Method for preparing trihydroxy cobalt hydroxide

A technology of cobalt hydroxide and trihydroxyl, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., which can solve the problems of low structural controllability, limited research on cobalt hydroxide materials, optimization and improvement of application performance, and limited types of cobalt hydroxide and other problems, to achieve the effect of simple preparation method, good crystallization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

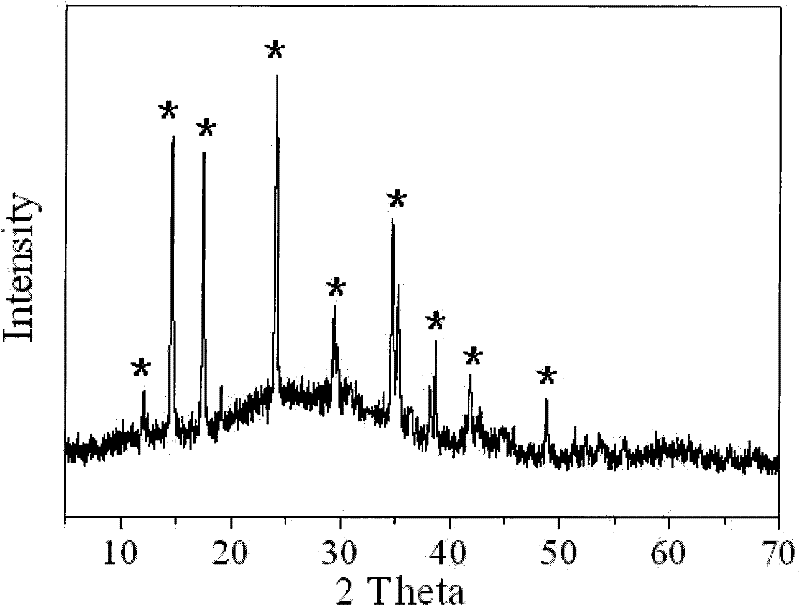

[0019] In a 100mL polytetrafluoroethylene reactor, weigh 0.03g of cobalt chloride, 0.012g of cetyltrimethylammonium chloride (CTAC) into 5mL of N,N-dimethylamide and 5mL of water In the mixture, stir gently until the cobalt chloride is completely dissolved, forming a red homogeneous solution. Then add 0.05mL under stirring, and content is the hydrogen peroxide of 30wt%, fully mixes, and the molar concentration of the cobaltous chloride in the solution is 2.5mM, and the molar concentration of cetyltrimethylammonium chloride is 4.0mM, The molar concentration of hydrogen peroxide is 0.04M. Tighten the reactor, place it in an oven at 150°C for 15 hours, centrifuge the product, wash it with water three times and dry it to obtain a dark red powder product. The product is a dandelion-shaped nanoribbon assembly, the length of a single band is about 1.5 μm, and the width is about 20 nm. XRD patterns such as figure 1 As shown, it shows that its crystallization is good.

Embodiment 2

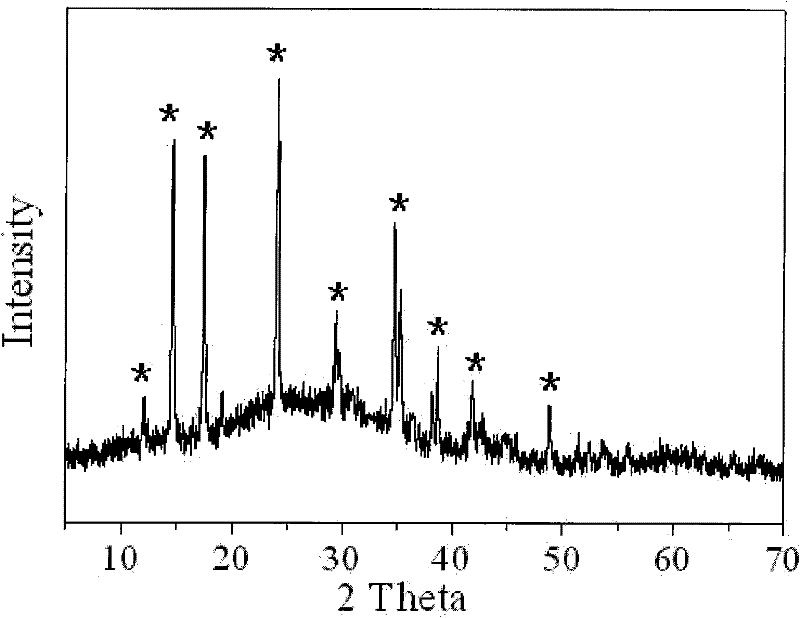

[0021] In a 100mL polytetrafluoroethylene reactor, weigh 0.03g of cobalt chloride, 0.012g of cetyltrimethylammonium chloride (CTAC) into 5mL of N,N-dimethylamide and 5mL of water In the mixture, stir gently until the cobalt chloride is completely dissolved, forming a red homogeneous solution. Add the hydrogen peroxide of 1.0mL (30%) under stirring then, mix well, the molar concentration of the cobaltous chloride in the solution is 2.5mM, and the molar concentration of cetyltrimethylammonium chloride is 4.0mM, pass The molar concentration of hydrogen oxide is 0.8M. Tighten the reactor, put it in an oven and let it stand at 150°C for 15 hours, then centrifuge the product, wash it with water twice and dry it to obtain a dark red powdery product. The product is a monodisperse needle-shaped nanobelt, the length of a single belt is about 10 μm, and the width is about 2 μm. The corresponding XRD pattern in Example 2 is similar to Example 1.

Embodiment 3

[0023] In a 100mL polytetrafluoroethylene reactor, weigh 0.03g of cobalt chloride, 0.012g of cetyltrimethylammonium chloride (CTAC) into 5mL of N,N-dimethylamide and 5mL of water In the mixture, stir gently until the cobalt chloride is completely dissolved, forming a red homogeneous solution. Add the hydrogen peroxide of 2.0mL (30%) under stirring then, mix well, the molar concentration of the cobaltous chloride in the solution is 2.5mM, and the molar concentration of cetyltrimethylammonium chloride is 4.0mM, pass The molar concentration of hydrogen oxide is 1.6M. Tighten the reactor, put it in an oven and let it stand at 150°C for 15 hours, then centrifuge the product, wash it with water 4 times and dry it to obtain a dark red powder product. The product is a monodisperse acicular nanoribbon, the length of a single band is about 50 μm, and the width is about 3 μm. Its hysteresis curve shows that the nanoribbon is a superparamagnet higher than 40K. The corresponding XRD spect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com