Method for preparing silicon carbide nano line

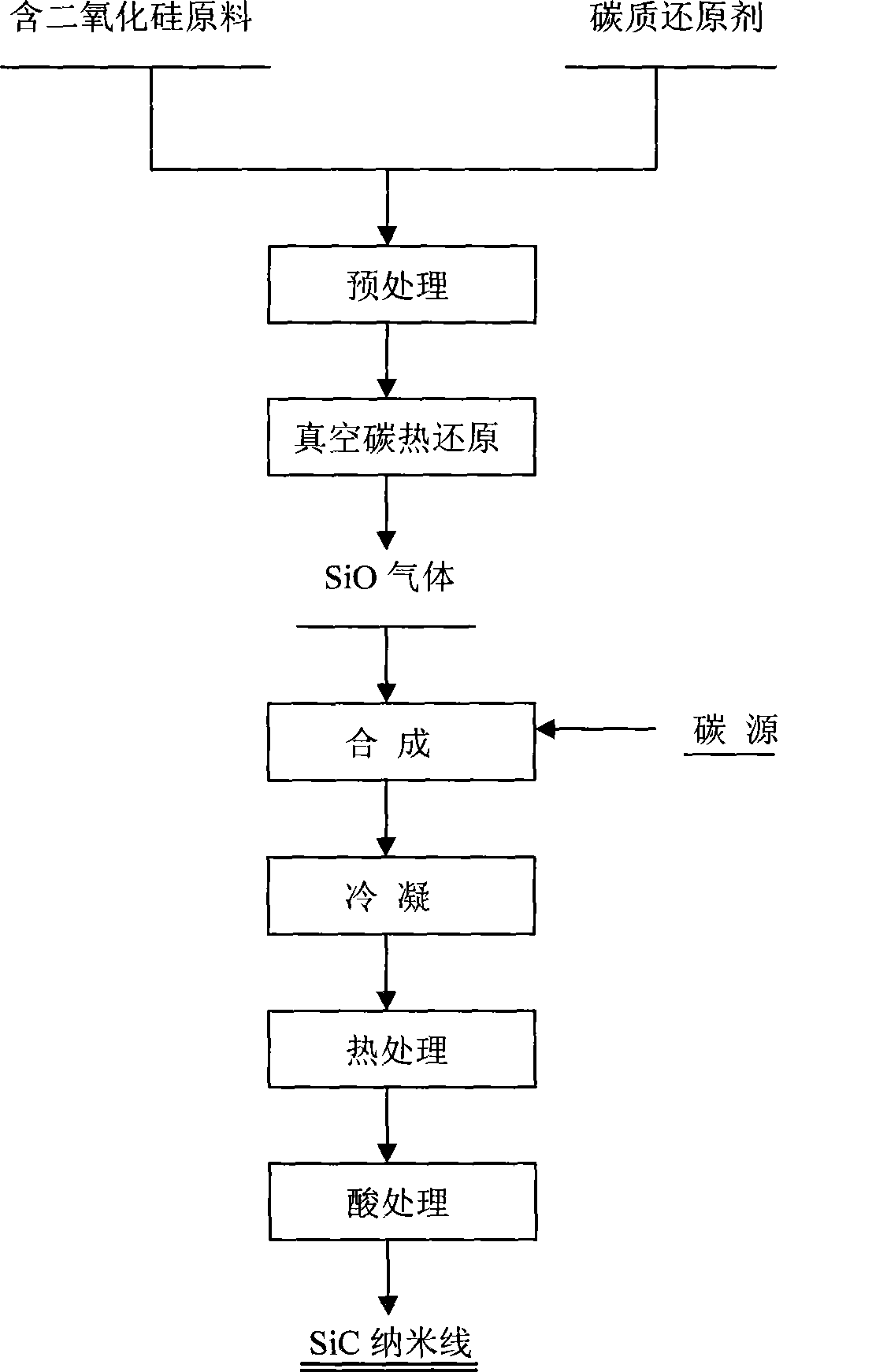

A silicon carbide nanowire and carbonaceous technology is applied in the field of preparing silicon carbide nanowires, which can solve the problems of poor dispersion and crystallization, high price of carbon nanotubes, restricting practical application, etc., and achieves low environmental pollution, cheap raw materials, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Using lignite with a fixed carbon content of 92% and silica ore with a purity of more than 99% as raw materials, after crushing, use a ball mill to grind it into a powder below 20 mesh, and then classify and sieve the raw material powder to obtain a particle size below 50 mesh powder; the SiO 2 Powder and carbon powder are mixed at a molar ratio of 1:1, and the mixed powder is placed in a graphite crucible in a vacuum induction furnace. After the system is closed, vacuumize for 10 -2 ~10 -4 Pa, heat up to 1200°C at a rate of 100°C / min, stop the reaction after 20 minutes of reaction, and then naturally cool to room temperature to obtain the primary reaction product, burn at 800°C for 1 hour, and remove excess in the product with hydrofluoric acid Silica, and then washed, filtered, and dried to prepare SiC nanowires with a diameter of 90-110 nm and a length of micron scale.

Embodiment 2

[0016] Embodiment 2; Adopting the bamboo charcoal that purity is 99% and the silica ore that purity is more than 99% are as raw material, after crushing, be ground into the powder more than 20 orders with ball mill, after crushing, be ground into the powder below 20 orders with ball mill, then The raw material powder is classified and sieved to obtain a powder with a particle size of 100 mesh. SiO 2 Powder and carbon powder are mixed at a molar ratio of 2:1, and the mixed powder is placed in a corundum crucible of a vacuum induction furnace. After the system is closed, vacuumize for 10 -2 ~10 -4 Pa, heat up to 1400°C at a rate of 100°C / min, stop the reaction after 30 minutes of reaction, and then naturally cool to room temperature to obtain the primary reaction product, burn at 700°C for 3 hours, and remove excess in the product with hydrofluoric acid silicon dioxide, and then washed, filtered, and dried to prepare SiC nanowires with a diameter of 30-80nm and a length in the...

Embodiment 3

[0017] Embodiment 3: adopt the activated carbon of more than 98% of purity and the waste quartz of more than 99.9% of purity as raw material, after crushing, use ball mill to grind into powder below 20 mesh, then raw material powder is graded and sieved, obtains the powder of particle size 150 mesh. SiO 2 Powder and activated carbon powder are mixed at a molar ratio of 3:1, and the mixed powder is placed in a graphite crucible of a vacuum induction furnace. After the system is closed, the air in the system is removed by vacuuming, and the temperature is raised to 1600°C at a rate of 100°C / min. After 40 minutes, the reaction was stopped, and then naturally cooled to room temperature to obtain the primary reaction product, which was burned at 900°C for 1 hour, and the excess silicon dioxide in the product was removed with hydrofluoric acid, and then washed, filtered, and dried to obtain SiC nanowires The diameter is 40-120nm, and the length is in the order of microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com