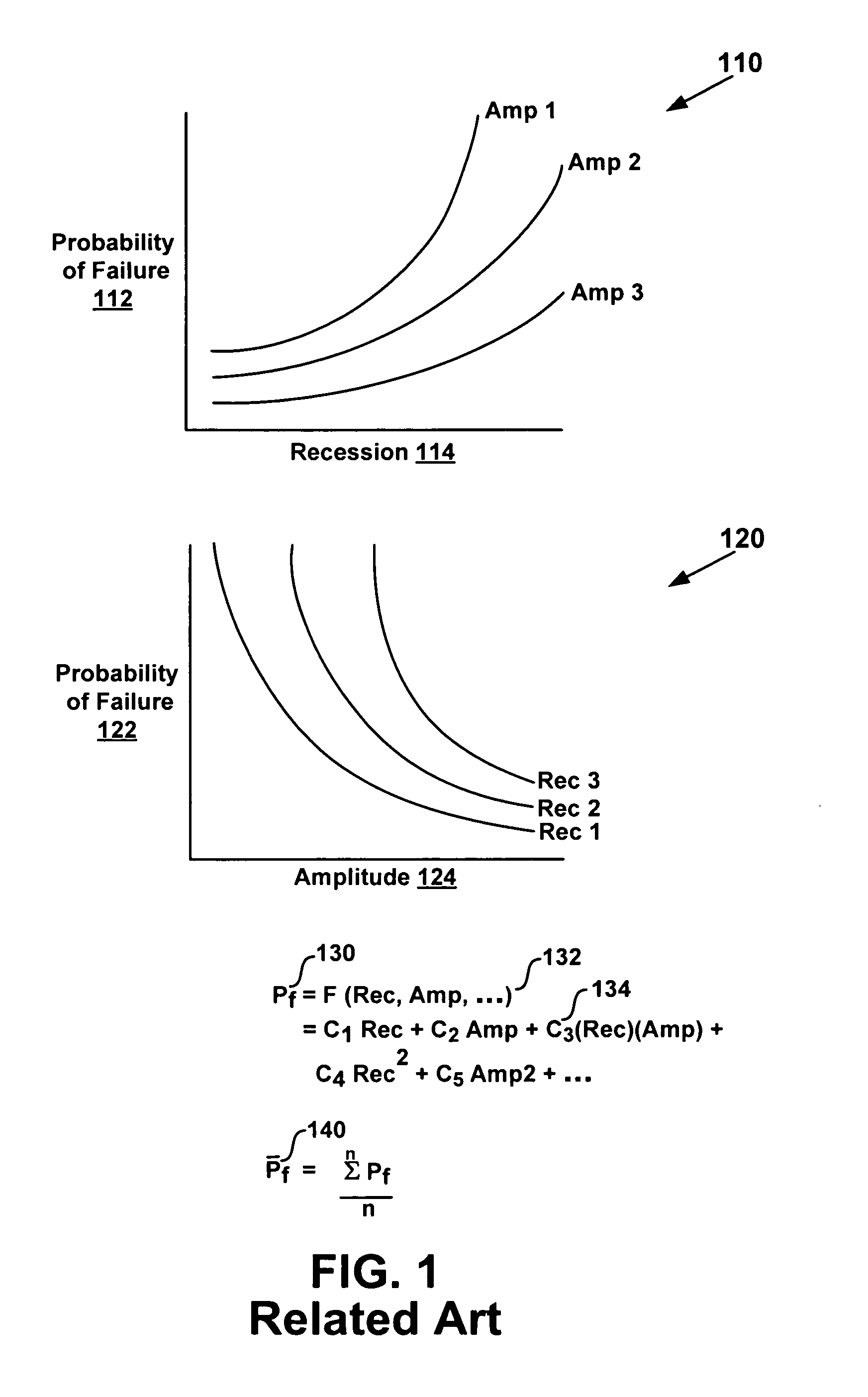

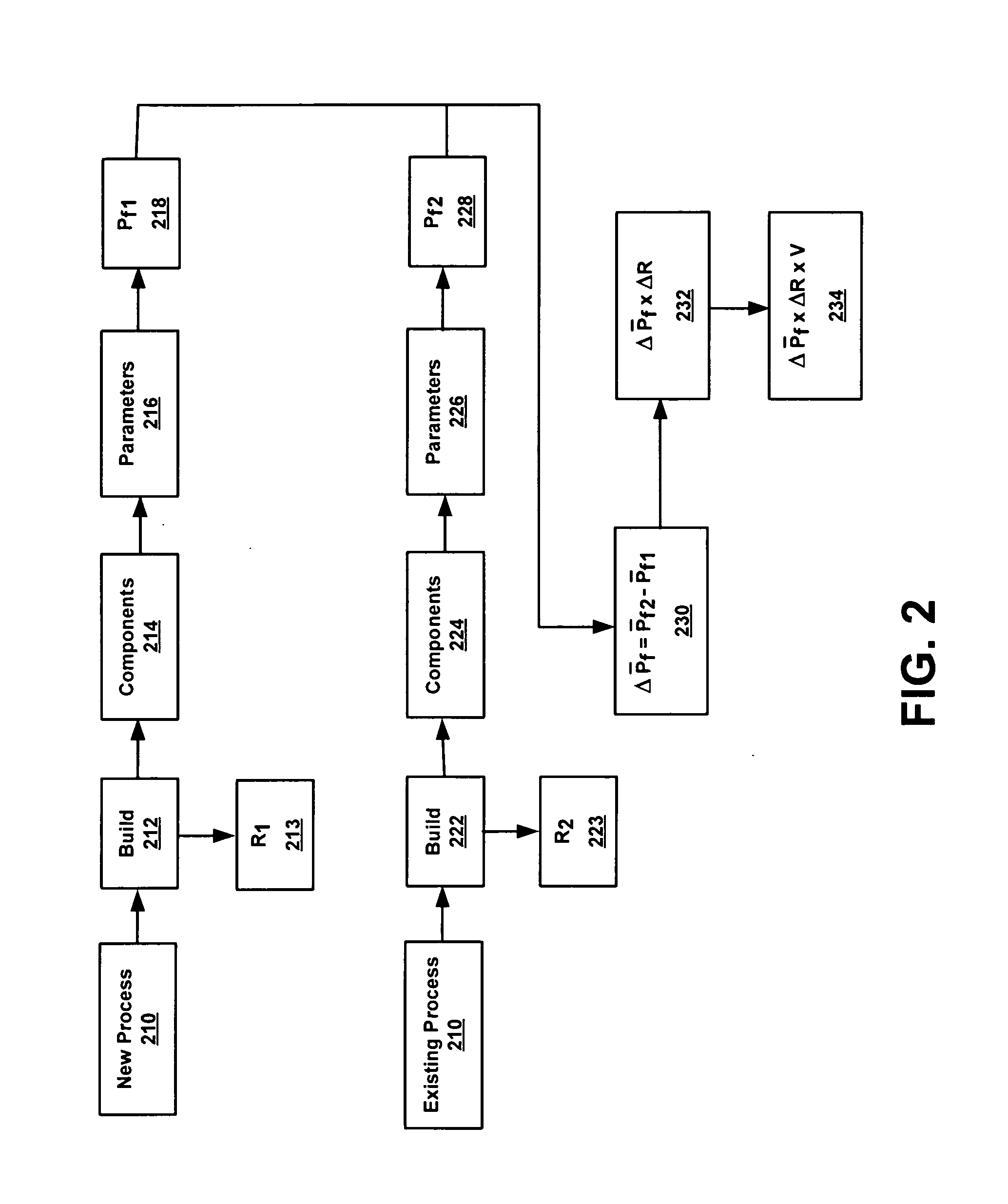

Method for evaluating processes for manufacturing components

Embodiments of the present invention pertain to methods of evaluating processes for manufacturing components. In one embodiment, an average probability of a first component to fail is calculated based on a measurement of a parameter where the first component was built using a new process. Another average probability of a second component to fail is calculated based on a measurement of the parameter where the second component was built using an existing process. A process index is calculated by determining a difference between the average probabilities for the second component and the first component. An estimation is made as to whether the new process is better than the existing process based on the process index.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

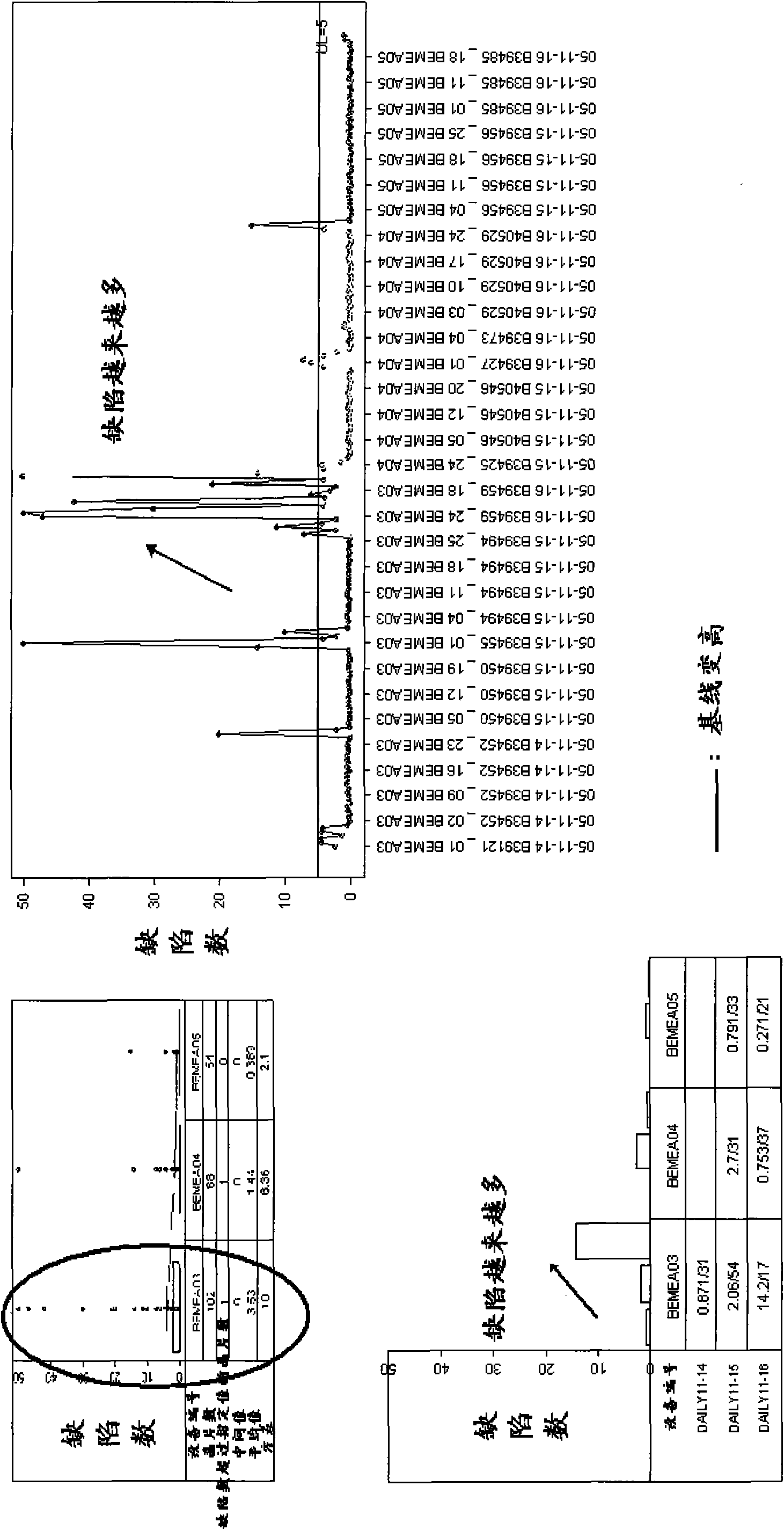

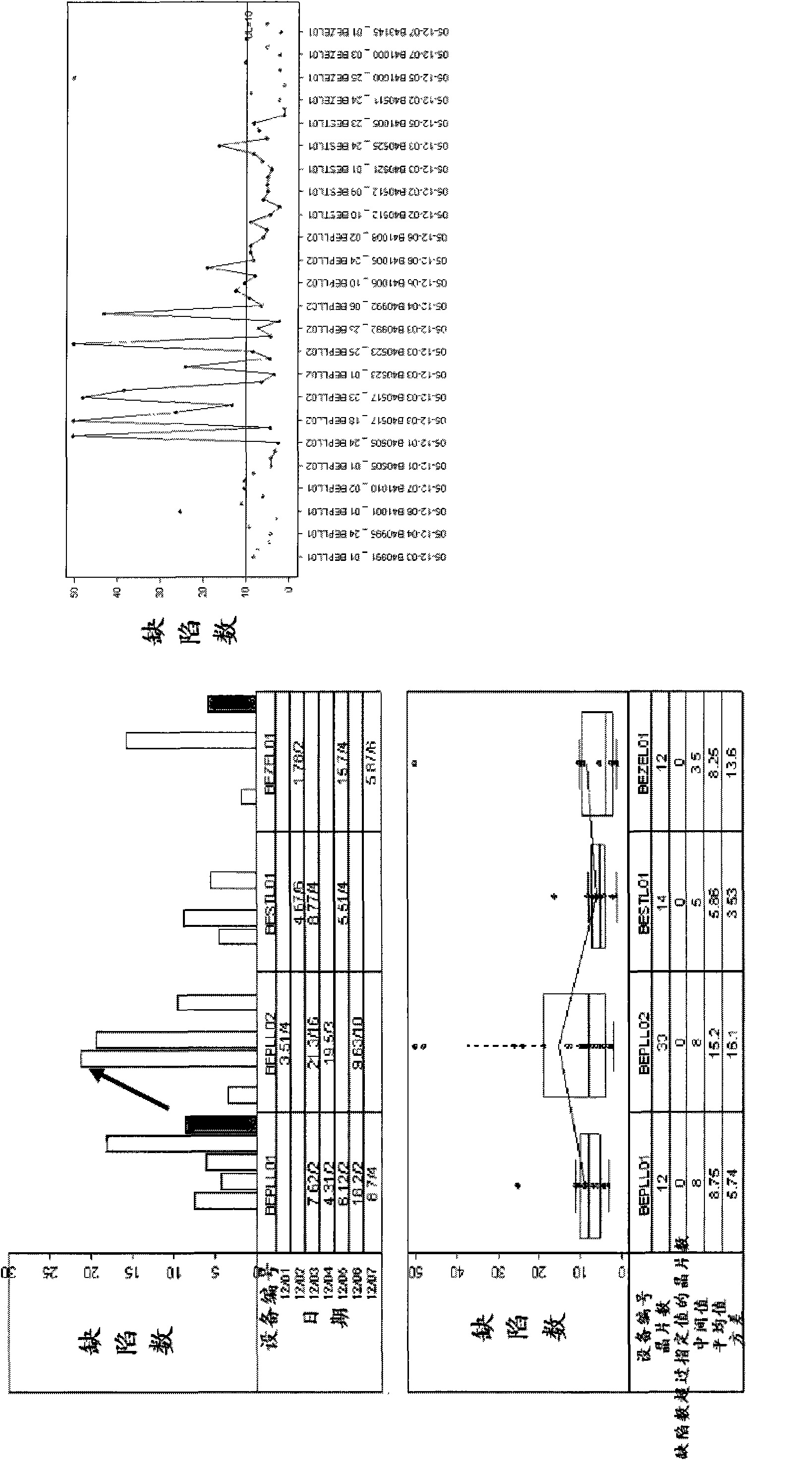

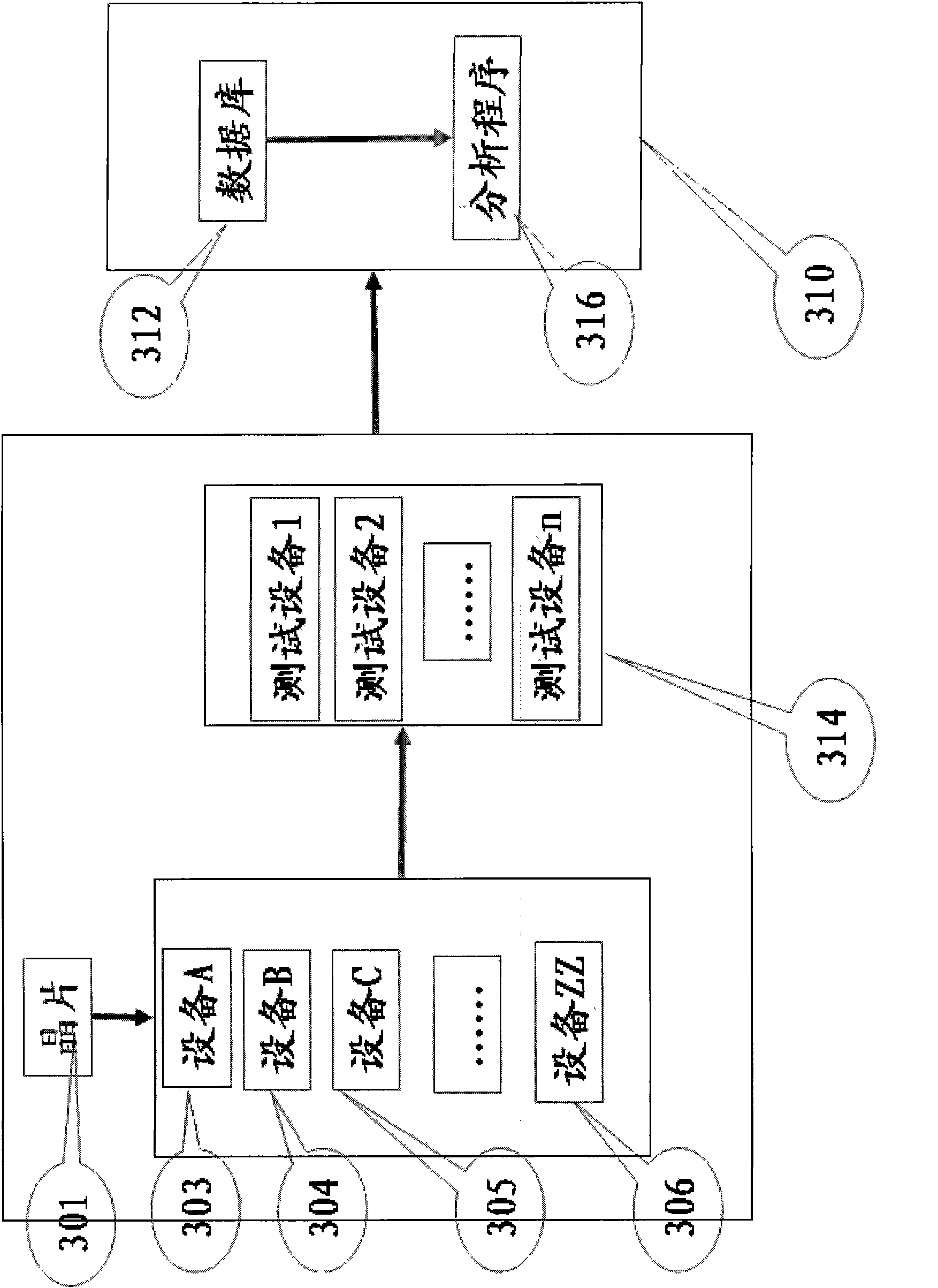

Method and system for detecting defects in manufacture of integrated circuit

InactiveCN101621016ASemiconductor/solid-state device testing/measurementElectronic circuit testingSemiconductor chipIntegrated circuit

The invention relates to a method and a system for detecting deflects in the manufacture of an integrated circuit. In one embodiment, the invention provides a method for detecting one or more sources possibly causing manufacturing deflects of the integrated circuit. The method comprises a step of providing a plurality of semiconductor substrates, a step of using a plurality of processing devices to process the plurality of semiconductor substrates in a plurality of processing steps, a step of providing a data base including the data related to the processing of the plurality of semiconductor substrates, a step of detecting a plurality of semiconductor chips after the processing of the plurality of semiconductor substrates, a step of detecting at least one defective feature related to the plurality of processed semiconductor substrates and a step of detecting a processing step collection, for example, the processing step collection is possibly related to the defective feature.

Owner:SEMICON MFG INT (SHANGHAI) CORP

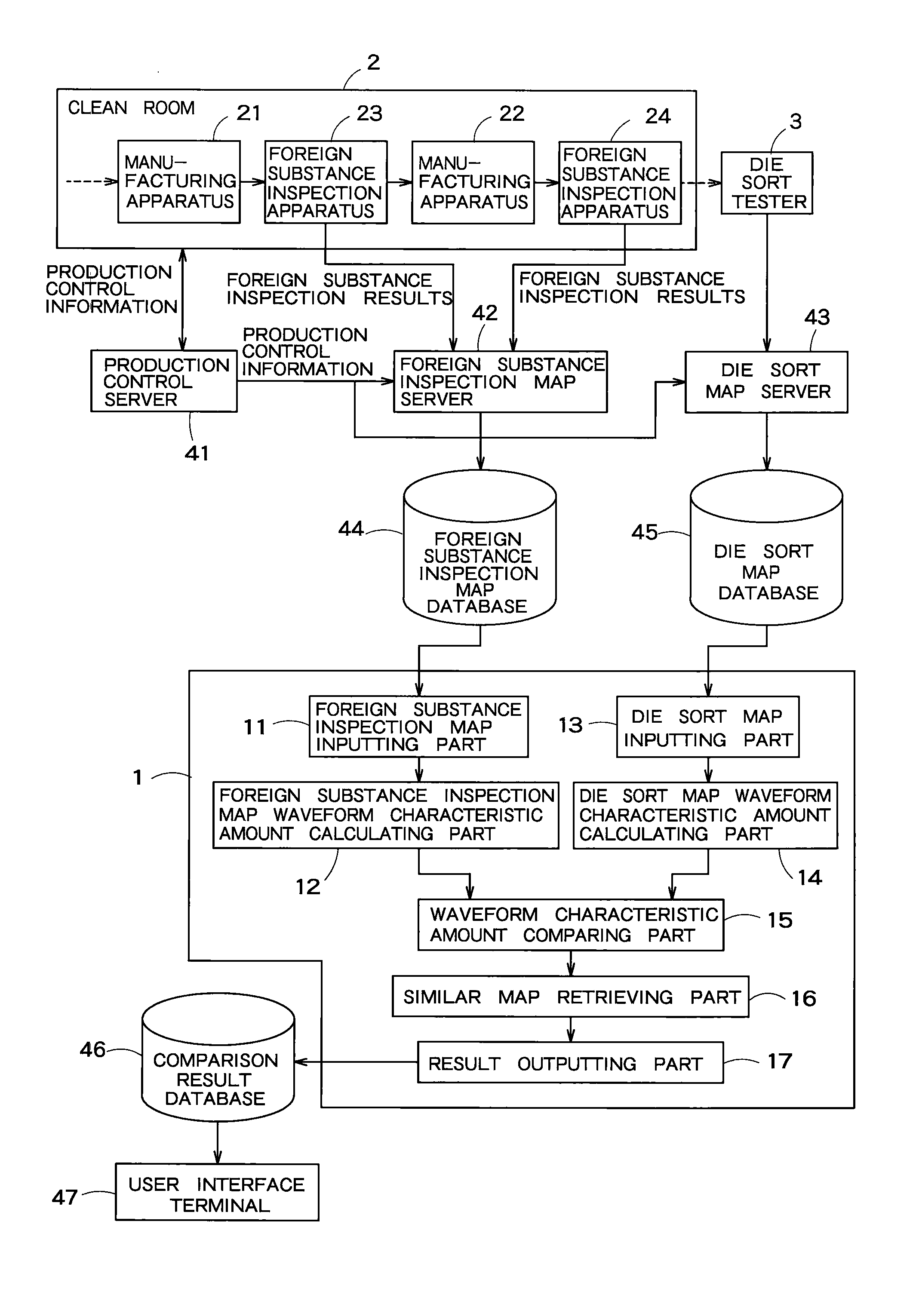

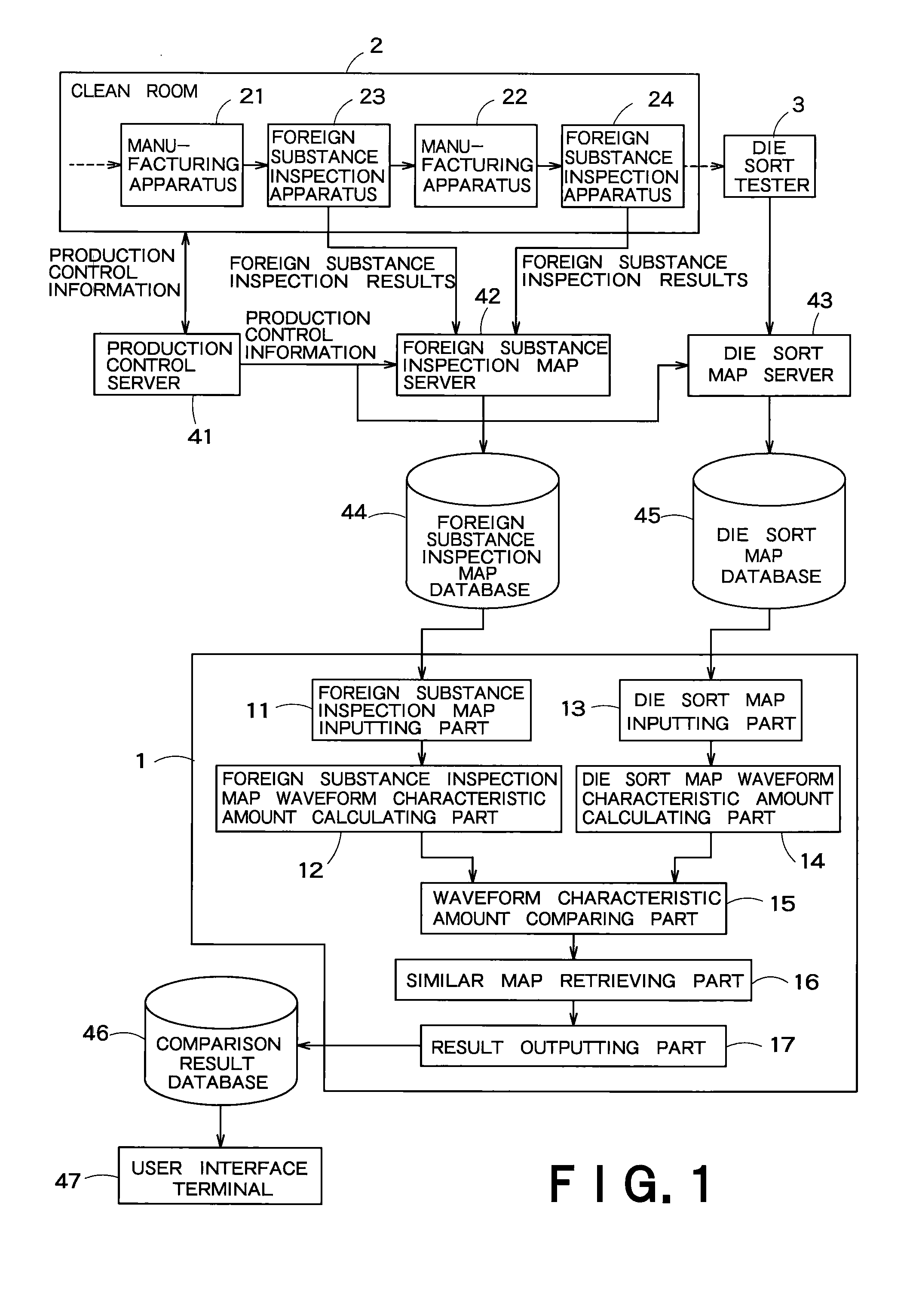

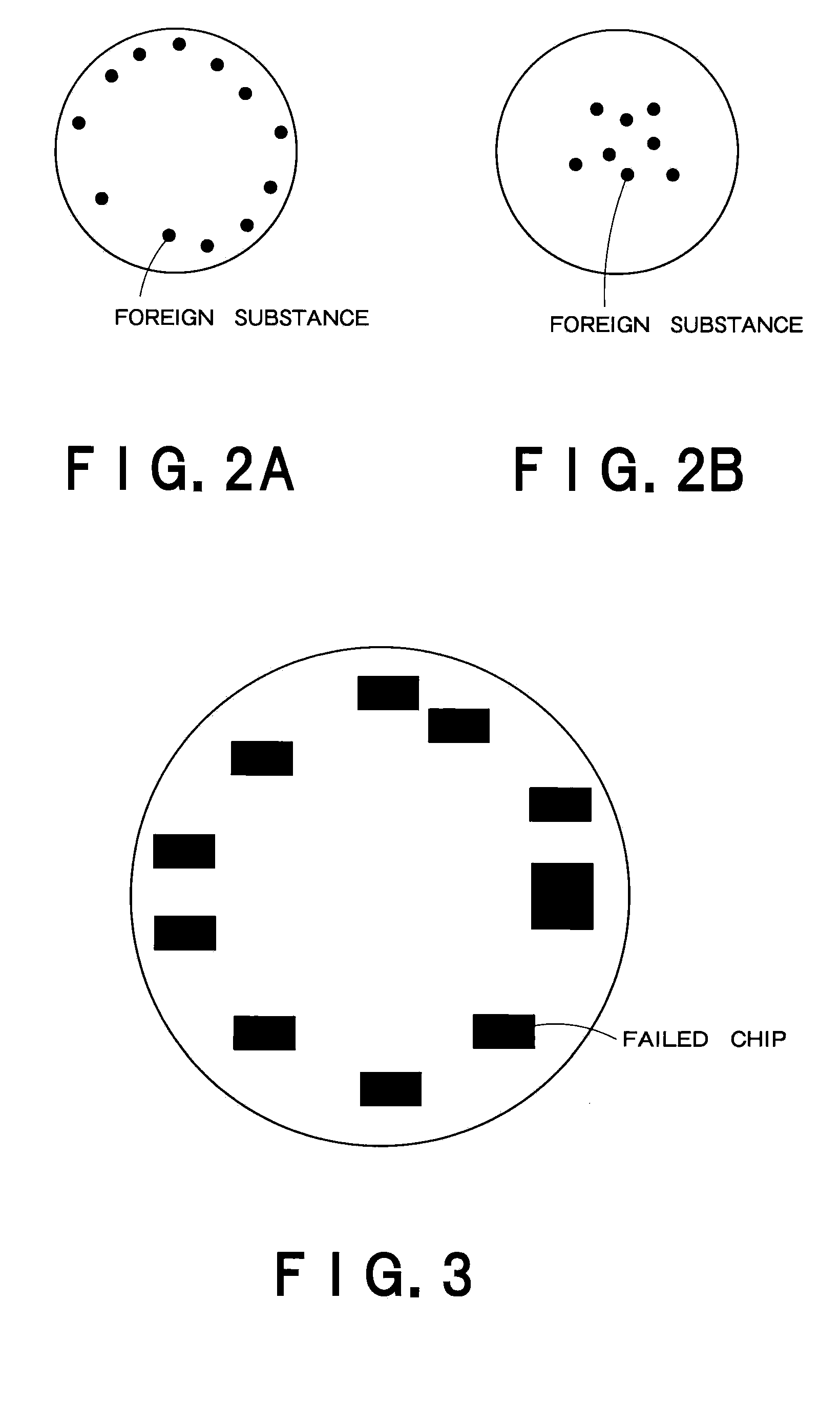

Failure detecting method, failure detecting apparatus, and semiconductor device manufacturing method

ActiveUS8170707B2Semiconductor/solid-state device testing/measurementTesting/monitoring control systemsForeign matterEngineering

A method for inputting a foreign substance inspection map created by foreign substance inspection for a wafer surface after each processing process in a wafer processing process, inputting a die sort map created by a die sort test after the wafer processing process, setting region segments in the wafer, setting a region number for each segment, calculating foreign substance density of the region segments, based on the foreign substance inspection map, and plotting the foreign substance density, using the region numbers, to calculate a foreign substance inspection map waveform characteristic amount, calculating failure density in the region segments, based on the die sort map, and plotting the failure density, using the region numbers, to calculate a die sort map waveform characteristic amount, calculating similarity between the foreign substance inspection map waveform characteristic amount and the die sort map waveform characteristic amount, and identifying a processing process cause of failure occurrence.

Owner:KIOXIA CORP

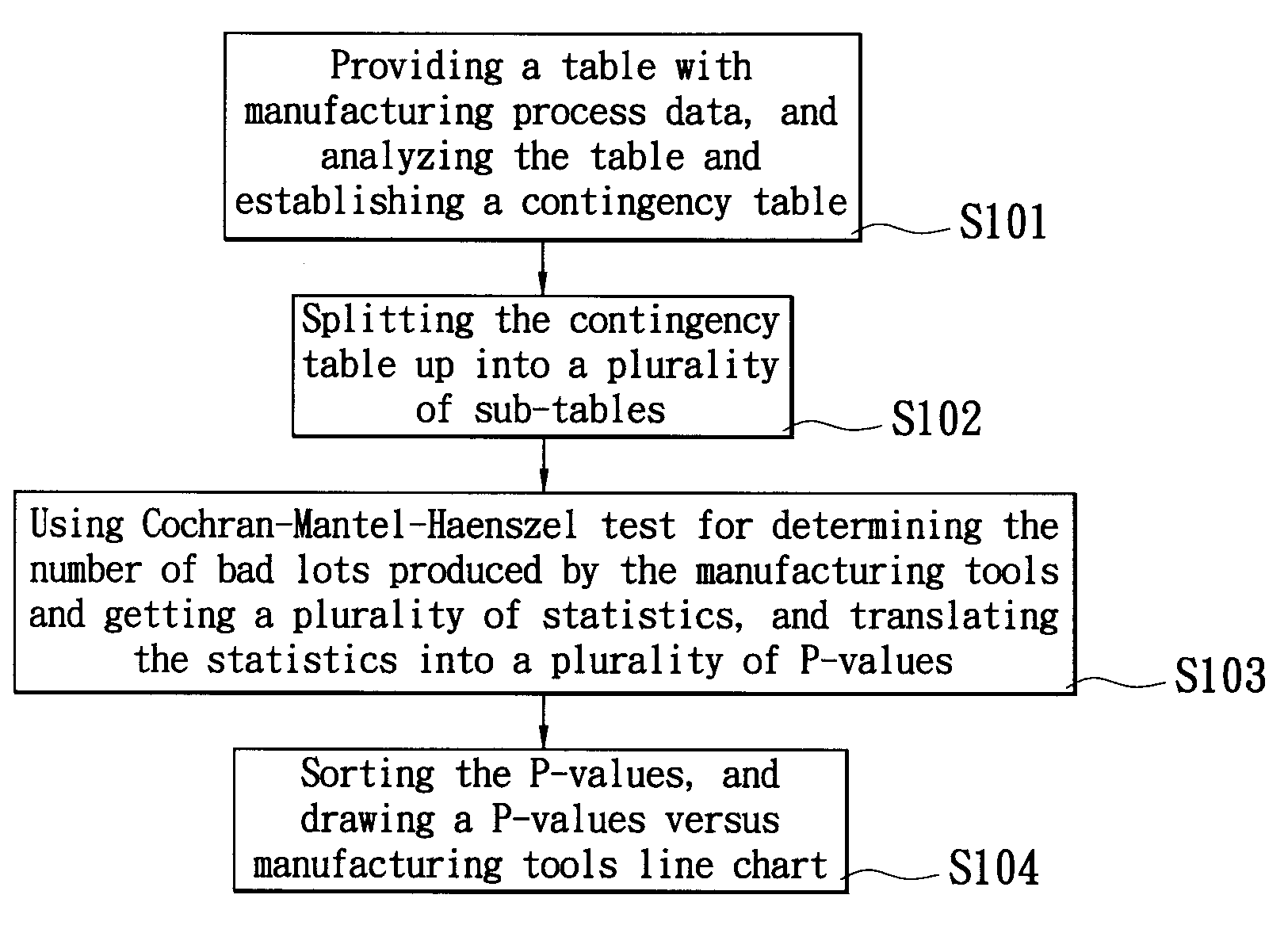

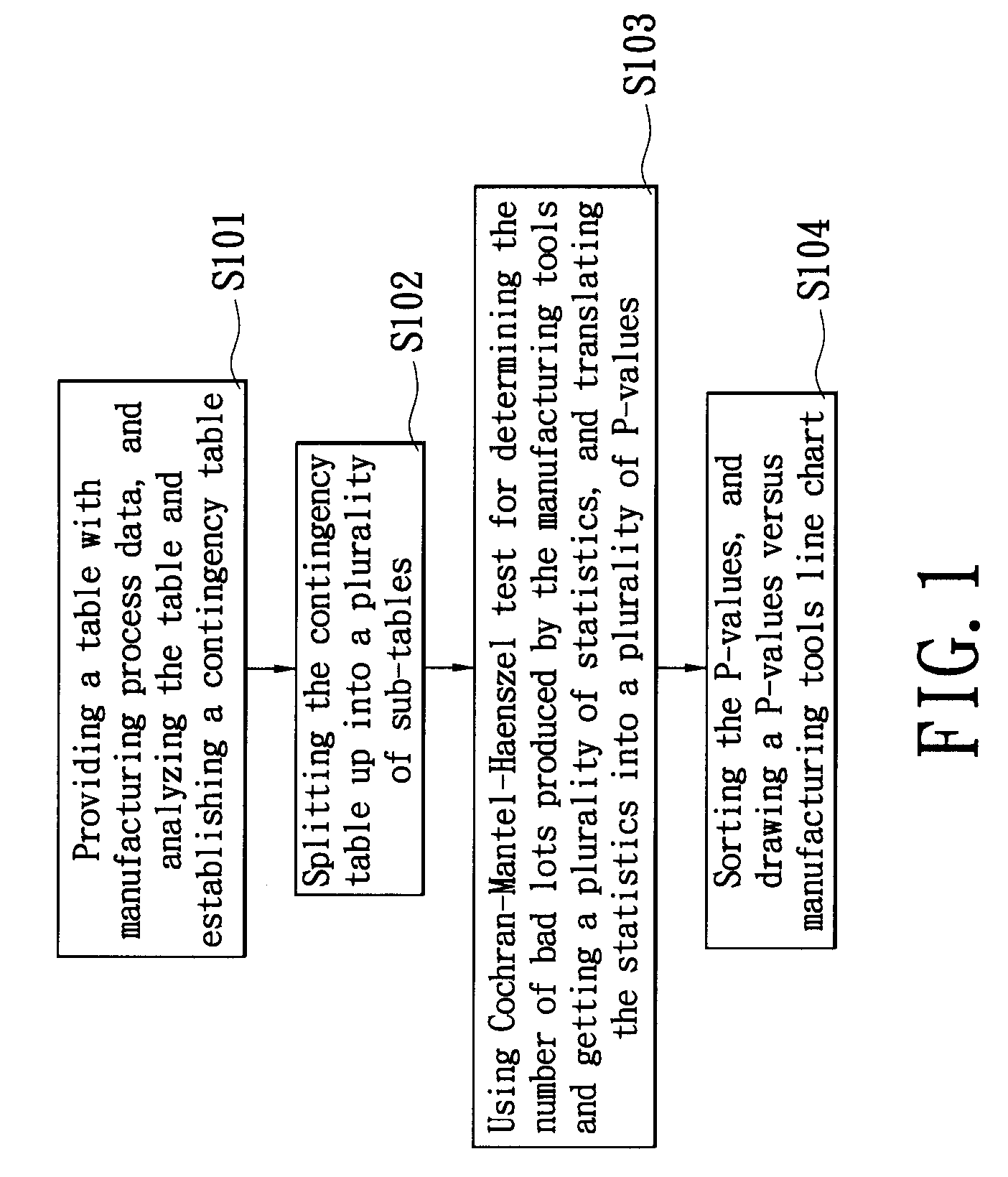

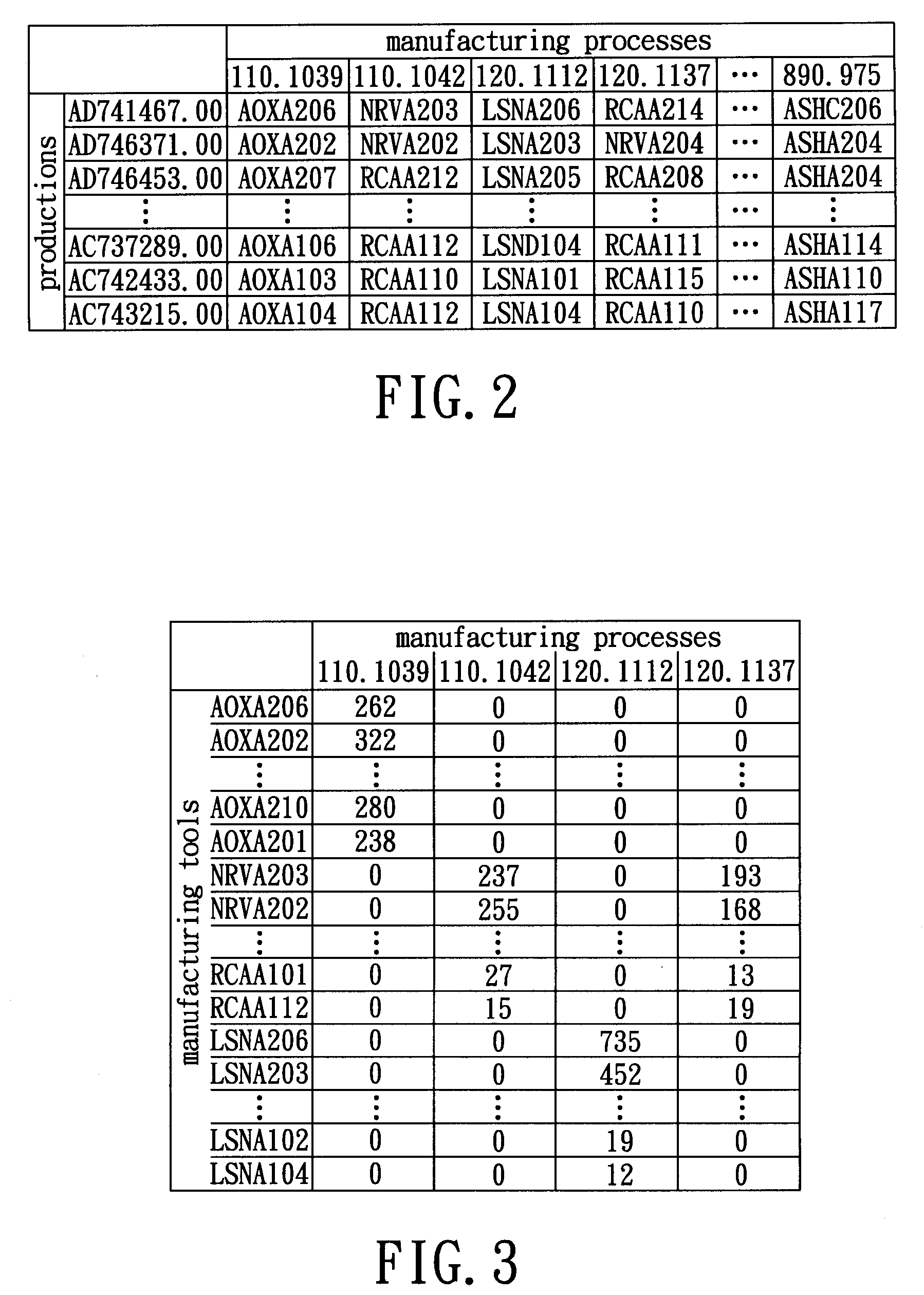

Method for determining tool's production quality

InactiveUS20100049355A1High yieldTesting/monitoring control systemsTotal factory controlContingency tableProduction quality

A method for determining manufacturing tool production quality includes providing a table with manufacturing process data. The table is analyzed and a contingency table is established. The contingency table comprises several manufacturing tools, manufacturing processes, and the number of occurrences of bad lots. Split the contingency table up into a plurality of sub-tables. Use Cochran-Mantel-Haenszel test for determining the number of bad lots produced by the manufacturing tools and getting a plurality of statistics. Translate the statistics into a plurality of P-values. Sort the P-values for examining data automatically. Draw a line chart for detecting substandard manufacturing tools. As a result, users can diagnose the quality of the manufacturing tools.

Owner:INOTERA MEMORIES INC

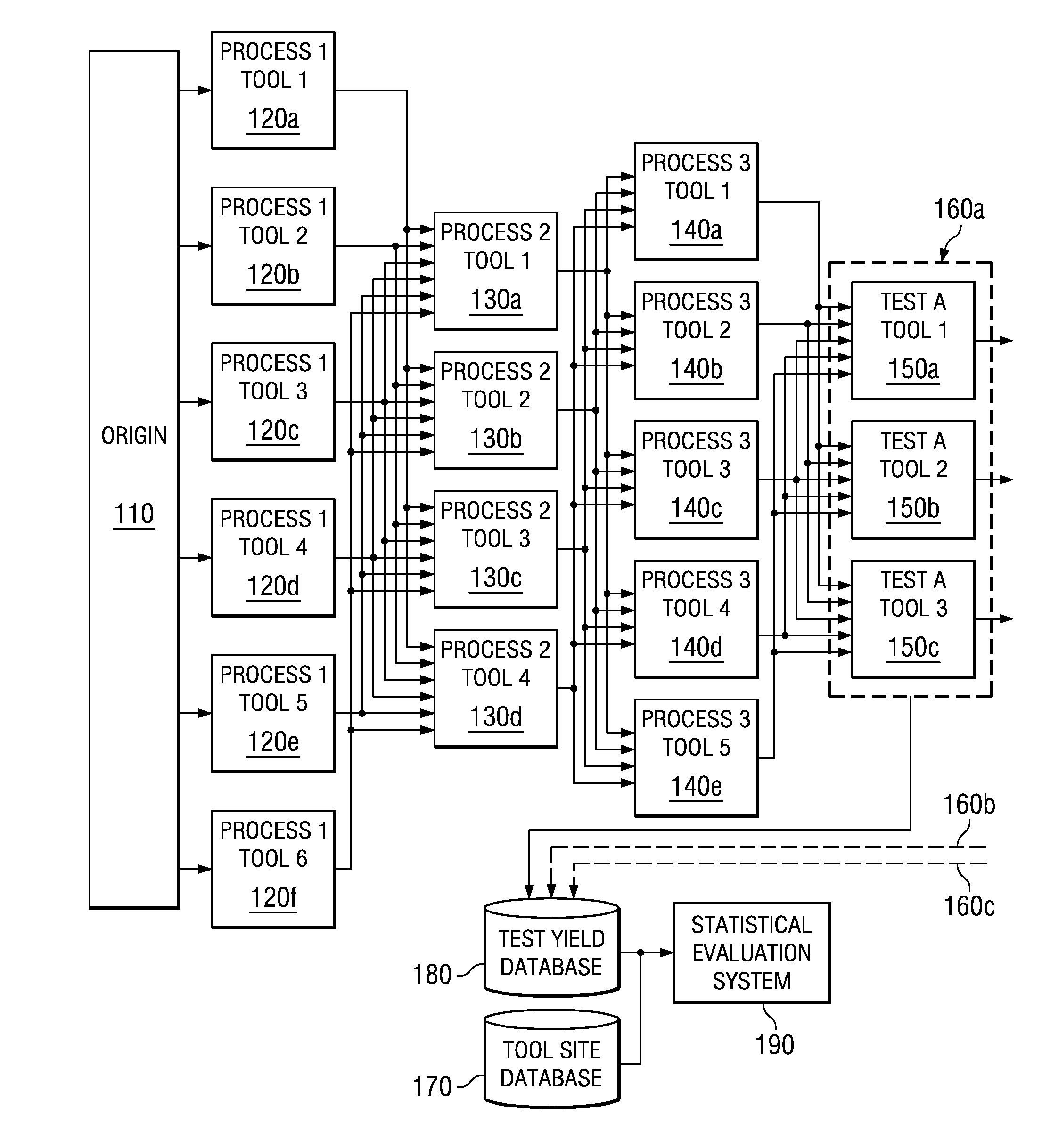

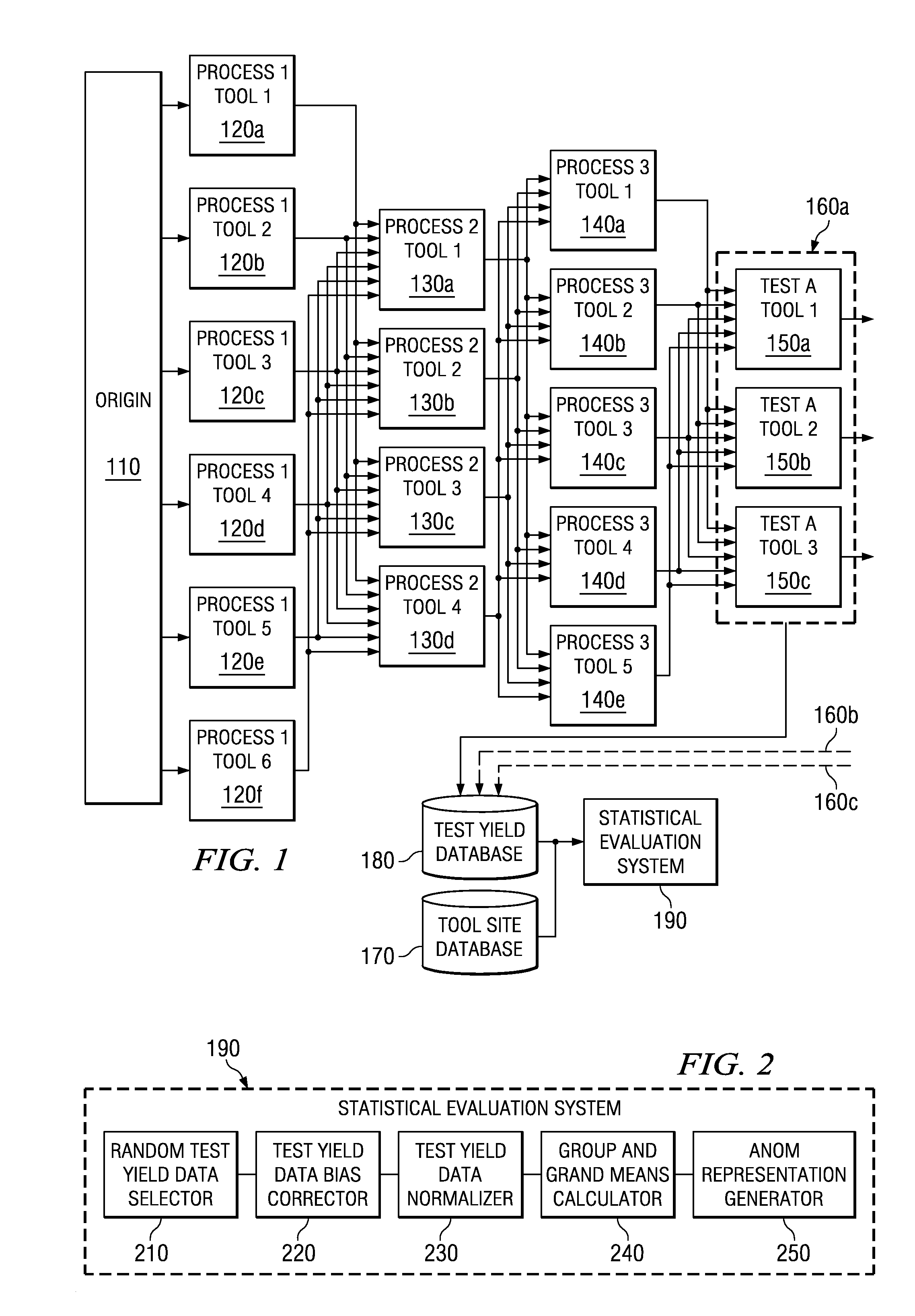

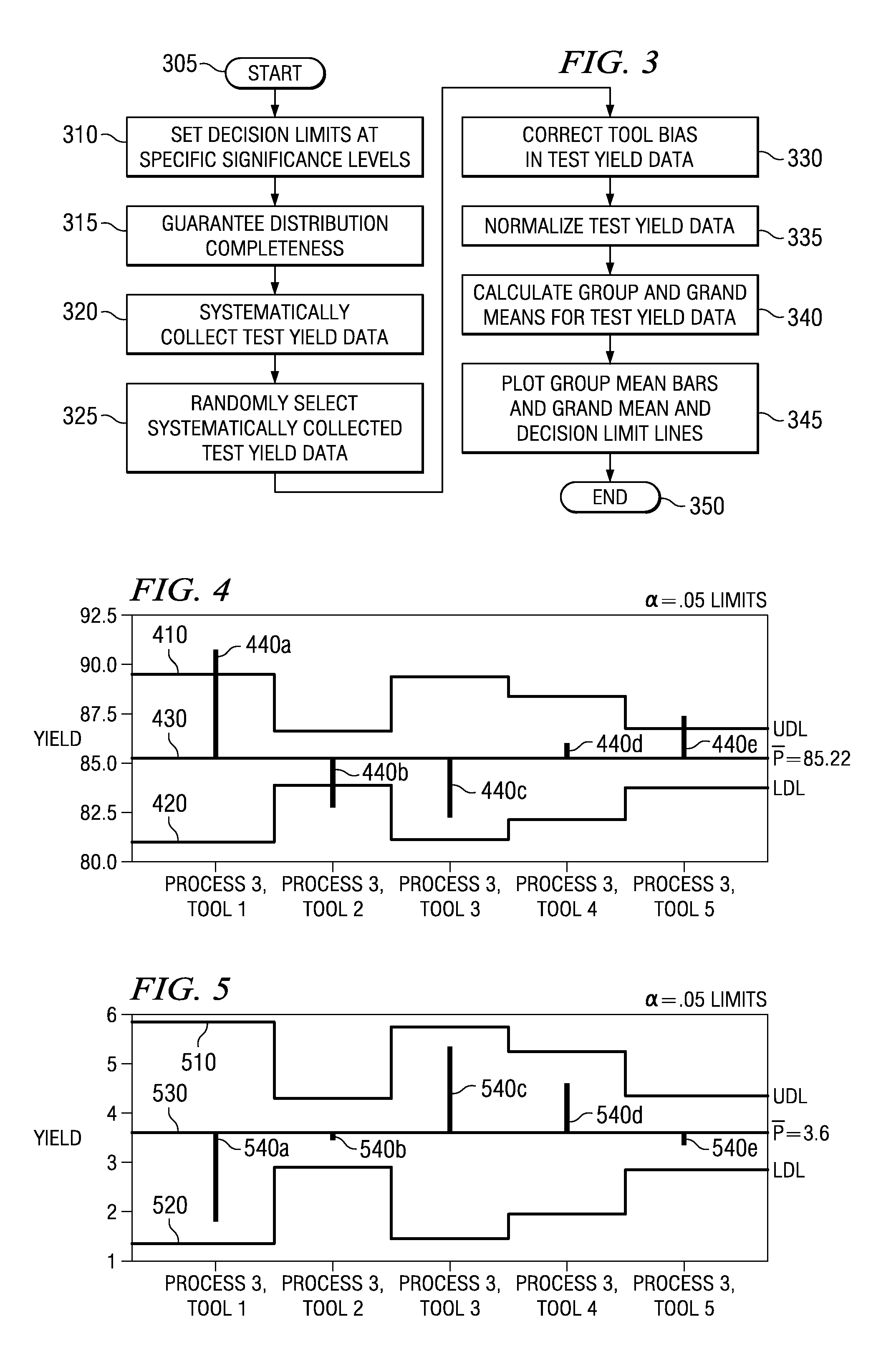

System and Method for Statistically Evaluating the Operation of Integrated Circuit Fabrication Tools

InactiveUS20090012744A1Testing/monitoring control systemsDigital computer detailsMultiplexerEvaluation system

For use with a manufacturing facility that carries out a plurality of processes, including a test process, to manufacture products, a plurality of alternative, equivalent tools being associated with each of the plurality of processes, a statistical evaluation system and a method of statistically evaluating the manufacturing facility. In one embodiment, the system includes: (1) a random test yield data selector configured to select test yield data on products subjected to a complete distribution randomly from the tools associated with the test process, (2) a group and grand means calculator associated with the random test yield data selector and configured to calculate group and grand means for the selected test yield data and (3) an analysis-of-means representation generator associated with the group and grand means calculator and configured to generate an analysis-of-means representation of at least one of the plurality of processes by plotting the group and grand means and decision limits corresponding to specific significance levels.

Owner:TEXAS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com