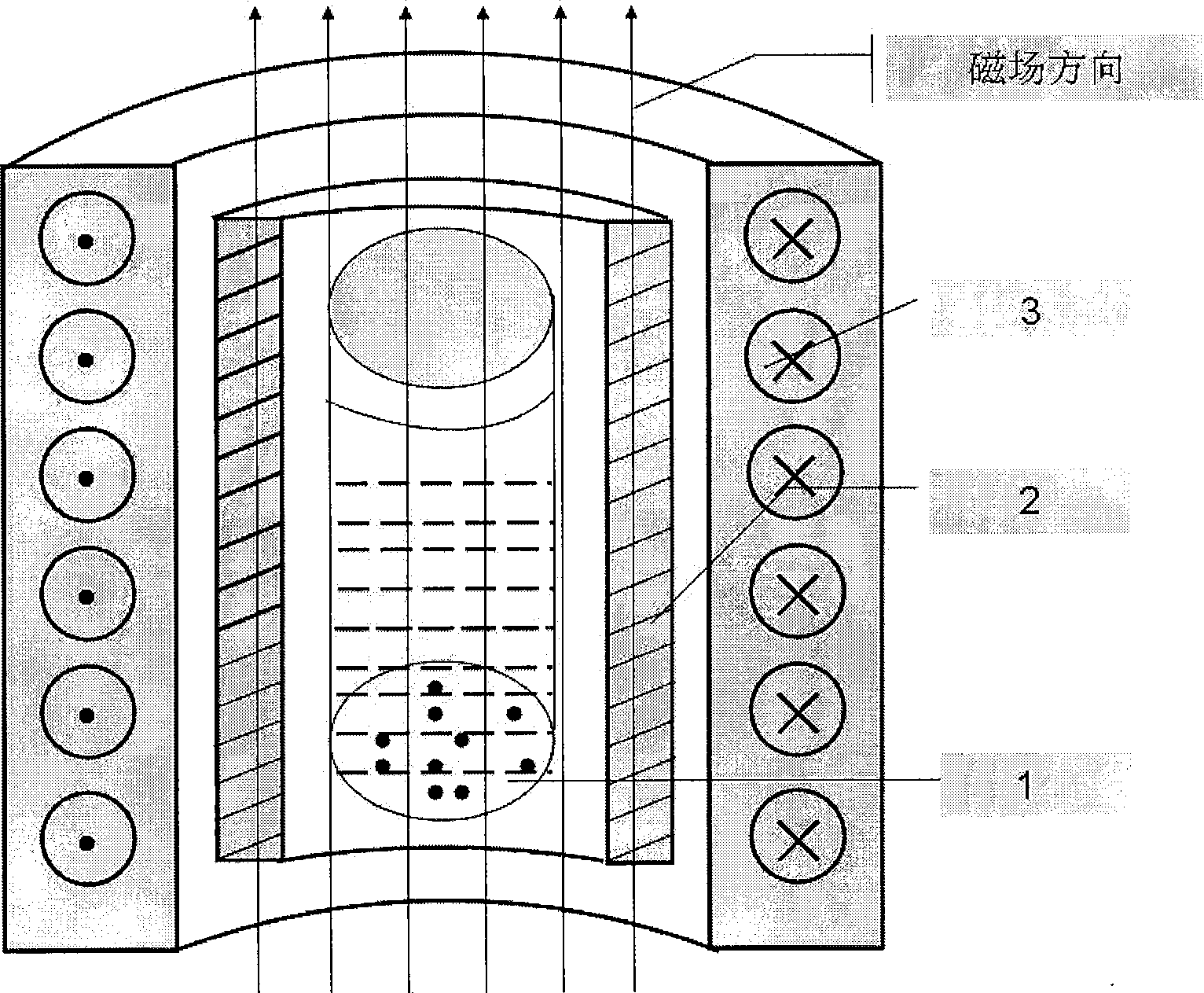

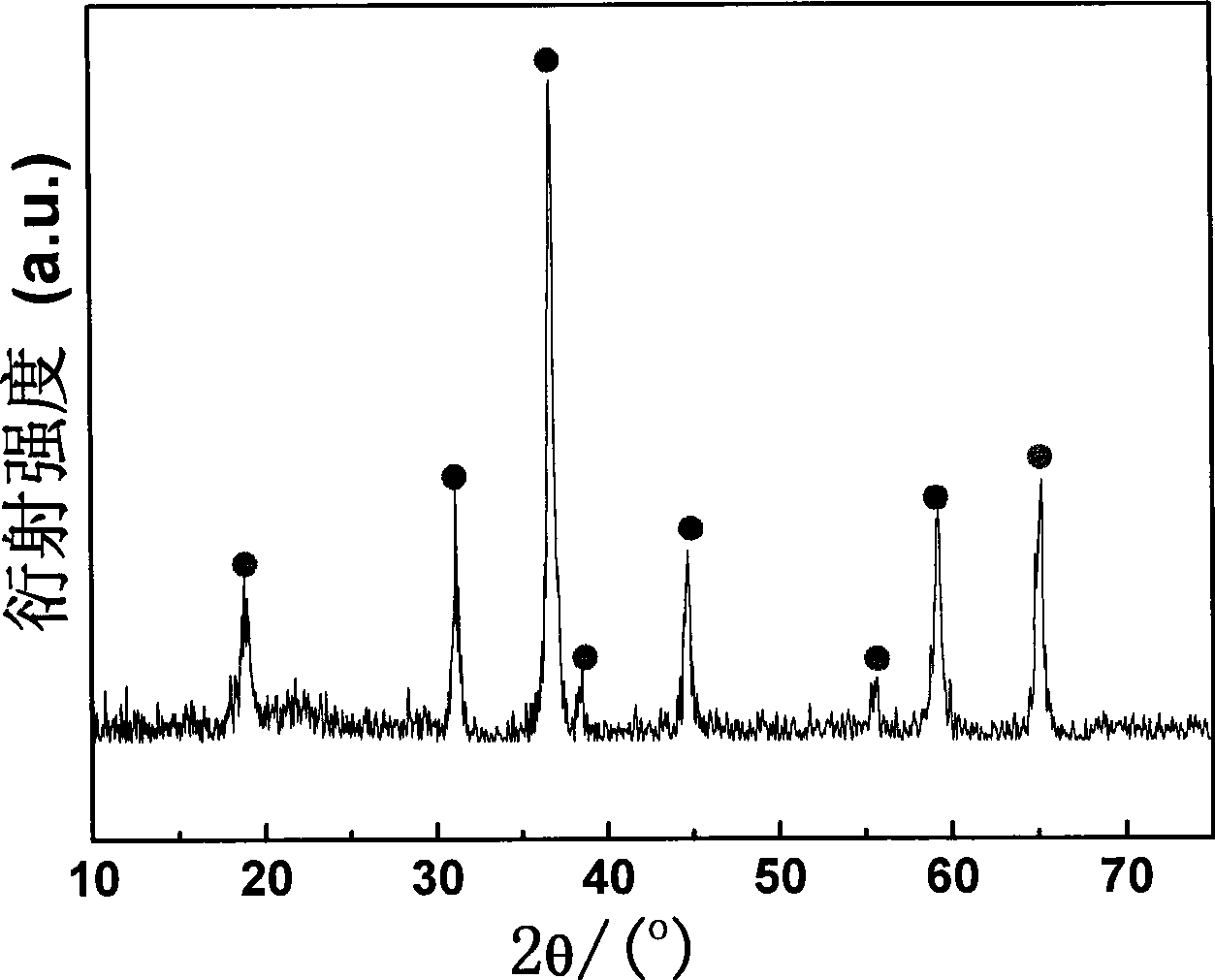

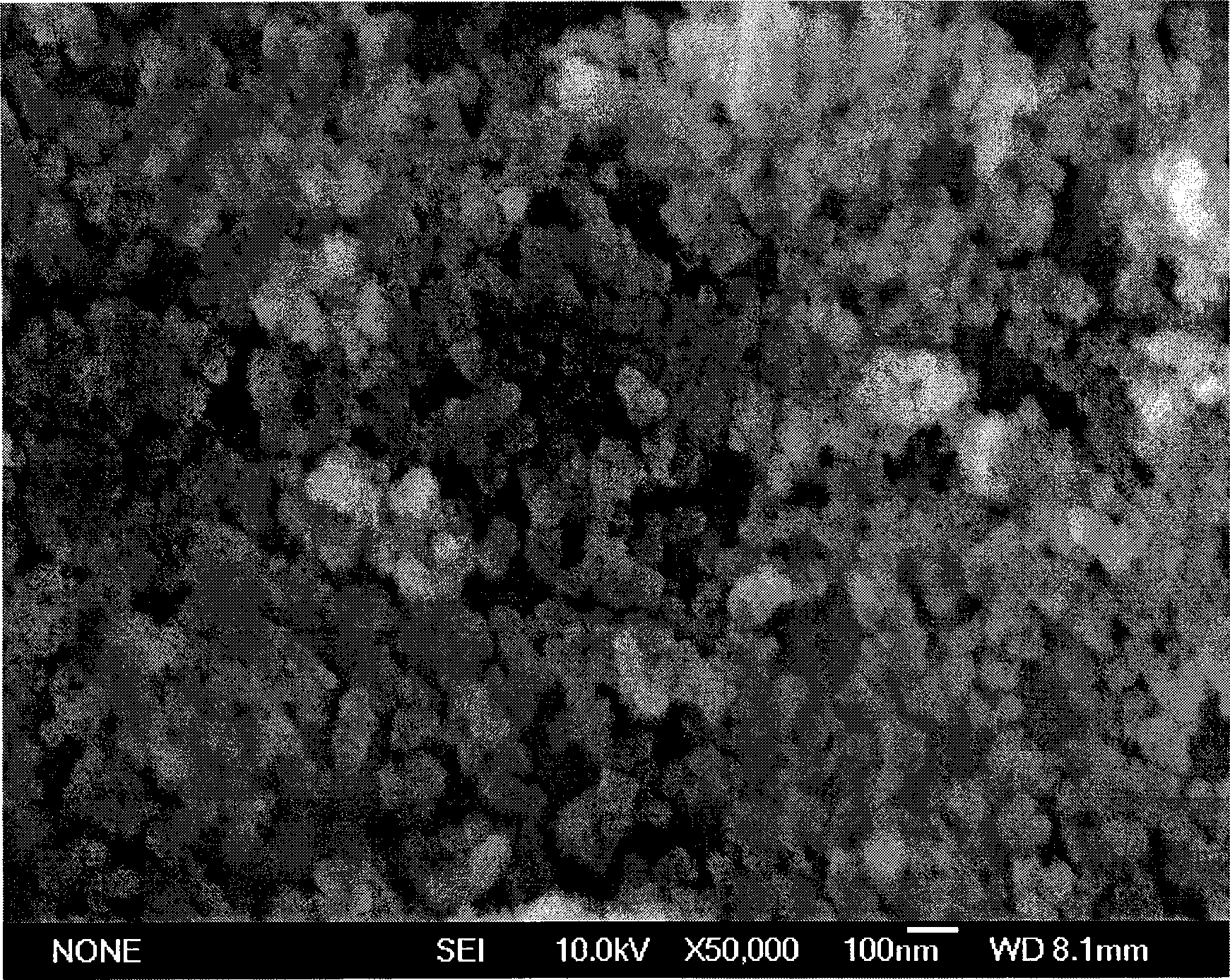

Method for preparing Co3O4 nano material by hydrothermal method under magnetic field effect

A nanomaterial and magnetic field technology, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of high equipment requirements and difficult to control microstructure, and achieve the effect of simplified process, grain refinement and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Co in this example 3 o 4 Nano powder material preparation steps are as follows:

[0025] (1) first use deionized water to cobalt nitrate is mixed with the cobalt brine aqueous solution of 0.56mol / L, and ammonium chloride and ammoniacal liquor are mixed with the ammonia buffer solution of pH=10 as precipitation agent, surfactant sodium lauryl sulfate ( SDS) was prepared as a 75.6g / L aqueous solution.

[0026] (2) According to NH 3 :Co 2+ The molar ratio=3:1, the filling degree is 70% and the setting parameters are carried out. Take 6.75ml of cobalt nitrate aqueous solution into a 100ml beaker, stir with a magnetic stirrer, then add 2.5ml of surfactant SDS, stir for 5 minutes, then add 2.5ml of precipitant ammonia buffer solution, continue stirring for 5 minutes, then add hydrogen peroxide 2.0ml, then after stirring for 30 minutes, move it into a 25ml polytetrafluoroethylene-backed autoclave, then add 3.75ml of solvent n-butanol to the autoclave, and finally seal the...

Embodiment 2

[0029]The preparation steps in this example are exactly the same as those in Example 1 above, the difference being: ①The magnetic field strength is 100T; ②Dry in a vacuum oven at 60°C for 8 hours; ③Use ethanol as a solvent; ④The holding time is 4 hours . Finally got Co 3 o 4 Nano powder material.

Embodiment 3

[0031] The preparation steps in this example are exactly the same as those in Example 1 above, except that: ①The magnetic field strength is 4T; ②Use 50g / L polyethylene glycol 20,000 instead of SDS; ③Heat up to a reaction temperature of 180°C; ④Insulate The time is 10 hours. Finally got Co 3 o 4 Nano powder material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com