Cosmetic containing oceanic shellfish active peptide and preparation method and application thereof

A technology of active peptides and cosmetics, which is applied in the field of cosmetics containing marine shellfish active peptides and its preparation, which can solve the problems of rare types of marine biological active peptides, underutilized ingredients, and single efficacy of active peptides, so as to achieve the effect of beauty and skin care Overall, skin roughness and skin tone improvement, skin tone improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

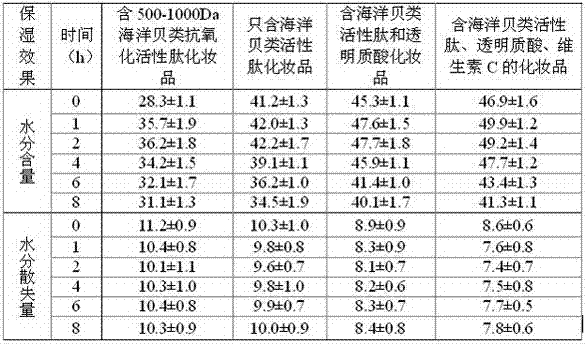

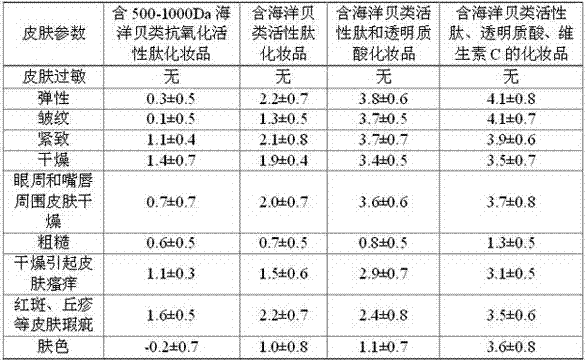

Examples

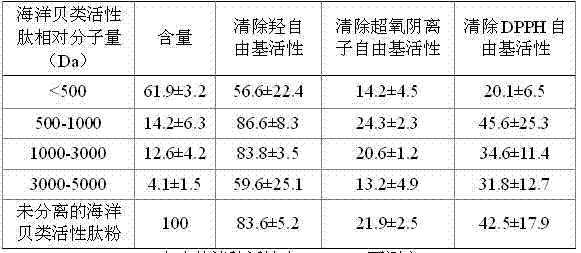

Embodiment 1

[0038] Take edible papain clams that meet the standards for the use of relevant seafood in my country, shell and viscera, add 2 times the volume of pure water to homogenate for 4 minutes, boil for 5 minutes, add papain after cooling to room temperature, and the amount of enzyme added is 1000U / g , after 170w ultrasonic treatment at room temperature for 8min, the pH is 7, the temperature is 50°C for 60min, enzymatic hydrolysis for 60min, boiling water bath for 6min, 8000r / m centrifugation for 15min, the supernatant is ultrafiltered through an ultrafiltration membrane with a molecular weight cut-off of 5000Da, and after freeze-drying The marine shellfish active peptide powder is prepared for use.

[0039] Preparation of oil phase: according to the parts by mass of each raw material, stearic acid 2, lanolin 1, white oil 6, simethicone oil 2, isopropyl palmitate 2. Stearic acid, lanolin, white oil, simethicone and isopropyl palmitate were selected and mixed, heated to 85-90°C under c...

Embodiment 2

[0044] Take edible sea clams, remove their shells and viscera, add 2.5 times the volume of pure water to homogenate for 5 minutes, boil for 10 minutes, cool to room temperature, add bromelain and glutenase (1:1), the amount of enzyme added is 2000U / g, at room temperature After ultrasonic treatment at 170w for 6 minutes, the pH is 6.5, the temperature is 40°C for 30 minutes, the enzyme is inactivated in a boiling water bath for 7 minutes, and centrifuged at 8000r / m for 12 minutes. Shellfish Active Peptide Powder, ready for use.

[0045] Phase A: 1 cyclopentasiloxane and 1 dioctyl carbonate, based on the parts by mass of each raw material. Choose cyclopentasiloxane and dioctyl carbonate to mix, heat to 80-95°C under constant stirring, and keep for 20 minutes for sterilization to obtain phase A, which is ready for use.

[0046] Phase B: according to the mass fraction of each raw material, glycerin 1, marine shellfish active peptide 6, hyaluronic acid 3, distilled water 69, xanth...

Embodiment 3

[0051] Take edible scallops and pearl oysters, remove their shells and viscera, add 3 times the volume of pure water to homogenate for 3 minutes, boil for 8 minutes, add alkaline protease after cooling to room temperature, the amount of enzyme added is 3000U / g, and after 170w ultrasonic treatment at room temperature for 5 minutes, in Under the conditions of pH 7.5 and temperature 60°C, enzymatic hydrolysis for 15 minutes, boiling water bath to inactivate the enzyme for 8 minutes, centrifugation at 8000r / m for 10 minutes, the supernatant was ultrafiltered through an ultrafiltration membrane with a molecular weight cut-off of 5000Da, and freeze-dried to obtain marine shellfish Active peptide powder, ready for use.

[0052] Preparation of water phase: according to the mass percentage of each raw material, marine shellfish active peptide 0.125, hyaluronic acid 1.25, V C 15. Glycerin 3, potassium hydroxide 0.3, ethylenediaminetetraacetic acid 0.2, deionized water 80.125. Marine sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com