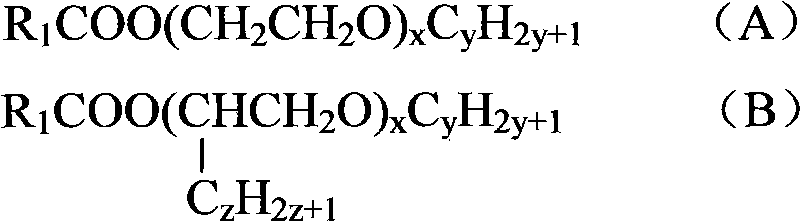

Vegetable oil and ester ether biodiesel and new use thereof

A biodiesel and vegetable oil technology, applied in biofuels, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of low oxygen content, low cetane number, difficult to meet the low emission requirements of diesel engines, etc., and achieve good emissions. Characteristics and combustion performance, HC emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 cottonseed oil diethylene glycol methyl ether ester

[0016] 1. Preparation

[0017] (1) Cottonseed oil and methanol are subjected to a transesterification reaction to obtain cottonseed oil methyl ester. The reaction conditions are as follows: the molar ratio of alcohol to oil is 6:1, the catalyst consumption is 1.1%, the reaction temperature is 50° C., and the reaction time is 40 minutes. Under this reaction condition, the yield of cottonseed oil methyl ester can reach 97.58%. The cottonseed oil methyl ester product is liquid-separated, distilled under reduced pressure, and put into the reactor.

[0018] (2) Add preheated diethylene glycol methyl ether into the reactor, add 0.6% to 0.8% cottonseed oil quality KOH powder, start the stirrer, and start the reaction.

[0019] (3) In the reaction process, since the methanol generated is continuously steamed out, the last reaction can be carried out to the end, and finally the cottonseed oil methyl ester is a...

Embodiment 2

[0047] Embodiment 2 cottonseed oil triethylene glycol methyl ether ester biodiesel

[0048] 1. Preparation

[0049] Method and step are with embodiment 1

[0050] 2. Chemical structure

[0051] Using FT-IR, 1 The refined product of cottonseed oil ethylene glycol methyl ether ester was characterized by H NMR and GPC, and the data are shown in Table 5, Table 6, and Table 7 below, respectively. According to these data, it can be determined that the structural formula of cottonseed oil ethylene glycol methyl ether ester is: RCOOCH 2 CH 2 OCH 2 CH 2 OCH 2 CH 2 OCH 3 .

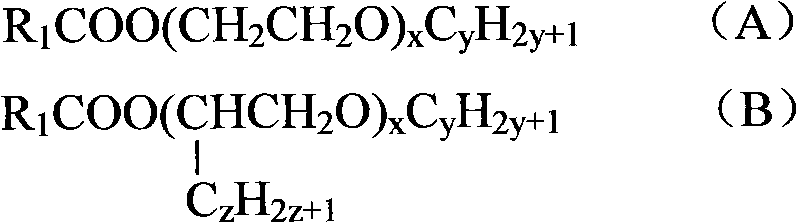

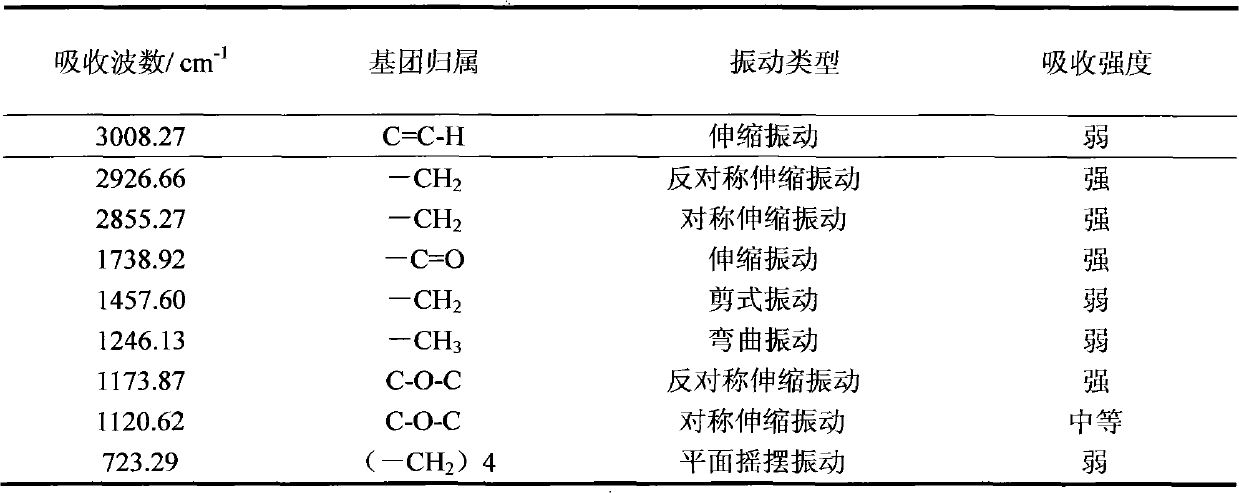

[0052] Table 5 cottonseed oil triethylene glycol monomethyl ether ester infrared spectrogram data

[0053]

[0054]

[0055] Table 6 Cottonseed oil triethylene glycol methyl ether ester hydrogen nuclear magnetic resonance spectrum analysis data

[0056]

[0057] The gel permeation chromatography experimental data of table 7 cottonseed oil triethylene glycol monomethyl ether ester

[0058]

...

Embodiment 3

[0076] Embodiment 3 palm oil ethylene glycol butyl ether ester biodiesel

[0077] 1. Preparation

[0078] (1) According to alcohol oil molar ratio is 6: 1 ~ 10: 1, KOH accounts for the mass fraction of palm oil (condensation point is 8 ℃) is 0.5% ~ 1.2%, take a certain amount of refining 8 degree palm oil, Ethylene glycol methyl ether and solid KOH powder. KOH was dissolved in ethylene glycol butyl ether to prepare a potassium alkoxide solution.

[0079] (2) Inject the preheated palm oil and potassium alkoxide solution into the reactor, heat and stir, control the reaction temperature at 60°C to 100°C, and stop the reaction after 30min to 120min.

[0080] (3) After the reaction time is up, stop stirring, transfer the reaction product into a separatory funnel, add dilute hydrochloric acid to neutralize, let stand to separate the liquid, and collect the oil phase and the water phase. The oil phase after liquid separation was distilled under reduced pressure to remove unreacted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com