Method of processing waste water and recycling protein

A waste water treatment and protein technology, which is applied to the preparation method of peptides, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of high investment and operation costs, seldom used, high salt content of protein, etc., to achieve The economic and environmental benefits are obvious, the effects of promoting gastrointestinal absorption and reasonable nutritional structure of animals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

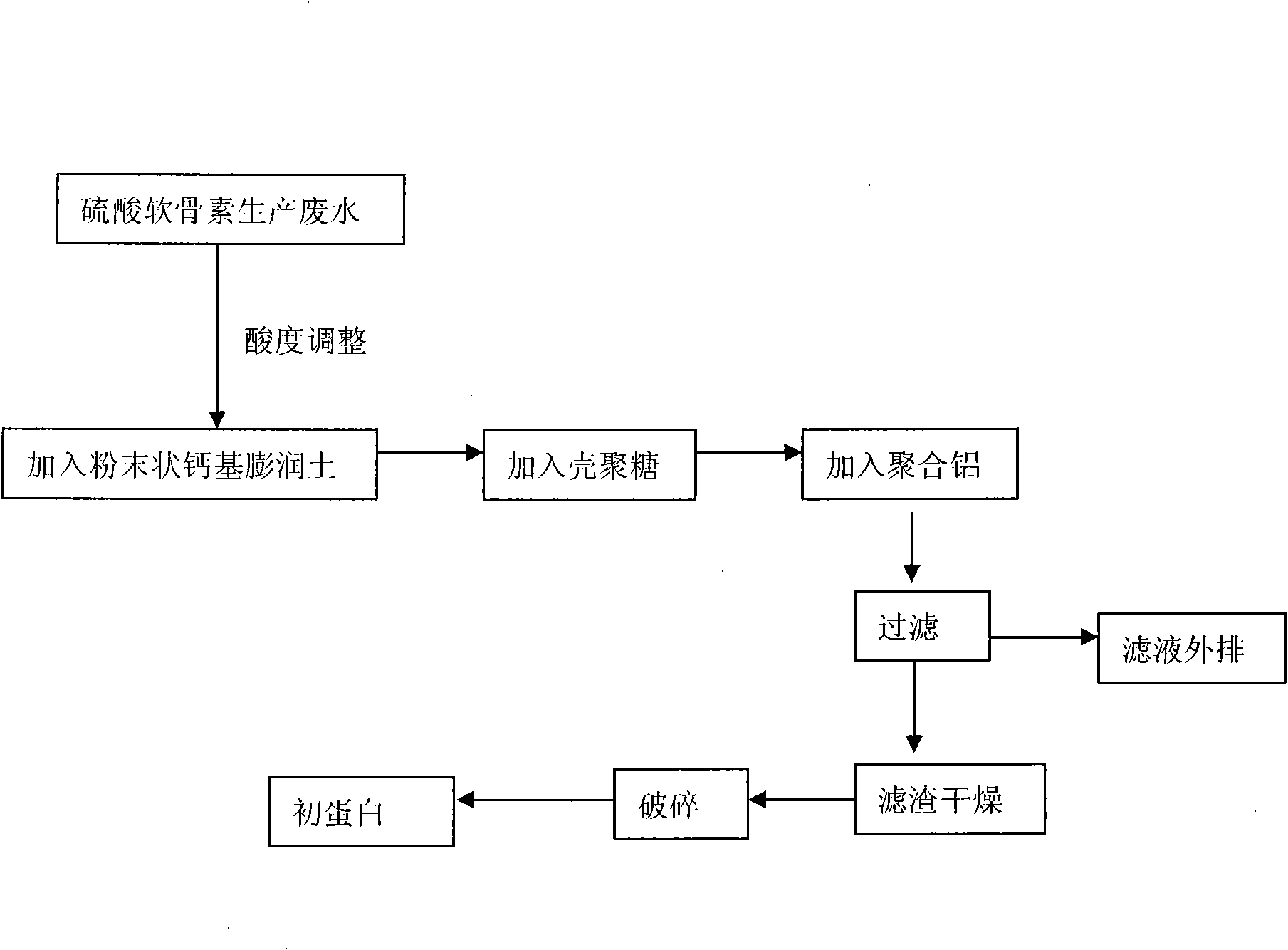

Image

Examples

Embodiment 1

[0018] (1) Take a certain amount of chondroitin sulfate production wastewater, adjust the pH value of the wastewater to 3.5 with dilute hydrochloric acid, and prepare solution I;

[0019] (2) Make a certain amount of powdery calcium-based bentonite and diatomite and other active clay minerals into a paste with warm water, and then slowly add the above-mentioned prepared solution I to prepare solution II, wherein the active clay minerals are in solution II The mass concentration is 1%, and the stirring is continued for about 10 minutes at a certain speed;

[0020] (3) Slowly add the chitosan solution with a mass concentration of 0.5% to the obtained solution II under stirring, and continue stirring at a certain speed for 3-5 minutes to obtain solution III, wherein the concentration of chitosan in solution III 200mg / L;

[0021] (4) Slowly add polyaluminum chloride with a mass concentration of 1% to the obtained solution III under stirring, and continue stirring at a certain spe...

Embodiment 2

[0025] The difference between this embodiment and Example 1 is only: the pH value is adjusted to 9.5 in the step (1); the mass concentration of the active clay mineral in the step (2) in the solution is 10%; in the step (3) Adding mass concentration is the chitosan solution of 1.5%, and the concentration of chitosan in solution III is 1000mg / L;; In step (4), adding mass concentration is 10% polymerized polyaluminum sulfate solution, polyaluminum sulfate is in solution The concentration in IV was 800 mg / L.

Embodiment 3

[0027] The difference between this embodiment and Example 1 is only: the pH value is adjusted to 6 in the step (1); the mass concentration of the active clay mineral in the solution in the step (2) is 5%; in the step (3) Adding mass concentration is the chitosan solution of 1%, and the concentration of chitosan in solution III is 600mg / L;; Adding mass concentration in step (4) is the polyaluminum ferric sulfate solution of 5%, polyaluminum ferric sulfate is in The concentration in solution IV was 450 mg / L.

[0028] Take a chondroitin sulfate production enterprise in Yantai, Shandong Province as an example: the raw material is chicken cartilage, the production capacity of chondroitin sulfate is 300-500 kg / day, and the waste water production is 3-8 tons / day, of which the COD value of waste water is 120000mg / L, TOC value 84000mg / L, protein content 3-18% in the waste water, waste water treatment mode is to adopt cooling water to dilute and discharge to local sewage treatment plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com