Titanium-hydroxylapatite gradient coating and preparation method and application thereof

A technology of hydroxyapatite and gradient coating, which is applied in coatings, medical science, and prostheses, and can solve problems such as insufficient bonding between coatings and implants, hydroxyapatite stability, and biological activity damage. Achieve good biological activity, improve long-term stability, and reduce driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Implant surface morphology observation

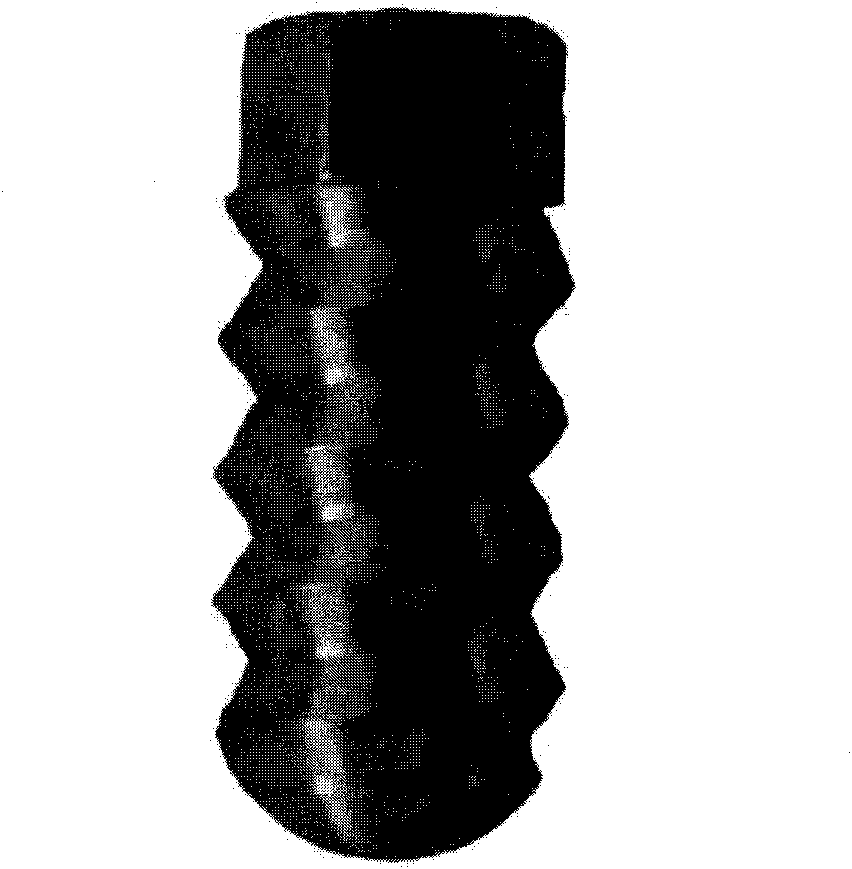

[0016] 100 solid cylindrical threaded implant bases were machined with titanium-6 aluminum-4 vanadium (Ti-6AL-4V) rods, and the materials and processing were provided by Guangzhou Nanfeng Biotechnology Co., Ltd. The specifications are: a total length of 7.5mm, a cylindrical shape with a length of 6.0mm at the lower end, a diameter of 3.0mm, a thread pitch of 1.0mm, and a thread depth of 0.3mm; figure 1 ). Degreasing and cleaning the implant matrix: Ultrasonic cleaning in acetone, 75% ethanol, and deionized water for 10 minutes each, and drying at 50° C. for 24 hours. Three sets of implants were constructed with different surface treatments:

[0017] ① Control group I: Mechanically cut implants (Machine Aided, MA), 25 implant bases were put into 50% nitric acid solution for passivation for 50 min.

[0018] ②Control group II: Hydroxyapatite-coated implants (Hydroxyapatite, HA), hydroxyapatite powder, using low-pressure...

Embodiment 2

[0022] Example 2 Analysis of Implant Surface Chemical Structure

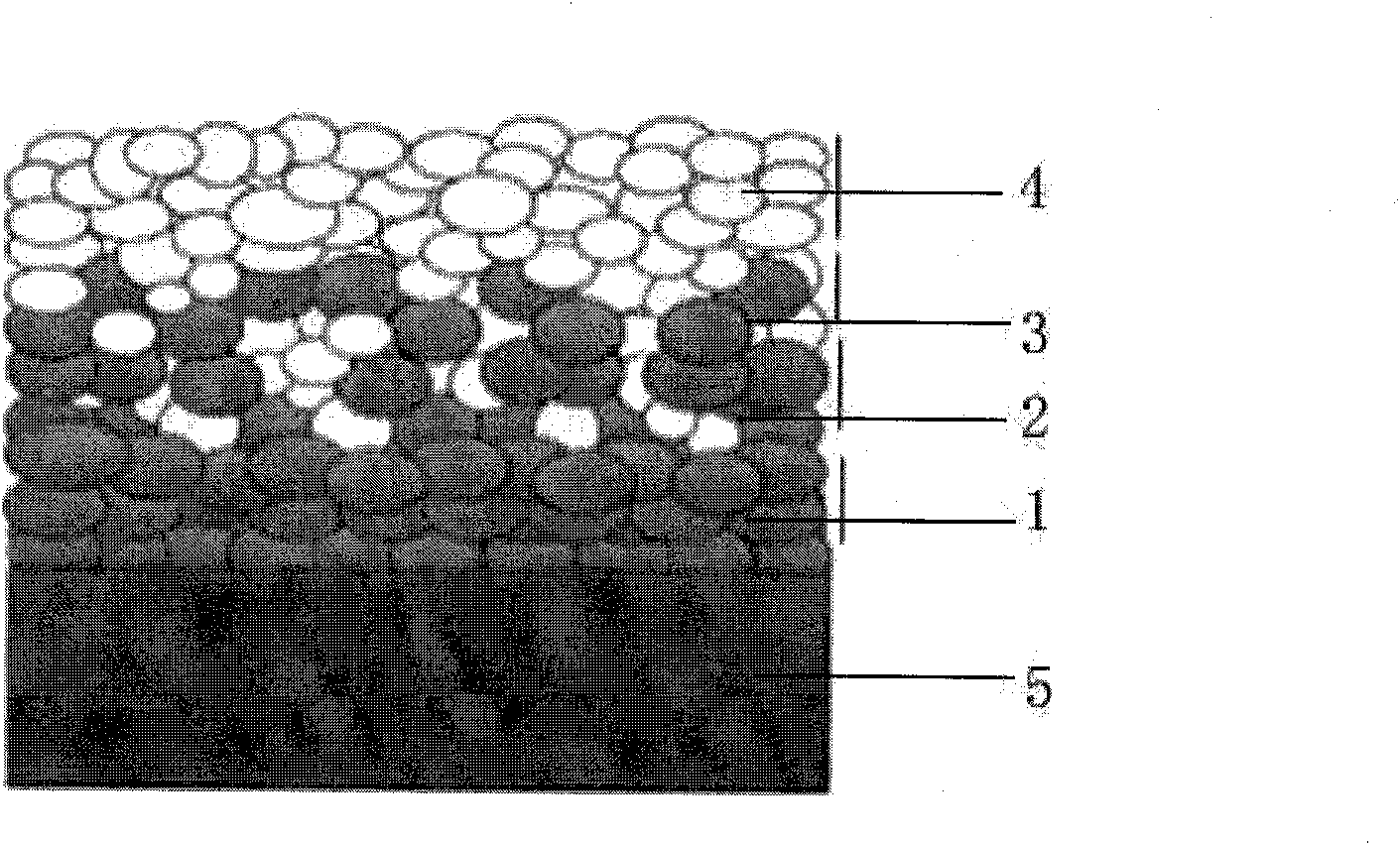

[0023] One implant was randomly sampled from each group of implants treated above, and the surface morphology of the samples was observed with a scanning electron microscope (Scanning Electron Microscopic, SEM, JSM-5910). After SEM observation, X-ray diffraction (XRD, D / max-rc) was used to analyze the chemical structure of the implant surface on the surface of each sample. Through the XRD pattern of HA powder, HA coating and Ti-HA gradient coating, it can be seen that the coating The crystallinity of apatite is lower than that of HA powder. In addition to the broadened apatite peak shape and enhanced CaO phase in the XRD patterns of the two coatings, there is also a TCP (tricalcium phosphate) phase, which may be caused by the spraying process. The high temperature in the medium increases the decomposition of apatite. Overall, the gradient coating design did not significantly change the apatite crystal phase.

Embodiment 3

[0024] The mensuration of embodiment 3 coating intensity

[0025]The bonding strength between the coating and the substrate is characterized by tensile strength. The test method of tensile strength is carried out with reference to the ASTM-C633279 standard, and the bonding strength of the two coatings is tested respectively by using a JDL-50KN tensile testing machine. Use two cylindrical titanium alloy rods with a diameter of 25mm, one end of which is Ti-HA gradient coating or HA coating, bonded together with another blank titanium alloy rod through E7 resin glue, and place in an oven at 100°C / 3h , and then use a tensile testing machine to stretch to both sides until the coating falls off. Four pairs of samples were tested for each coating, and the average value of the test results was used to represent the bonding strength of the coating.

[0026] It was found that the design of the gradient coating improved the bonding strength between the coating and the substrate to a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com