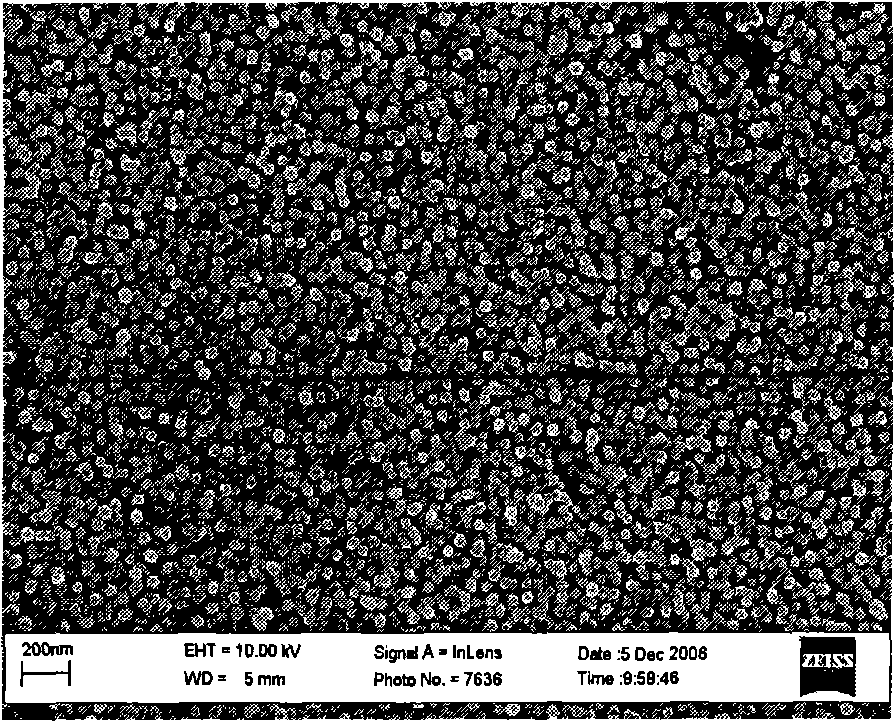

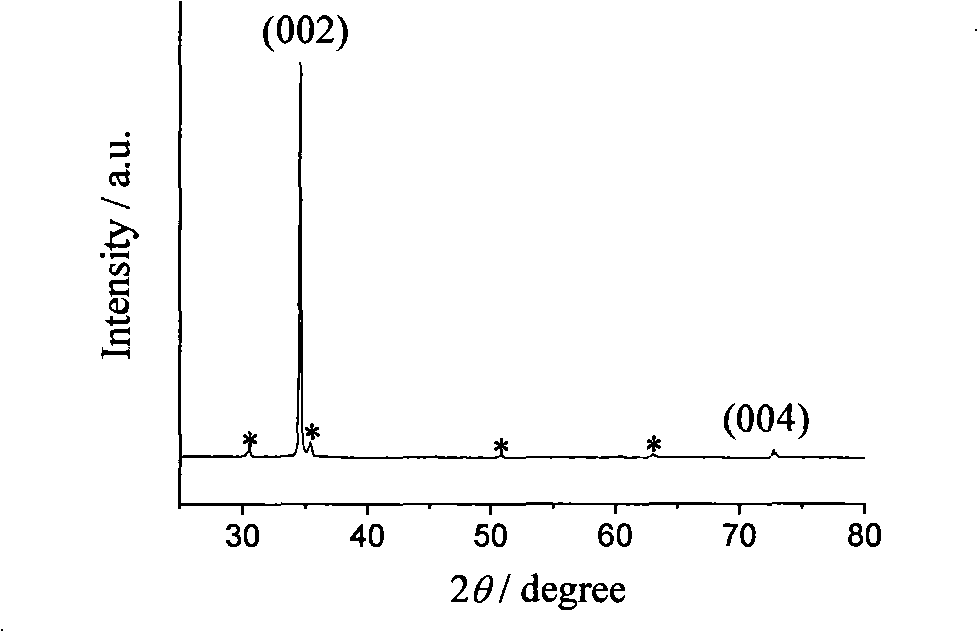

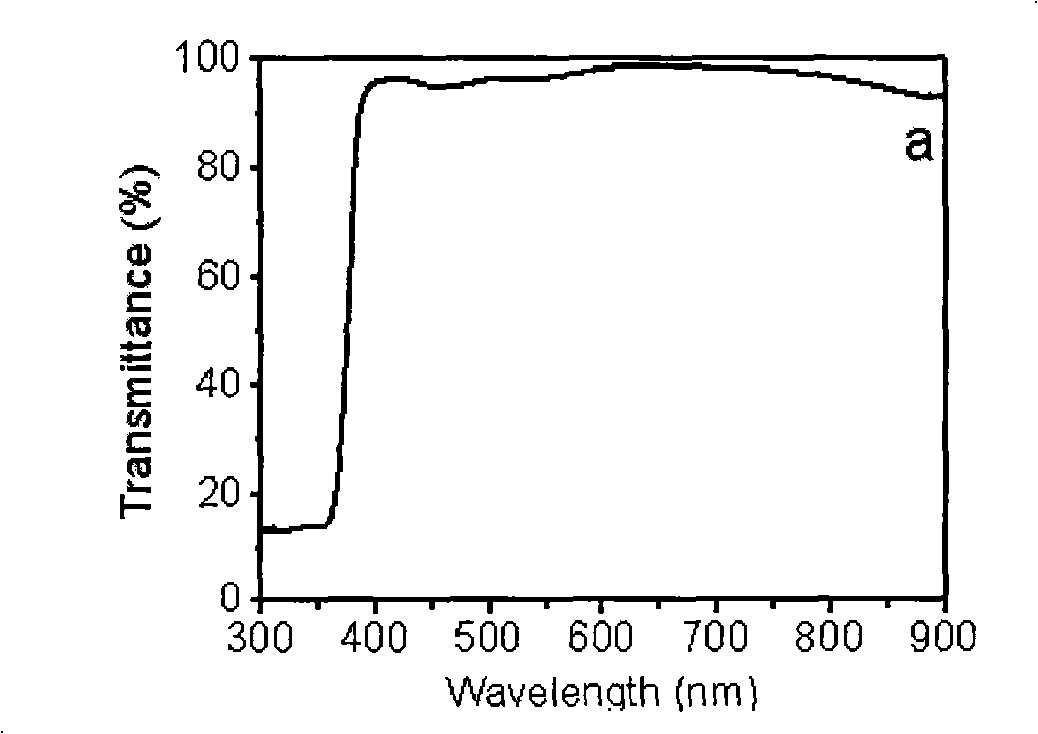

Method for preparing uniform transparent zinc oxide nanorod array film by pulse electrodeposition

A transparent zinc oxide and nanorod array technology, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve problems such as uneven film thickness, impure products, and different rod lengths. Achieve the effects of ensuring uniformity and transparency, easy operation and control, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Dissolve analytically pure zinc chloride and potassium chloride in an electrolytic cell with distilled water, stir to obtain a stable and transparent solution, the concentration of the zinc chloride solution is 0.0005mol / L, and the concentration of the potassium chloride solution is 0.1mol / L;

[0020] (2) Take the above solution and place it in a water bath at a constant temperature of 60°C until the reaction is completed;

[0021] (3) Pass oxygen into the above solution for 10 minutes in advance before pulse electrodeposition, and always pass oxygen into the solution during the process of pulse electrodeposition;

[0022] (4) A three-electrode system is used for square wave pulse electrodeposition, with the ITO conductive glass coated with ZnO nanoparticle film as the working electrode (i.e. the cathode), the platinum sheet as the counter electrode (i.e. the anode), and the saturated calomel electrode as the reference Electrodes, under the applied voltage of -0.8...

Embodiment 2

[0025] (1) Dissolve analytically pure zinc chloride and potassium chloride in an electrolytic cell with distilled water, stir to obtain a stable and transparent solution, the concentration of the zinc chloride solution is 0.0006mol / L, and the concentration of the potassium chloride solution is 0.4mol / L;

[0026] (2) Take the above solution and place it in a water bath at a constant temperature of 70°C until the reaction is completed;

[0027] (3) Pass oxygen into the above solution for 14 minutes in advance before pulse electrodeposition, and pass oxygen into the solution during the process of pulse electrodeposition;

[0028] (4) A three-electrode system is used for square wave pulse electrodeposition, with the ITO conductive glass coated with ZnO nanoparticle film as the working electrode (i.e. the cathode), the platinum sheet as the counter electrode (i.e. the anode), and the saturated calomel electrode as the reference Electrodes, under the applied voltage of -1.0V, cont...

Embodiment 3

[0031] (1) Dissolve analytically pure zinc chloride and potassium chloride in an electrolytic cell with distilled water, stir to obtain a stable and transparent solution, the concentration of the zinc chloride solution is 0.0008mol / L, and the concentration of the potassium chloride solution is 0.8mol / L;

[0032] (2) Take the above solution and place it in a water bath at a constant temperature of 70°C until the reaction is completed;

[0033] (3) Pass oxygen into the above solution for 15 minutes in advance before pulse electrodeposition, and pass oxygen into the solution all the time during the process of pulse electrodeposition;

[0034] (4) A three-electrode system is used for square wave pulse electrodeposition, with the ITO conductive glass coated with ZnO nanoparticle film as the working electrode (i.e. the cathode), the platinum sheet as the counter electrode (i.e. the anode), and the saturated calomel electrode as the reference Electrodes, under the applied voltage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com