Laying hen composite premix for prolonging egg laying peak time

A compound premix and peak time technology, applied in animal feed, animal feed, application, etc., can solve the problems of increased fatty liver hemorrhage syndrome, affecting the gastrointestinal health of laying hens, and reducing the nutritional effectiveness of feed, etc., to achieve Reduce the occurrence of fatty liver hemorrhagic syndrome, improve feed conversion efficiency, and improve animal digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

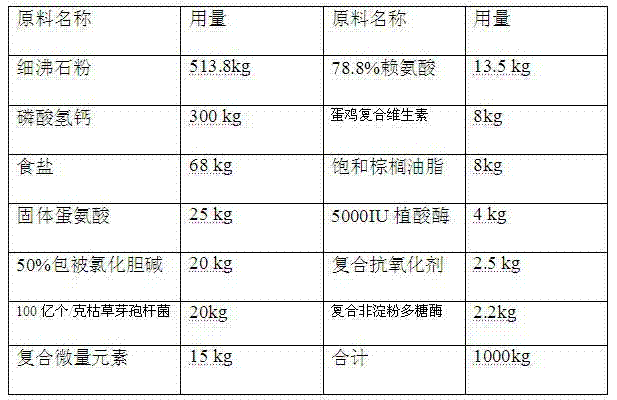

[0016] Embodiment 1 (best embodiment):

[0017]

[0018] Among them, composite trace elements refer to copper 165mg / kg, iron 1200mg / kg, zinc 1450mg / kg, manganese 1200mg / kg, selenium 7mg / kg, iodine 8.5mg / kg. (Note: Converted to the content in this product). Layer multivitamin refers to vitamin A 165670IU / kg, vitamin D3 58330IU / kg, vitamin E 640mg / kg, vitamin K3 50mg / kg, vitamin B1 38mg / kg, vitamin B2 140mg / kg, vitamin B6 95mg / kg, vitamin B12 0.636mg / kg, niacinamide 925mg / kg, pantothenic acid 245mg / kg, folic acid 20mg / kg, D-biotin 4.24mg / kg, choline 20g / kg. (Note: Converted to the content in this product). Composite antioxidants refer to antioxidants compounded with 15%≥EQ≥10%, 5%≥BHT≥3%. Composite non-starch polysaccharase (among them, cellulase ≥ 750U / g, xylanase ≥ 5000U / g, β-glucanase ≥ 1500U / g, amylase ≥ 300U / g, protease ≥ 300U / g).

[0019] Production method: Mix the above ingredients evenly.

Embodiment 2

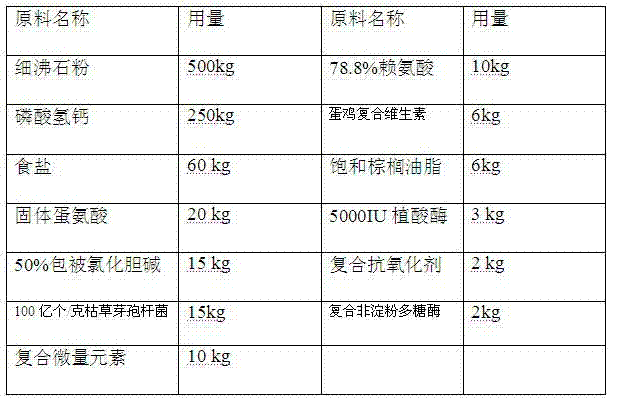

[0021]

[0022] Among them, composite trace elements refer to copper 165mg / kg, iron 1200mg / kg, zinc 1450mg / kg, manganese 1200mg / kg, selenium 7mg / kg, iodine 8.5mg / kg. (Note: Converted to the content in this product). Layer multivitamin refers to vitamin A 165670IU / kg, vitamin D3 58330IU / kg, vitamin E 640mg / kg, vitamin K3 50mg / kg, vitamin B1 38mg / kg, vitamin B2 140mg / kg, vitamin B6 95mg / kg, vitamin B12 0.636mg / kg, niacinamide 925mg / kg, pantothenic acid 245mg / kg, folic acid 20mg / kg, D-biotin 4.24mg / kg, choline 20g / kg. (Note: Converted to the content in this product). Composite antioxidants refer to antioxidants compounded with 15%≥EQ≥10%, 5%≥BHT≥3%. Composite non-starch polysaccharase (among them, cellulase ≥ 750U / g, xylanase ≥ 5000U / g, β-glucanase ≥ 1500U / g, amylase ≥ 300U / g, protease ≥ 300U / g).

[0023] Production method: Mix the above ingredients evenly.

Embodiment 3

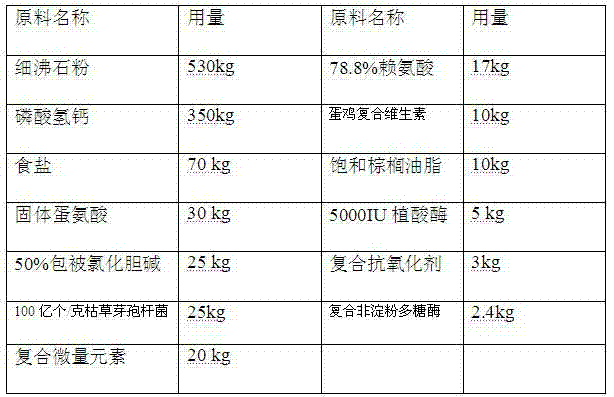

[0025]

[0026] Among them, composite trace elements refer to copper 165mg / kg, iron 1200mg / kg, zinc 1450mg / kg, manganese 1200mg / kg, selenium 7mg / kg, iodine 8.5mg / kg. (Note: Converted to the content in this product). Layer multivitamin refers to vitamin A 165670IU / kg, vitamin D3 58330IU / kg, vitamin E 640mg / kg, vitamin K3 50mg / kg, vitamin B1 38mg / kg, vitamin B2 140mg / kg, vitamin B6 95mg / kg, vitamin B12 0.636mg / kg, niacinamide 925mg / kg, pantothenic acid 245mg / kg, folic acid 20mg / kg, D-biotin 4.24mg / kg, choline 20g / kg. (Note: Converted to the content in this product). Composite antioxidants refer to antioxidants compounded with 15%≥EQ≥10%, 5%≥BHT≥3%. Composite non-starch polysaccharase (among them, cellulase ≥ 750U / g, xylanase ≥ 5000U / g, β-glucanase ≥ 1500U / g, amylase ≥ 300U / g, protease ≥ 300U / g).

[0027]

[0028] Production method: Mix the above ingredients evenly.

[0029]In the present invention, the compound premix for laying hens with an addition ratio of 5% for pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com