Ultraviolet nanoimprint resist and components thereof

A nano-imprinting and resist technology, applied in optics, opto-mechanical equipment, instruments, etc., can solve the problem of increasing environmental pollution and the harshness of the glue-sweeping process, the inability to achieve high-fidelity graphics transfer, and unfavorable promotion and application of imprinting technology, etc. problems, to achieve the effect of ensuring true transfer, low shrinkage and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

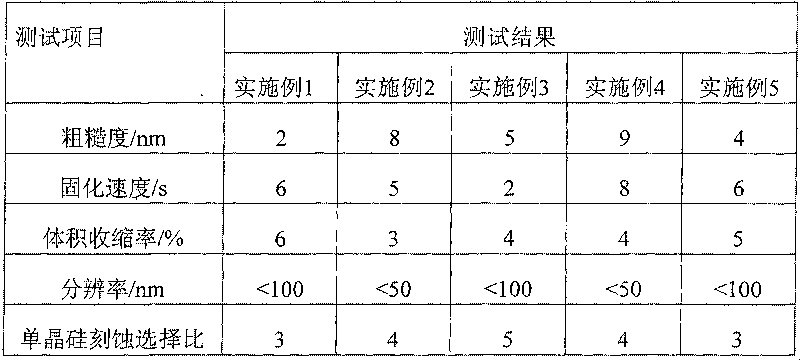

Embodiment 1

[0038] A resist for UV nanoimprinting was produced by combining the following ingredients.

[0039] Prepolymer: hyperbranched polyester acrylate (SARTOMER, CN2301), 10 parts

[0040] Aromatic monoacrylate (SARTOMER, CN131), 60 parts

[0041]Polyurethane acrylate (SARTOMER, CN963B80), 5 parts

[0042] Monomer: Isobornyl Methacrylate, 10 parts

[0043] Dipropylene glycol diacrylate, 10 parts

[0044] Photoinitiator: 1-Hydroxy-cyclohexyl-phenylmethanone, 2 parts

[0045] 2-Hydroxy-2-methyl-1-phenylpropanone, 2 parts

[0046] Additive: ethoxylated nonionic fluorosurfactant (Dupont, FSO-100), 1 part

Embodiment 2

[0048] A resist for UV nanoimprinting was produced by combining the following ingredients.

[0049] Prepolymer: epoxy acrylate (CYTEC, EBECRYL 9626), 10 parts

[0050] Aliphatic urethane triacrylate (CYTEC, EBECRYL 9260), 60

[0051] share

[0052] Monomer: 2-phenoxyethyl methacrylate, 15 parts

[0053] 1,3-Butanediol diacrylate, 10 parts

[0054] Photoinitiator: 2-phenylbenzyl-2-dimethylamine-1-(4-morpholinebenzylphenyl) butanone, 3 parts

[0055] Auxiliary agent: fluorine-containing nonionic surfactant (HENSIC, H-6910), 2 parts

Embodiment 3

[0057] A resist for UV nanoimprinting was produced by combining the following ingredients.

[0058] Prepolymer: aromatic epoxy acrylate (COGNIS, PHOTOMER 3016-25T F), 7 parts

[0059] Epoxy acrylate (COGNIS, PHOTOMER 3016-40RF), 55 parts

[0060] Monomer: Ethoxylated nonylphenol acrylate, 14 parts

[0061] 1,6-Hexanediol diacrylate, 14 parts

[0062] Photoinitiator: 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanone, 6 parts

[0063] Auxiliary: fluorocarbon modified polyacrylate (CIBA, EFKA3277), 4 parts

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com