Method for coproducing cellulosic ethanol, furfural, lignin and feed from plant fibers

A plant fiber and cellulose technology, applied in the direction of microorganism-based methods, animal feed, animal feed, etc., can solve the problems of low raw material utilization rate, poor economic benefit, high production cost, etc., and achieve improved utilization rate, improved utilization efficiency, Realize the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

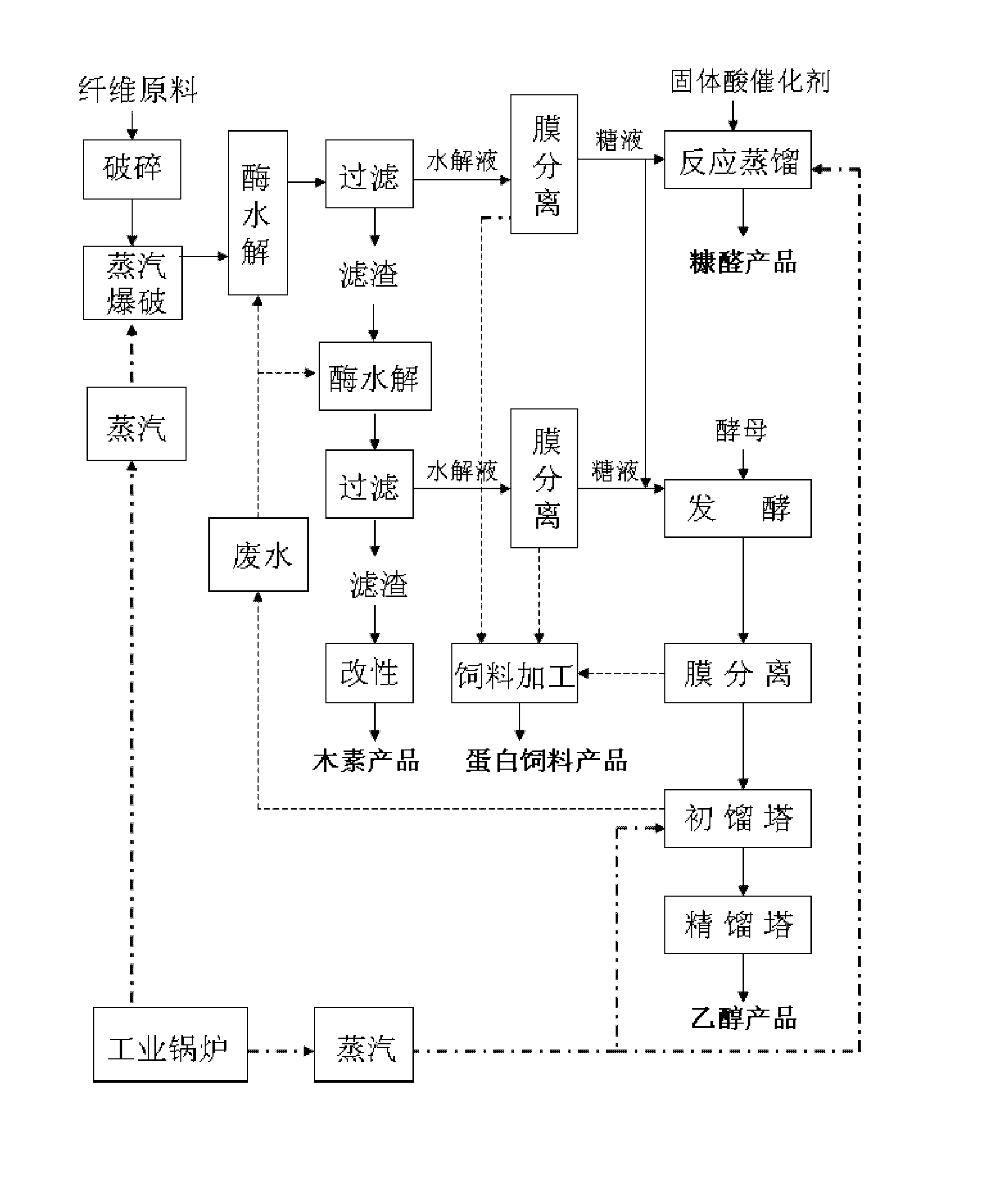

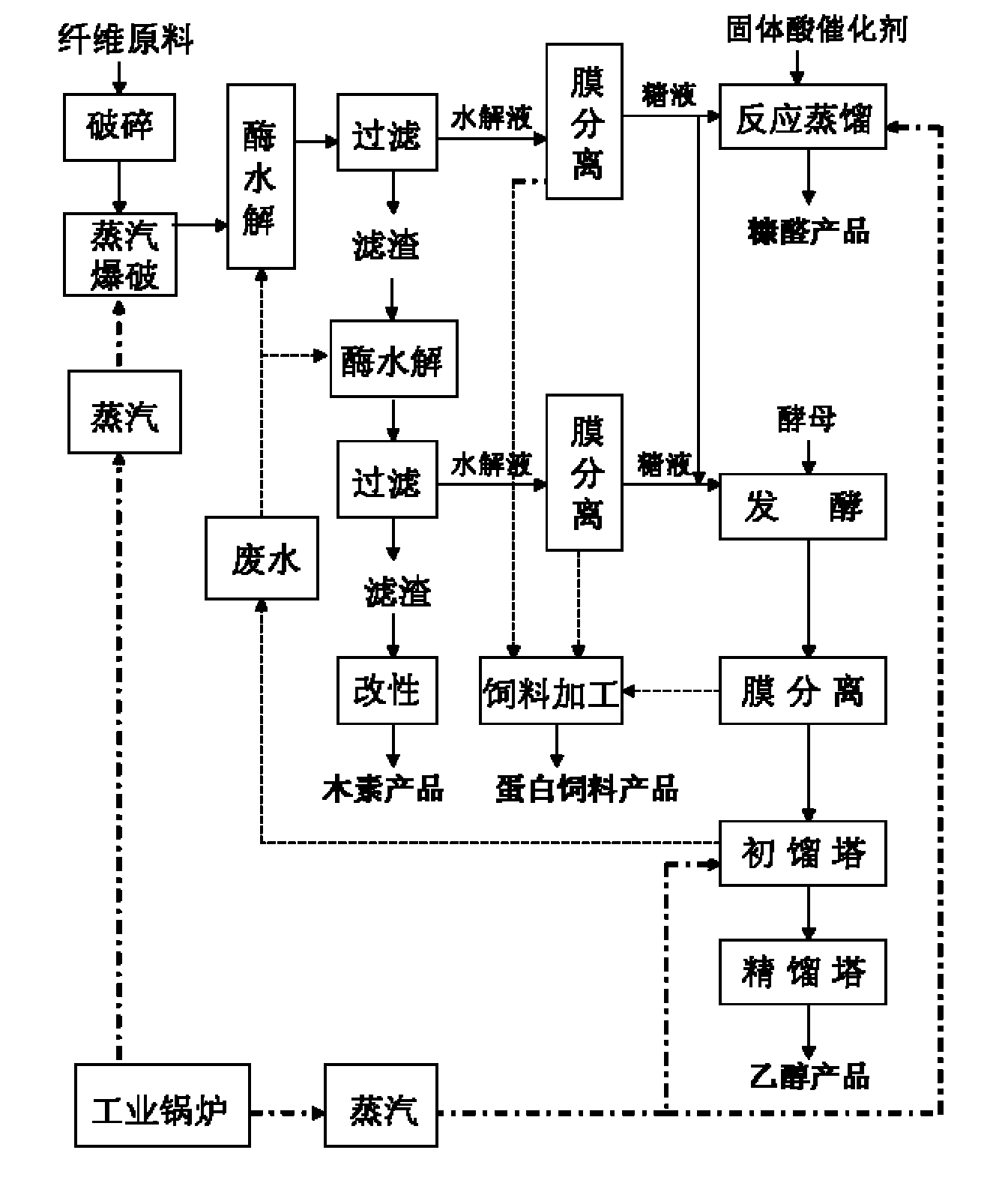

Method used

Image

Examples

Embodiment 1

[0032] Put 100g of corn stalks crushed into a size of about 10mm into a steam explosion device, add 0.05-0.1% dilute sulfuric acid solution according to the liquid-solid ratio of 1:1, and then add steam to increase the pressure to 1.4-1.6MPa, and maintain 2-3 A few minutes later, the quick-opening valve is opened to release the material, and the slag water is separated by filtration and washed with a small amount of water to obtain a pentosan hydrolyzate. Add pH5.0 citric acid-disodium hydrogen phosphate buffer solution according to liquid-solid ratio 9:1 to the solid matter after steam explosion pretreatment, add the hemicellulase that enzyme dosage is 100U / g substrate after sterilization, in Enzymolysis was carried out at 50°C and 120 rpm for 36 hours, the solid residue was separated by filtration, and the filtrate was deproteinized to obtain pentosan hydrolyzate. The two parts of the pentosan hydrolyzate were combined and concentrated to obtain a pentose solution with a red...

Embodiment 2

[0034] Put 50g of corn stalks crushed into about 5mm in size into a 1000mL Erlenmeyer flask, add pH5.0 citric acid-disodium hydrogen phosphate buffer solution according to the liquid-solid ratio of 9:1, and add enzyme at 100U / g base after sterilization The hemicellulase of the product was hydrolyzed at 50°C and 120rpm for 36 hours, and the solid residue was separated by filtration. The filtrate was deproteinized and concentrated to obtain a pentose sugar solution with a reducing sugar content of 80g / L. Take 100mL of the pentose solution, put it in a 1L reaction kettle, add 2% titanium-zirconium composite solid acid catalyst, dehydrate and cyclize at 140°C for 2 hours, filter and recover the catalyst, and obtain furfural by distillation and condensation of the reaction product under reduced pressure Product, analyze and calculate the yield of furfural. In the solid slag obtained after enzymatic hydrolysis of hemicellulose, add pH5.0 citric acid-disodium hydrogen phosphate buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com